Patents

Literature

58results about How to "Improve process pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

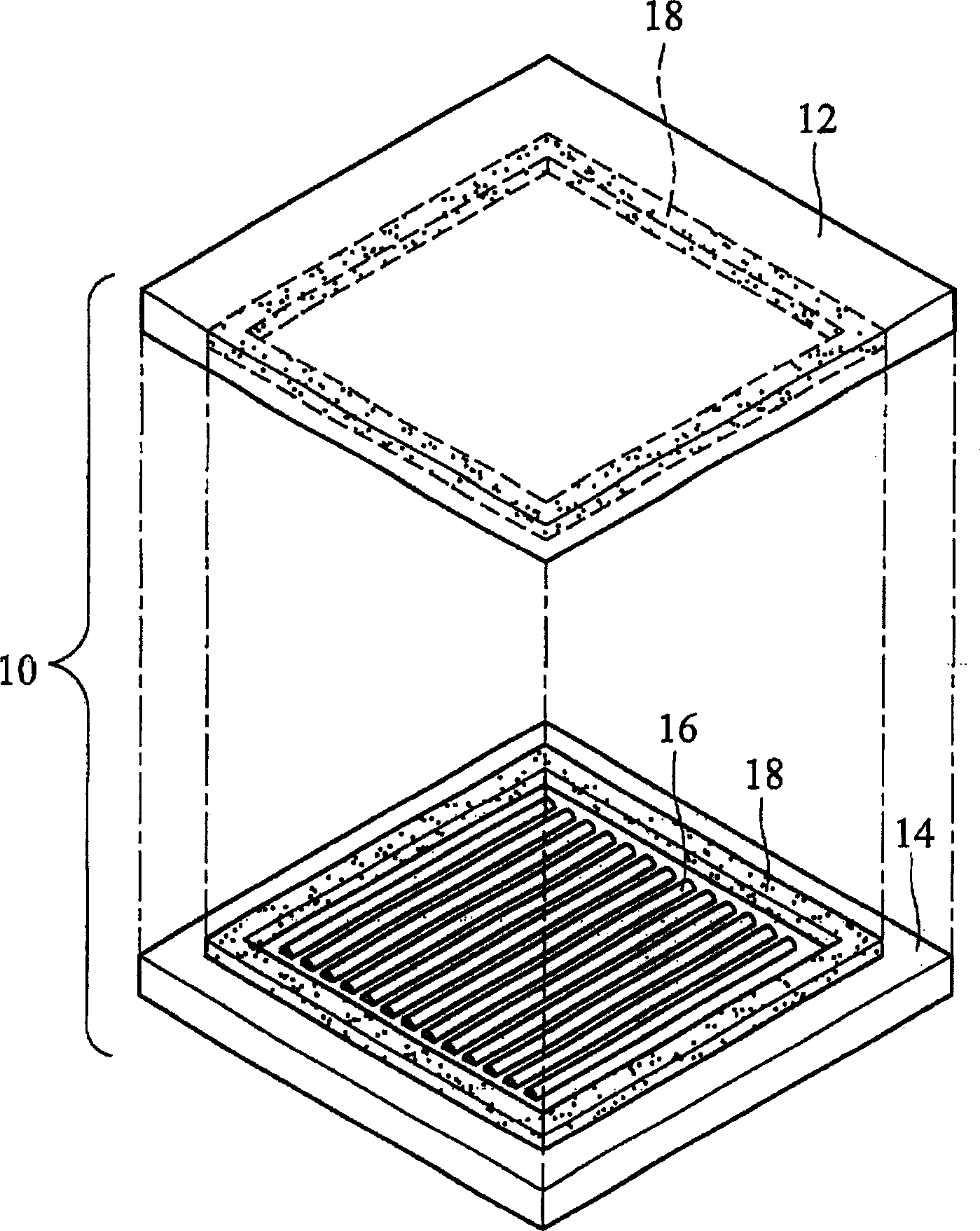

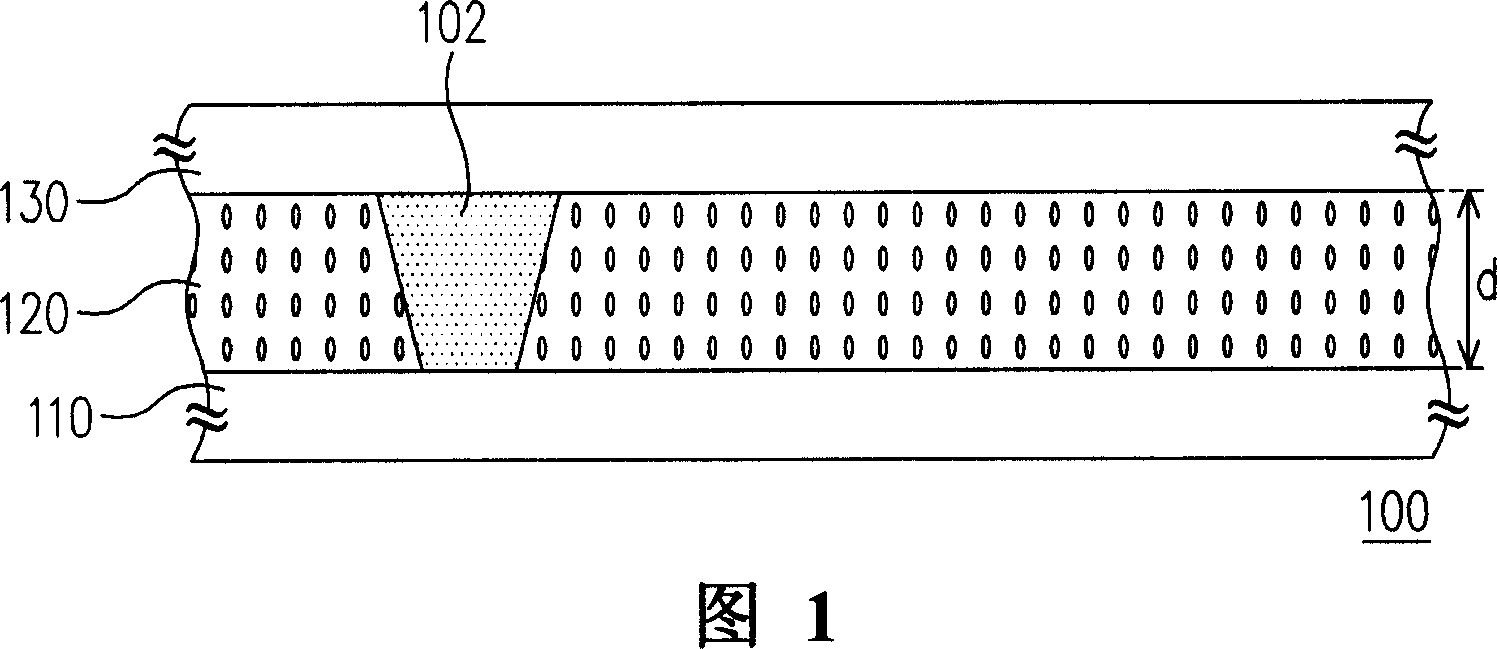

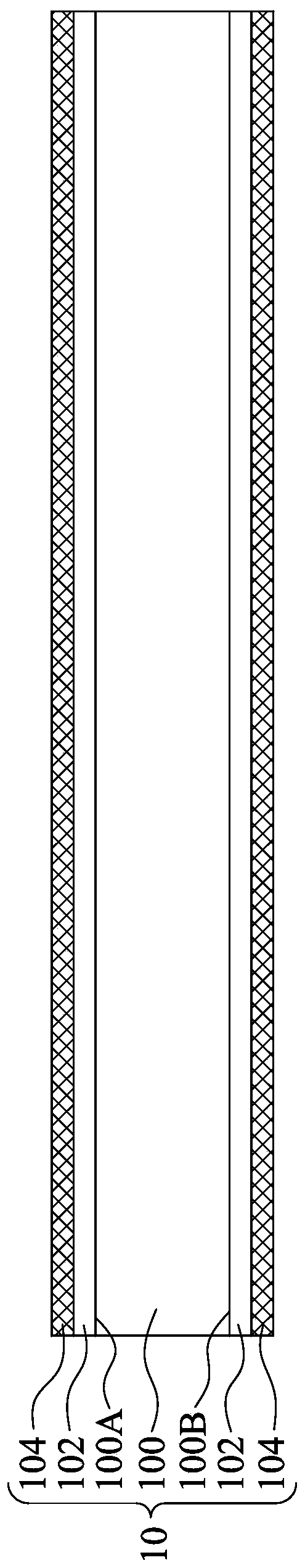

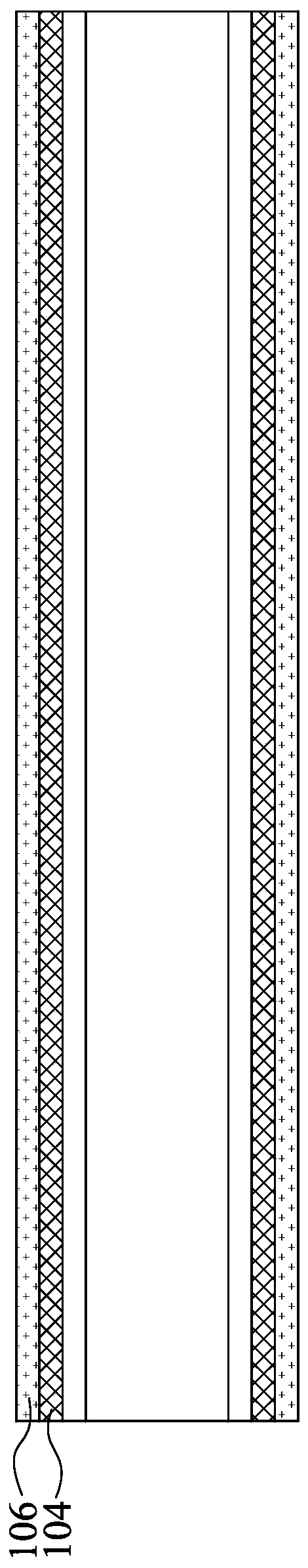

Two base plate sealing structure with high airtight strength and plasma display device

InactiveCN1545120AAdhesivelyAvoid problems such as separationSolid cathode detailsCold-cathode tubesDisplay deviceUltimate tensile strength

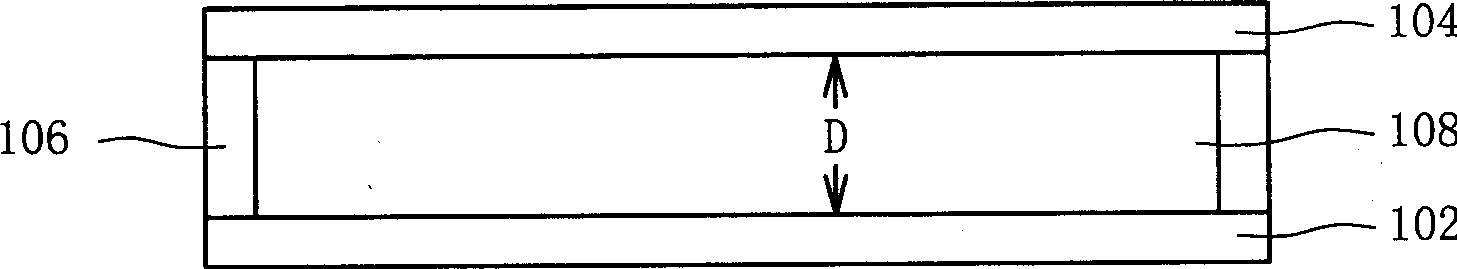

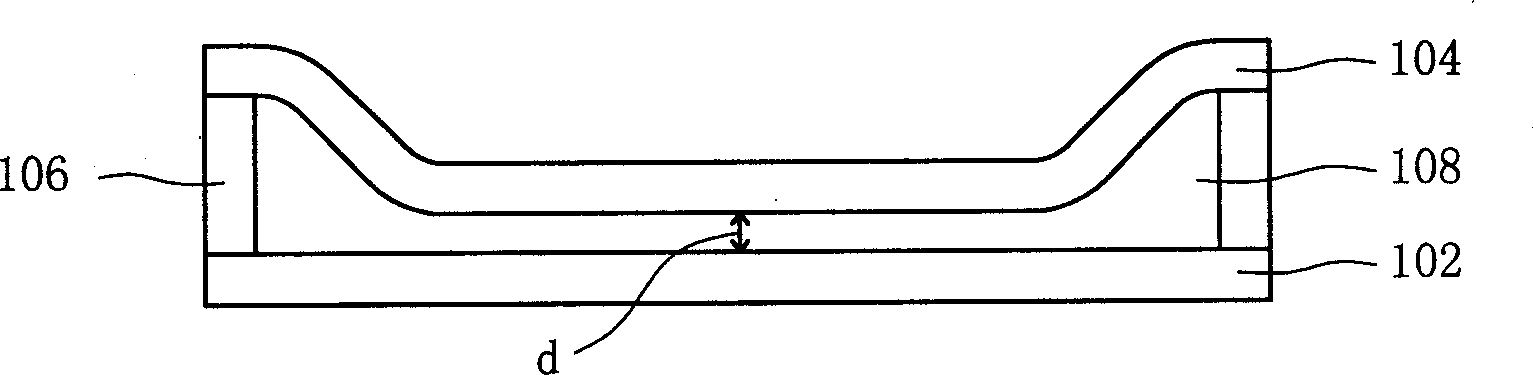

The invention discloses a high stealing strength two-basal plate sealed structure and a plasma display device containing it. It mainly improves and designs geometrical shape and structure of sealed materials, providing a high stealing strength plasma display device to make the front and back plates of the plasma display device adhere to each other closely, and avoiding the problems of fragmentation or separation of basal plates. The sealed structure includes: a first basal plate with a first surface and a second basal plate, set over the first basal plate and jointed with the first basal plate by packaging material, the second basal plate is opposite to the first surface of the first basal plate by the second surface, and the boundary of the second surface extending outwards is a first boundary line and the above first surface has a second boundary line is situated in the corresponding position to the first basal plate in the normal direction of the first boundary line.

Owner:AU OPTRONICS CORP

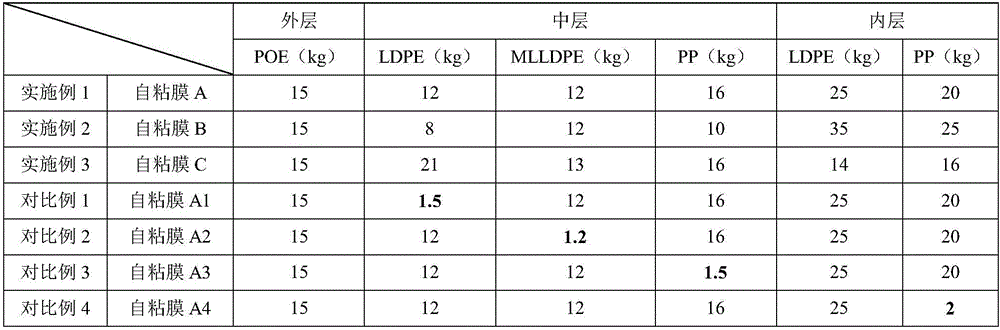

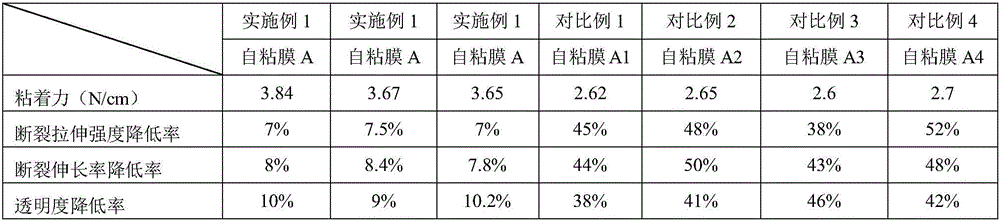

Solar panel high-temperature-resistant anti-ultraviolet self-adhesive film

ActiveCN105882094AFulfil requirementsImprove high temperature resistanceSynthetic resin layered productsFlat articlesUltravioletEngineering

The invention provides a solar panel high-temperature-resistant anti-ultraviolet self-adhesive film. The self-adhesive film is formed by an outer layer, a middle layer and an inner layer through co-extrusion film blowing and is characterized in that by weight, the mass ratio of the outer layer to the middle layer to the inner layer is (10-20):(30-50):(30-60), the outer layer is a viscous layer made of POE, the middle layer is prepared by blending LDPE, MLLDPE and PP by the weight ratio of (4-1):(1-4):(1-5), and the inner layer is prepared by blending LDPE and PP by the weight ratio of (4-1):(1-3). Reasonable composition and matching are adopted in the self-adhesive film three-layer structure, viscosity of the self-adhesive film can meet requirements of clients, the self-adhesive film is good in high temperature resistance and stretchability, and good in ageing resistance under long-term ultraviolet irradiation compared with a glue coated film, and viscosity is enhanced little.

