Solar cell and solar cell module group

A solar cell and electrode technology, applied in the field of solar cells, can solve the problems that the current density of the solar cell 100 cannot be effectively increased, the cell efficiency cannot be improved, and the efficiency of carrier collection is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

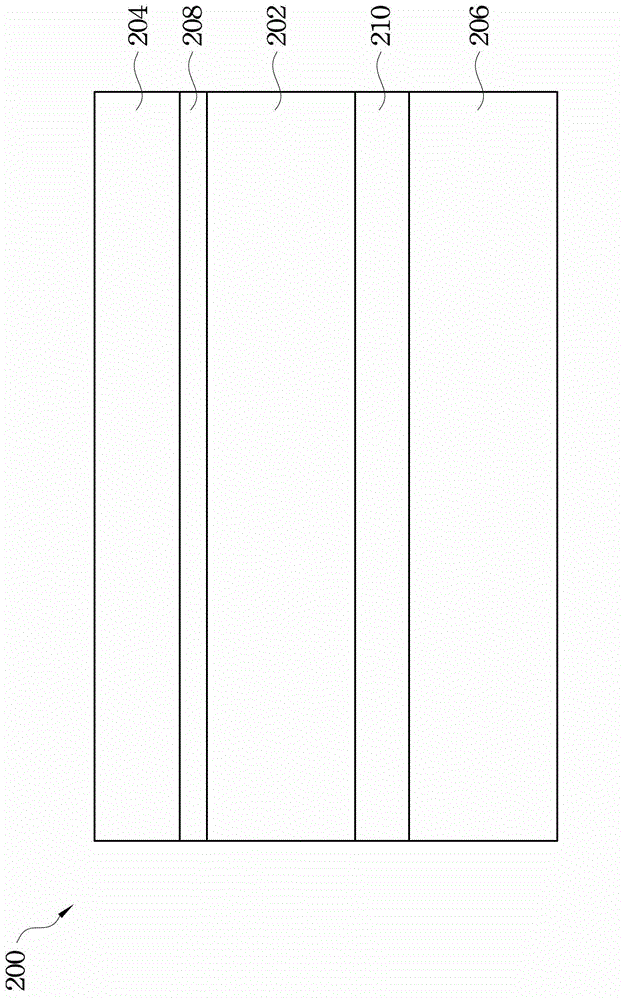

[0064] Please refer to figure 2 , which is a schematic cross-sectional view illustrating a solar cell module according to an embodiment of the present invention. In this embodiment, the solar cell module 200 mainly includes an upper plate 204, a lower plate 206, a solar cell 202, and one or more packaging material layers, such as packaging material layers 208 and 210, such as ethylene vinyl acetate copolymer (EVA) material.

[0065] Such as figure 2 As shown, in the solar cell module 200 , the solar cell 202 is disposed on the lower plate 206 and is disposed under the upper plate 204 . Therefore, the upper plate 204 is disposed on the lower plate 206 , and the solar cell 202 is disposed between the lower plate 206 and the upper plate 204 . In addition, the two packaging material layers 208 and 210 are respectively disposed between the upper plate 204 and the solar cell 202 , and between the lower plate 206 and the solar cell 202 . The encapsulation material layers 208 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com