Method for increasing crystal circlr cleaning efficiercy and improving process qualification rate

A technology of cleaning efficiency and pass rate, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as abnormal conduction and unusable components, and achieve the goal of improving process pass rate and wafer cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

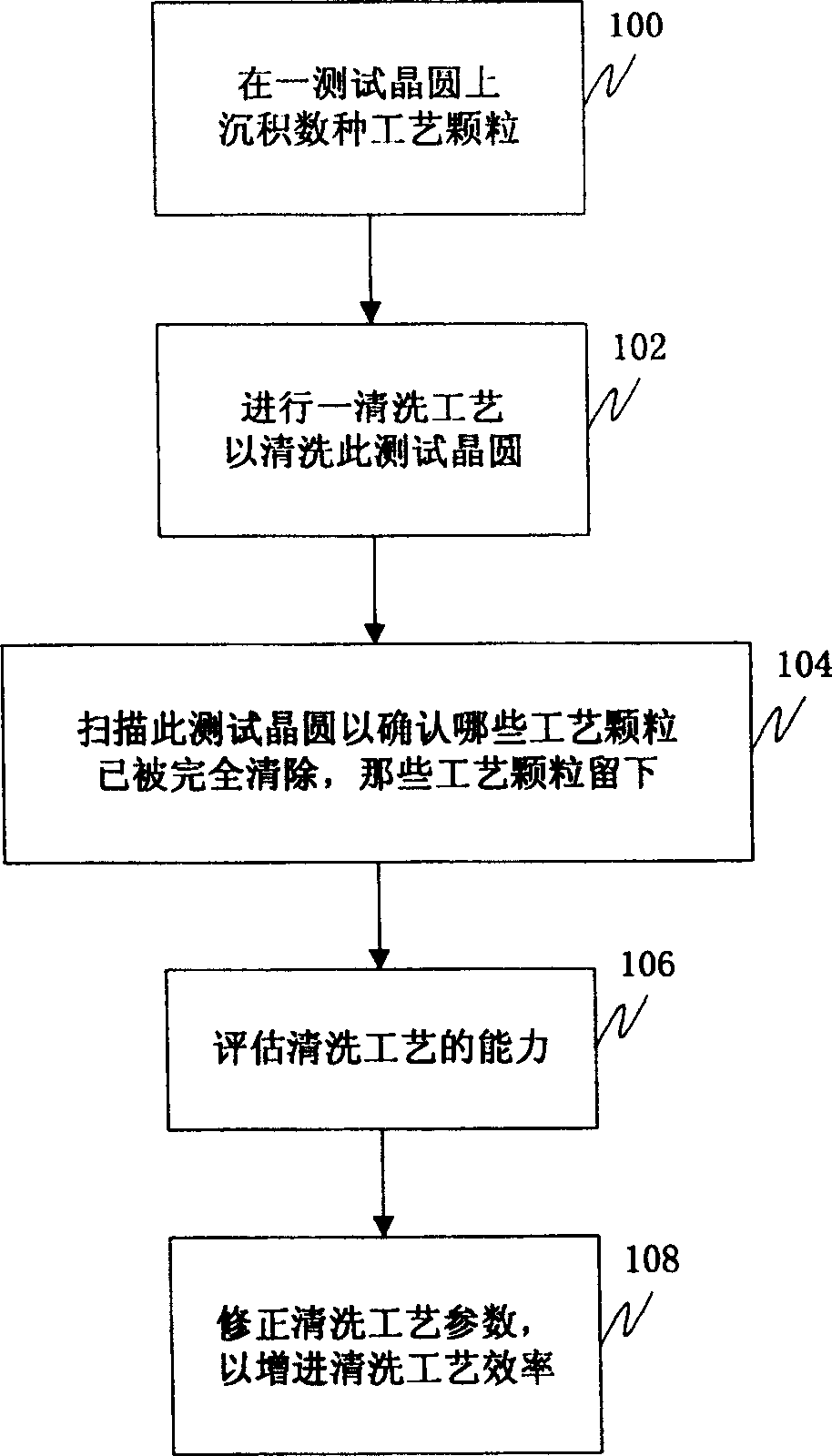

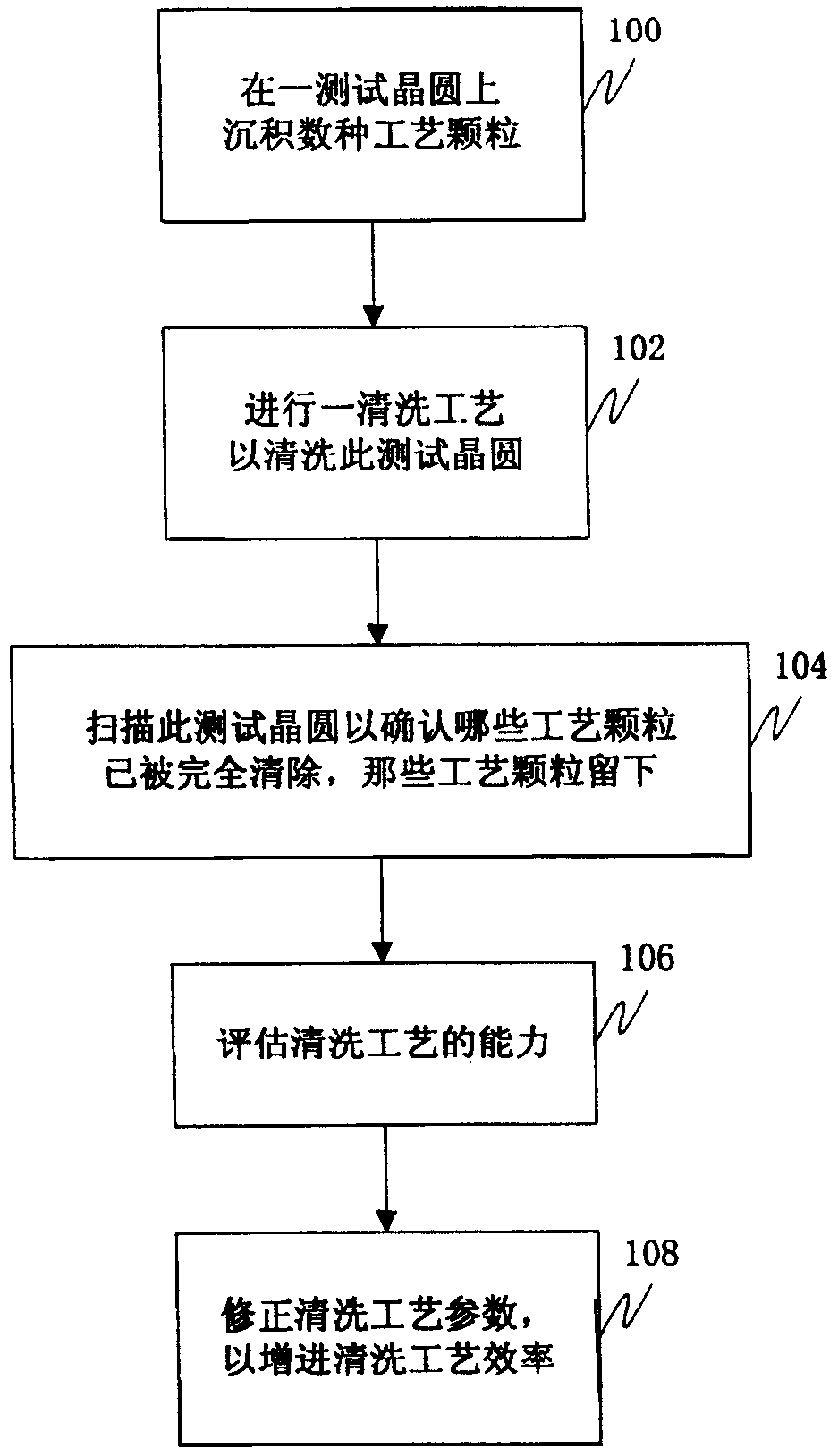

[0015] figure 1 As shown, it is a flowchart of a method for improving wafer cleaning efficiency according to a preferred embodiment of the present invention.

[0016] Please refer to figure 1 First, deposit several kinds of process particles on a test wafer (step 100). Among them, these process particles include all types of process particles in an actual process. Moreover, the process particles deposited on the test wafer further include all types of process particles of different materials, different sizes, and different shapes.