Owner:GUANGDONG DONGLI NEW MATERIALS SCI & TECH CO LTD

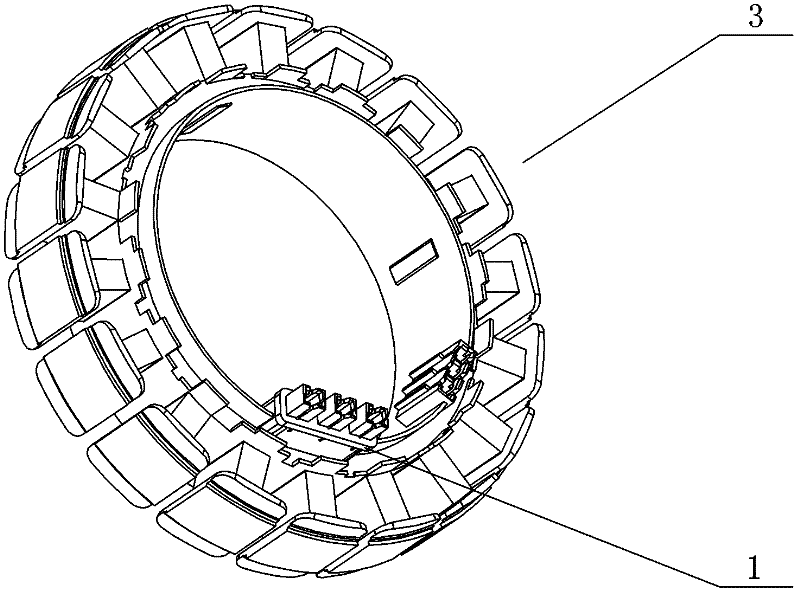

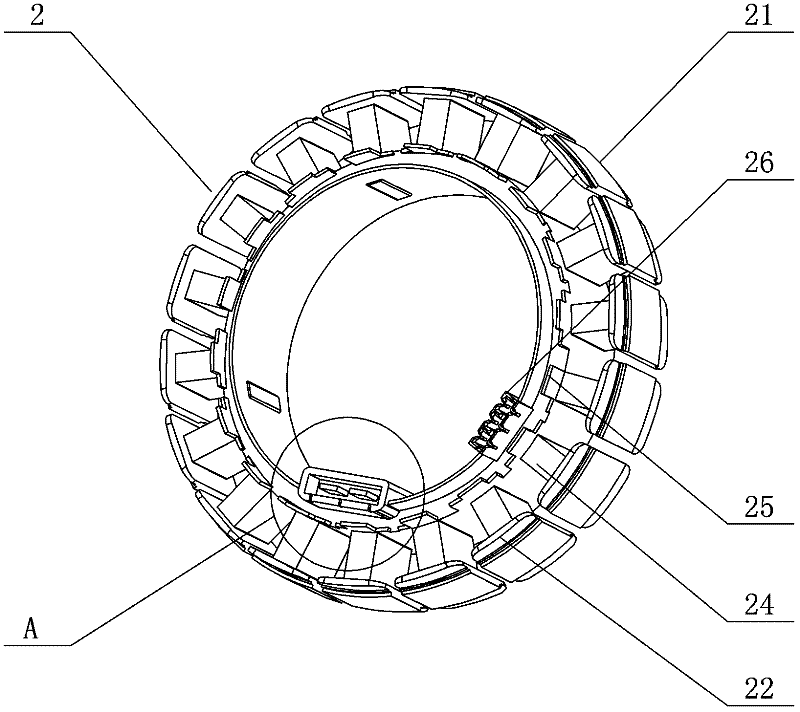

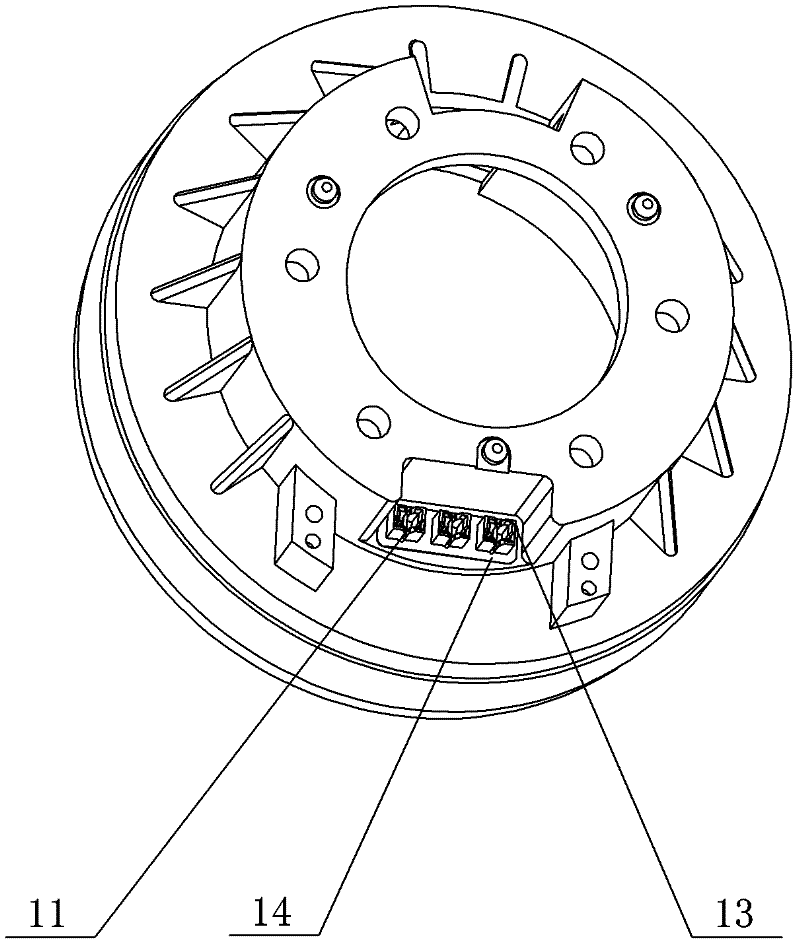

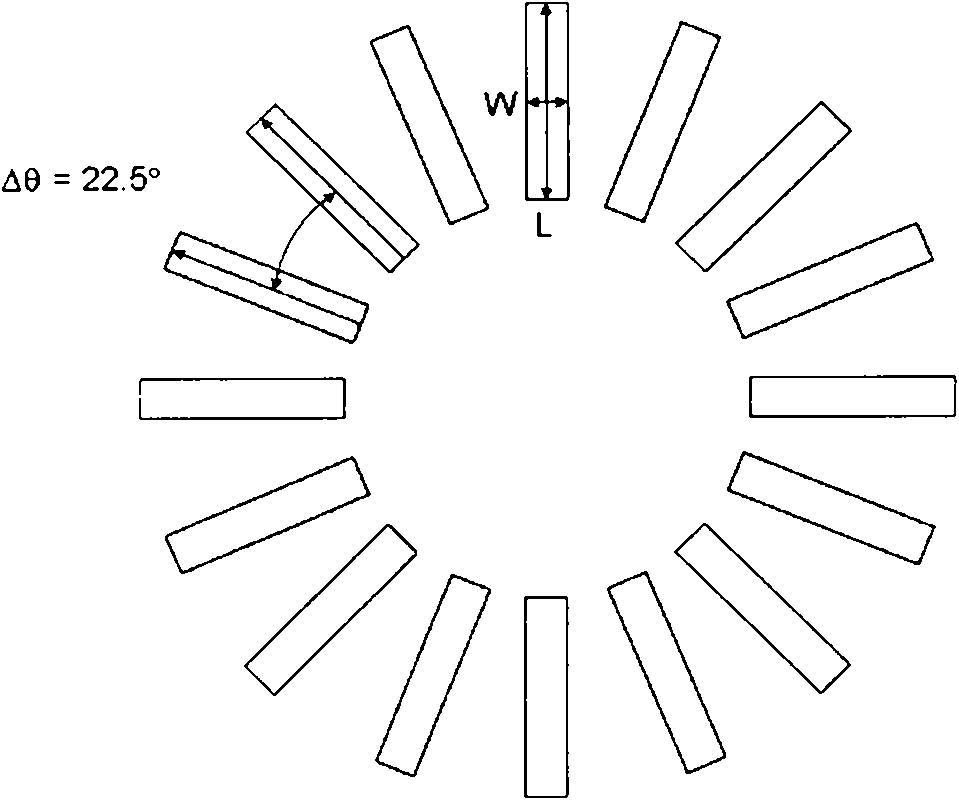

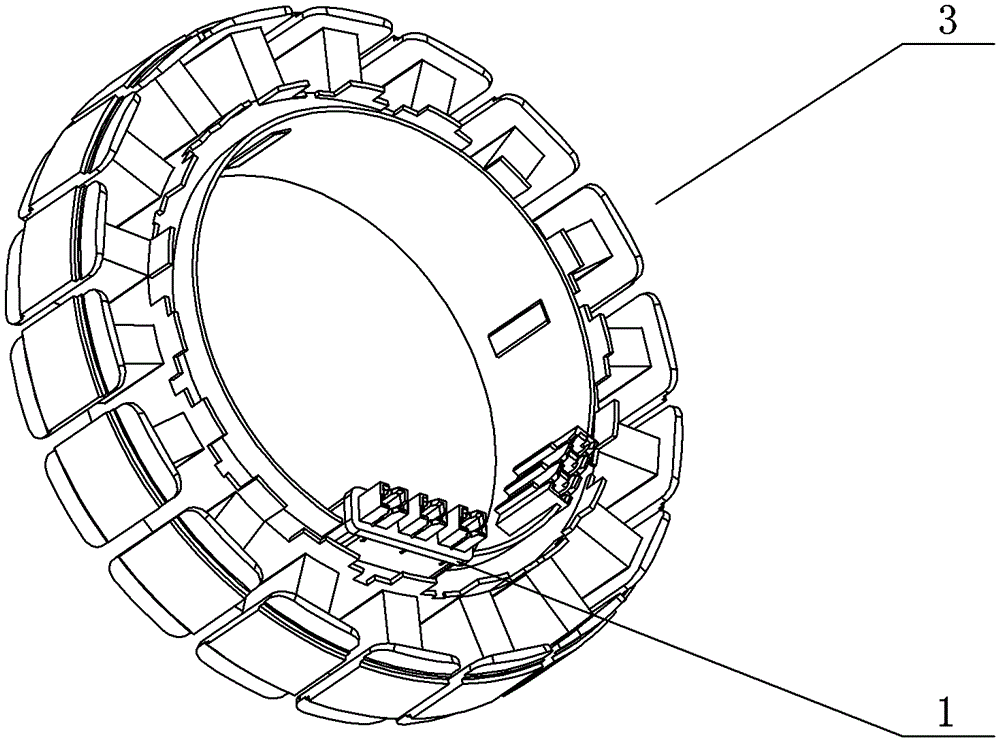

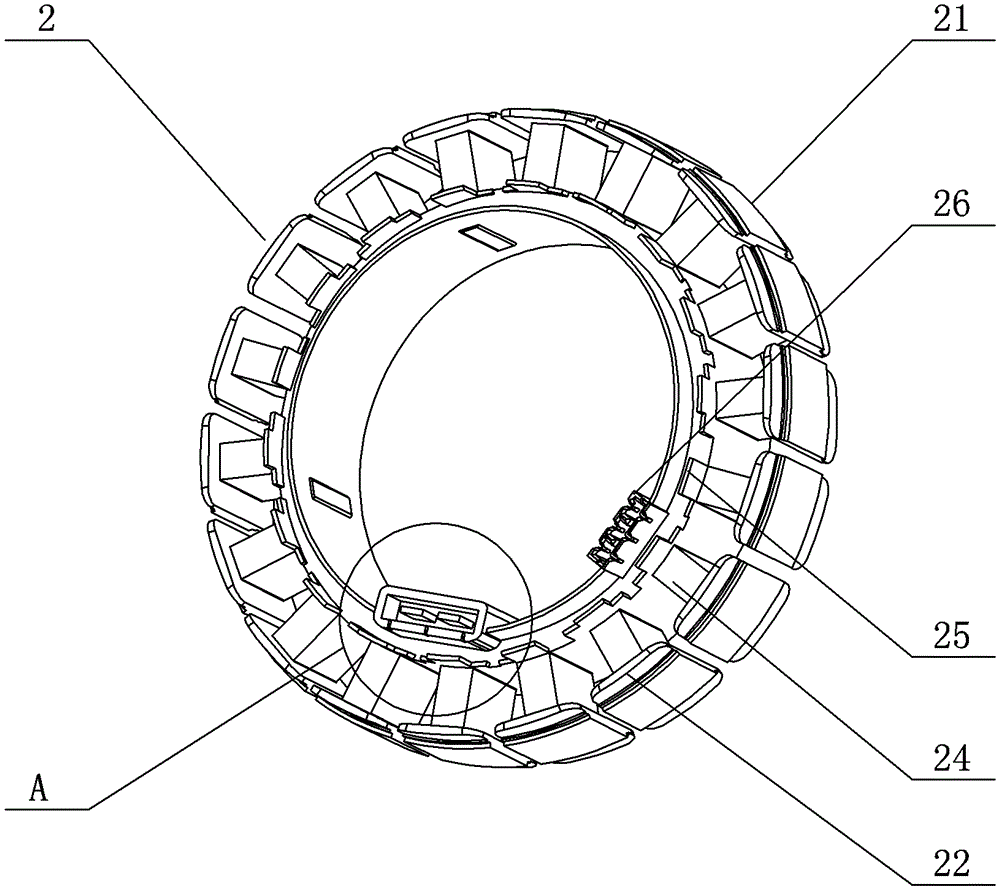

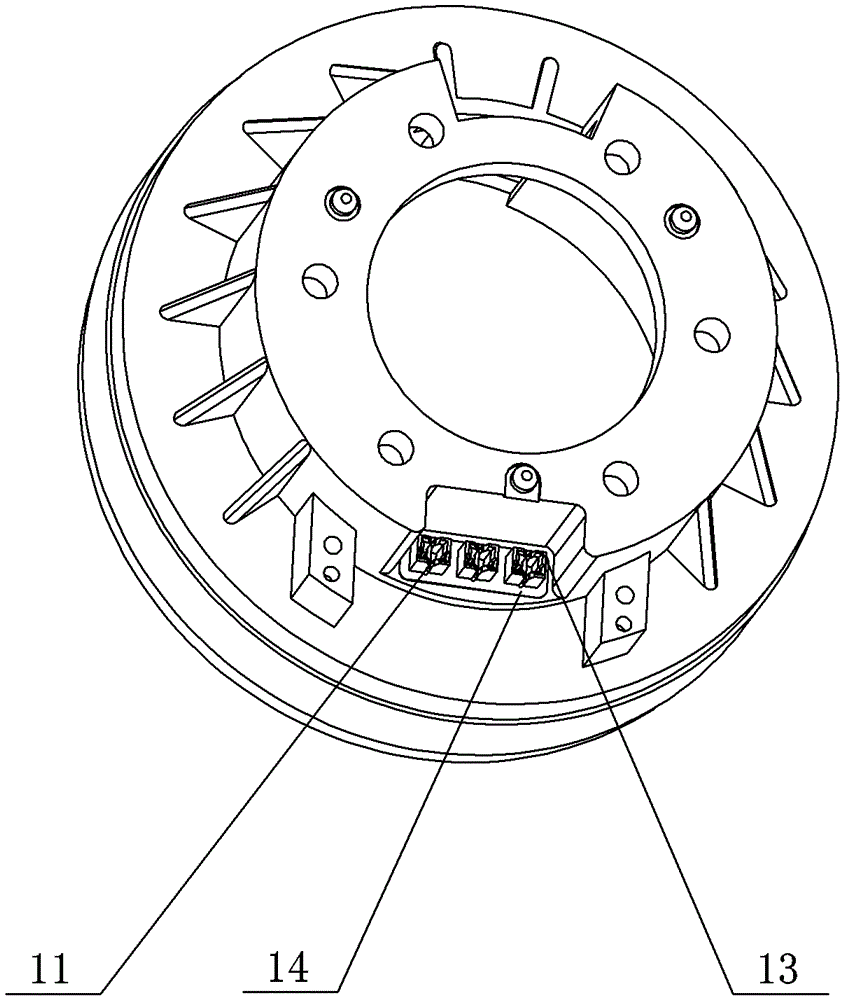

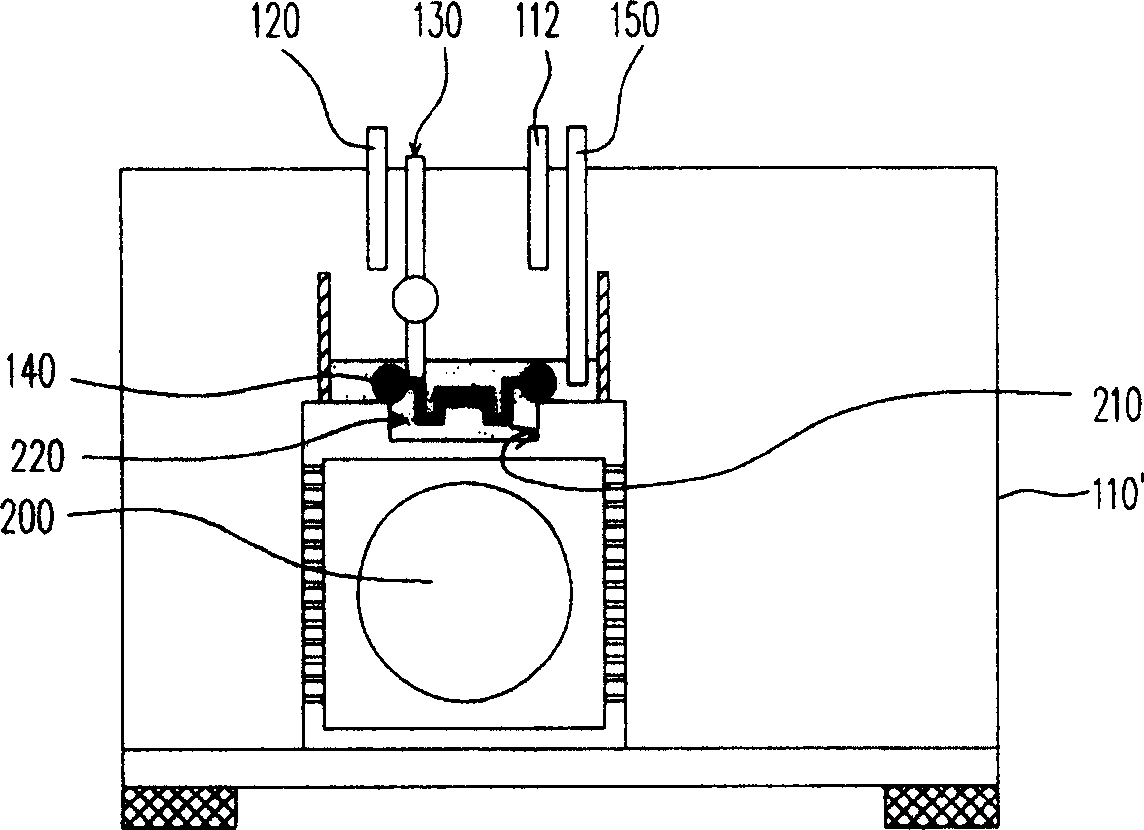

Stator structure of molding electrical machine for washing machine

ActiveCN102377254AReduce manufacturing costEasy to produceWindingsMagnetic circuit stationary partsElectricityWhole body

The invention provides a stator structure of a molding electrical machine for a washing machine, which comprises a stator iron core insulating piece and an terminal part, wherein the terminal part and the stator iron core insulating piece are respectively to be a separated part and are connected with each other into a whole body in the manner of inserting, fastening, bonding or molding. The middle of the terminal part is provided with a plane which is named as a middle plane of the terminal part, the middle plane of the terminal part is provided with a protecting hole for protecting an enameled wire, and the enameled wire is arranged in the protecting hole of the enameled wire when the terminal part is molded, so that the terminal part can be directly molded without arranging a conventional cover for protecting the terminal part, the material and the time can be saved, and the hidden trouble that the enameled wire is crushed by the conventional structure can be avoided. Furthermore, a certain height difference exists between a groove at a place where the enameled wire is inserted and the middle plane, so that a waterproof material can not be fed into or covered on the end part of an electric connecting coil, and the defective product of the stator of the electrical machine since a molding material is fed into the end part of the electric connecting coil can be reduced.

