Germanium ingots/wafers having low micro-pit density (mpd) as well as systems and methods for manufacturing same

A density, micro-pit technology, used in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth, etc., can solve problems such as reduction, low yield, and reduction in the number of useful crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

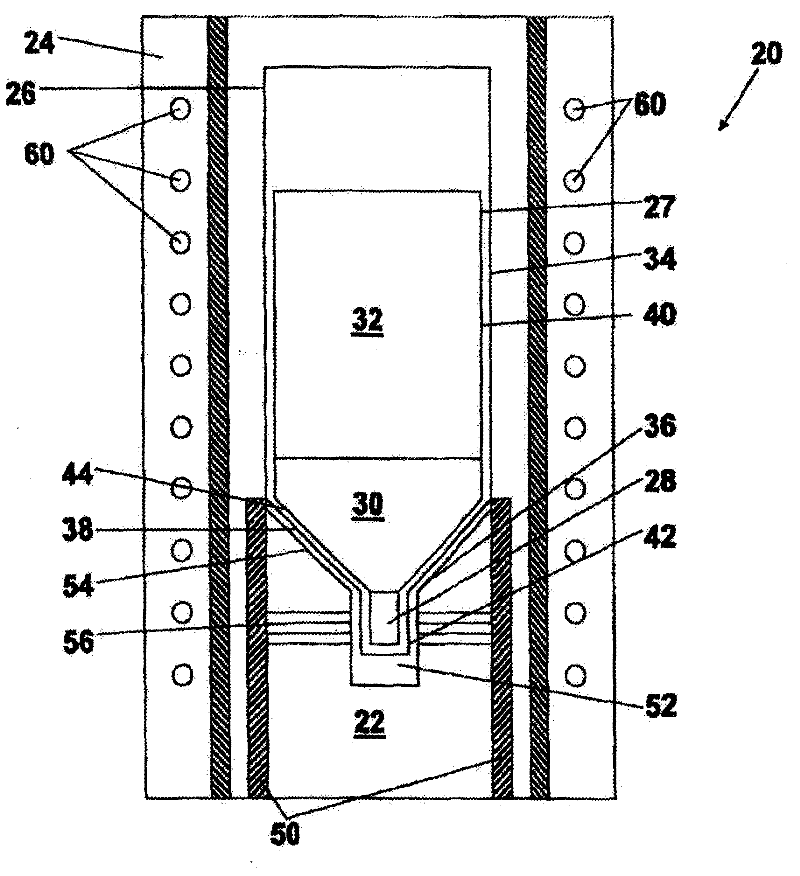

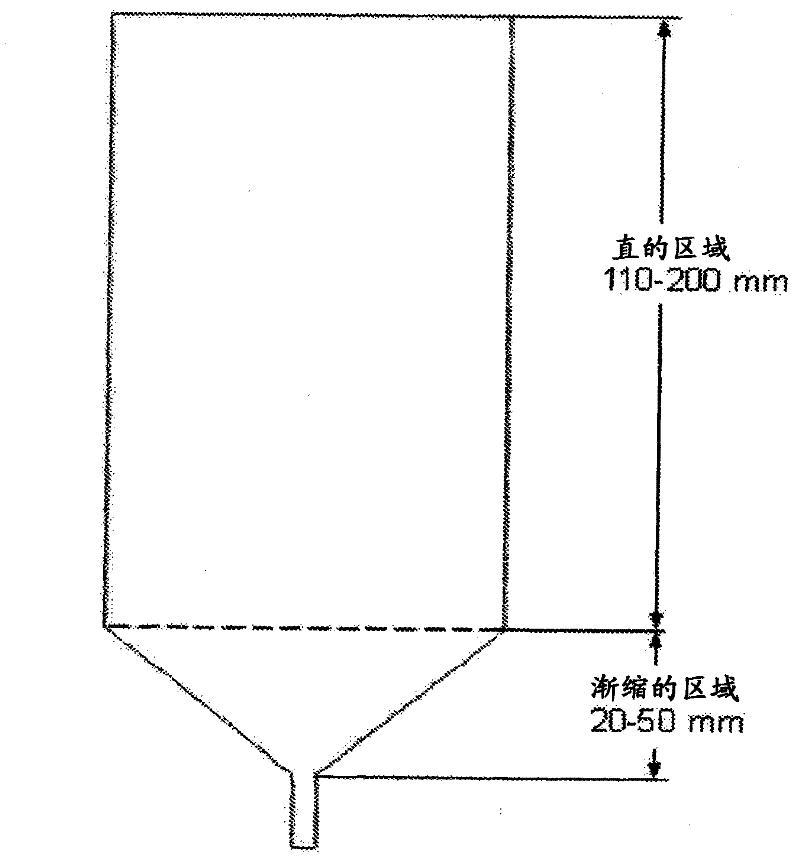

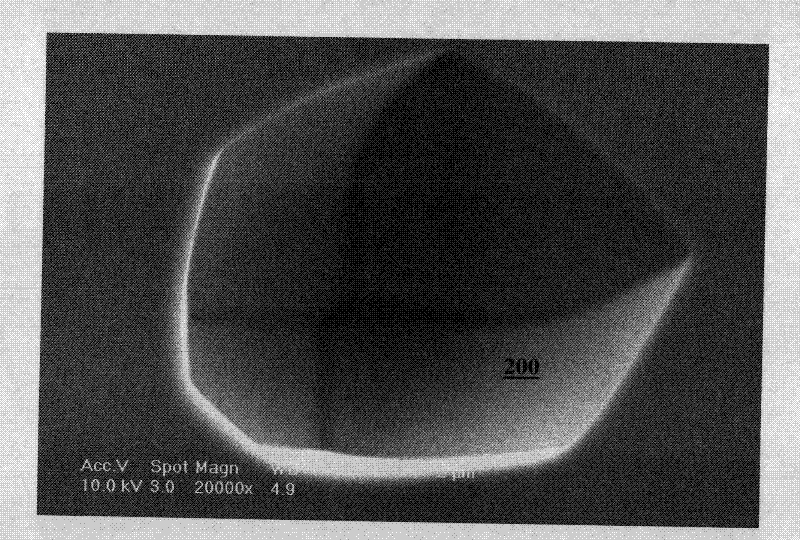

[0017] The invention will now be described in detail, embodiments of which are illustrated in the accompanying drawings. The implementations presented below do not represent all implementations consistent with the claimed invention. Rather, they are merely some examples related to specific aspects of the invention. Wherever feasible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0018] The devices and methods are particularly applicable to devices and methods for germanium (Ge) crystal growth, and such devices and methods are described in this context. It should be understood, however, that the apparatus and method may have greater utility, as the apparatus and method may be used to produce other monocrystalline and / or polycrystalline ingots having low dimple densities.

[0019] Figure 1A is a cross-sectional view of one embodiment of crystal growth apparatus 20 . This example apparatus may include a crucible support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com