Method for producing display substrate

A technology of substrate and light-transmitting area, which is applied in semiconductor/solid-state device manufacturing, static indicator, photolithography process of pattern surface, etc., can solve the problems of high process complexity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

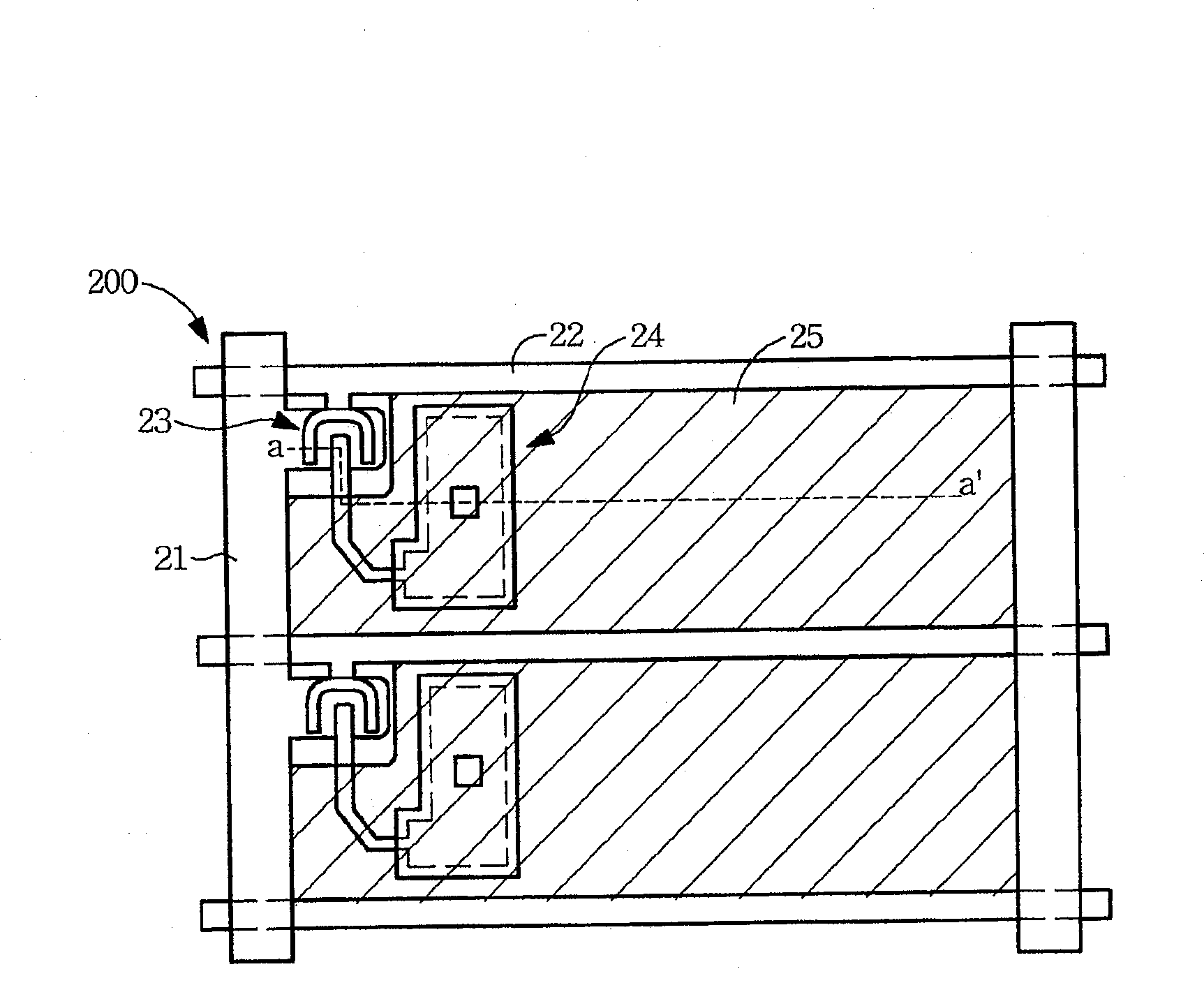

[0054] Please refer to figure 2, which is a top view of the display substrate of the present invention. Each pixel 200 of the display substrate at least includes a gate line 21 , a common line 22 , a TFT 23 , a capacitor structure 24 and a pixel electrode 25 . And technical content of the present invention, roughly with figure 2 The cross-sectional view of the a-a' line in the middle is introduced as follows.