Owner:FOSHAN WEILING WASHER MOTOR MFG

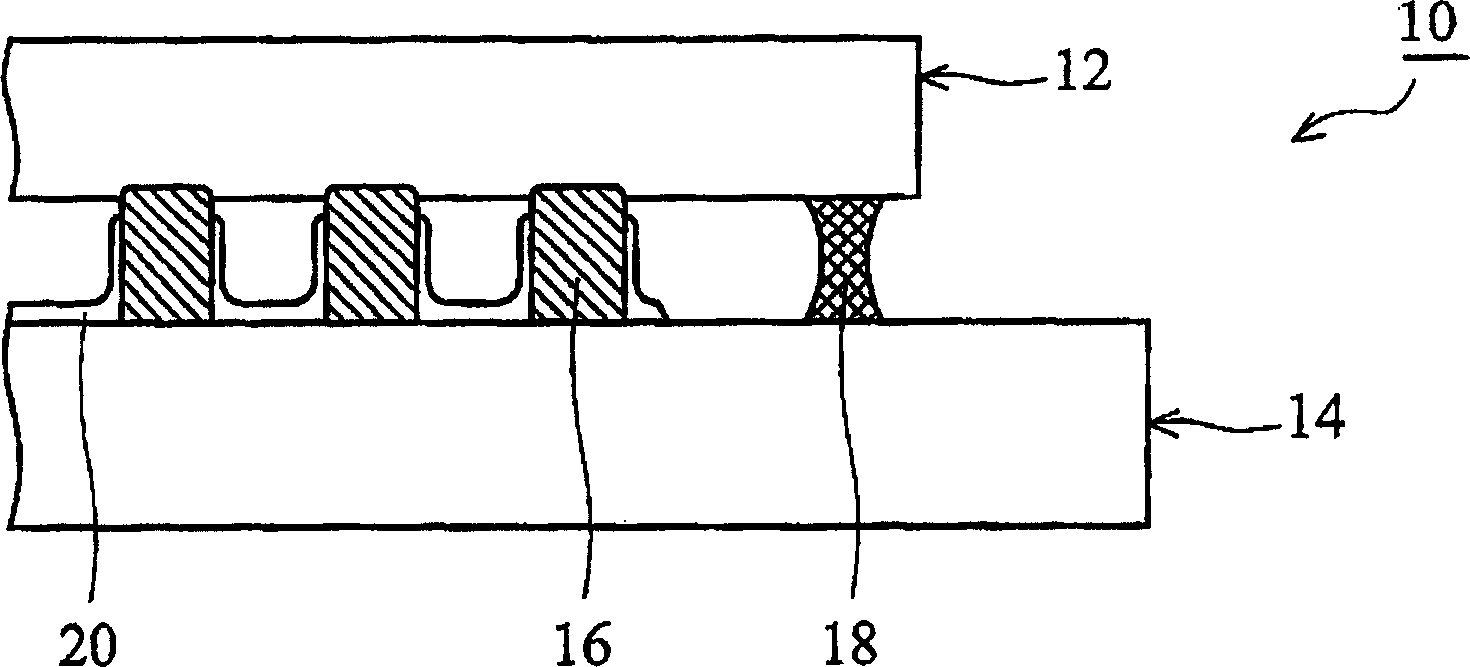

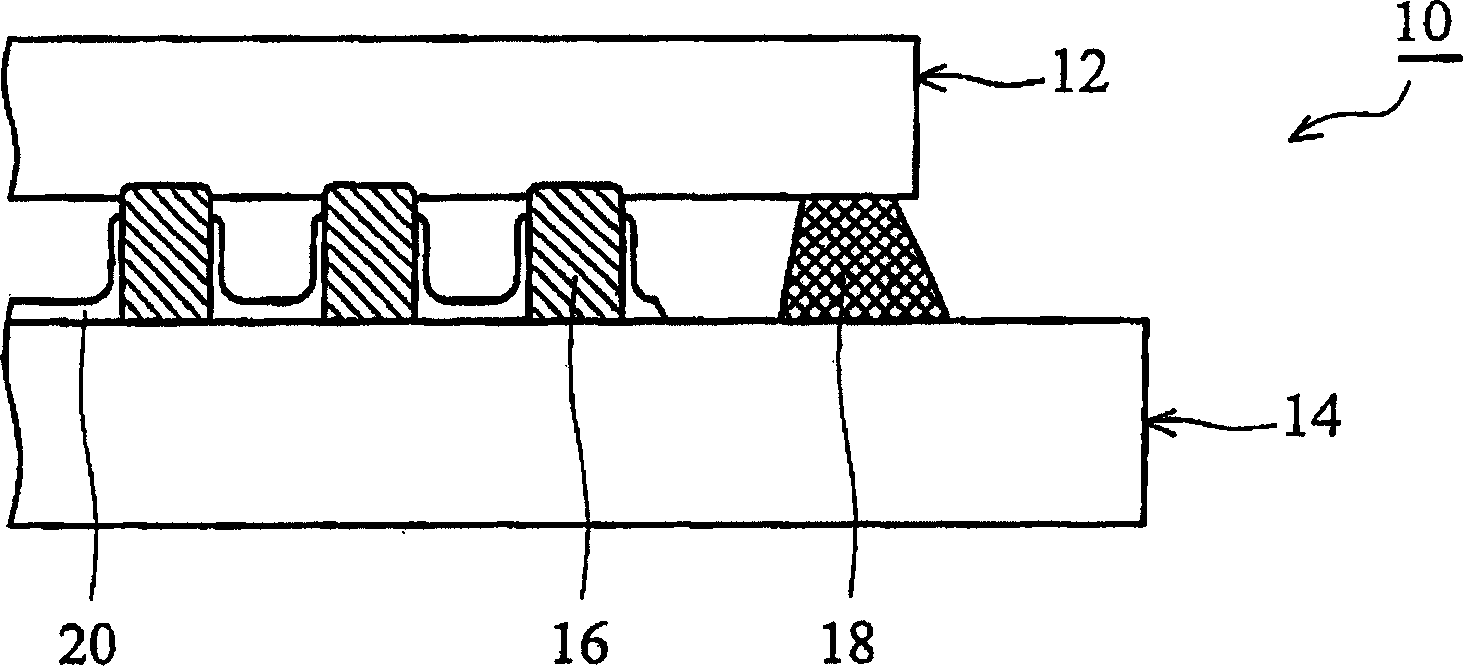

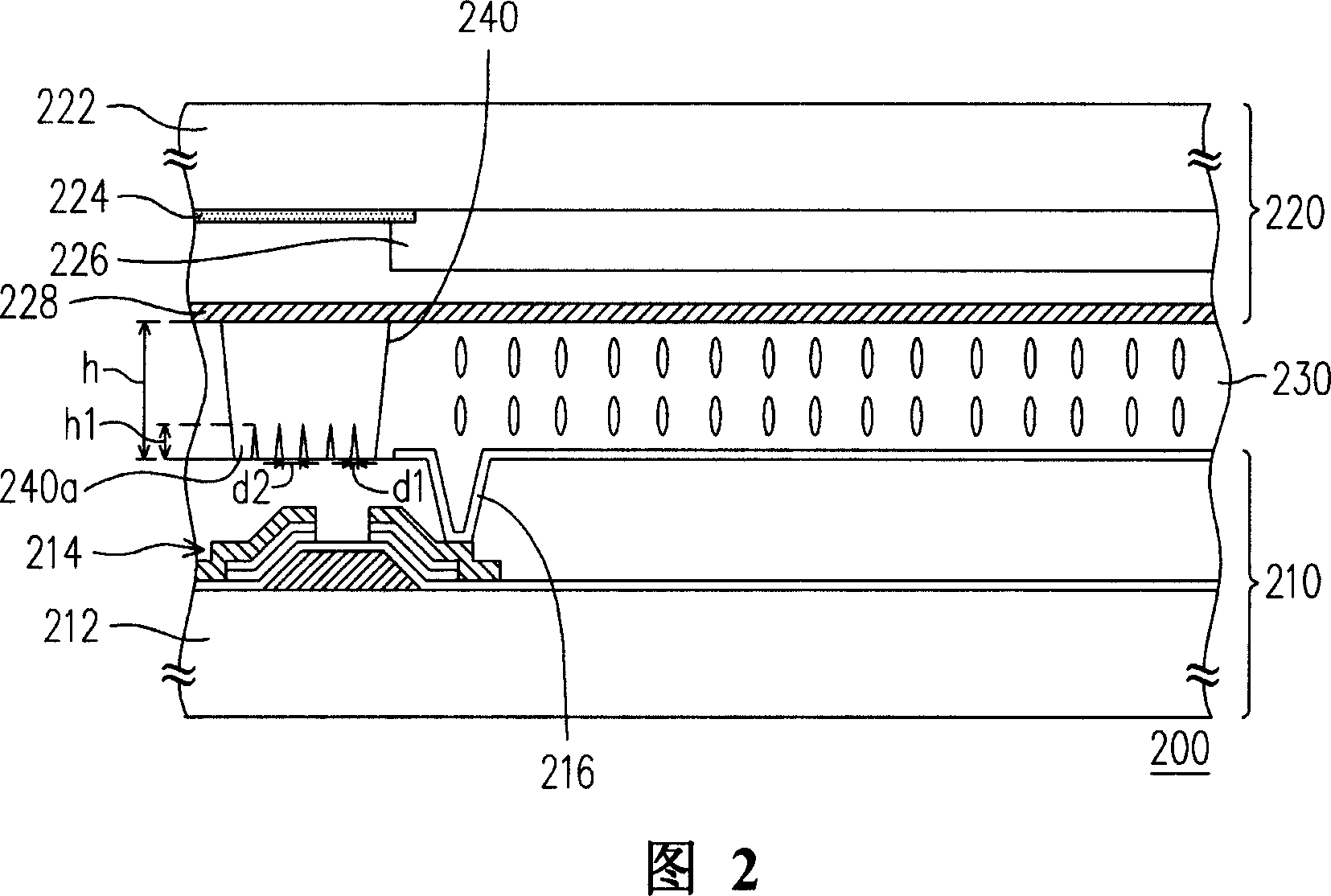

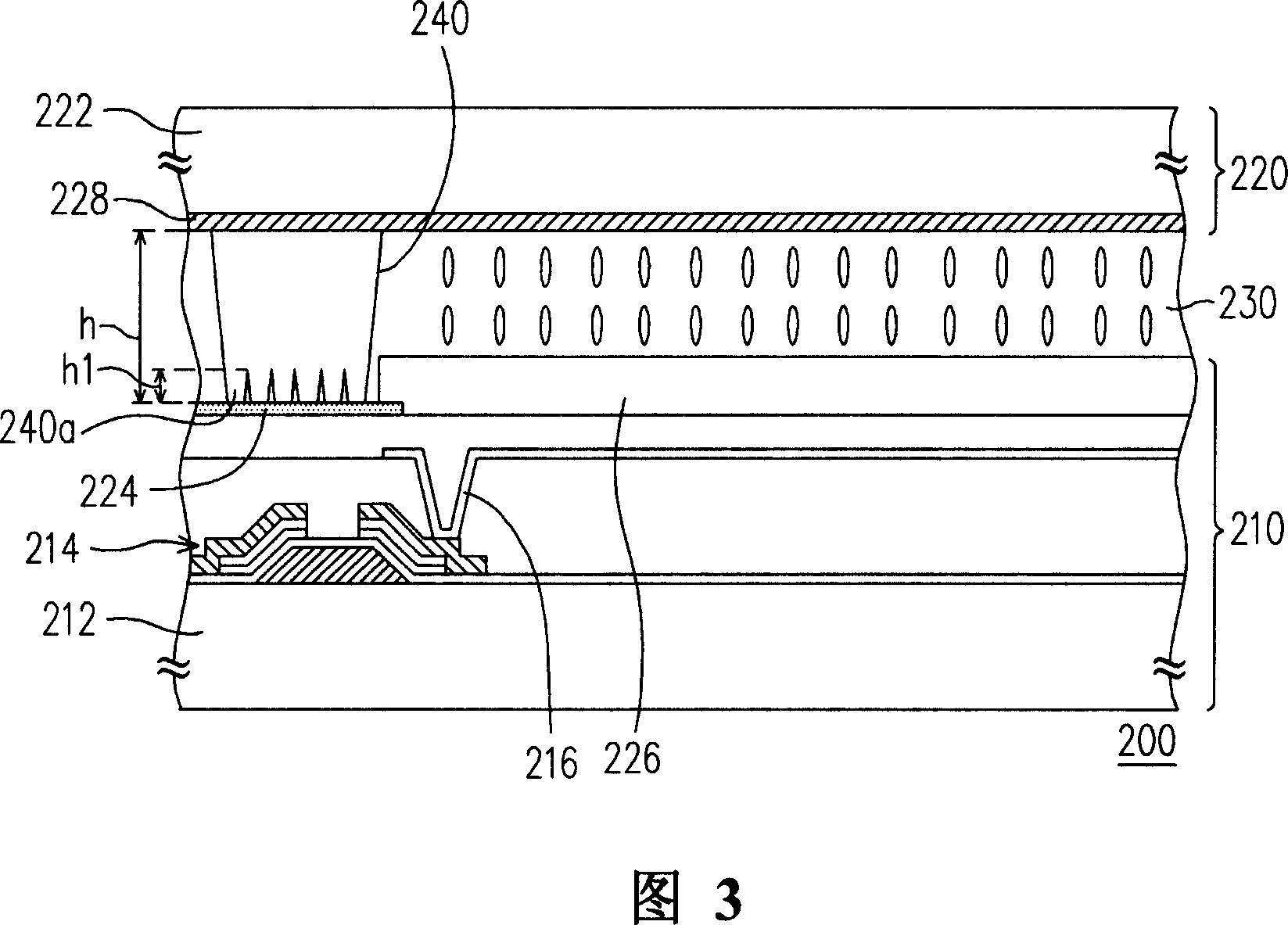

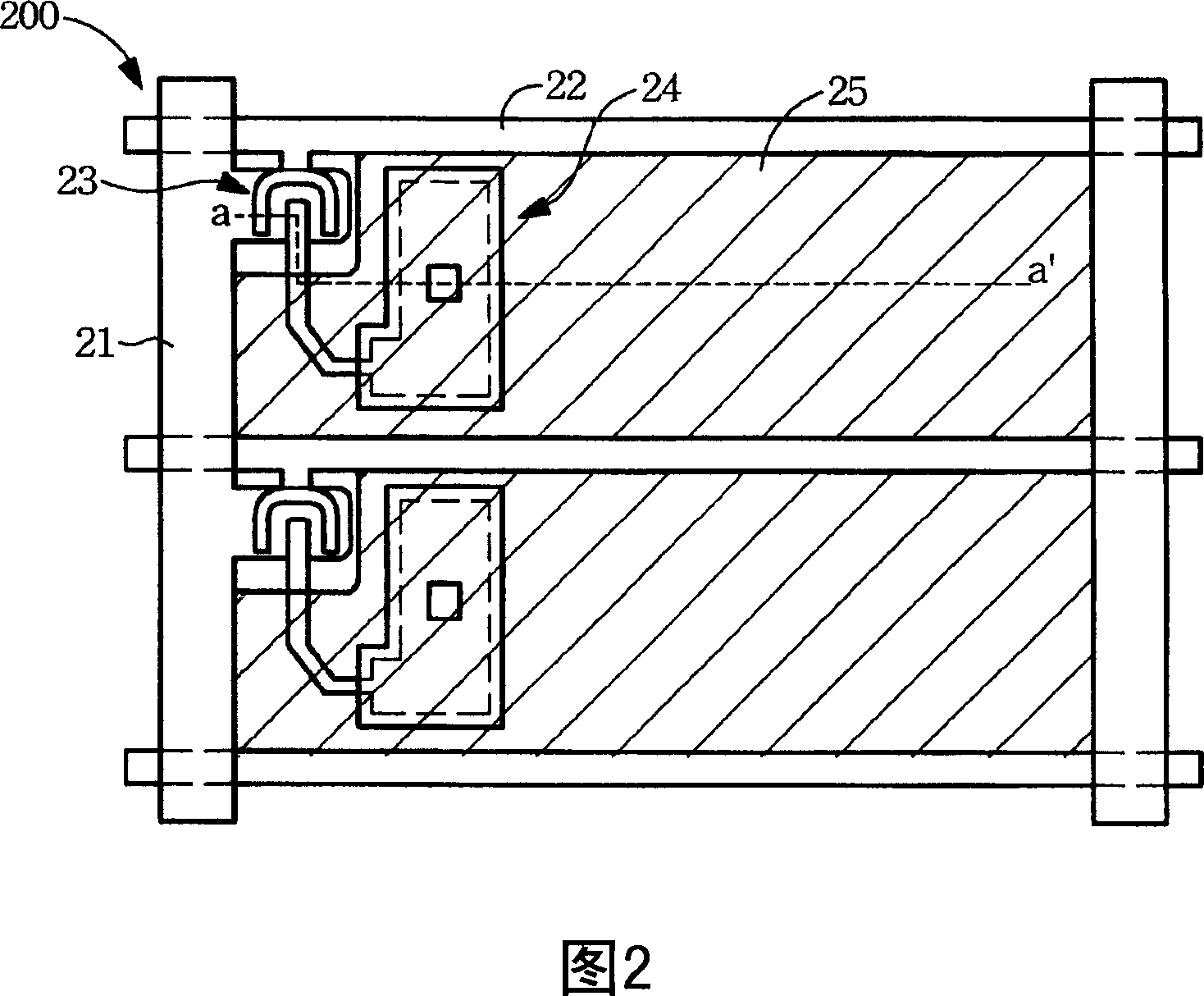

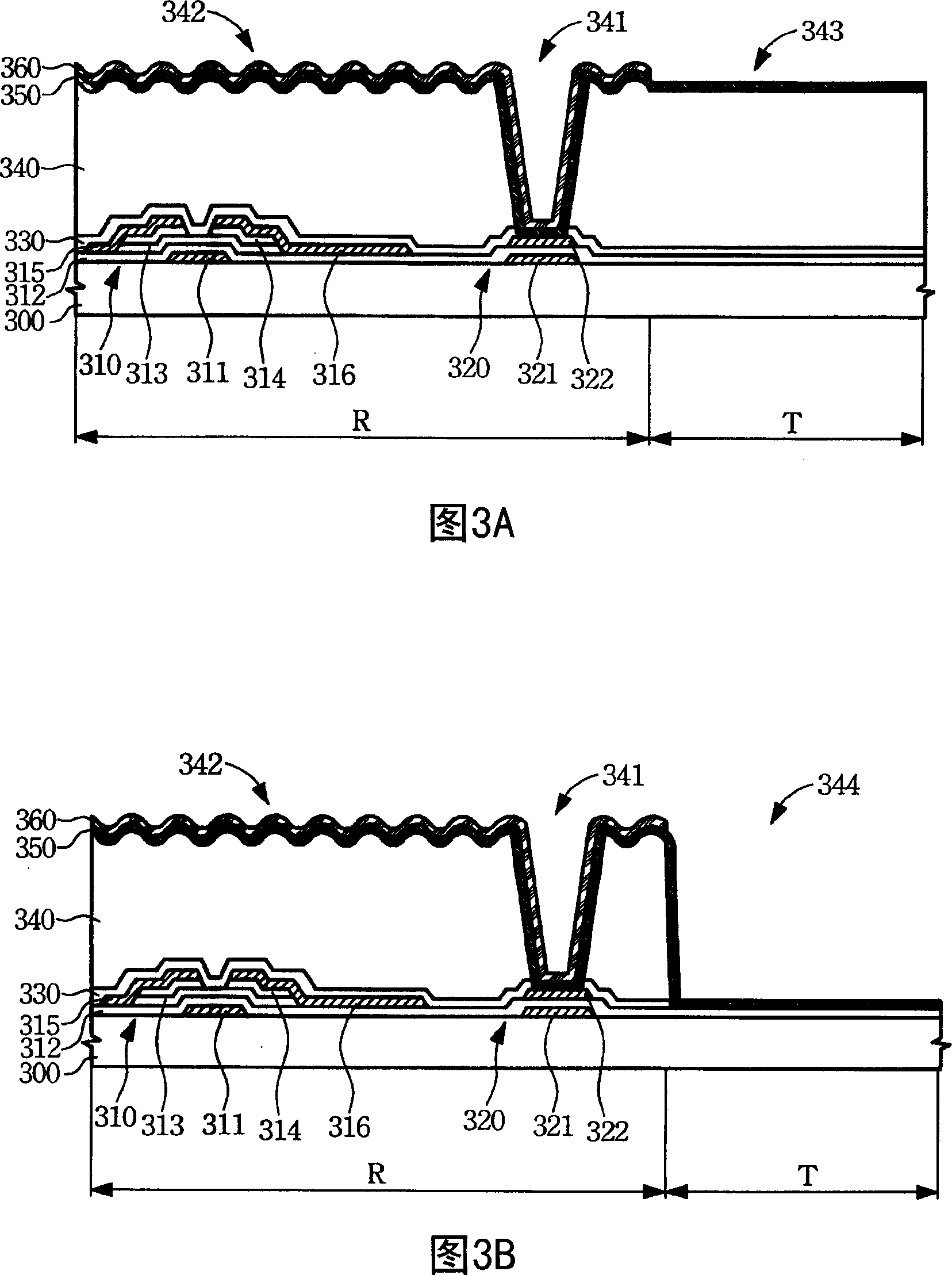

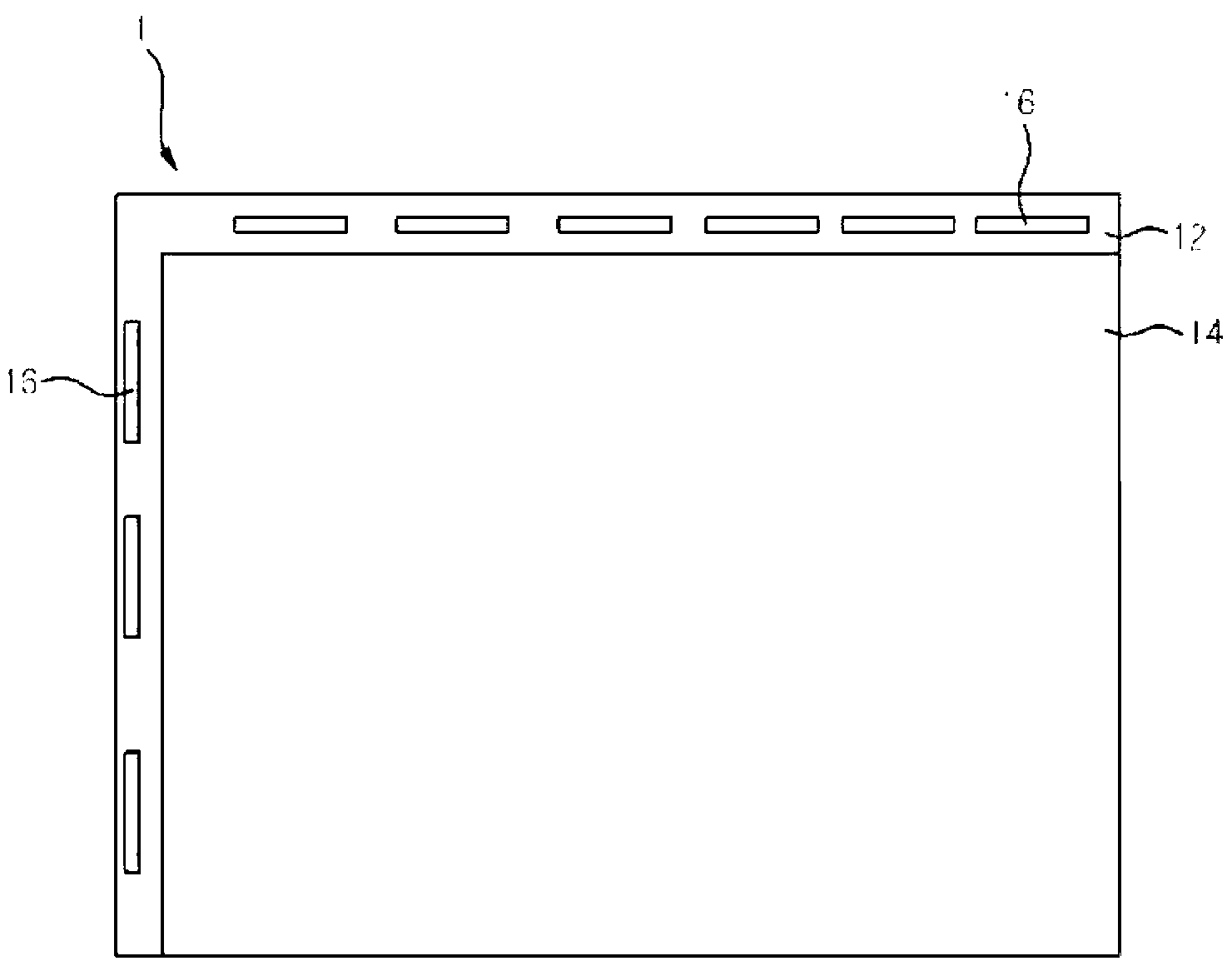

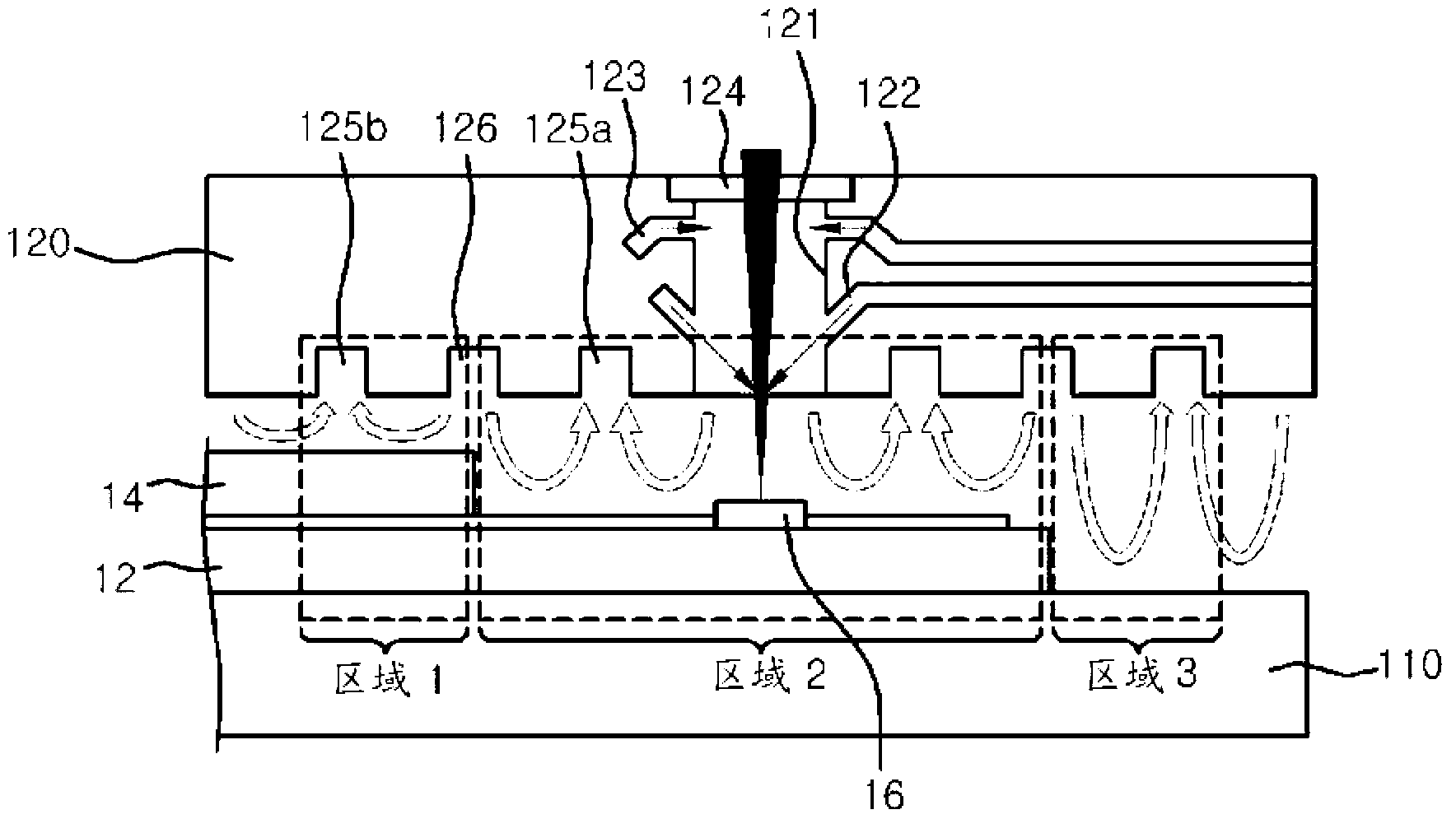

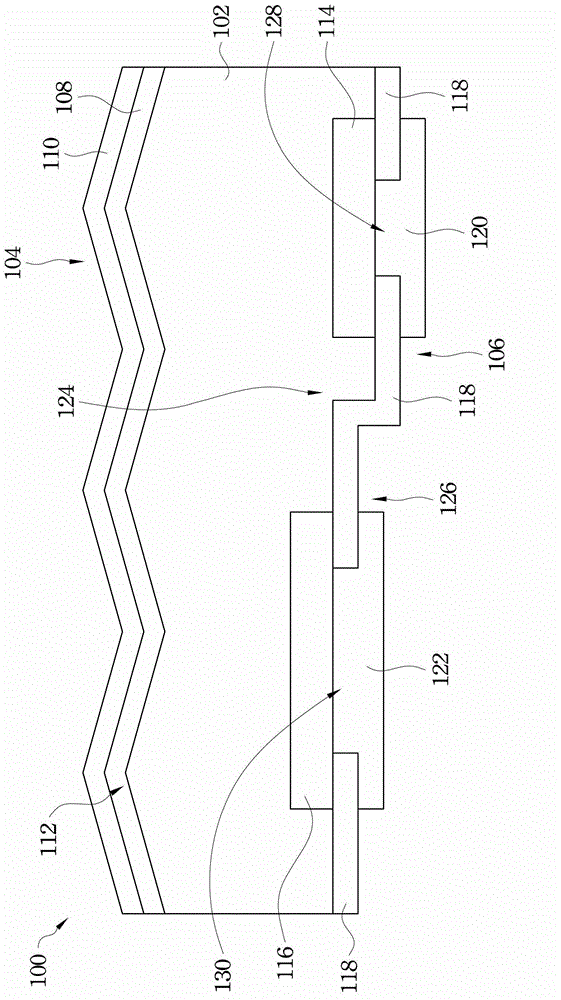

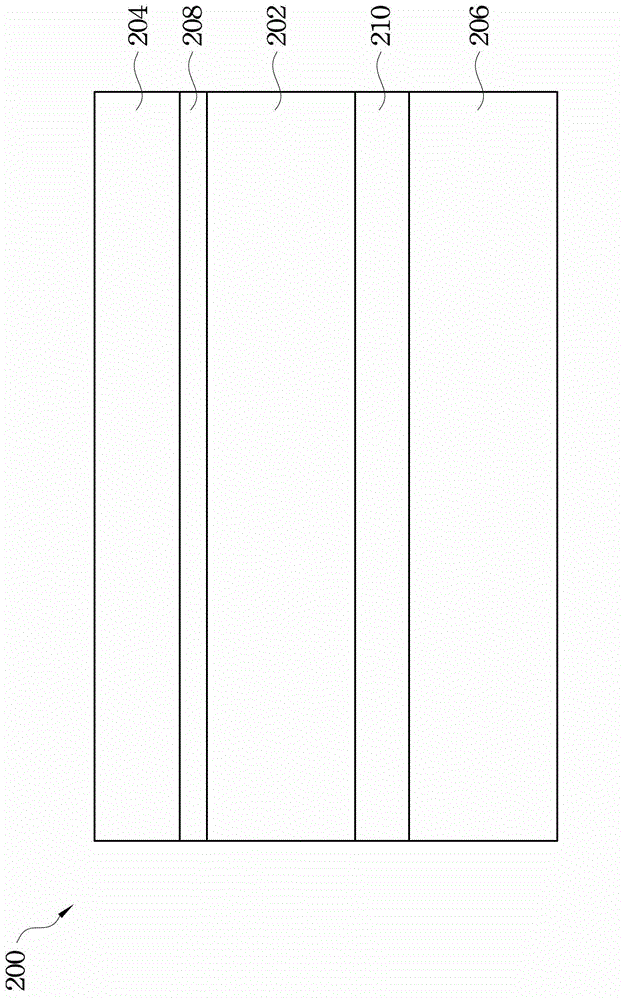

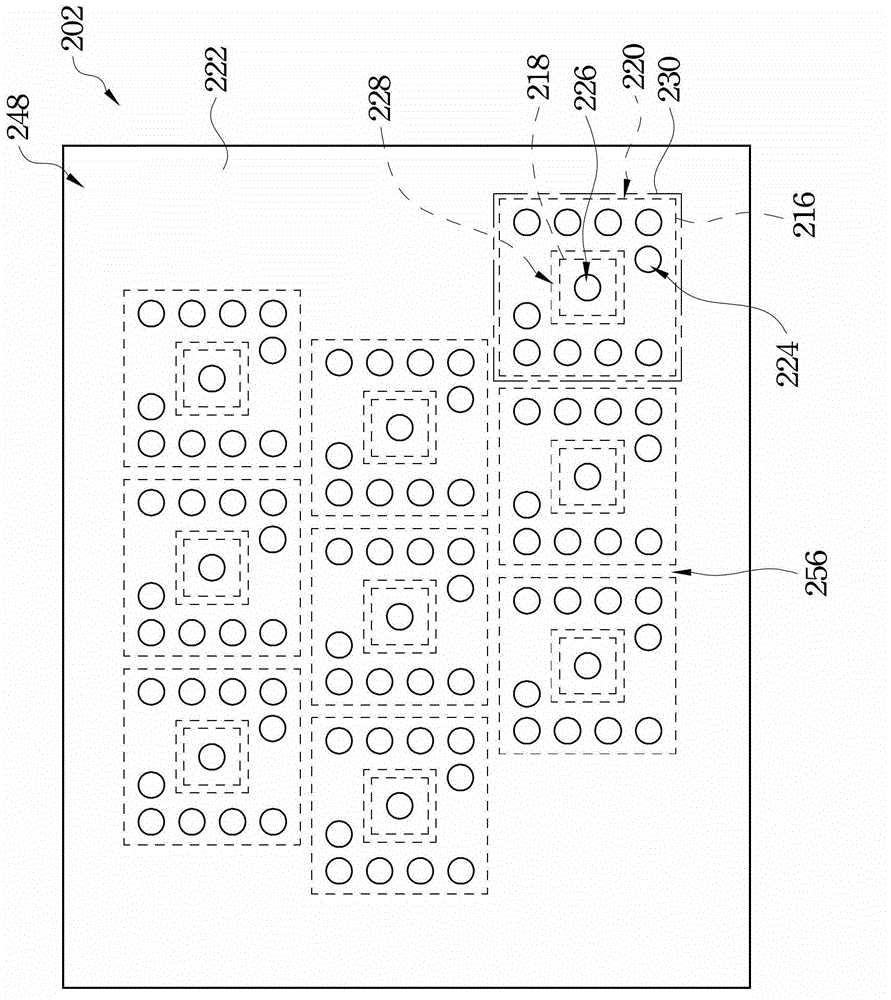

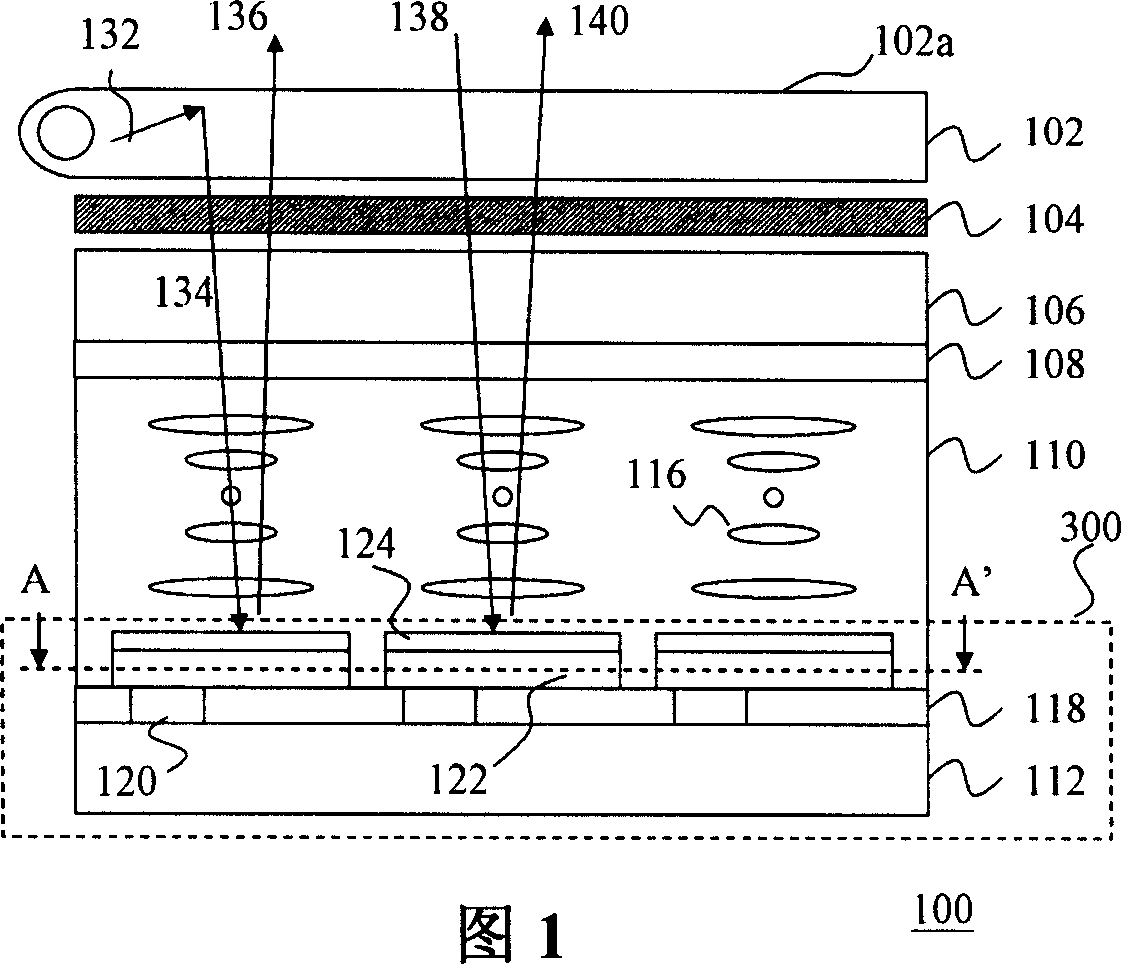

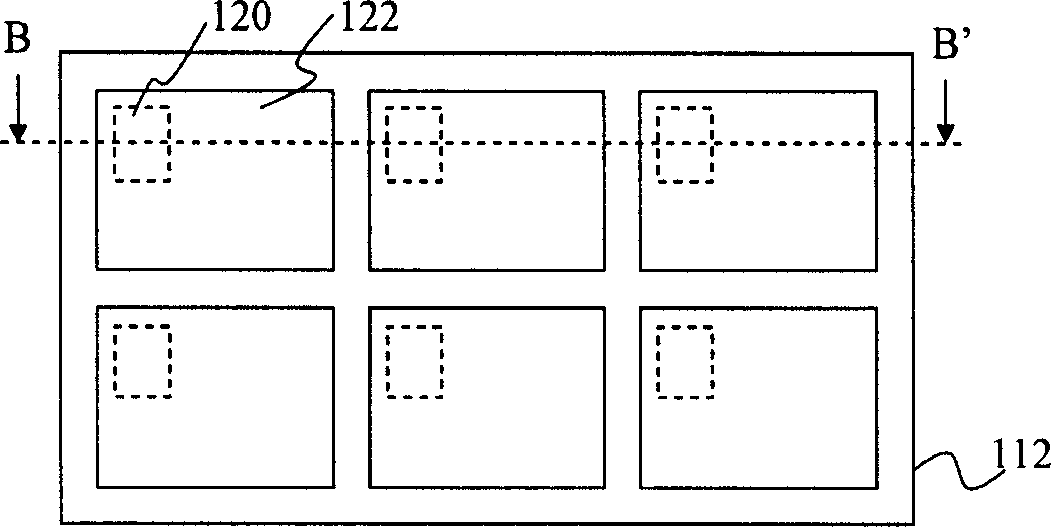

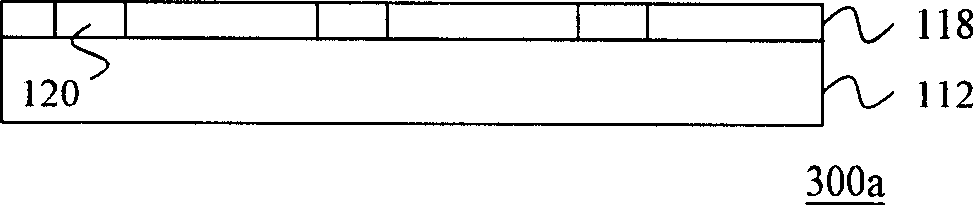

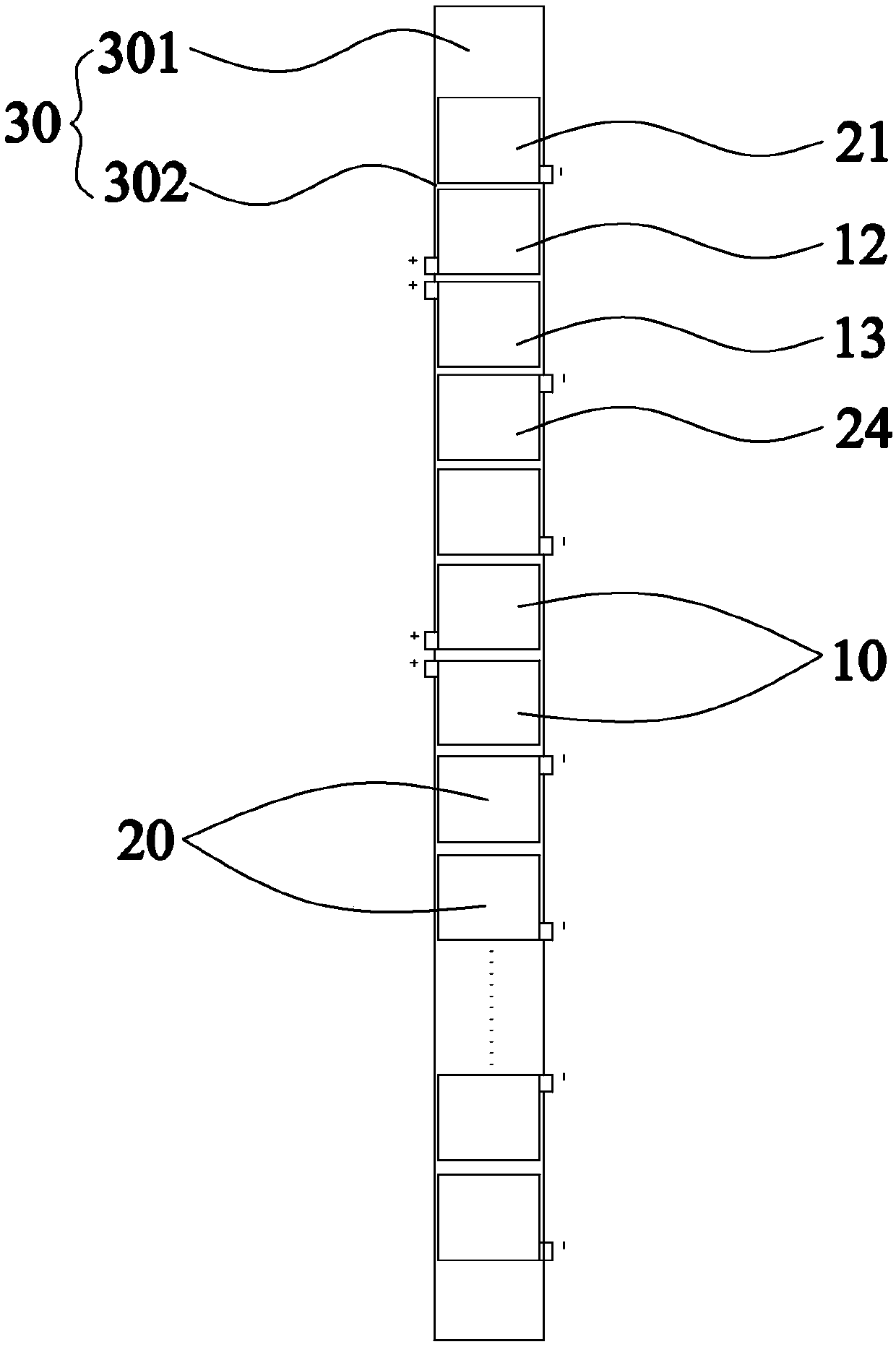

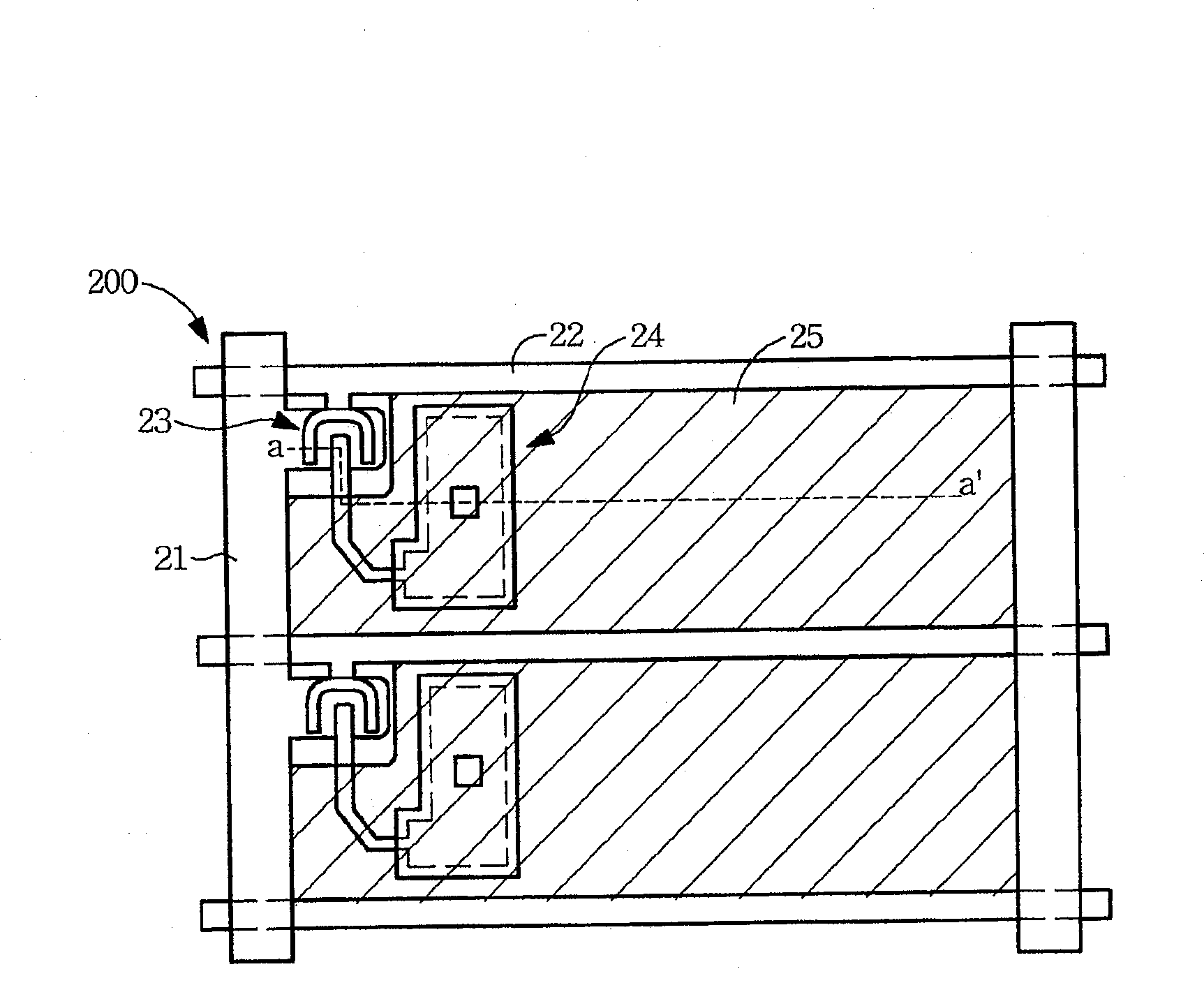

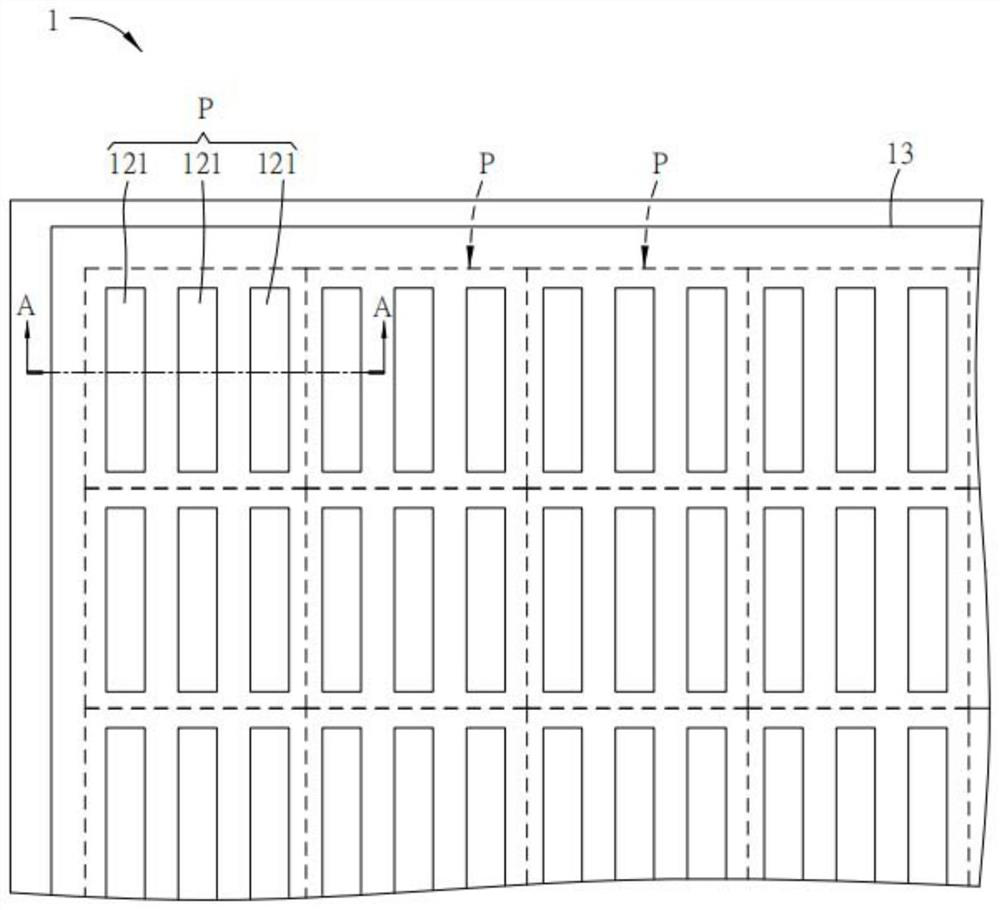

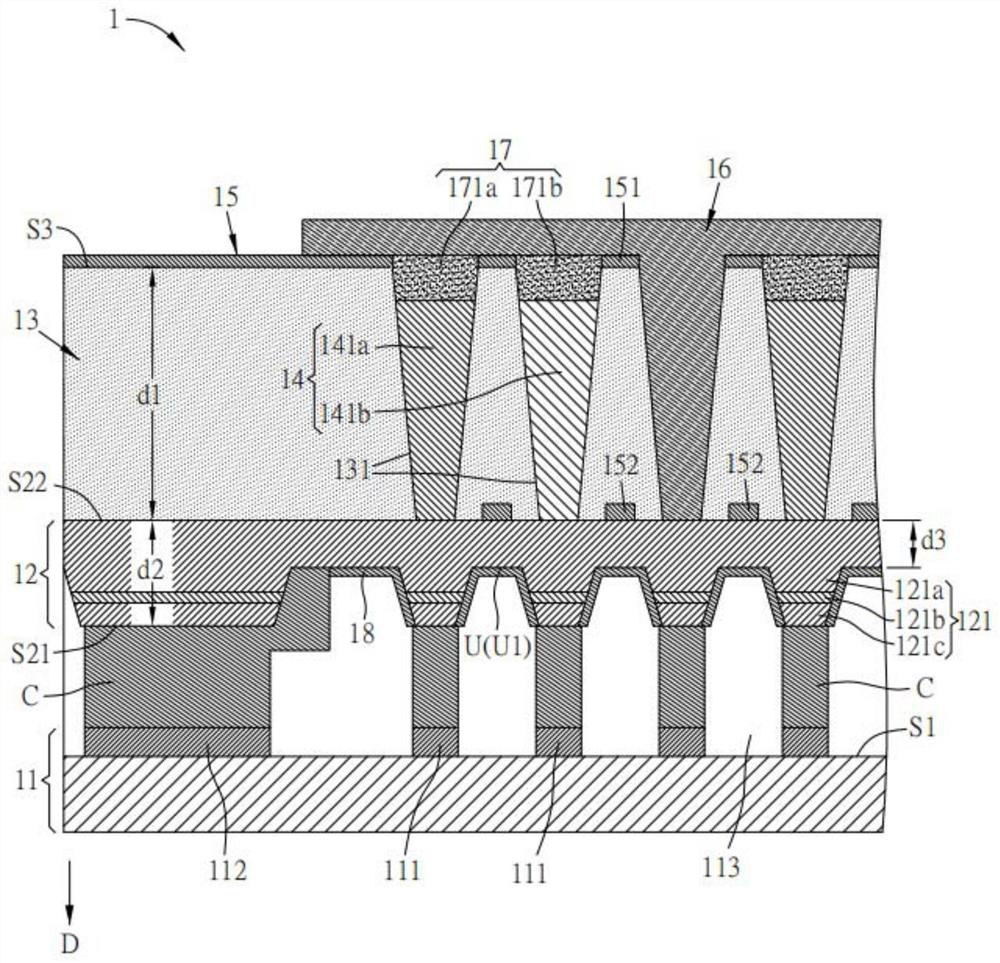

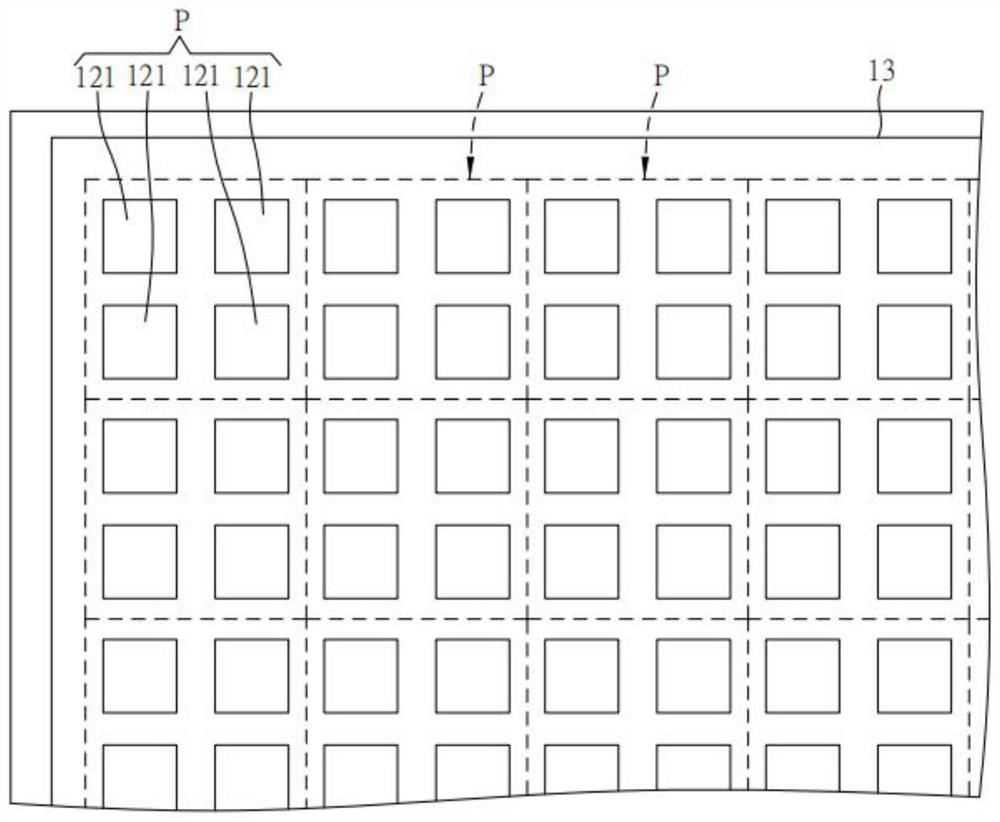

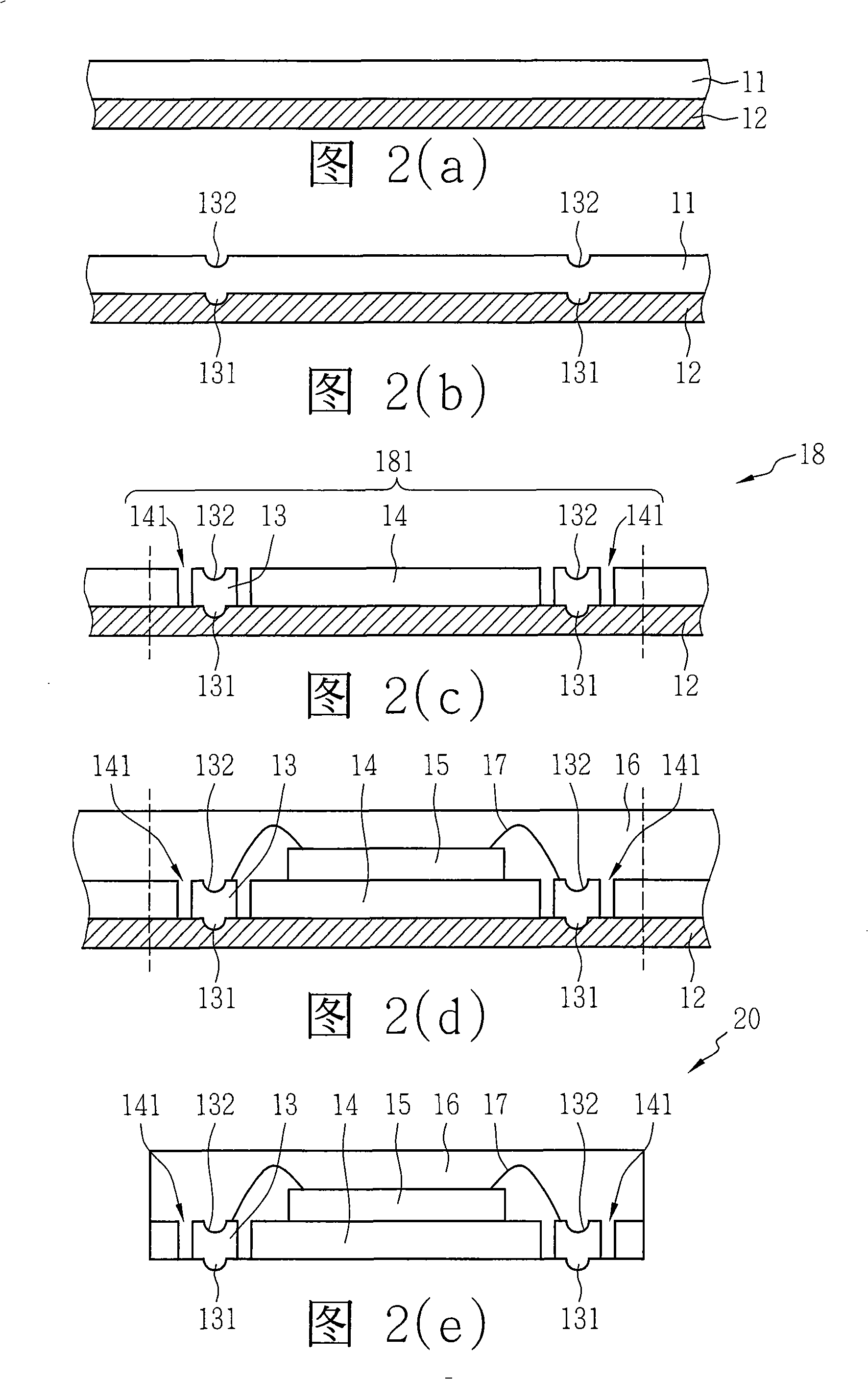

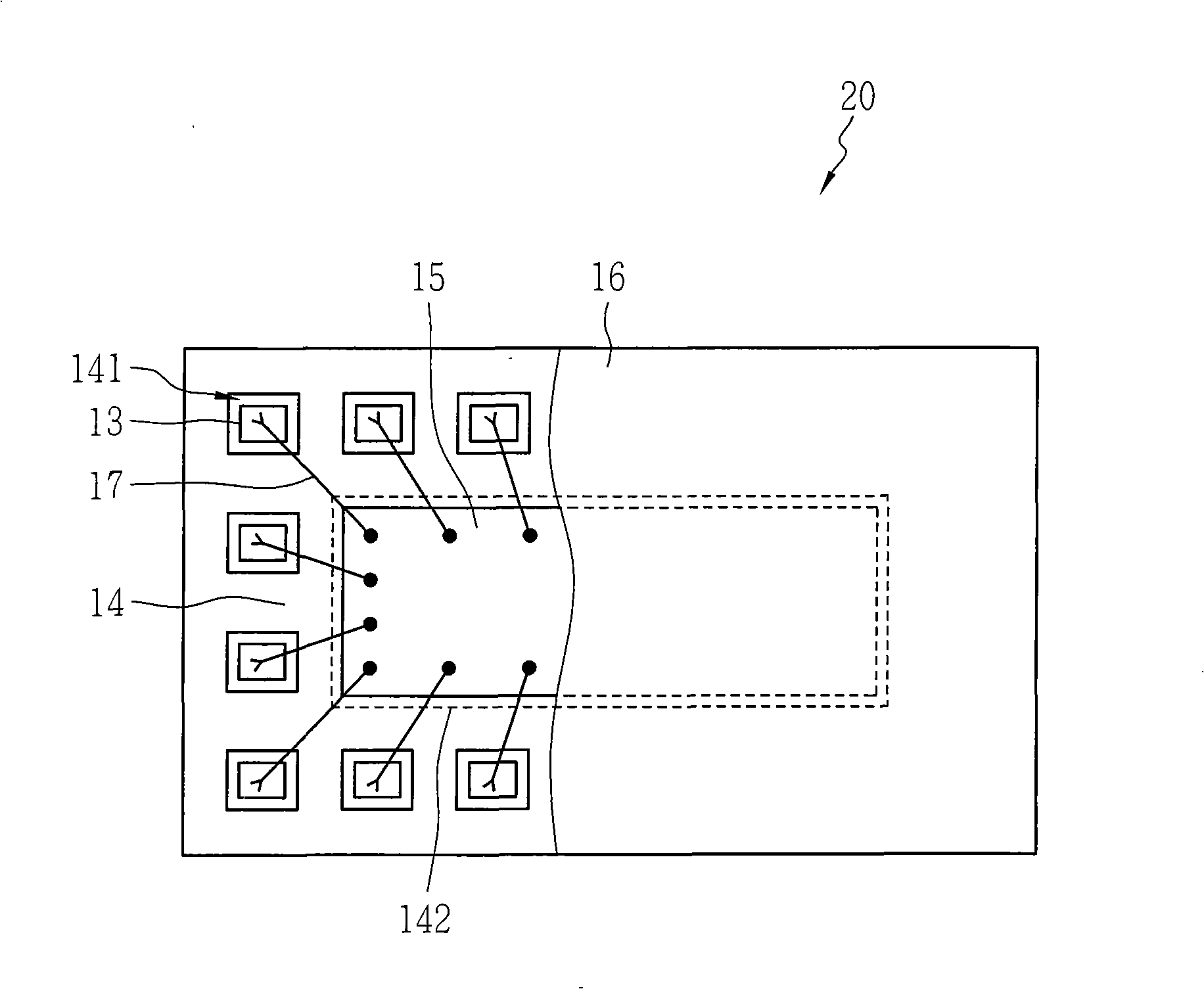

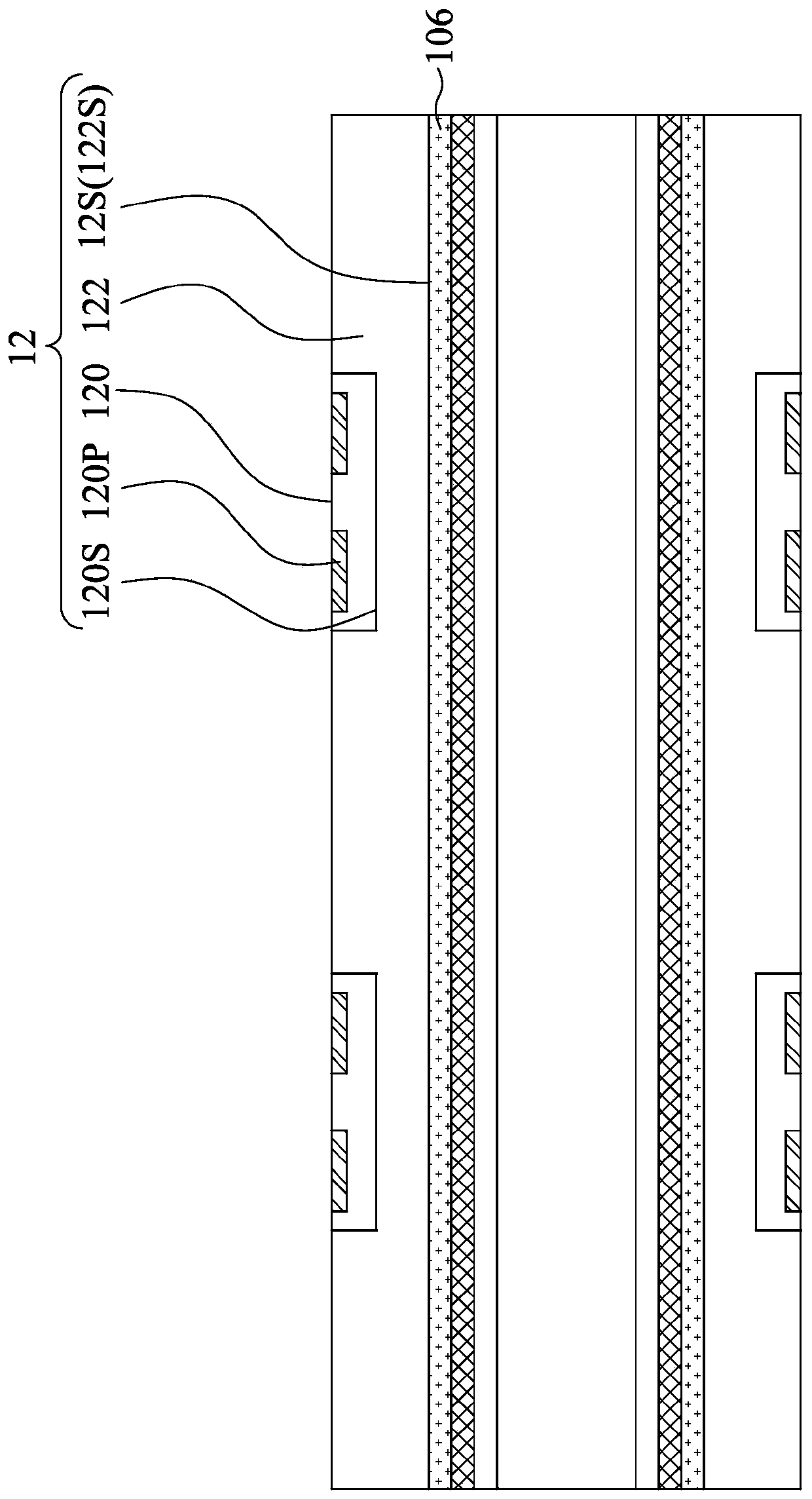

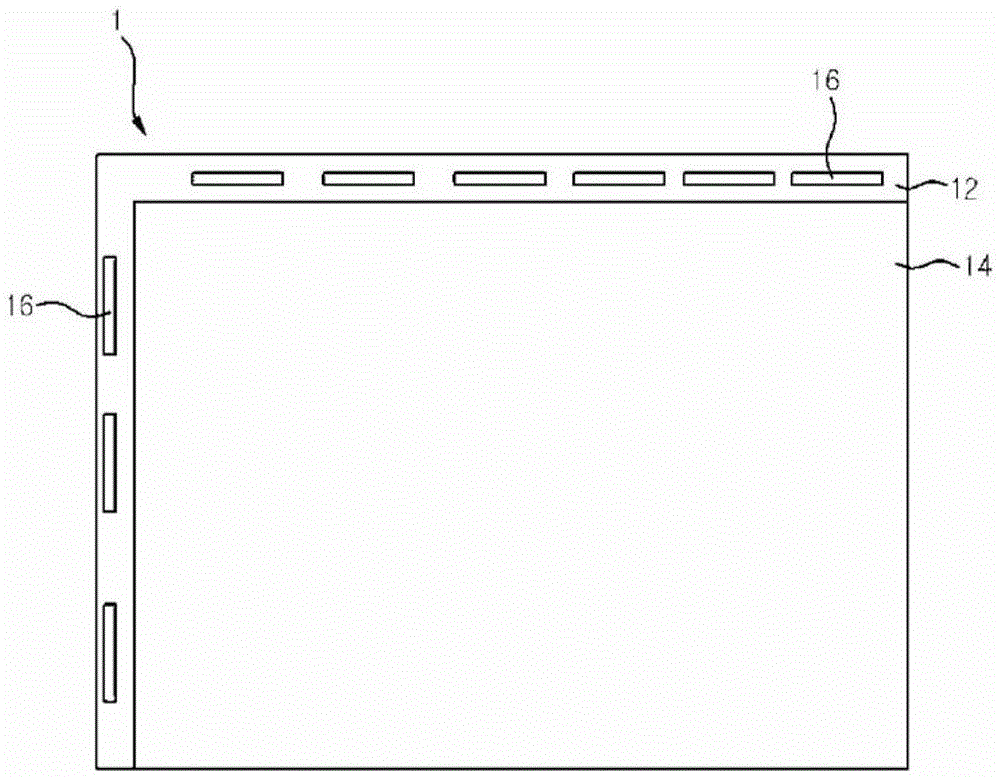

Liquid crystal display board

InactiveCN1928671AImprove process pass rateAvoid damageNon-linear opticsLiquid-crystal displayEngineering

The LCD panel comprises: a first substrate with a second one on top, a LC layer and some gap support material both arranged between substrates. Wherein the support material includes multiple support structures every with two parts, the near first parts connect with each other, while the second part separates away. This invention can improve panel assembly up-to-standard rate.

Owner:CHUNGHWA PICTURE TUBES LTD

Method for producing display base plate

