Method for reducing dust in clean room, storage system and transfer device thereof

A transfer device, dust cover technology, applied in the direction of pollution prevention methods, cleaning methods and appliances, storage devices, etc., can solve the problems of semiconductor and display device process qualification rate decline, article pollution, etc., to improve the process qualification rate , improve cleanliness, and save electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

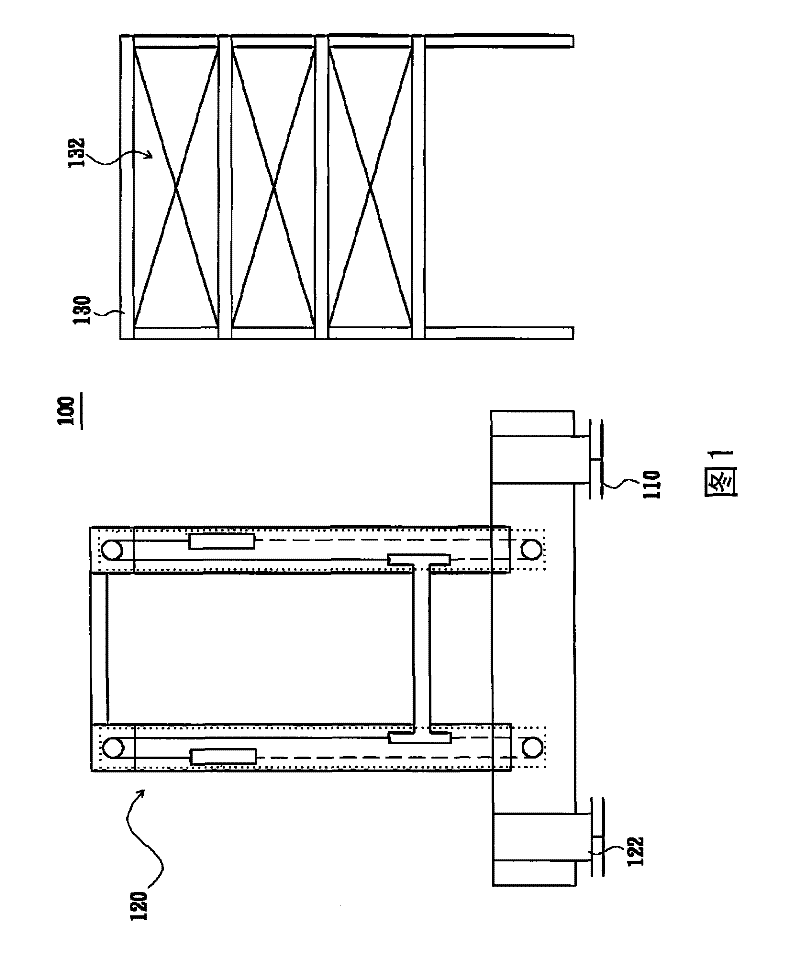

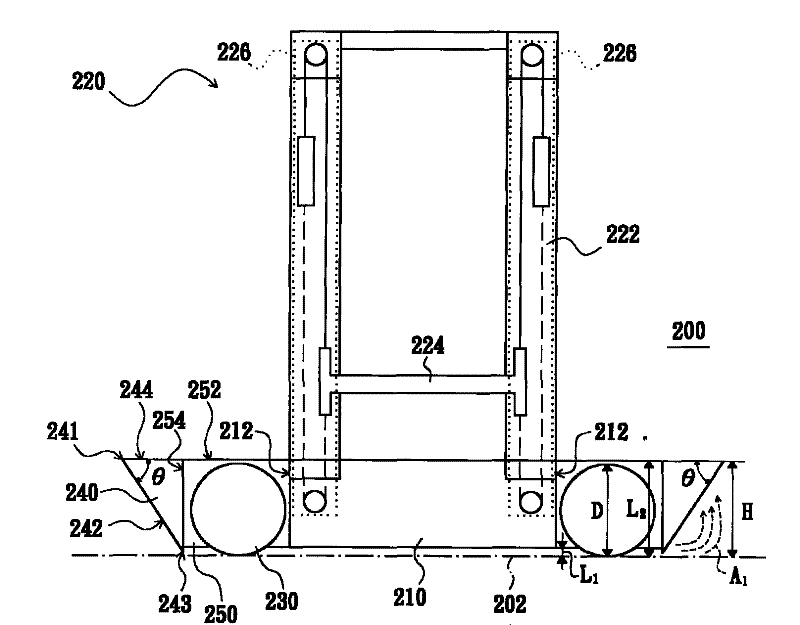

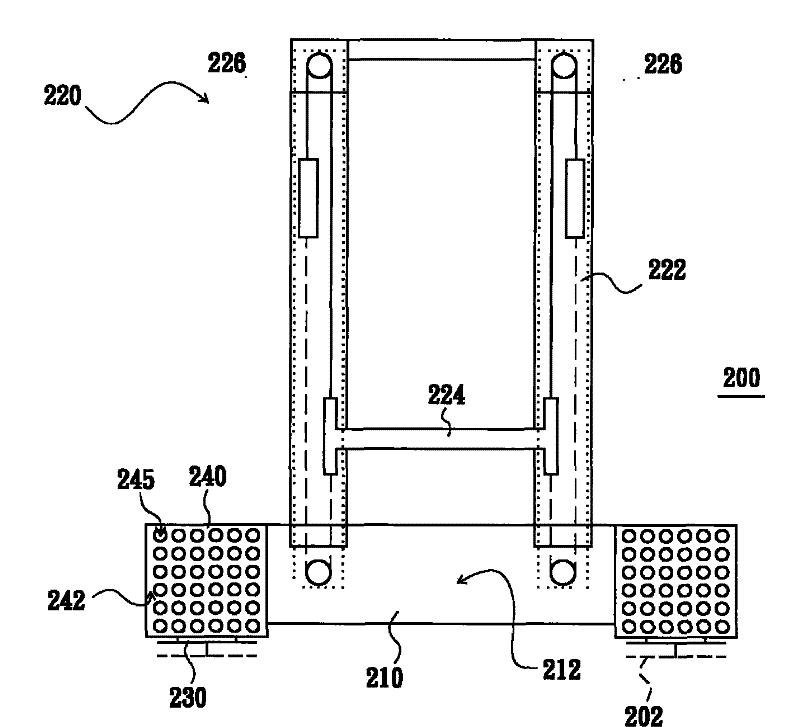

[0043] Figure 2A It is a side view of the transfer device in an embodiment of the present invention, Figure 2B Then it is the front view of the transfer device in an embodiment of the present invention. Please refer to Figure 2A and Figure 2B , the transfer device 200 includes a base 210 , a carrying body 220 , a transmission member 230 and a deflector 240 . Wherein, the carrying body 220 is configured on the base 210 , and it includes, for example, a bracket 222 and a carrying platform 224 . The carrying platform 224 is connected to the support 222 for carrying the items to be transported (not shown). In particular, the carrying body 220 of this embodiment may also include a lifting mechanism 226, which is configured in the bracket 222 to drive the carrying platform 224 up and down, so as to transport the items on the carrying platform 224 to different heights. storage space or location.

[0044] The transmission member 230 is used to drive the base 210 to move on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com