[0017] In this embodiment, the process particles deposited on the test wafer include silicon material particles, dielectric material particles, metal material particles, metal oxide particles, and so on. Among them, the silicon material particles are, for example, silicon (Si) particles and polysilicon (Polysilicon) particles. The dielectric material particles are, for example, silicon nitride (Si 3 N 4 ) Particles and silicon oxide (SiO 2 ) Particl...

no. 2 example

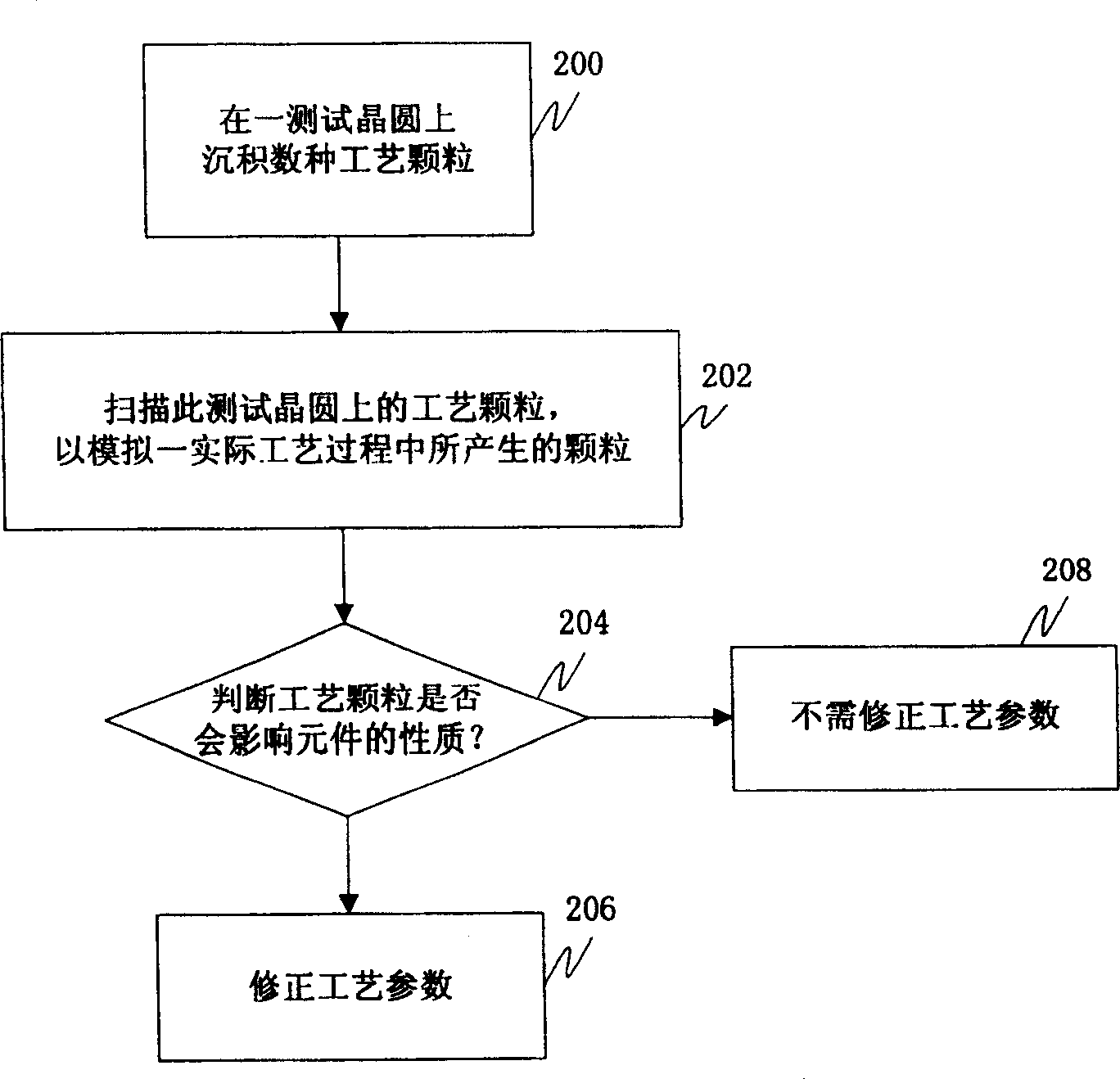

[0024] figure 2 As shown, it is a flow chart of the method for improving the process yield according to the second embodiment of the present invention.

[0025] Please refer to figure 2 First, deposit several kinds of process particles on a test wafer (step 200). Among them, these process particles include all types of process particles in an actual process. And the process particles deposited on the test wafer further include all types of process particles of different materials, different sizes, and different shapes.

[0026] In this embodiment, the process particles deposited on the test wafer include silicon material particles, dielectric material particles, metal material particles, metal oxide particles, and so on. Among them, the silicon material particles are, for example, silicon (Si) particles and polysilicon (Polysilicon) particles. The dielectric material particles are, for example, silicon nitride (Si 3 N 4 ) Particles and silicon oxide (SiO 2 ) Particles. The metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com