InactiveCN101017301AThe process steps are simpleReduce processing costsStatic indicating devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayCapacitance

This invention relates to one method to process display baseboard, which is applied in the process of semi-transparent reflection LCD one and comprises the following steps: forming source element and capacitor on baseboard; forming flat layer on source element and capacitor structure; using the mask film with multiple transparent areas to etch flat layer to form different structure property on flat layer.

Owner:AU OPTRONICS CORP

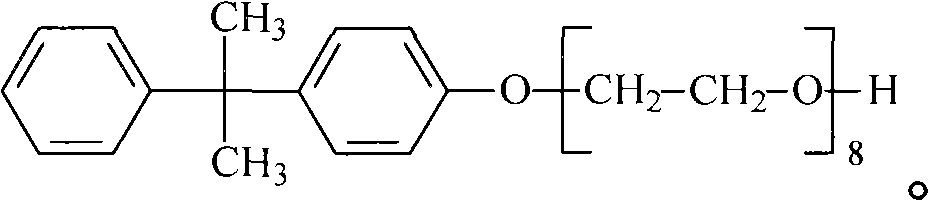

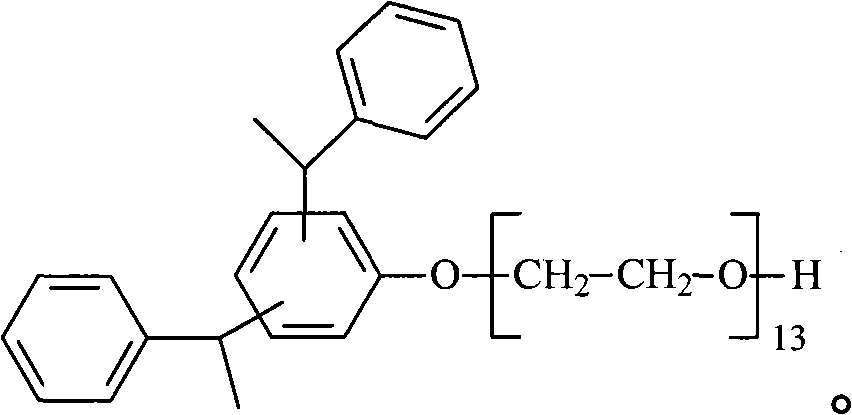

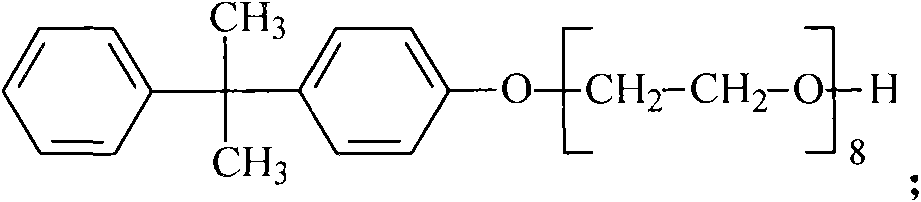

Cleaning solution composition

InactiveCN102486619ANo harmImprove cleaning proceduresPhotosensitive material processingColor gelPhotoresist

The invention provides a cleaning solution composition used for cleaning a developing trough. The composition comprises (A) 1 to 40 wt% of an alkali metal alkaline compound, (B) 0.3 to 20 of a nonionic surfactant, (C) a chelating agent and (D) water. The cleaning solution composition provided in the invention is applicable to cleaning of a developing trough and pipelines in photoetching of a color filter, can improve a cleaning effect on the developing trough and the pipelines and enables reverse adhesion of a photoresist or affection of the photoresist on pattern making in the process of development to be avoided, a color filter glass substrate to have stable quality after development, a qualified rate in photoetching to be improved and cost to be reduced.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

