Air-flotation type mechanical polishing method

A mechanical polishing and air-floating technology, which is applied in surface polishing machine tools, grinding/polishing equipment, metal processing, etc., can solve the problems of low pass rate, inability to meet mass production, unstable polishing quality, etc., and achieve process qualification rate rise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

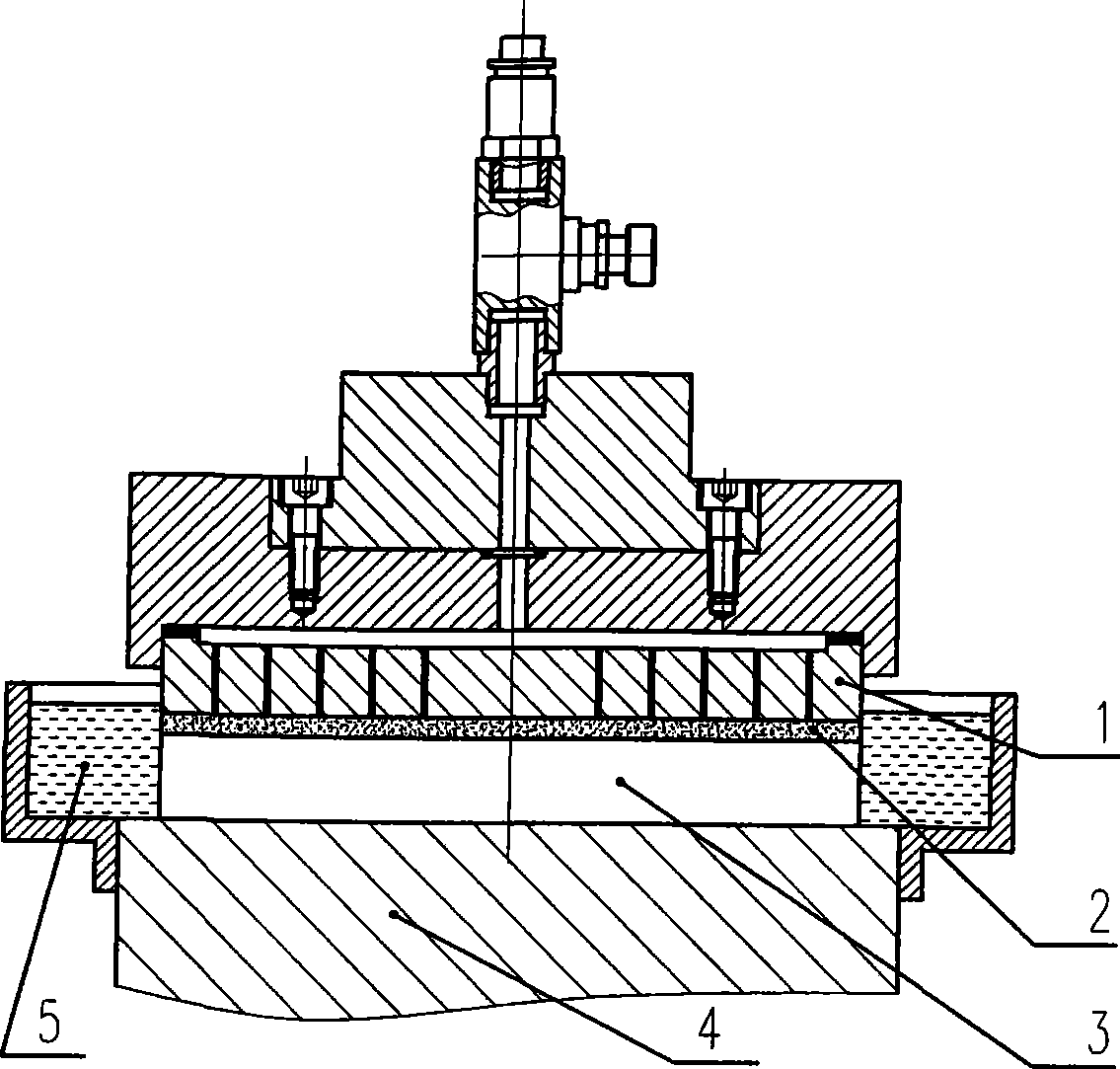

[0013] refer to figure 1 , the main technical scheme of the present invention illustrates: adopt a grinding disc 1 of uniform jet, close to the surface of the workpiece 3 rotating on the chassis 4, the grinding disc and the workpiece are immersed in the polishing solution 5 containing certain abrasives, the grinding disc 1 rotates in the opposite direction of the workpiece, It can also not be rotated. During the polishing process, there is a naturally formed gap between the air jet surface of the grinding disc 1 and the processing surface of the workpiece 3, and a layer of gas-liquid film 2 is naturally formed in the gap, so that the grinding disc floats on the workpiece and maintains soft contact. , the abrasive in the gas-liquid film sandwiched between the grinding disc and the workpiece performs uniform and flexible friction polishing on the workpiece, and the processing of the workpiece is determined according to the polishing time.

