Problem cell identification method

A discrimination method and cell technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as equipment and production safety damage, customer zero voltage failure, polluted cells, etc., to save manpower and material resources, The effect of improving production efficiency and reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

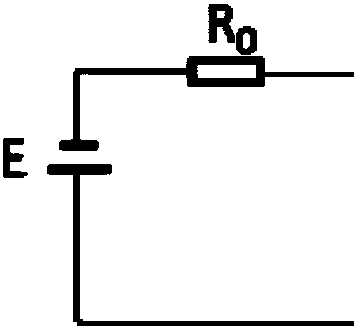

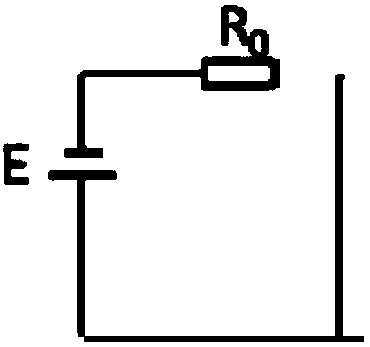

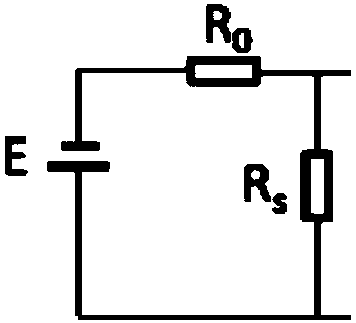

[0025] Refer below Figure 1-Figure 5 The method 40 for identifying a problematic cell according to an embodiment of the present invention will be described in detail.

[0026] Such as Figure 5 As shown, the discrimination method 40 according to the embodiment of the present invention includes the following steps: S10, charging the battery; S20, connecting the detection circuit to the battery, detecting the current and judging the battery according to the change of the current: the current is within a predetermined time If the internal value decreases to 0, it is determined that the cell is a qualified cell; when the current is in any of the following situatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com