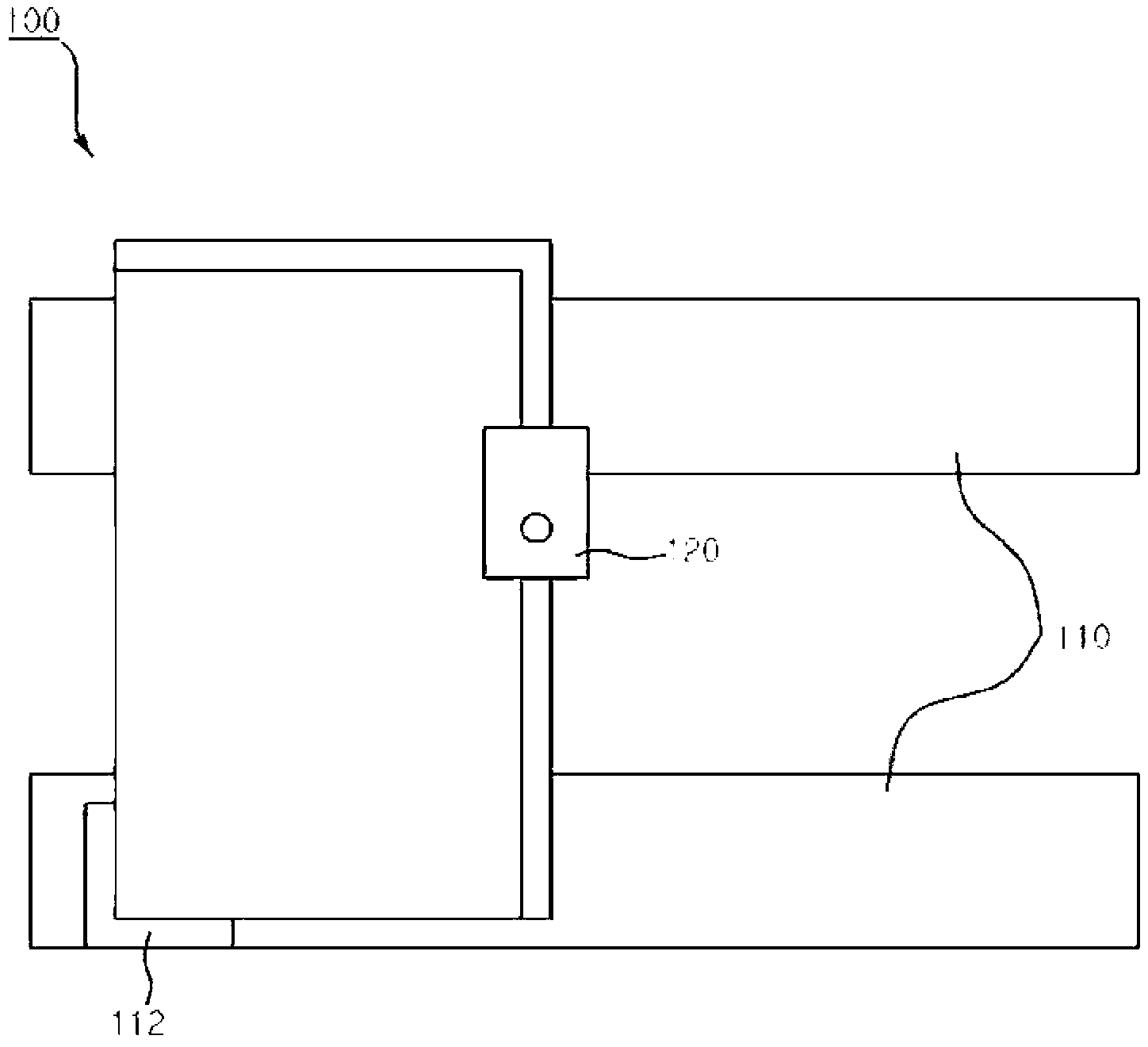

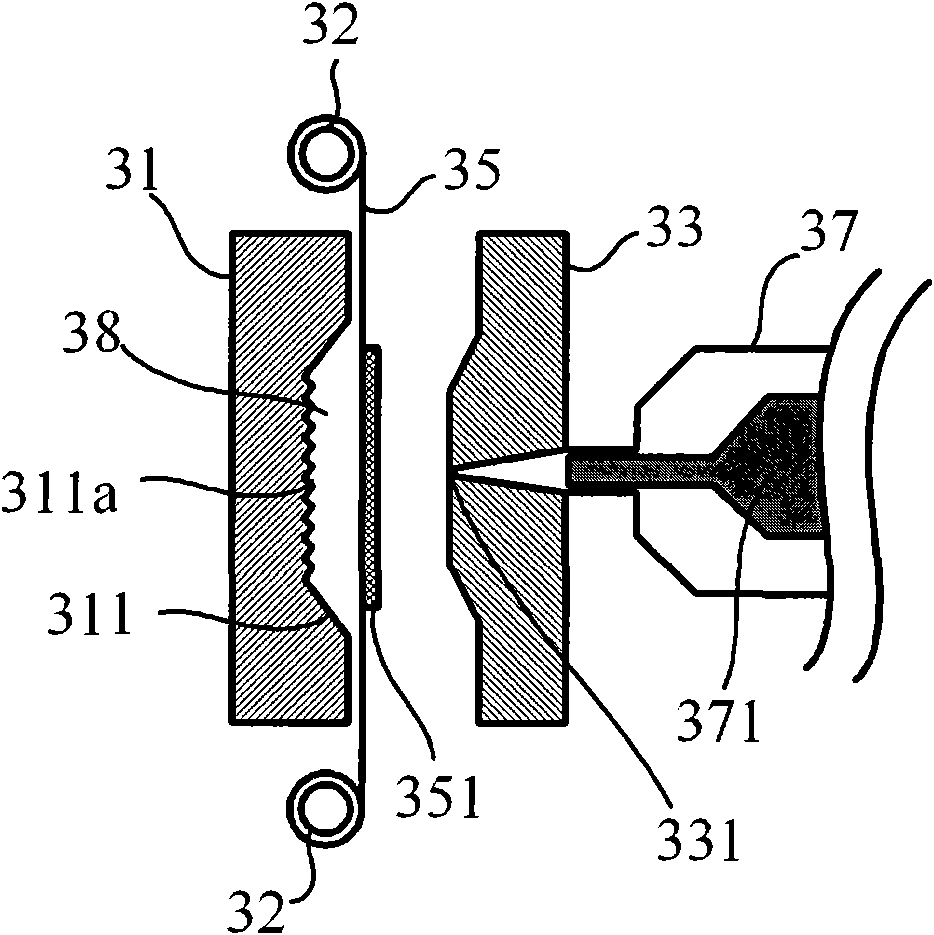

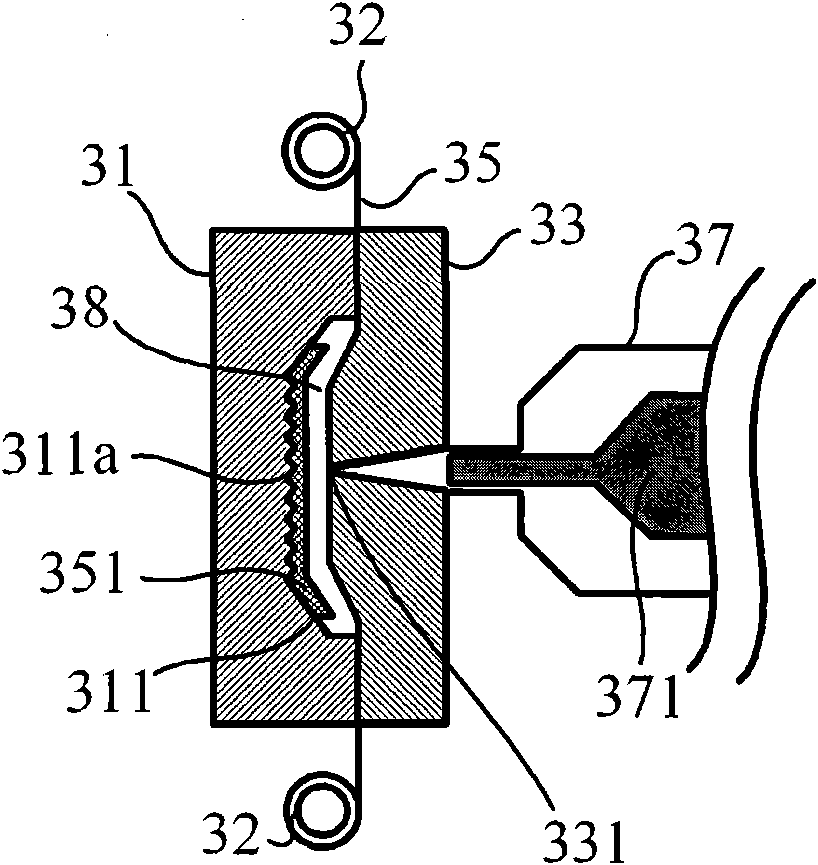

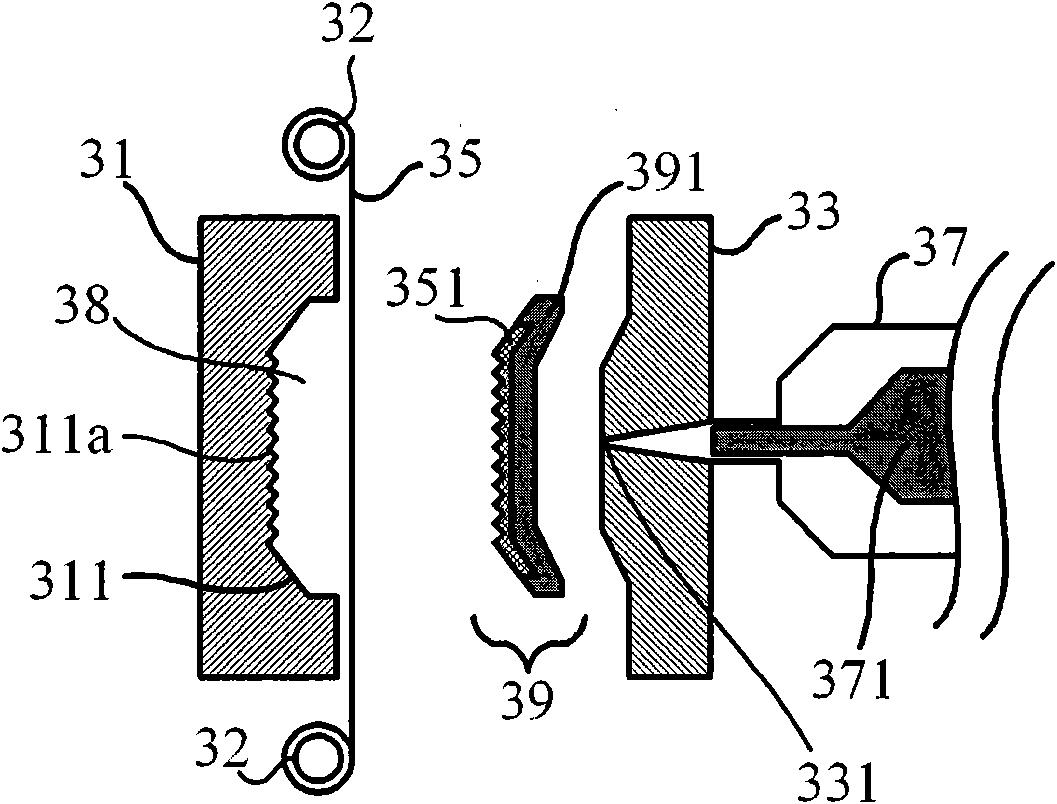

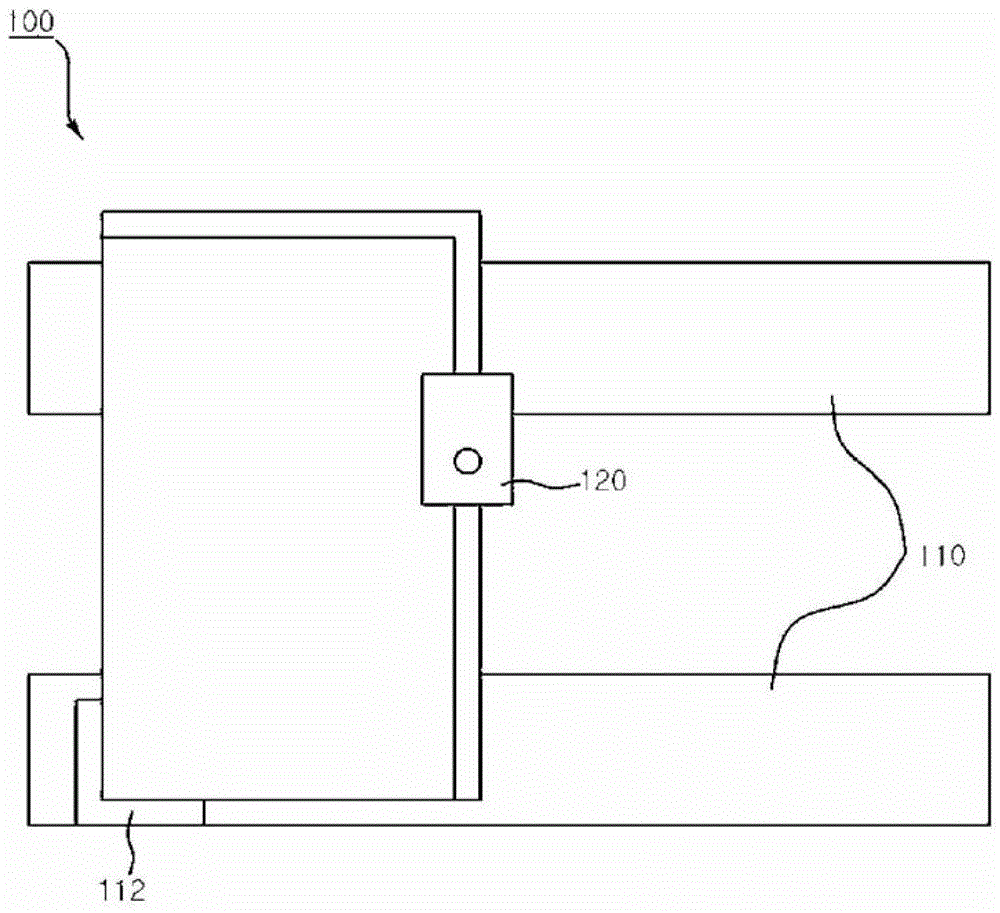

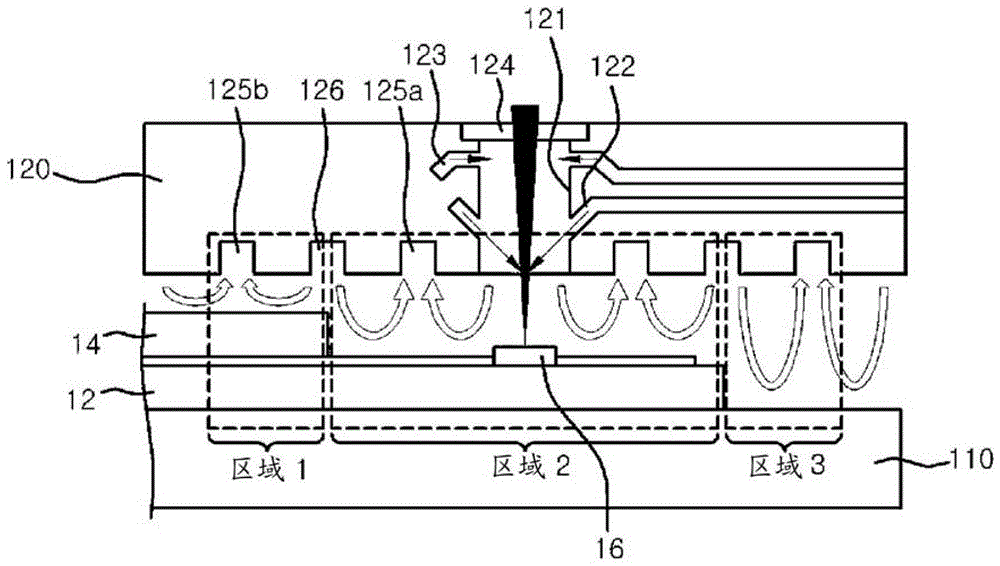

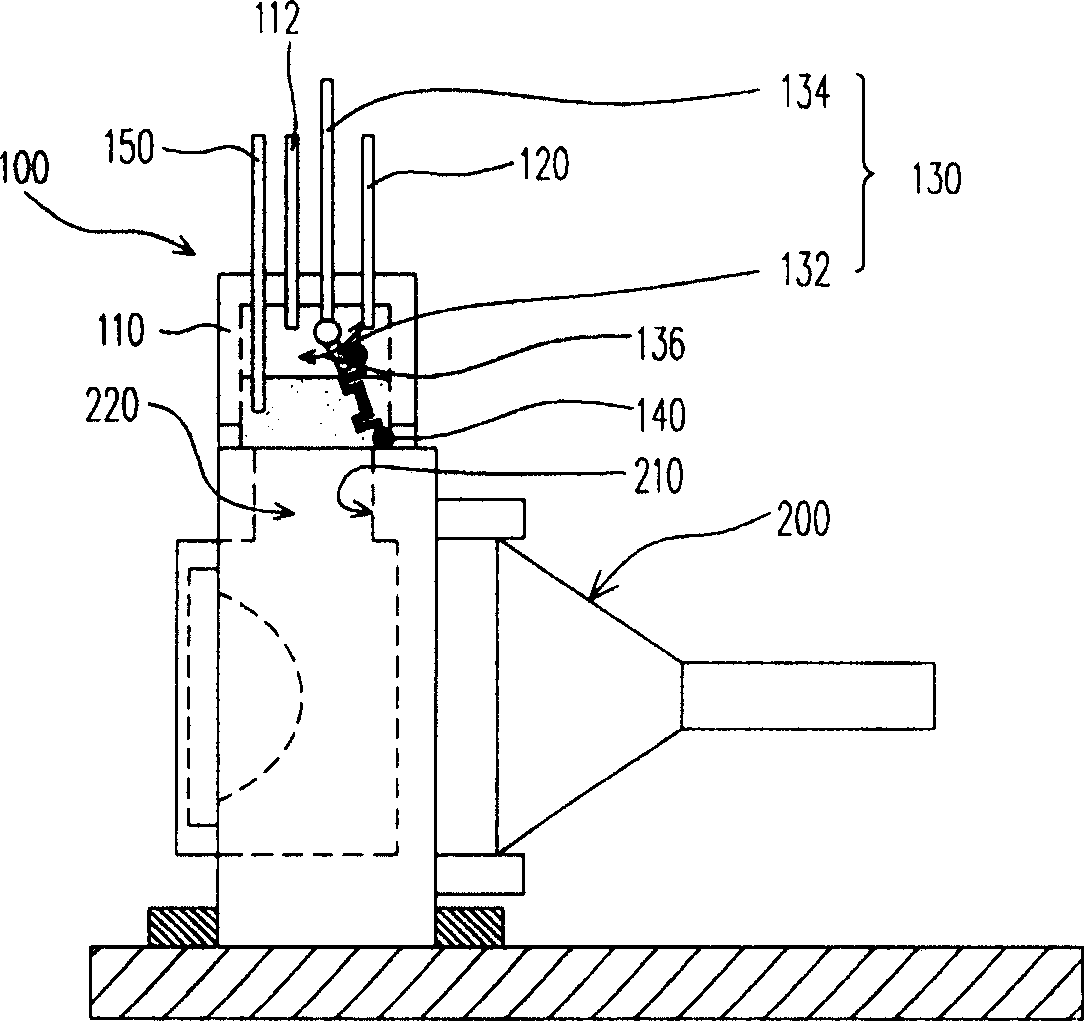

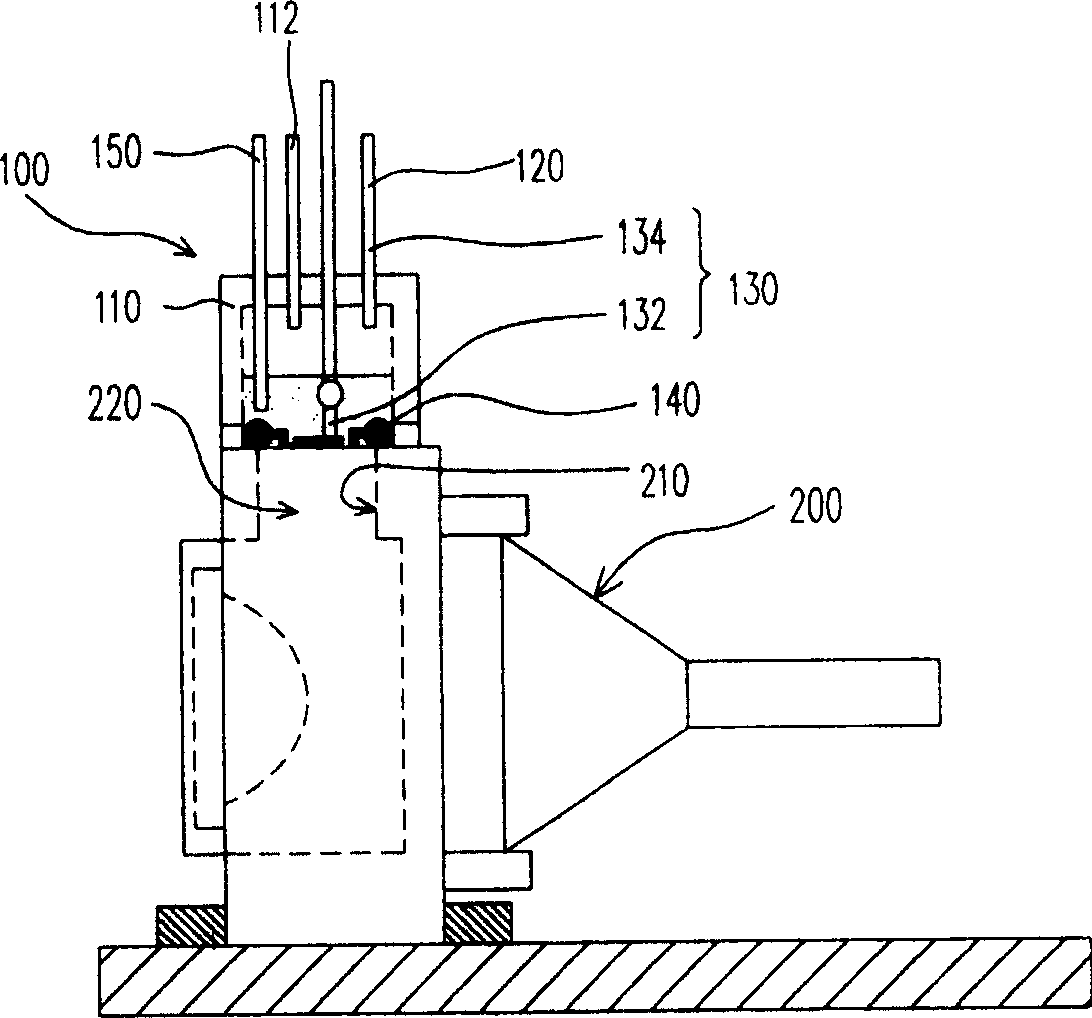

Pad pattern repair apparatus

ActiveCN102939544AImprove process pass rateSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingShielding gasLaser light

The present invention relates to a pad pattern repair apparatus. The present invention provides an apparatus for repairing defects in pad electrodes equipped for applying signals to one of multiple substrates, comprising a stage into the reference surface of which the substrate is loaded; a chamber where a first exhaust, a shield gas outlet, and a second exhaust are formed sequentially in the lower surface of the chamber with respect to a laser light emission hole being equipped on the stage and moving to the defect position of the pad electrode and having structure to discharge purifying gas and raw gas in the middle of the hole; ; and a clamp being installed on the stage and supporting the opposite surface of a substrate adhered closely to the reference surface, the gap between the substrate and the lower surface of the chamber varying in the inside and outside of the lower surface of the chamber. A pad pattern repair apparatus according to the present invention maintains the pressure in the area where repairing a defect is carried out at a constant level, improving a process yield.

Owner:苏州科韵激光科技有限公司

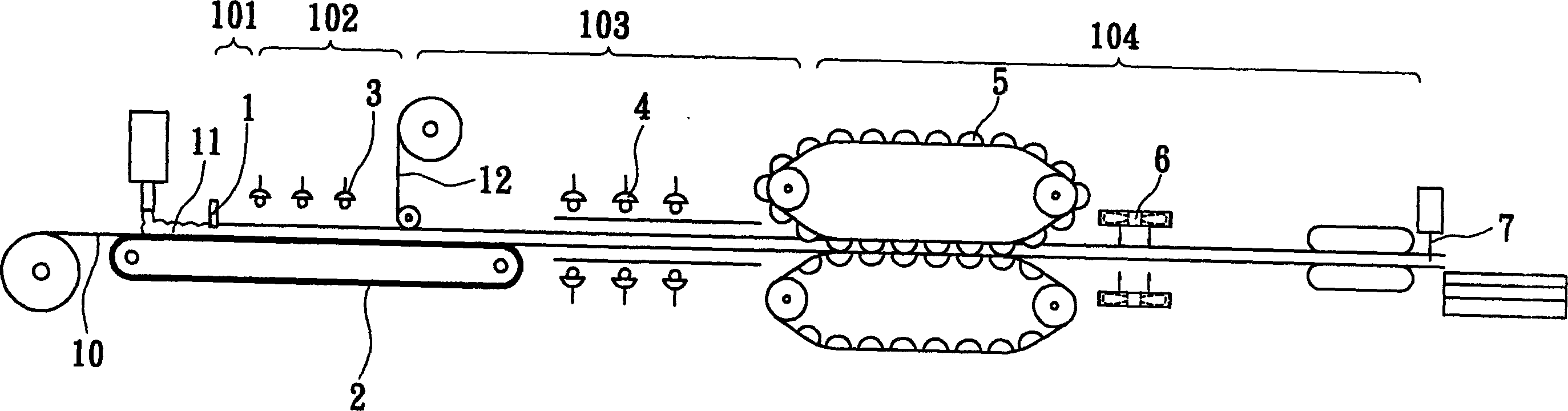

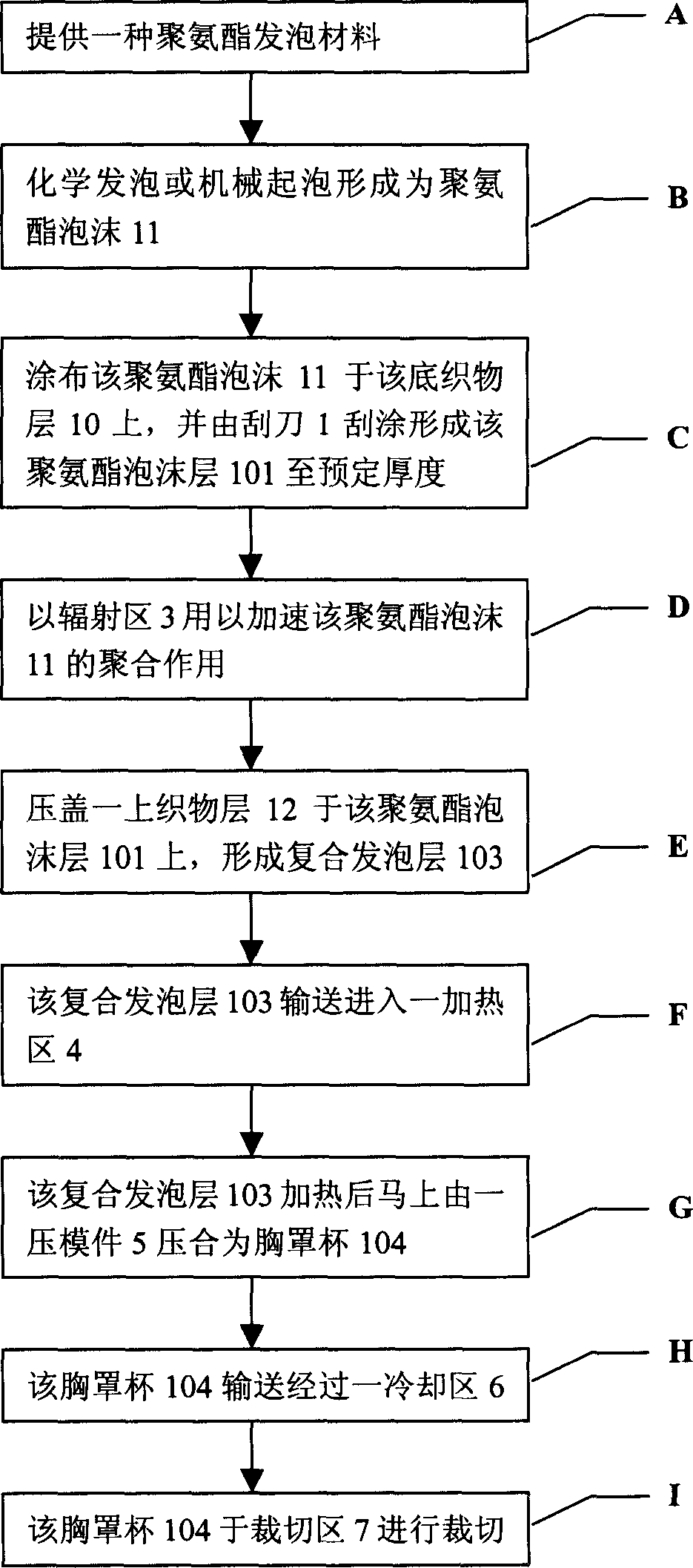

Technology of continuous producing polyurethane sponge bra cups

InactiveCN1590065ACausing discolorationImprove process pass rateBrassieresFoaming agentPolymer science

A process for preparing the polyurethane sponge bowls of bra includes such steps as proportionally mixing isocyanate, polyol, foaming agent and catalyst, stirring, directly pouring the mixture on fabric layer, reacting to form polyurethane foam material, sticking another fabric layer, and die pressing.

Owner:薛攀霆

Manufacturing method of appearance part

Owner:PEGATRON

Solar cell and solar cell module group

InactiveCN103915513AImprove efficiencyReduce movement distancePhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention discloses a solar cell and a solar cell module group. The solar cell includes a second conductive substrate, a plurality of first conductive layers and second conductive layers, a passivation layer, a plurality of first holes and second holes, a first electrode, and a second electrode. The second conductive substrate includes a light receiving side and a back side. The first conductive layers are arranged on the back side. The second conductive layers are arranged on the back side in a two-dimensional array manner and the second conductive layers are independent from each other and are not connected with each other. Each second conductive layer is enclosed by the first conductive layer. The passivation layer is arranged on the first conductive layers and second conductive layers. The first holes and second holes are arranged in the passivation layer and are corresponding to the first first conductive layers and second conductive layers. The first electrode and the second electrode are arranged on the passivation layer, and are respectively contacted with the first conductive layers via the first hole and with the second conductive layers via the second hole.

Owner:MOTECH INDUSTRIES

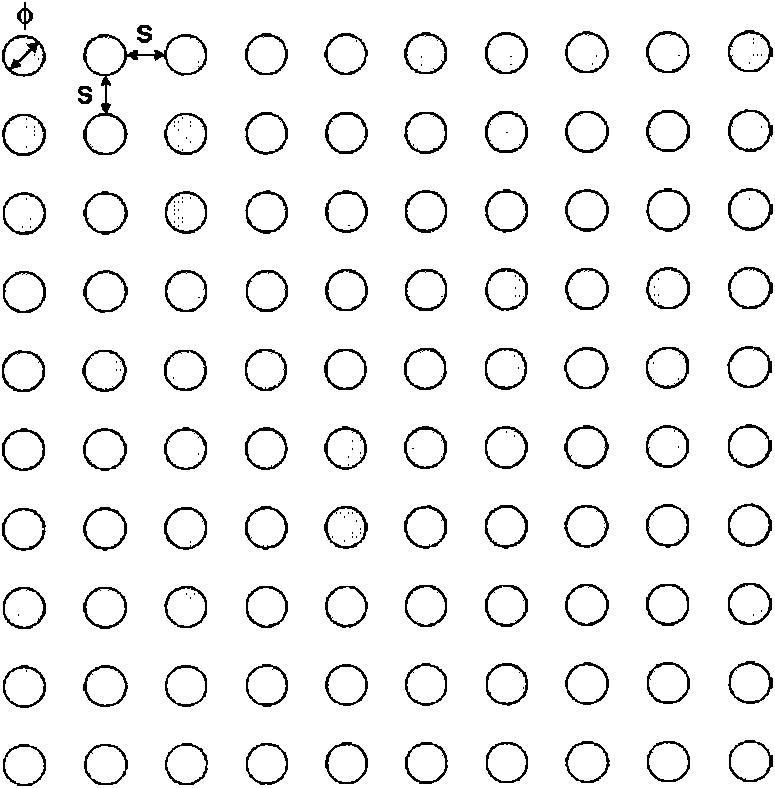

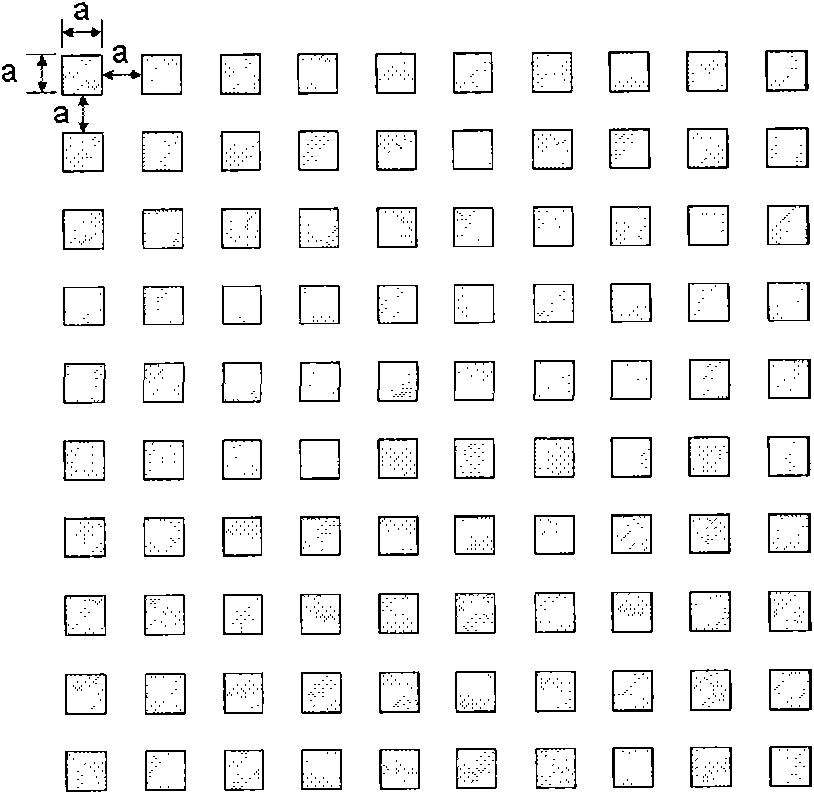

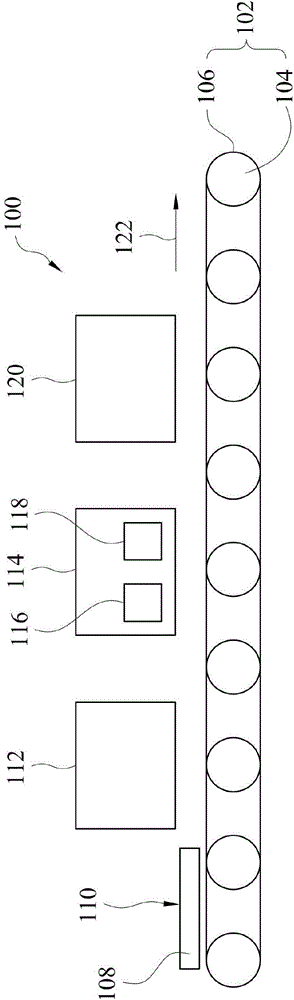

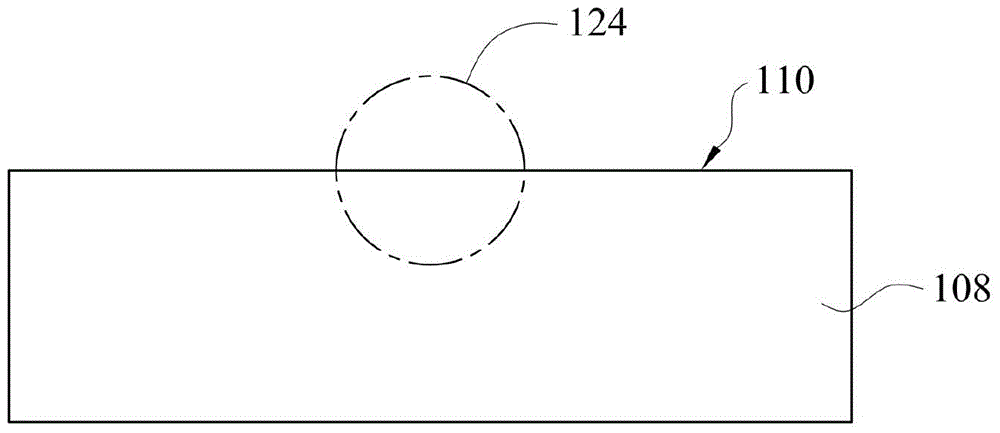

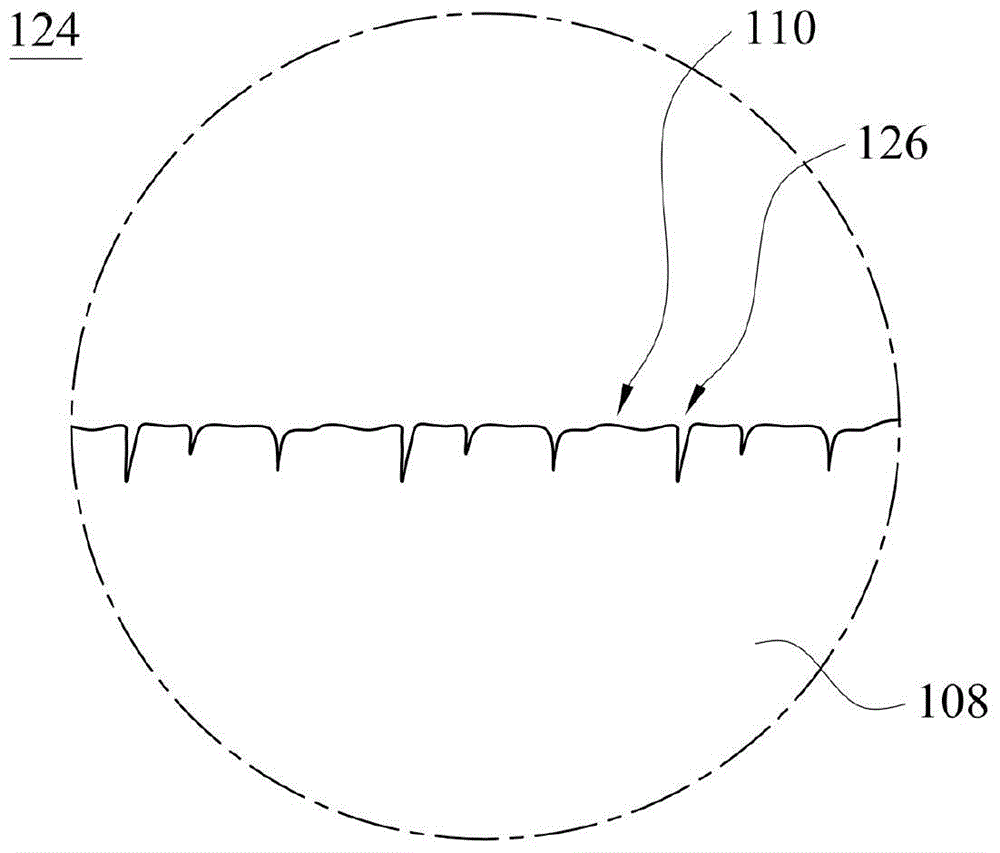

Method for testing ink-jet printing equipment

The invention discloses a method for testing ink-jet printing equipment. The ink-jet printing equipment comprises a machine table and an ink-jet head, and the method comprises the following steps of: providing a test pattern, and evaluating and detecting the drawing capacity of the machine table and the control capacity of the ink-jet head by using the test pattern. By adopting the method for testing the ink-jet printing equipment of the invention and the test pattern provided in the testing process, the drawing capacity of the machine table and the control capacity of the ink-jet head can be comprehensively evaluated. Besides, the test method can also be used for regularly monitoring ink-jet printing mass production type processing modules and improving the qualification rate of processing color filters.