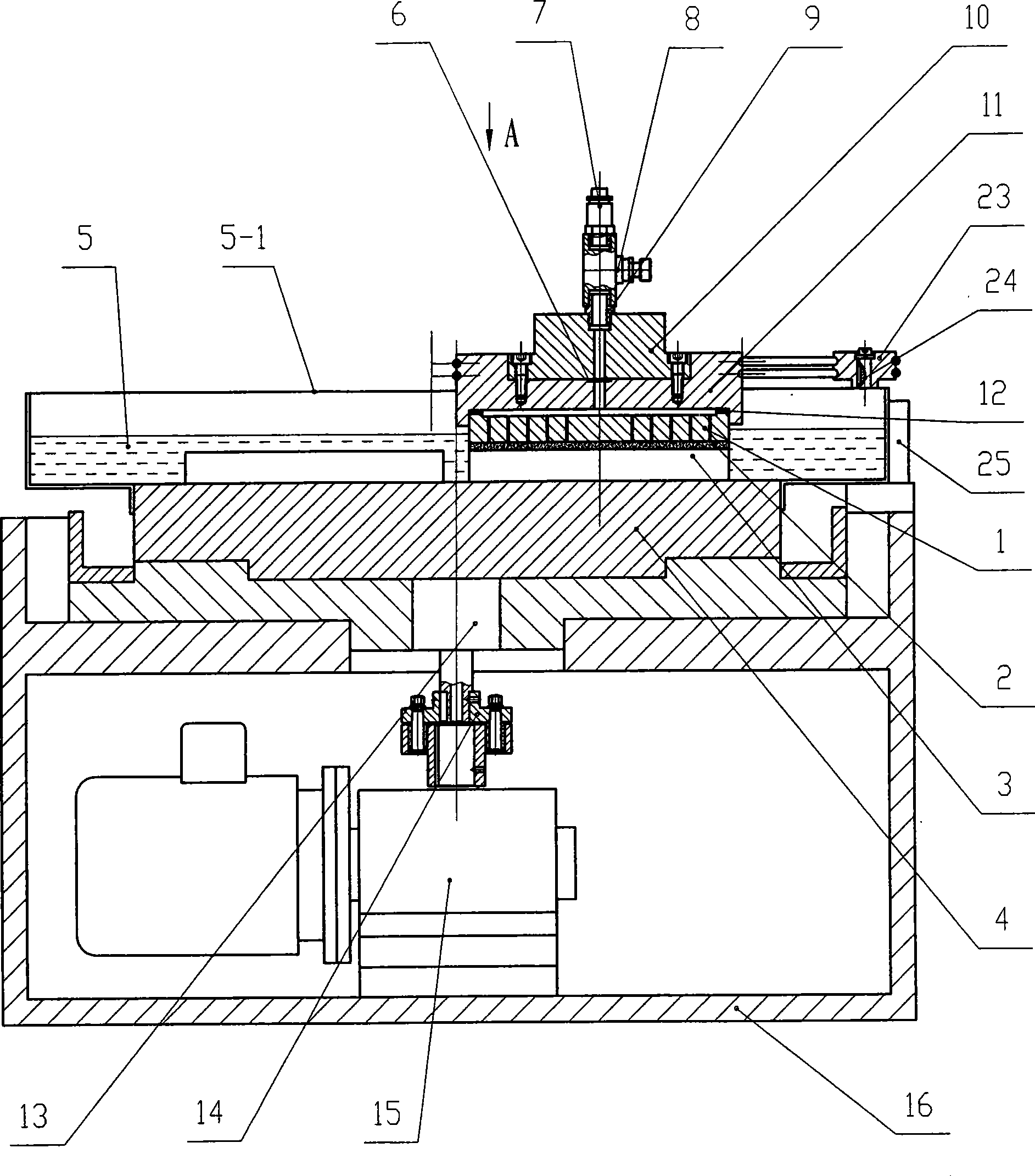

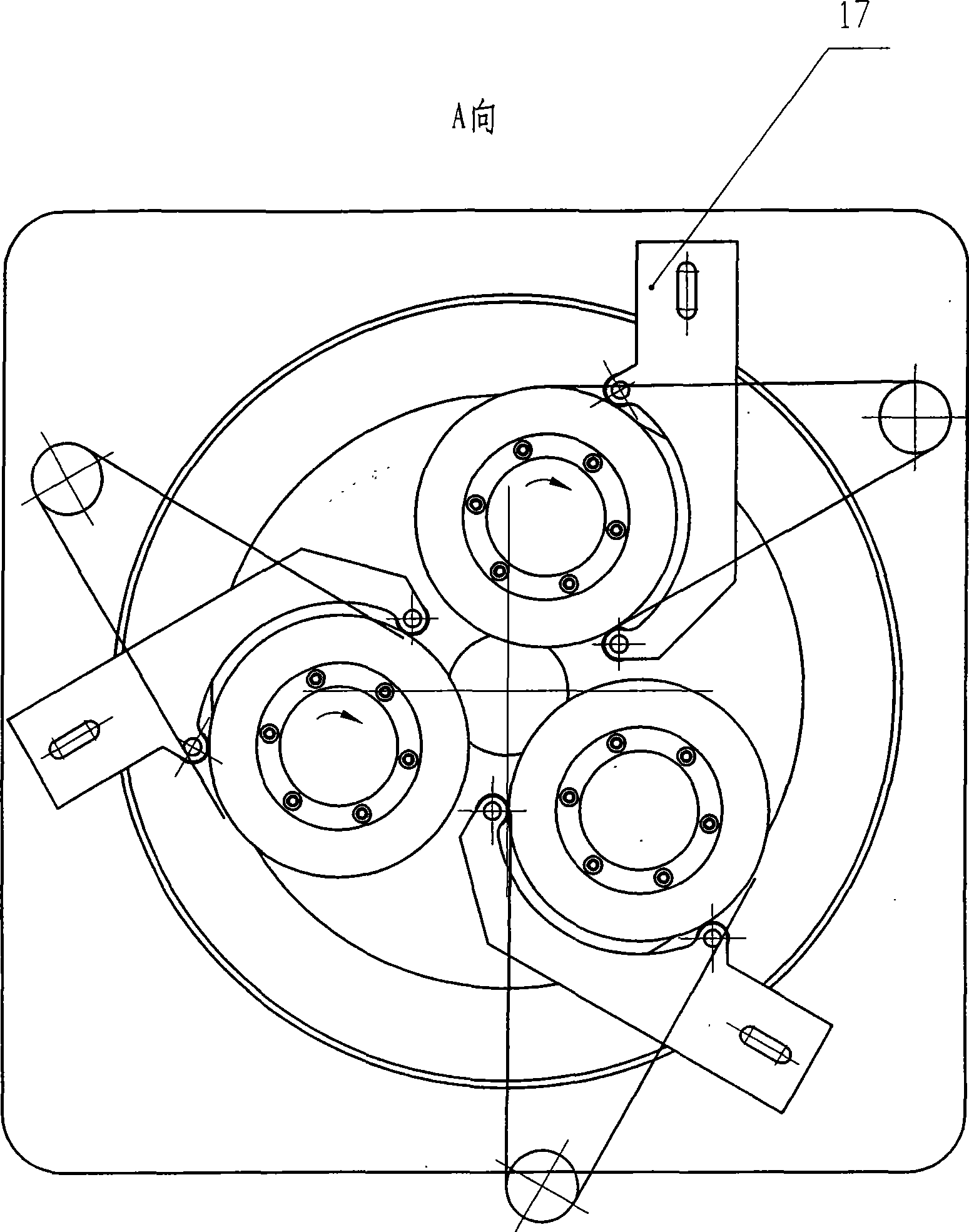

[0014] refer to figure 2 , 3 , 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com