Owner:AU OPTRONICS CORP

Light interference type display unit structure and producing method

InactiveCN1549041AIncrease the lengthShorten the lengthPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringUnit structure

The light interference type display unit structure includes one first electrode and one second electrode supported by some supporting matter. The present invention features that the second electrode in different thickness has different stress so that the second electrode is shifted in the thermal process and the distance between the first electrode and the second electrode is altered. The manufacture process of the light interference type display unit includes successively forming the first electrode and the sacrificial layer on the substrate; forming opening in the first electrode and the sacrificial layer; defining the support inside the opening with at least one support top arm located on the sacrificial layer; forming the second electrode in different thickness over the sacrificial layer and the support; performing one thermal process; and finally removing the sacrificial layer to obtain the light interference type display unit.

Owner:IDC LLC

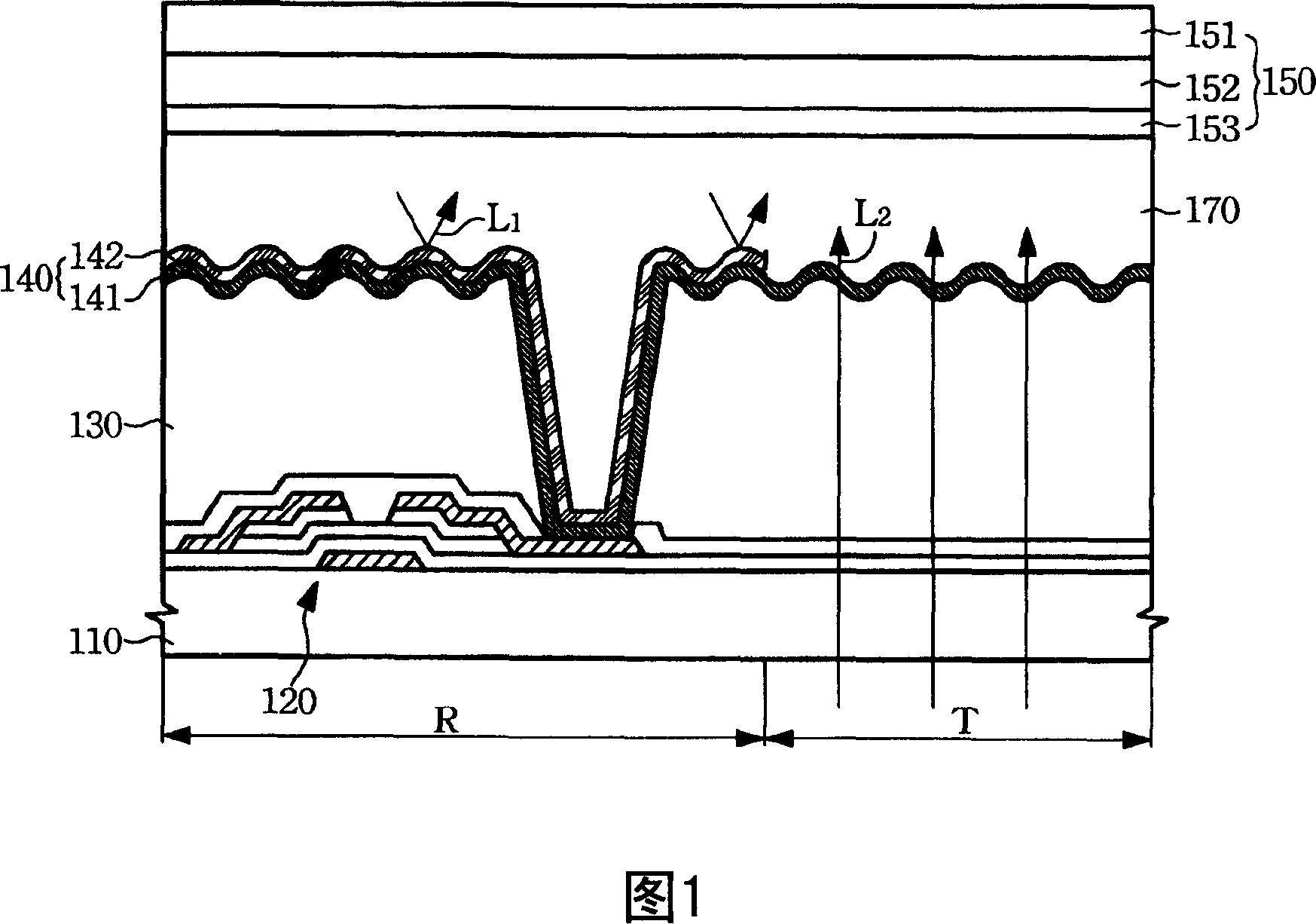

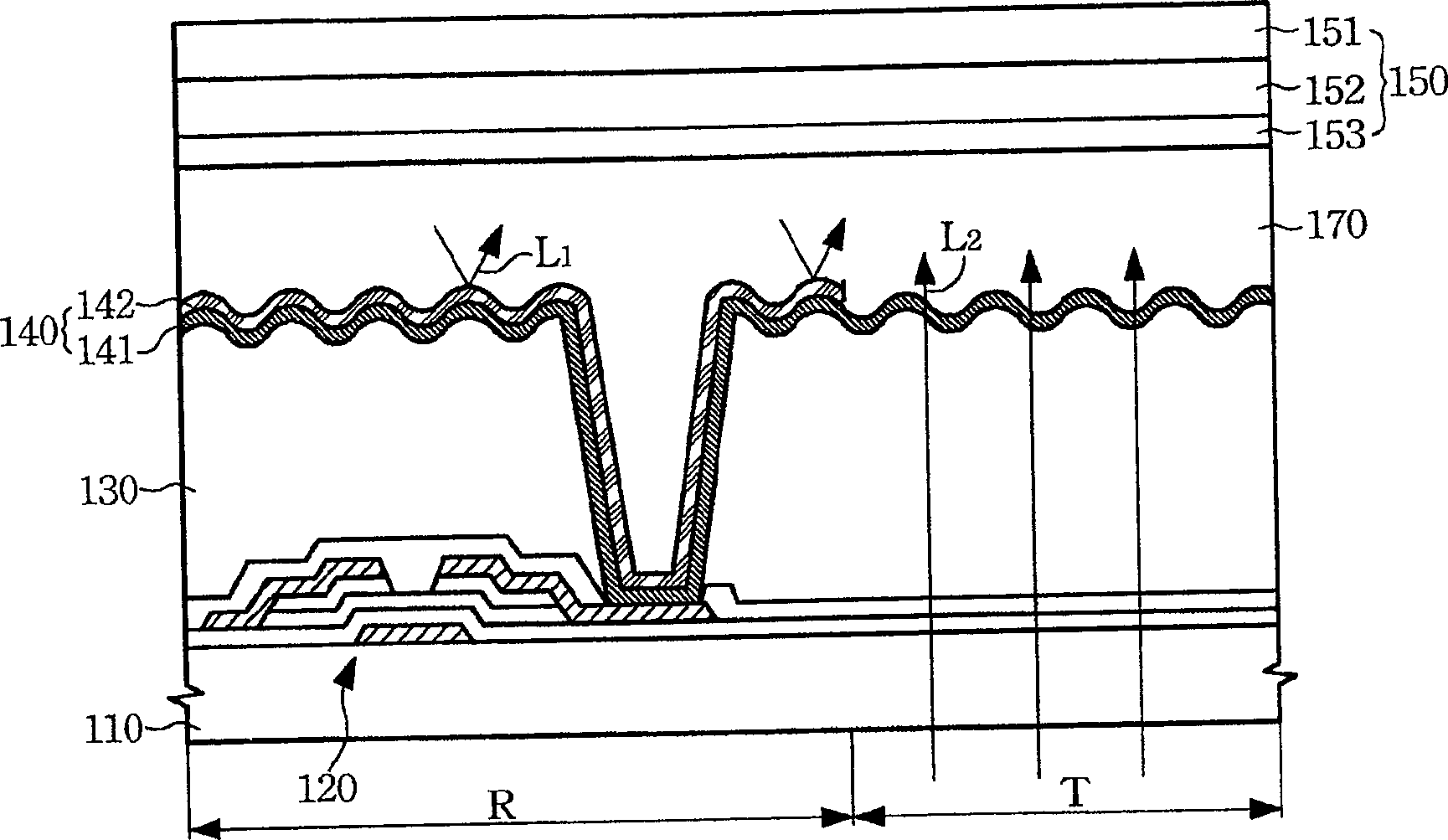

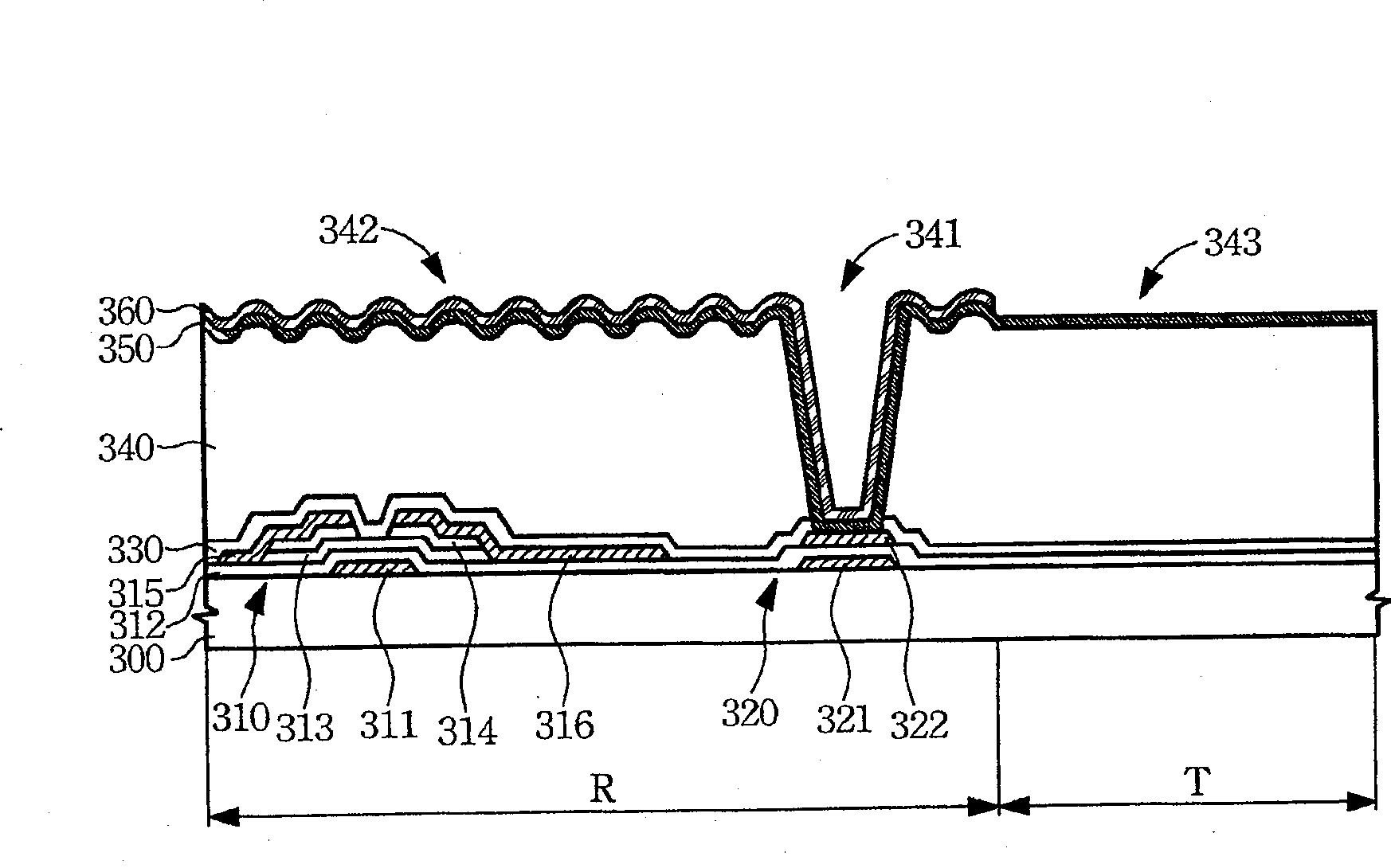

Manufacturing method of reflective layer of display device, reflective LCD device and transflective lcd device

InactiveCN1847947AImprove process pass rateAvoid destructionStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

A reflective and a transflective liquid crystal display device and a manufacturing method thereof are provided. The manufacturing method includes the following steps. First, a substrate structure of a reflective or a transflective liquid crystal display device is provided. Next, a reflection layer is formed over the substrate structure, a protection layer is formed over the reflection layer, and a photoresist layer is formed over the protection layer. Then, the photoresist layer is patterned to form a patterned photoresist layer, the protection layer is patterned to form a patterned protection layer, and the reflection layer is patterned to form a patterned reflection layer. Thereafter, the patterned photoresist layer is removed.

Owner:TPO DISPLAY

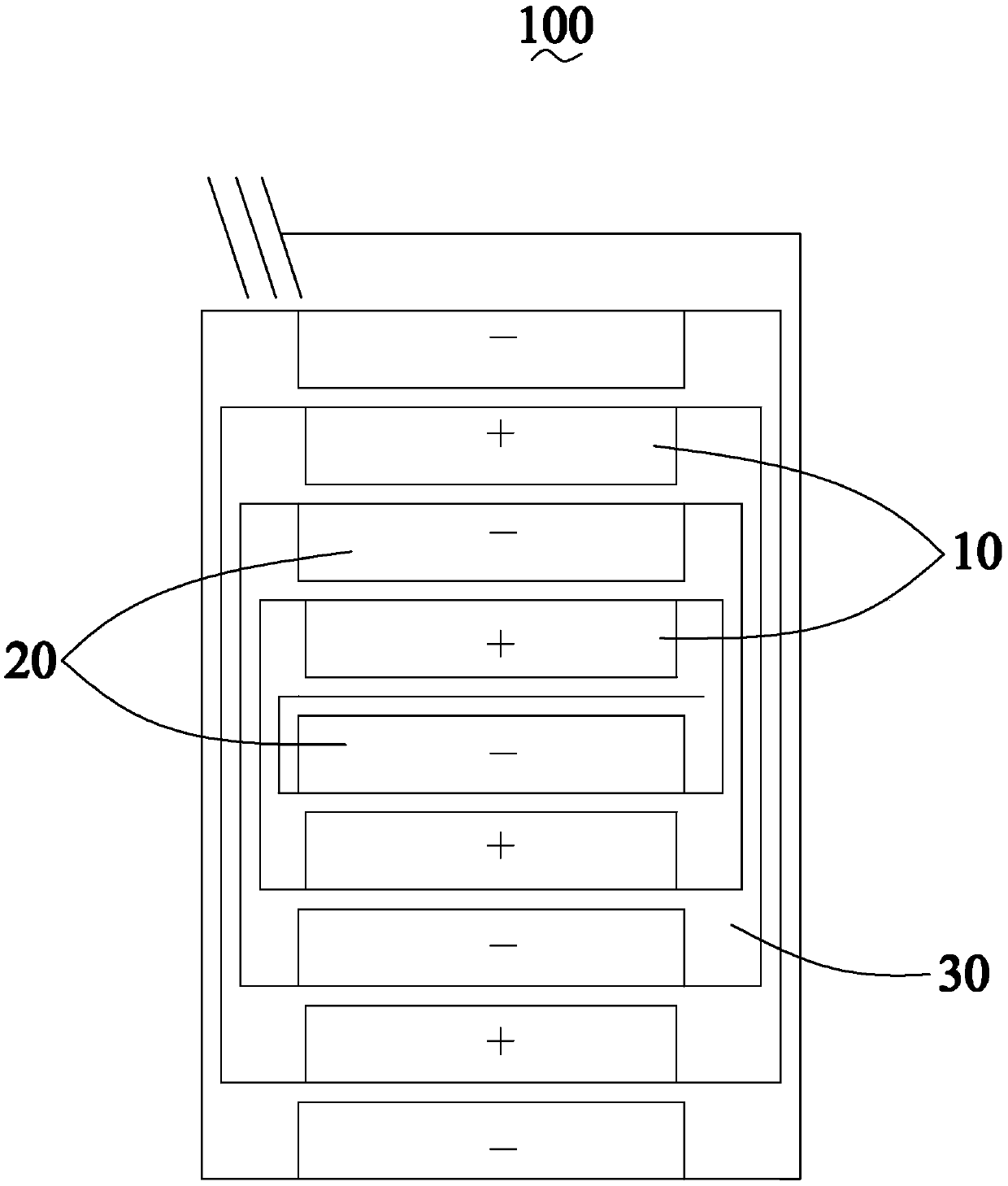

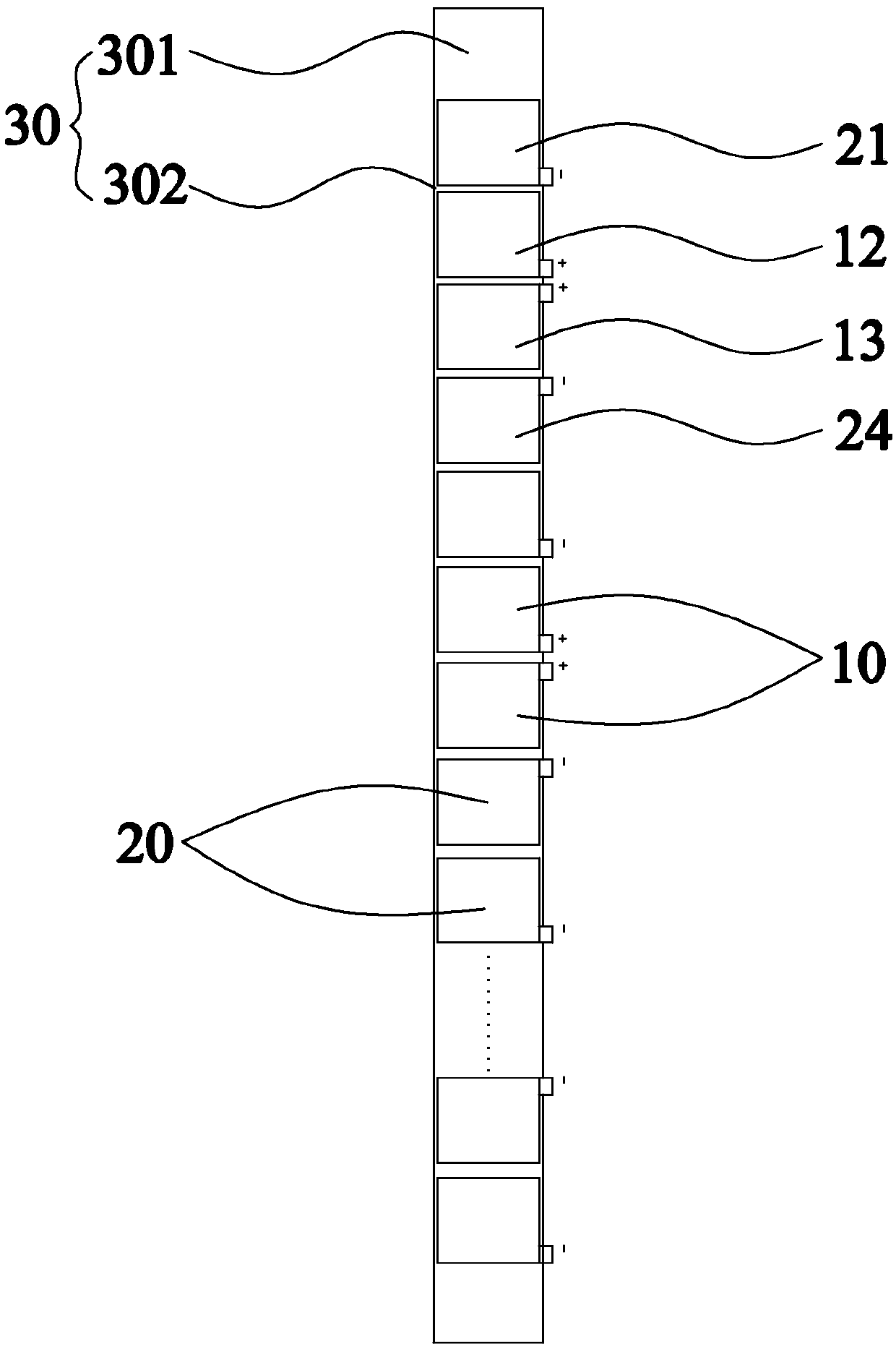

Square battery cell

PendingCN107732280AImprove securityAvoid croppingFinal product manufactureWound/folded electrode electrodesEngineeringBattery cell

The invention provides a square battery cell. The square battery cell comprises multiple unit positive plates, multiple unit negative plates and a diaphragm, wherein the diaphragm comprises a reservezone and a winding zone, and the winding zone is used for arranging the unit positive plates and the unit negative plates; the quantity of the unit negative plates is one more than the quantity of theunit positive plates; the unit positive plates and the unit negative plates are cyclically arranged in the winding zone in a sequence of the unit negative plate, the unit positive plate, the unit positive plate and the unit negative plate, the reserve zone covers a first unit negative plate in the winding zone, and the first unit negative plate is sequentially and cyclically wound with the adjacent unit positive plate, unit positive plate and unit negative plate; or the unit positive plates and the unit negative plates are cyclically arranged in the winding zone in a sequence of the unit positive plate, the unit negative plate, the unit negative plate and the unit positive plate, the reserve zone covers the first unit positive plate in the winding zone, and the first unit positive plate is sequentially cyclically wound with the adjacent unit negative plate, unit negative plate and unit positive plate.

Owner:OPTIMUM BATTERY CO LTD

Method for producing display substrate

InactiveCN100543566CThe process steps are simpleReduce processing costsStatic indicating devicesSemiconductor/solid-state device manufacturingCapacitanceLiquid-crystal display

A method for manufacturing a display substrate. The method is applied to manufacture a transflective liquid crystal display. The method steps at least include: forming an active element and a capacitance structure on the substrate. A planarization layer is formed above the active components and capacitor structures. The planar layer is subjected to a photolithographic etching process using a mask with various light-transmitting regions, so as to simultaneously form different structural features on the planar layer.

Owner:AU OPTRONICS CORP

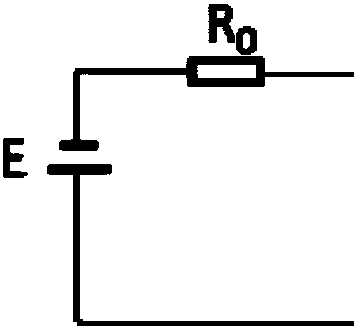

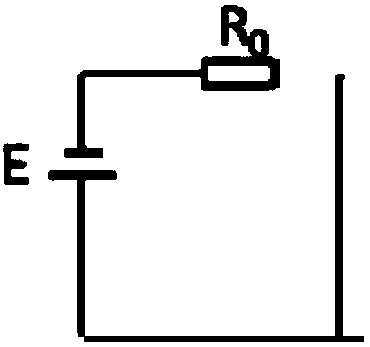

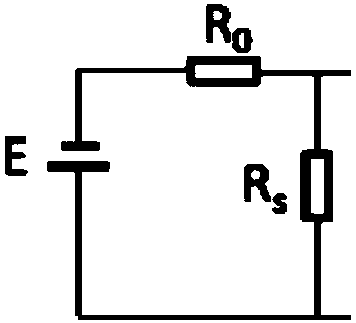

Problem cell identification method

InactiveCN109709491AQuick and efficient selectionImprove process pass rateElectrical testingPass rateComputer science

The invention discloses a problem cell identification method. The method comprises steps that S10, cell loading is performed; S20, a detection circuit is connected with a cell, the current is detected, and the cell is determined according to change of the current; the current turns small to 0 within the predetermined time, and the cell is determined to be a qualified cell; if the current is underany one of a, b and c conditions, a, the current is bigger than a first predetermined value or is infinitely large; b, the current decreases to a stable value, and the stable value is greater than 0;c, the current is lower than a second predetermined value or is 0, the cell is determined to be a problem cell, and the first determined value is greater than the second determined value; if the current is not under any of the a, b and c conditions, the cell is determined to be a to-be-detected cell. The method is advantaged in that through coordination of the S10 and the S20, the problem cell canbe rapidly and effectively selected, the formation process pass rate can be improved, operation energy consumption is reduced, production efficiency can be further improved, and manpower and materialresources can be further saved.

Owner:NINGDE AMPEREX TECH

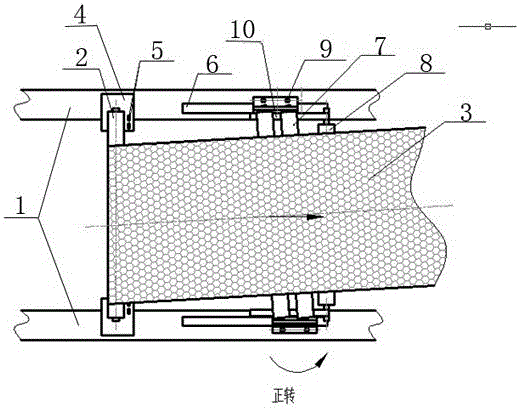

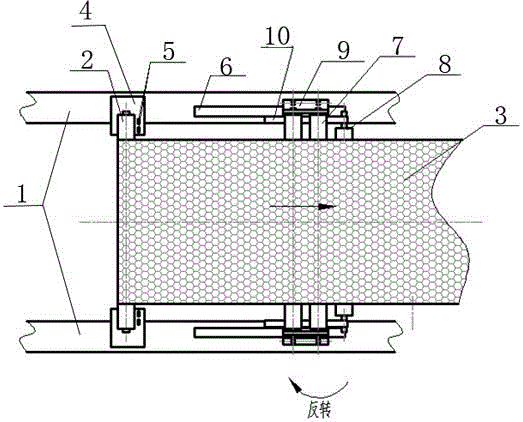

Glass transmission line mesh belt motor deviation rectification device

InactiveCN106516645AReduce failure rateReduce maintenance costsControl devices for conveyorsRollersDrive shaftElectric machine

The invention provides a glass transmission line mesh belt motor deviation rectification device which comprises a support. The support is provided with transmission shafts, a conveying mesh belt is arranged between the transmission shafts, and inductors are symmetrically arranged on bearings at the two ends of the transmission shafts; the support is further provided with a guide rail, a deviation rectification shaft is arranged on the guide rail and is supported at the bottom of the conveying mesh belt, and the two ends of the deviation rectification shaft are provided with a linear bearing and a linear bearing tooth belt; and the deviation rectification shaft is installed on the guide rail through the linear bearing, one end of the guide rail is provided with a linear bearing conveying motor, and a relay is connected to the linear bearing conveying motor. When the glass transmission line mesh belt motor deviation rectification device is used, the photoelectric switch inductors and electric control are adopted for achieving the aim of deviation rectification, safety and reliability are achieved, the fault occurrence rate is effectively reduced, the equipment maintaining expenditure is saved, the working procedure yield is effectively improved, and the working efficiency is improved.

Owner:十堰冠达汽车零部件有限公司

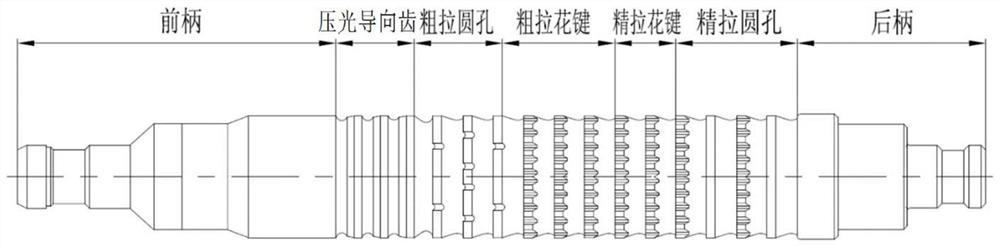

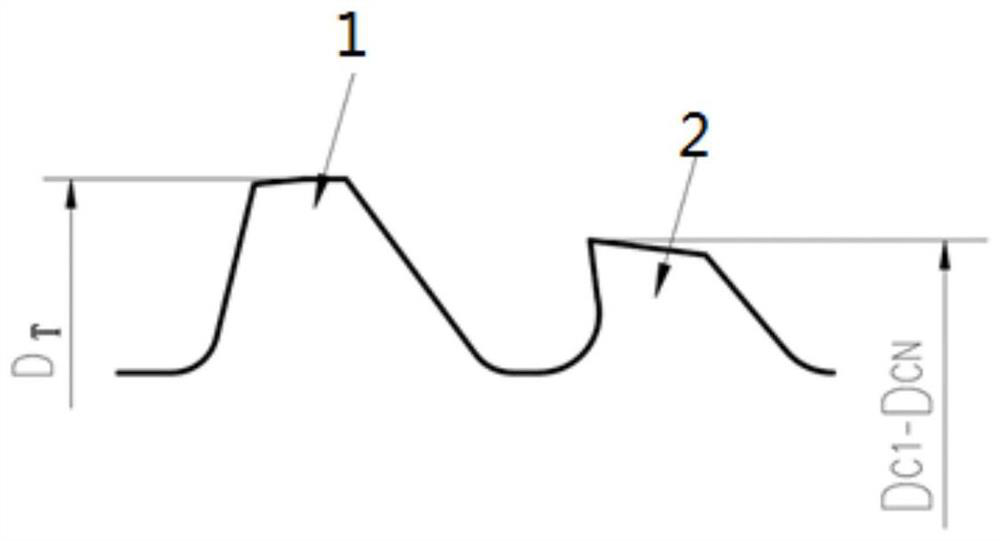

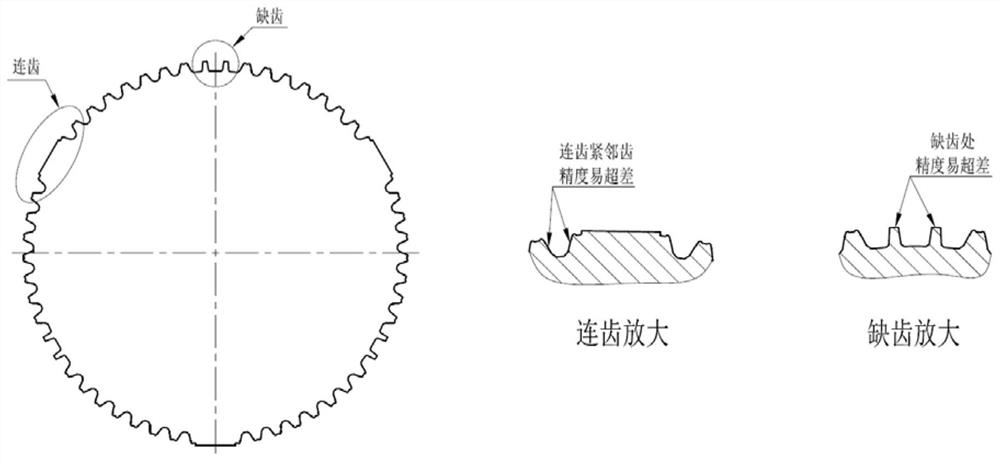

High-precision involute spline broach and design method thereof

InactiveCN112222524AReduced broaching forceEliminate or reduce distortionBroaching toolsBroachingTooth part

The invention discloses a high-precision involute spline broach and a design method thereof. The high-precision involute spline broach comprises a calendaring guide tooth part, wherein the calendaringguide tooth part comprises a plurality of calendaring guide tooth rings that are concentrically arranged, the calendaring guide tooth rings are used for guiding a workpiece, and each calendaring guide tooth ring comprises a plurality of calendaring guide teeth that are annularly distributed; the outer diameter of a first tooth of the calendaring guide tooth is DY1, and DY1 is equal to D0l-delta;the outer diameter of the last calendaring guide tooth is DYN, wherein DYN=DYN+phi / 2, the tooth number NY of the calendaring guide tooth, and NY is equal to [(DYN-DY1) / fy]; D0l is the lower differenceof the hole before drawing of the workpiece, D0[mu] is the upper difference of the hole before drawing of the workpiece, delta is a guide gap, phi is a roundness error of the hole before drawing of the workpiece, fy is the tooth rise amount of the press polish guide teeth, and [] represents the nearby rounding of the result. According to a synchronizer thin-wall part machined by the structure, the procedure percent of pass is greatly increased, the machining quality of a workpiece is guaranteed, and meanwhile, due to separation of a rough broaching procedure and a fine broaching procedure, rough cutting teeth do not participate in final tooth profile forming, so that the cutting allowance of fine broaching teeth is small, and the service life of a broach is prolonged.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

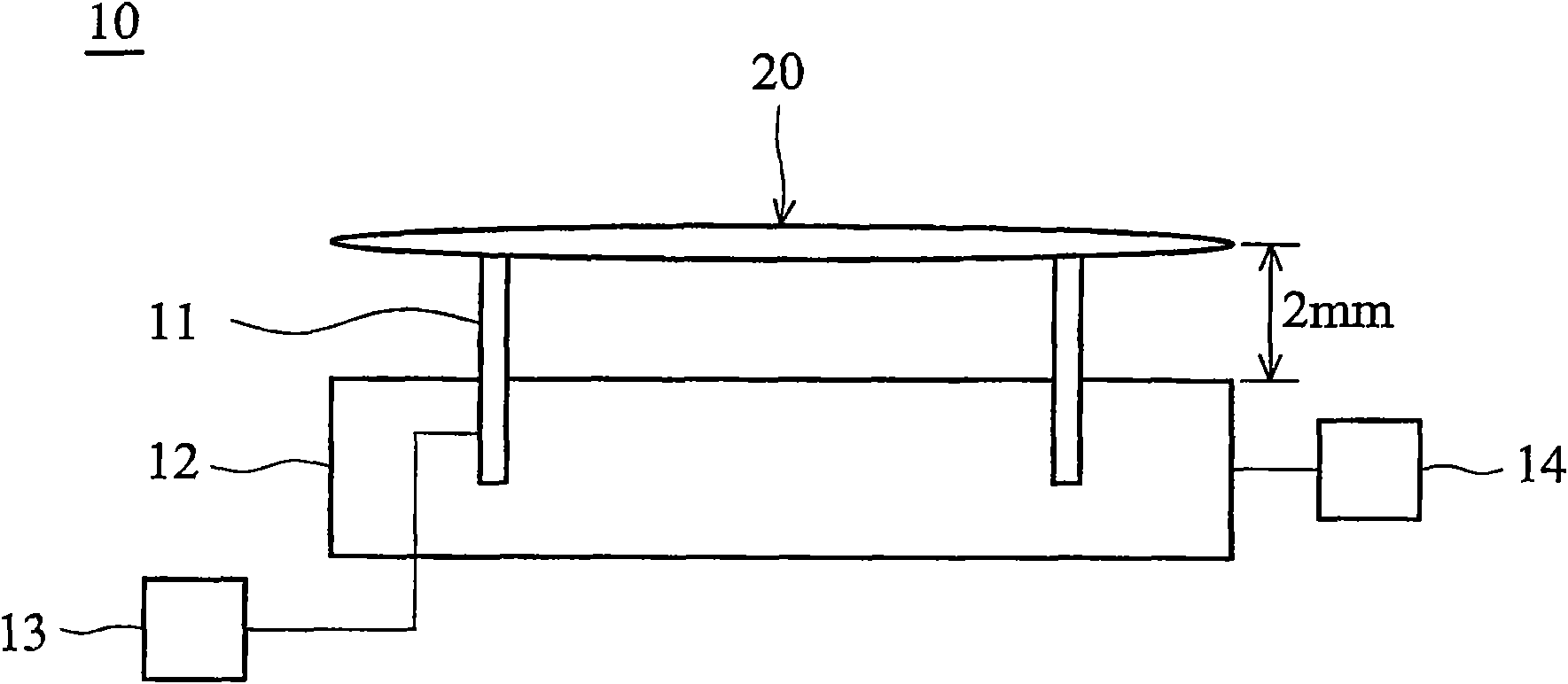

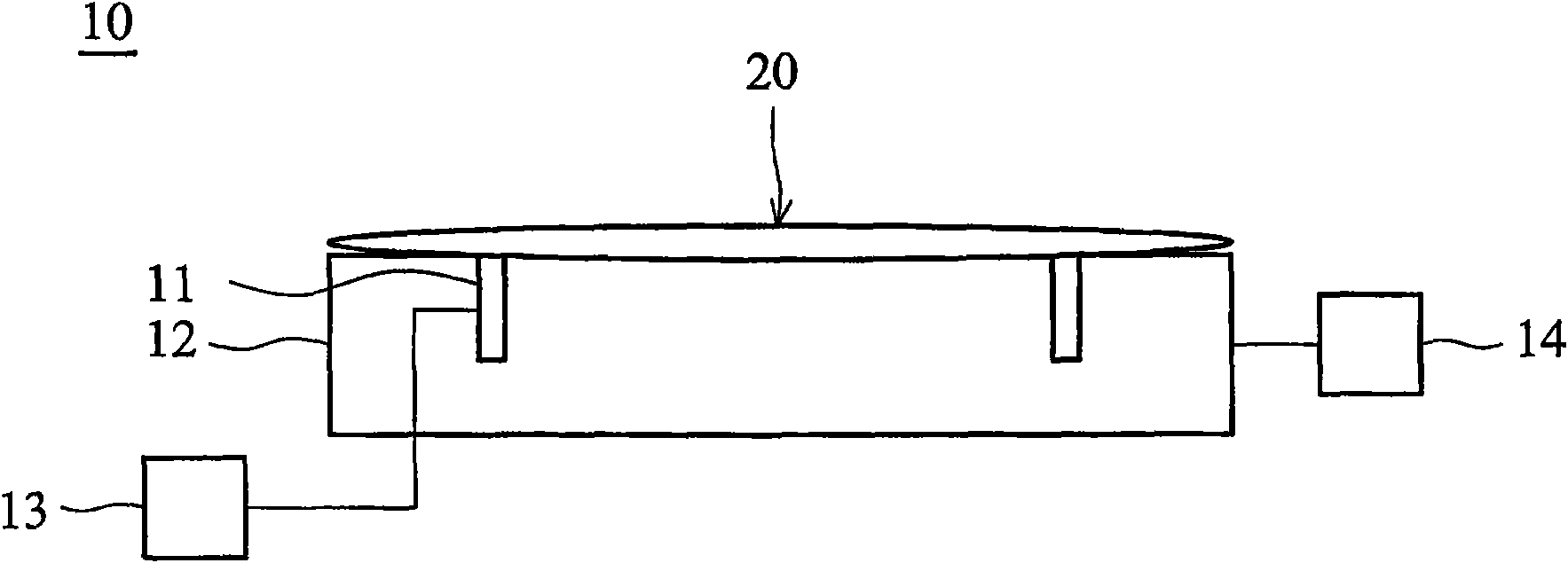

Photoresist removing machine station and photoresist removing process

InactiveCN101571678APrevent burstImprove process pass ratePhotosensitive material processingResistEngineering

The invention provides a photoresist removing machine station and a photoresist removing process. The photoresist removing machine station comprises a heater, a wafer carrier, a motor and a height control unit, wherein the wafer carrier is provided for a wafer to make vertical displacement relative to the heater; the motor is electrically connected with the wafer carrier and the height control unit respectively; and the height control unit is used for controlling the wafer to stop on at least three positions. The photoreist removing process comprises the following steps: positioning the wafer at a bearing position by utilizing the wafer carrier when the wafer enters the photoresist removing machine station; moving the wafer carrier to move the wafer to a temperature-reduction position; and moving the wafer carrier to move the wafer to a process position. The invention can avoid cracking of photoresist caused by overheating of the wafer, thereby improving the qualification rate.

Owner:TAIWAN SEMICON MFG CO LTD

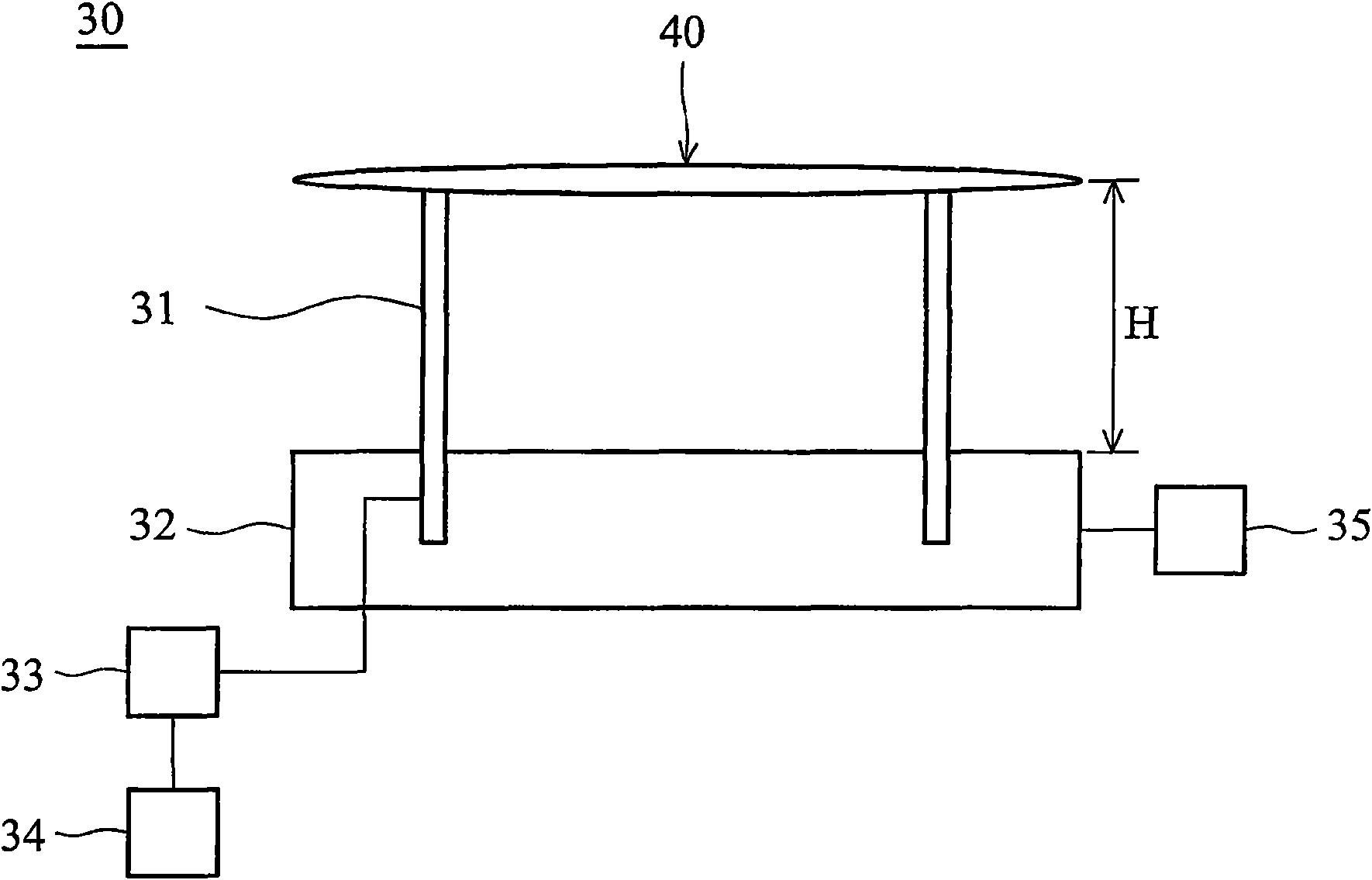

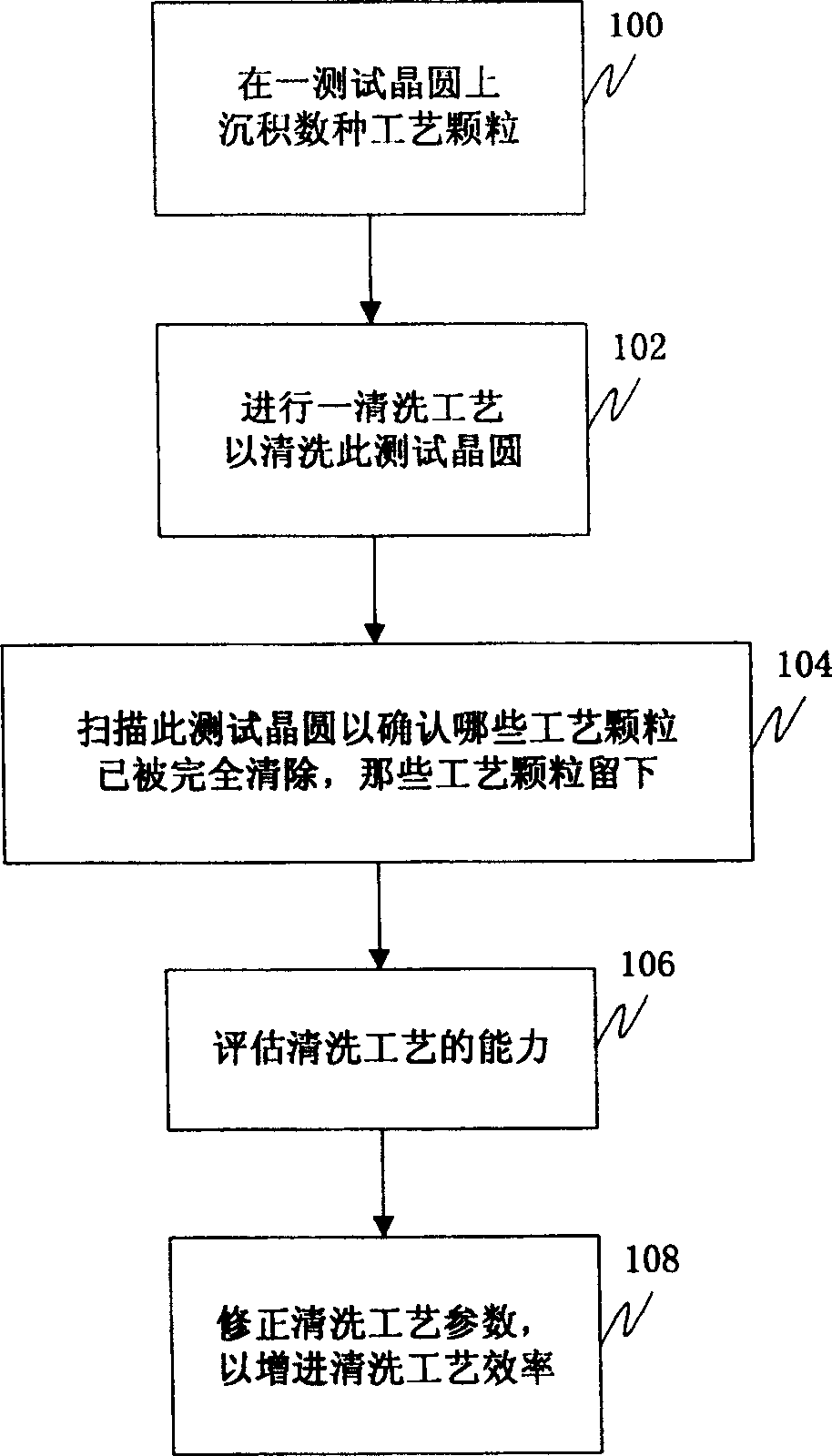

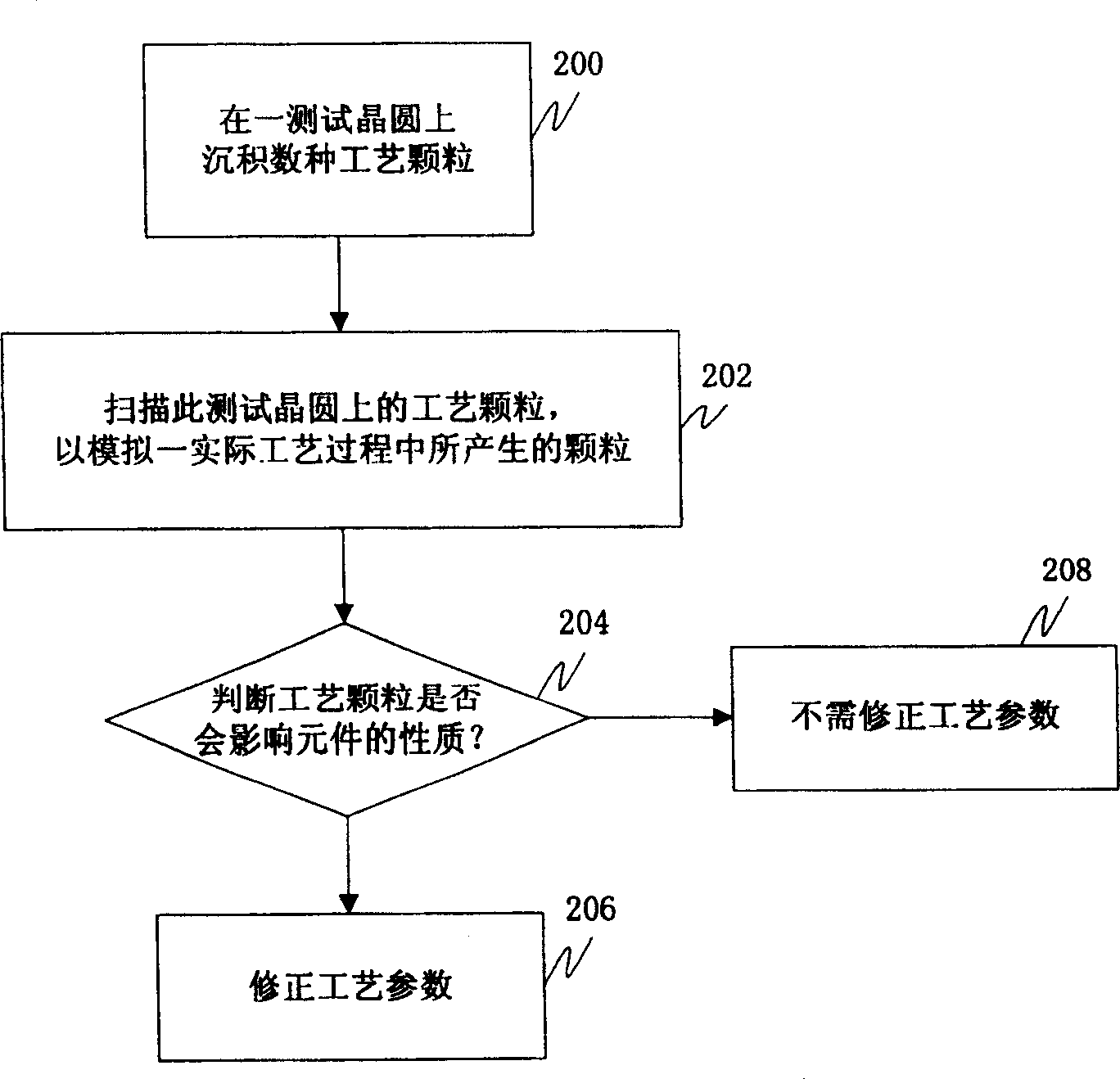

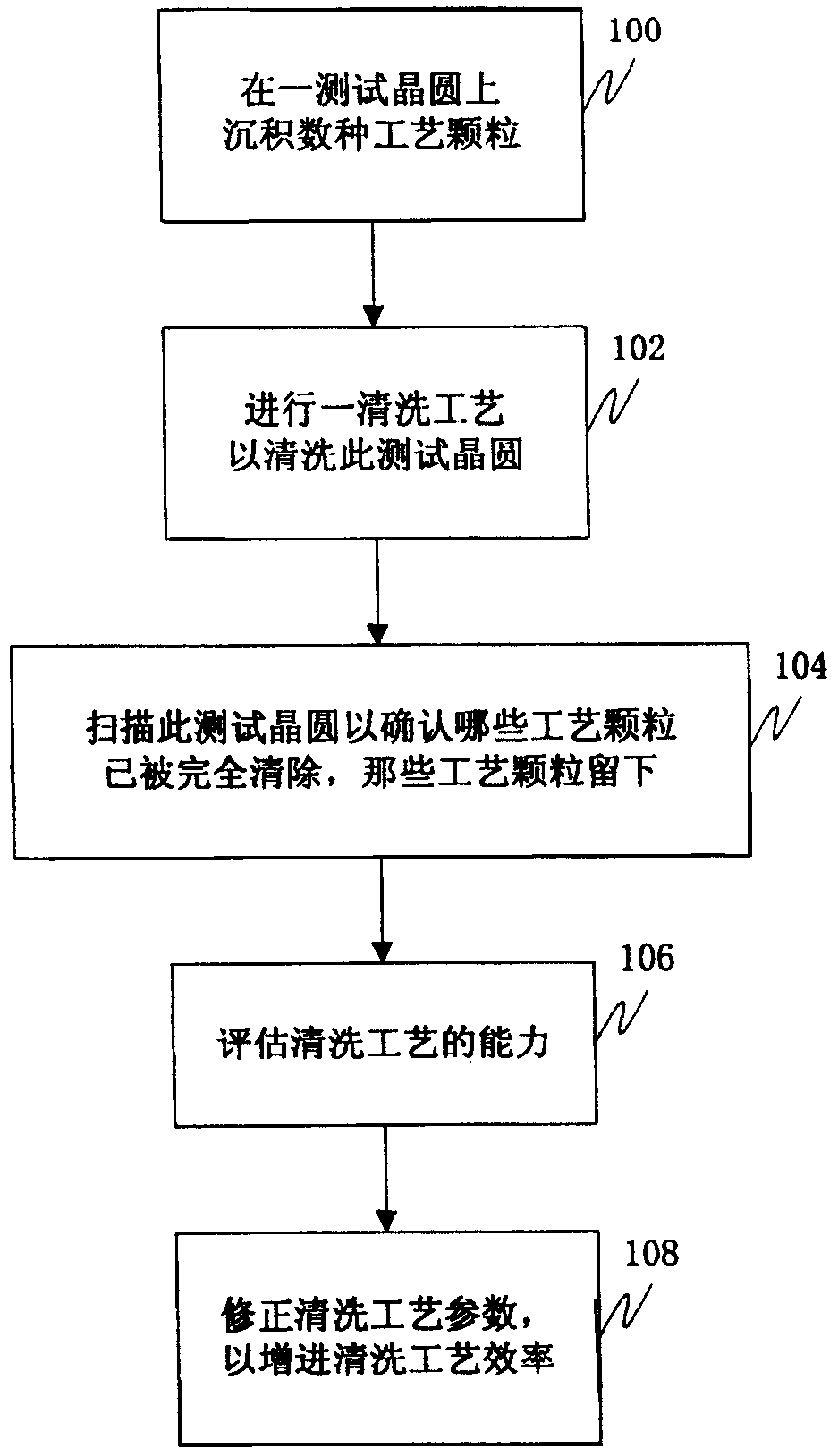

Method for increasing crystal circlr cleaning efficiercy and improving process qualification rate

InactiveCN1282225CImprove cleaning efficiencyImproved cleaning efficiency and enhancedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringCrystal

A method for improving wafer cleaning efficiency and process pass rate, wherein the method for improving wafer cleaning efficiency is to firstly deposit several kinds of process particles on a test wafer. Then a cleaning process is performed to clean the test wafer. Afterwards, the test wafer is scanned to confirm which process particles have been completely removed and which process particles remain on the test wafer. Then, a result of scanning the test wafer is used to evaluate the cleaning capability of the cleaning process. Then, modify the parameters of the cleaning process to improve the efficiency of the cleaning process.

Owner:MACRONIX INT CO LTD

Miniature light emitting diode display device

PendingCN113675324AImprove resolutionImprove process pass rateSolid-state devicesSemiconductor devicesDisplay deviceLight-emitting diode

The invention discloses a miniature light emitting diode display device which comprises a circuit substrate, an epitaxial structure layer, a metal conductive layer, a light conversion layer and a shading structure. The epitaxial structure layer comprises a first surface facing the circuit substrate, a second surface far away from the circuit substrate, and a plurality of micro light emitting diode units arranged at intervals, and the micro light emitting diode units are electrically connected with the circuit substrate. The metal conductive layer is arranged on the second surface and is in direct contact with the epitaxial structure layer. Each light conversion area of the metal conductive layer corresponds to one of the miniature light emitting diode units. The light conversion layer is arranged in part of the light conversion areas. The light shielding structure does not cover the light conversion areas. The thickness of the metal conductive layer is greater than the thickness of the epitaxial structure layer in the direction perpendicular to the bonding surface of the linear substrate.

Owner:PLAYNITRIDE DISPLAY CO LTD

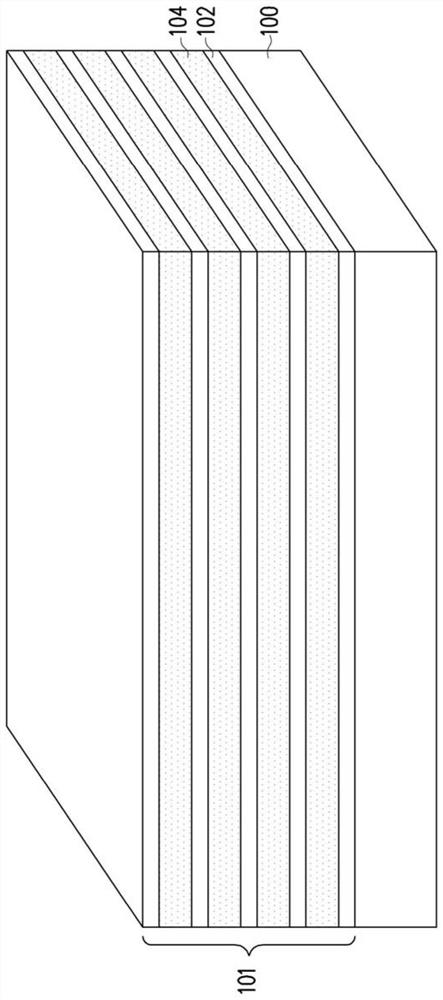

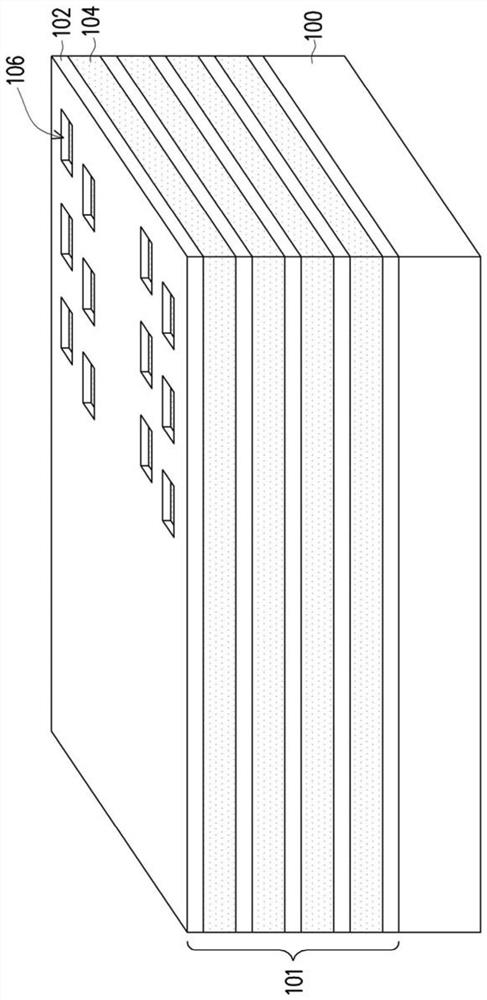

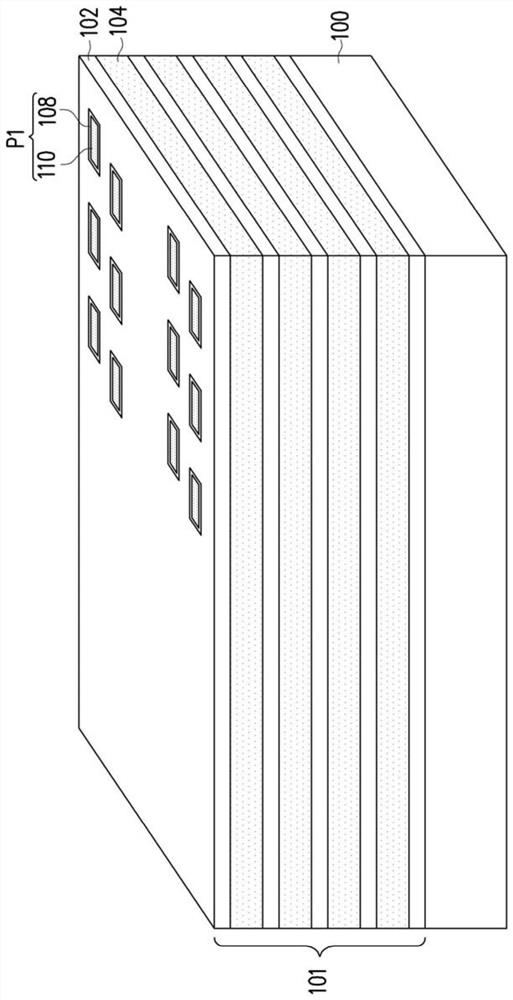

Three-dimensional and flash memory and manufacturing method thereof

PendingCN112687697AFast operationImprove process pass rateSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricElectrical conductor

The invention discloses a three-dimensional and flash memory and a manufacturing method thereof. The manufacturing method comprises the following steps of forming a stacked structure including alternately stacked first insulating layers and first sacrificial layers; forming a first pillar structure penetrating through the stack structure and including a second insulating layer and a second sacrificial layer surrounding the second insulating layer; forming a second column structure which penetrates through the laminated structure and comprises a channel layer and an insulating column surrounding the channel layer, wherein the second sacrificial layers are located at the two sides of the channel layer; removing the first sacrificial layer to form a lateral opening exposing a portion of the second insulating layer and the channel layer; and forming a gate dielectric layer surrounding the exposed second insulating layer and the channel layer in the lateral opening; filling a gate layer in the lateral opening; and replacing the second sacrificial layer with a conductor layer.

Owner:MACRONIX INT CO LTD

Method and apparatus for manufacturing glass structure

InactiveCN105198229AHigh surface hardnessImprove surface strengthCoatingsCeramic membraneGlass structure

Owner:CREATING NANO TECH INC +1

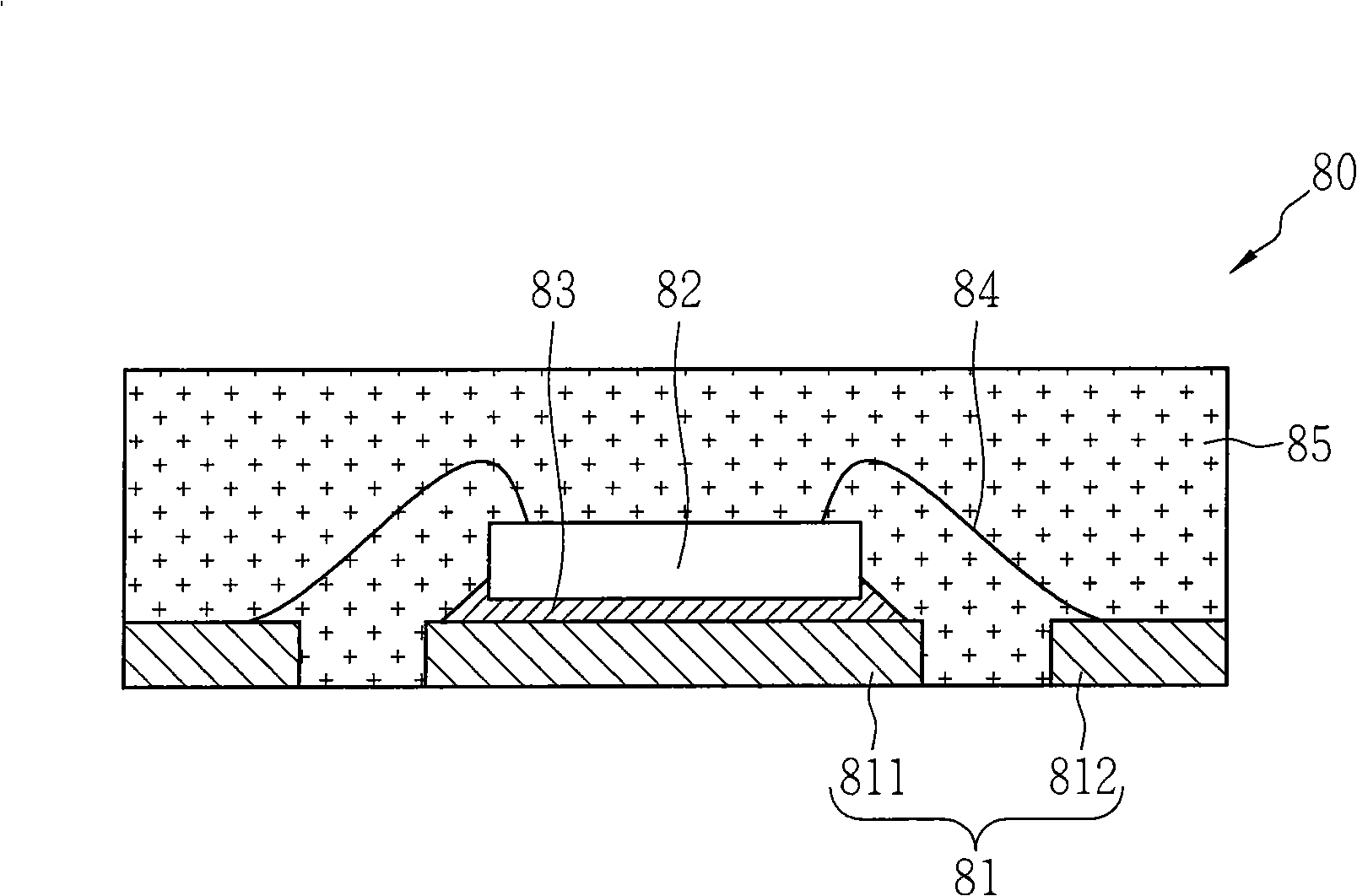

Lead frame for leadless encapsulation, encapsulation construction and manufacture method thereof

ActiveCN101308832AImprove cooling efficiencyReduce peelingSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The invention discloses a lead frame without a lead enclosure, which comprises a plurality of enclosing units and an adhesive tape. Each enclosing unit comprises a chip seat which is provided with a plurality of through holes, and a plurality of pins which are respectively arranged in the through holes. The adhesive tape is affixed to the surfaces of the enclosing units and fixes the chip seat and the pins.

Owner:CHIPMOS TECH INC

Stator structure of plastic-molded motor for washing machine

ActiveCN102377254BReduce manufacturing costEasy to produceWindingsMagnetic circuit stationary partsWhole bodyHeight difference

Owner:FOSHAN WEILING WASHER MOTOR MFG

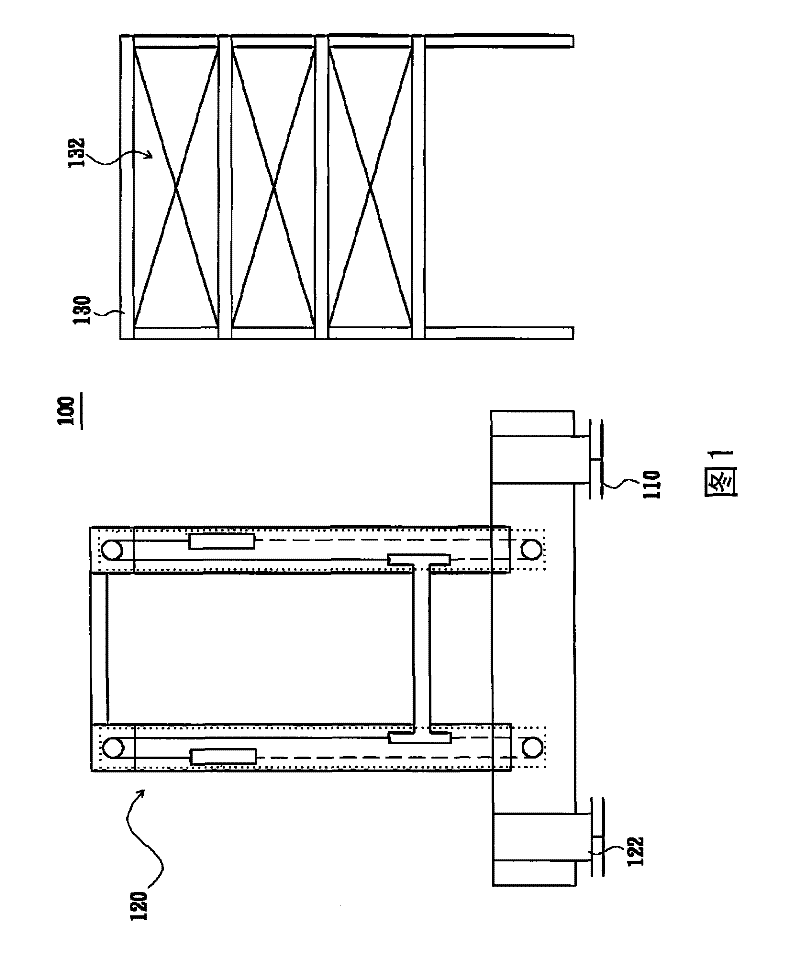

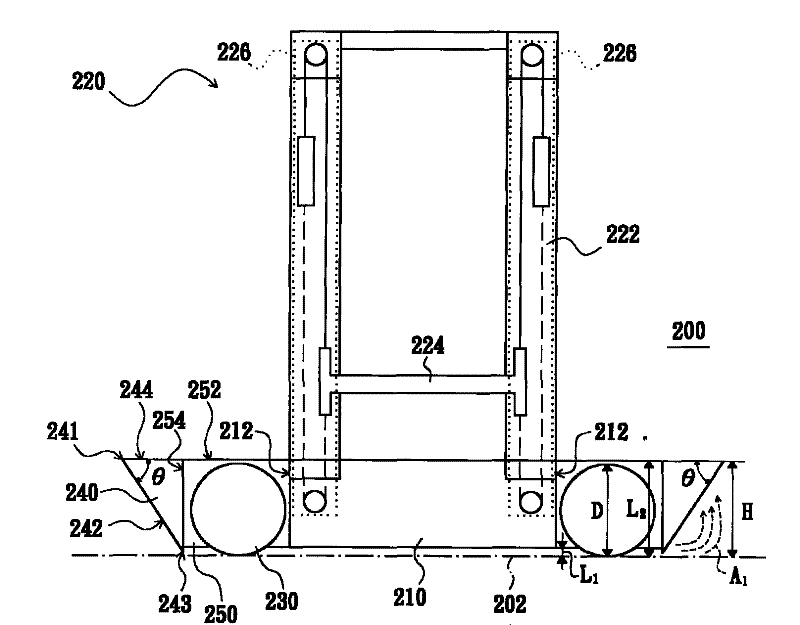

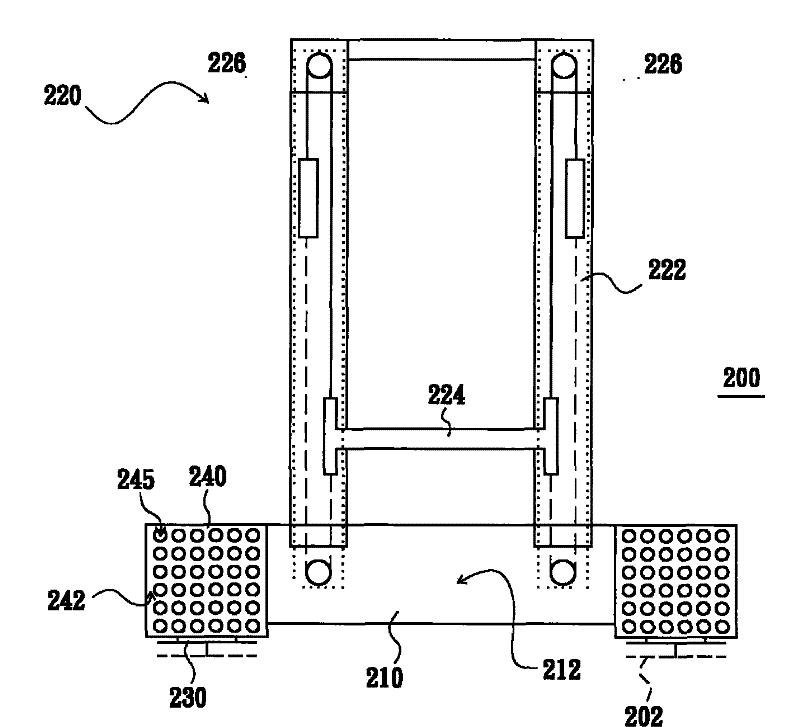

Method for reducing dust in clean room, storage system and transfer device thereof

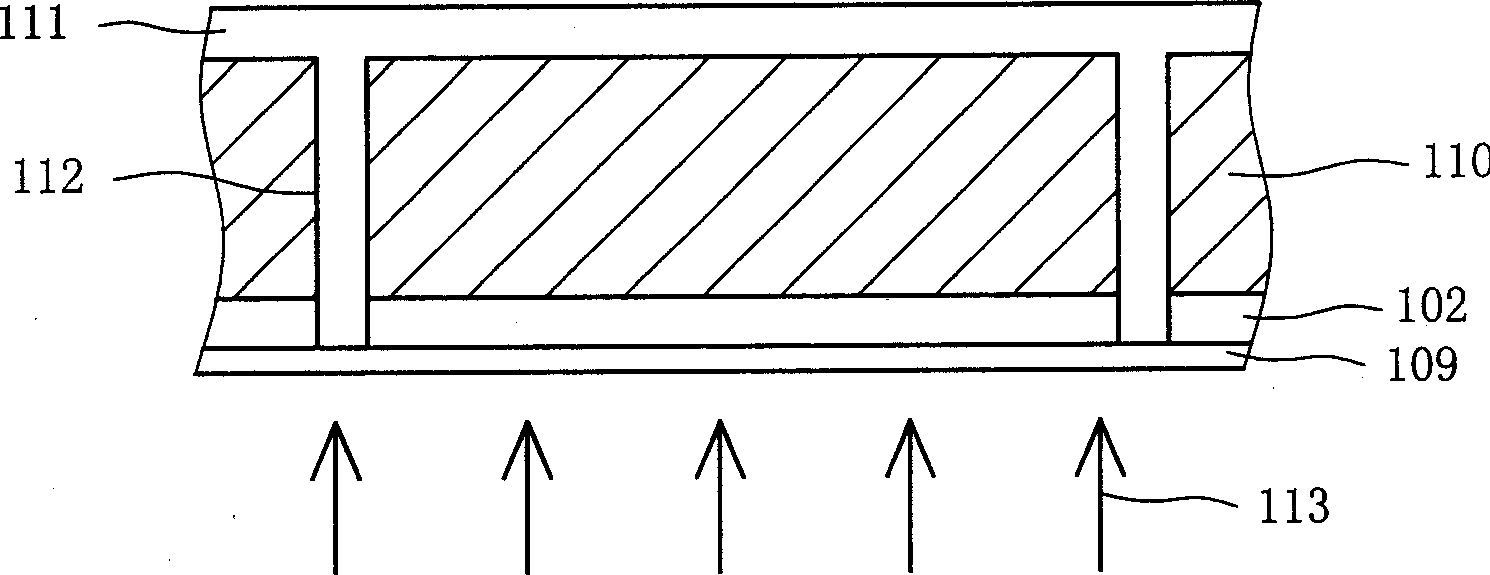

InactiveCN101492118BAvoid pollutionImprove process pass rateFouling preventionCharge manipulationCharacteristic lengthEngineering

The invention relates to a method for reducing dust in a clean room, a storage system and a transfer device thereof. The storage system includes rails, transfer devices, storage racks and spoilers. The transfer device can travel on the track, and it includes a base, a bearing body, a transmission part and a deflector. The carrying body is configured on the base. The transmission member is used to drive the base to move, and has a characteristic length D. The deflector has a plane and a guide slope, wherein the plane is arranged on the first height H, and 0.1D≤H≤9D. There is an angle θ between the guide slope and the plane, and the angle θ corresponds to the characteristic length D. The storage rack is arranged on one side of the track and has a storage space. The spoiler baffle is located below the storage space and is arranged on the second height h, and 0.025D≤h≤2.5D. The invention can prevent the dust or particles raised by the airflow caused by the moving of the transfer device from polluting the items on the storage rack.

Owner:AU OPTRONICS CORP

Package structure and manufacturing method thereof

ActiveCN109273426BImprove reliabilityAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesWaferingInorganic materials

The invention discloses an encapsulation structure and a manufacturing method thereof. The encapsulation structure comprises a metal layer, a composite layer of a non-conductor inorganic material and an organic material, a sealant, a wafer, a circuit layer structure and an insulating protection layer. The composite layer of non-conductive inorganic material and organic material is arranged on the metal layer. The sealant is combined on the composite layer of non-conductive inorganic material and organic material. The chip is embedded in the encapsulant, and the chip has a plurality of electrode pads. The wiring layer structure is formed on the encapsulant and the wafer. The circuit layer structure includes at least one dielectric layer and at least one circuit layer, the dielectric layer has a plurality of conductive blind holes, the circuit layer is located on the dielectric layer, and the bottommost circuit layer is electrically connected to the electrode pad through the conductive blind holes. The insulation protection layer is formed on the circuit layer structure. The insulating protection layer has a plurality of openings, so that part of the surface of the circuit layer structure is exposed in the openings. The invention can strengthen the overall structural strength to prevent warpage.

Owner:UNIMICRON TECH CORP

Pad Pattern Repair Equipment

ActiveCN102939544BImprove process pass rateSemiconductor/solid-state device testing/measurementMeasurement leads/probesShielding gasLaser light

Owner:苏州科韵激光科技有限公司

Coolant injection process and suitable clamping fixture for same

InactiveCN100464390CImprove reliabilityReduce air bubble contentTelevision system detailsColor television detailsCooling fluidBiomedical engineering

This invention relates to cooling liquid injection process, which comprises the following steps: a, setting one sealed element into cooling liquid injection entrance; then under one negative environment injecting the liquid into projection tube to facilitate cooling liquid higher than cooling liquid mouth; then injecting sealed parts into injection mouth sealing; then injecting cooling liquid into cooling liquid. This invention provides one cooling liquid injection clamper into projection tube.

Owner:CHUNGHWA PICTURE TUBES LTD

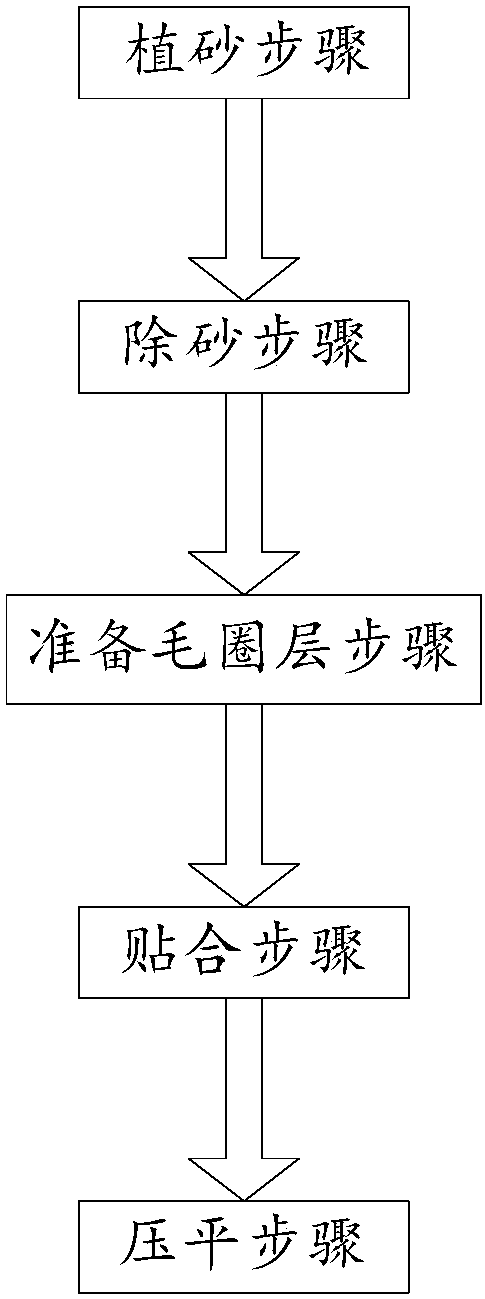

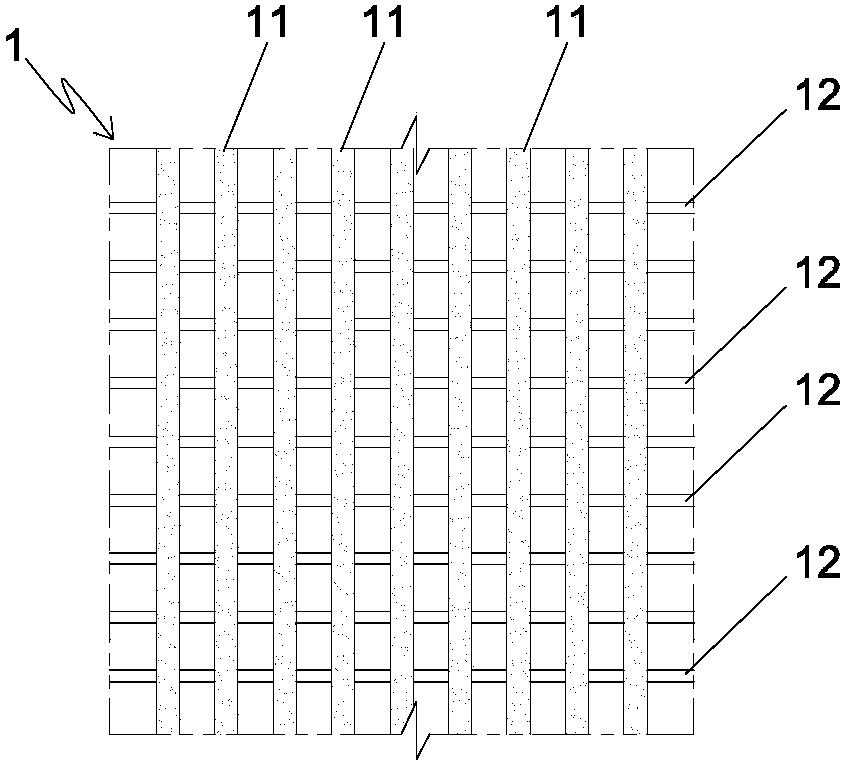

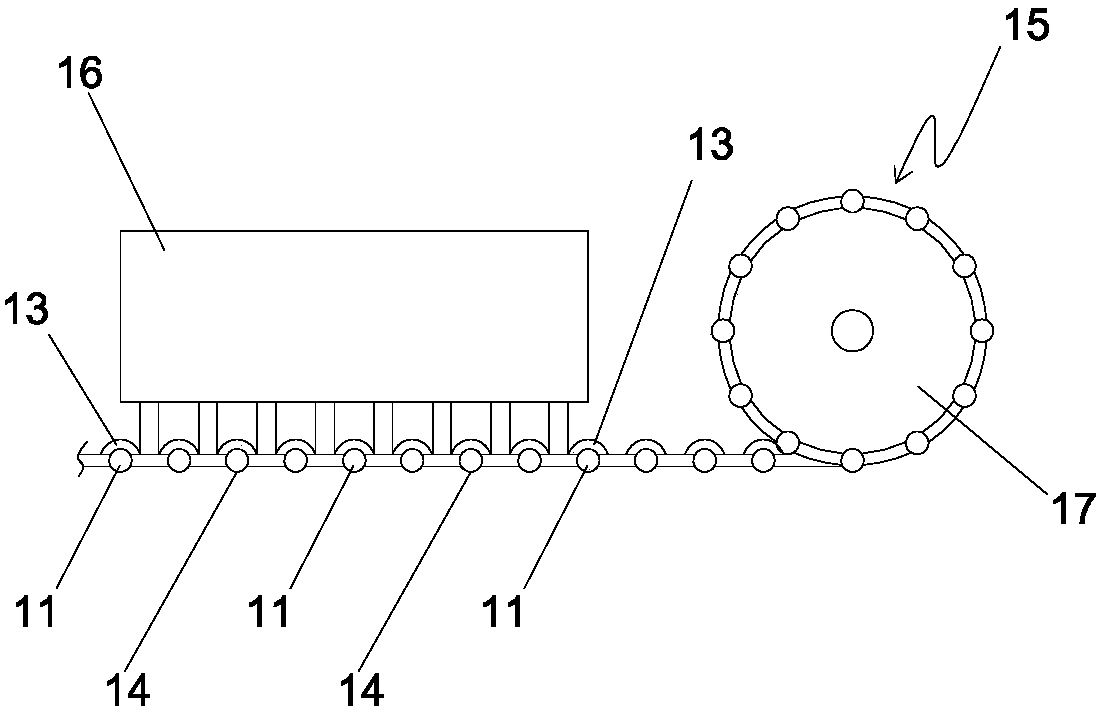

Method for producing grid gauze having opened holes

InactiveCN107804058ALarge grid distanceEasy chip removalLaminationLamination apparatusEngineeringWeft yarn

The invention provides a method for producing grid gauze having opened holes. The method comprises the following steps: a sand-planting step, a desanding step, a looped pile preparation layer, an applying step, and a pressing step. The grid gauze having opened holes can remove an emery layer on weft yarn through a die, the grid distance of the grid gauze is large, and the grid gauze has good chip-removal effect.

Owner:YOAN HORNG INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com