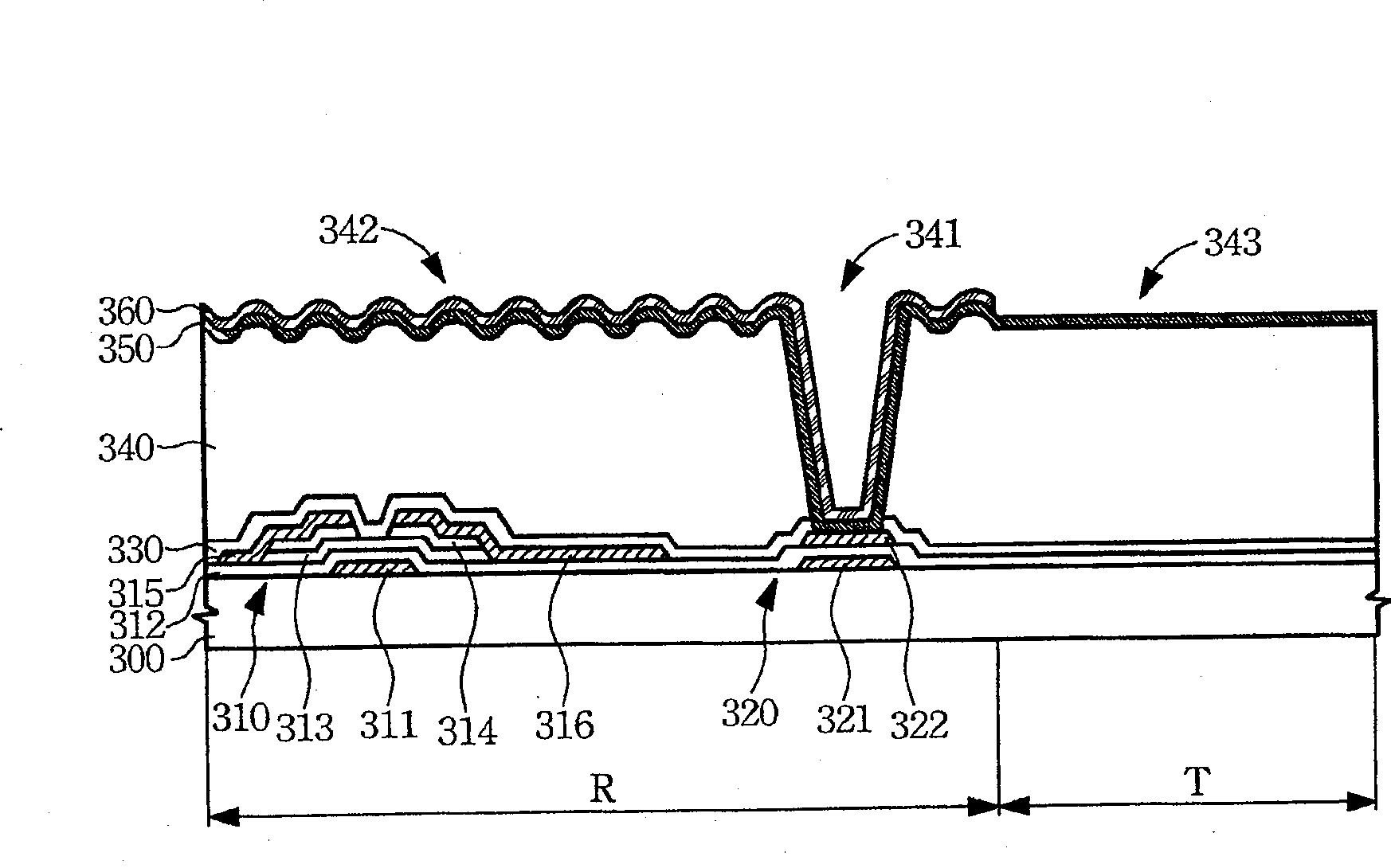

[0055] Please refer to Figure 3A to Figure 7B , which is a cross-sectional view of a display substrate in various structural forms of the present invention. Since the main technical content of the present invention lies in the display substrate in the transflective panel, and the color filter substrate disposed on the opposite side of the display substrate is similar to the known technology, so it will not be described in detail.

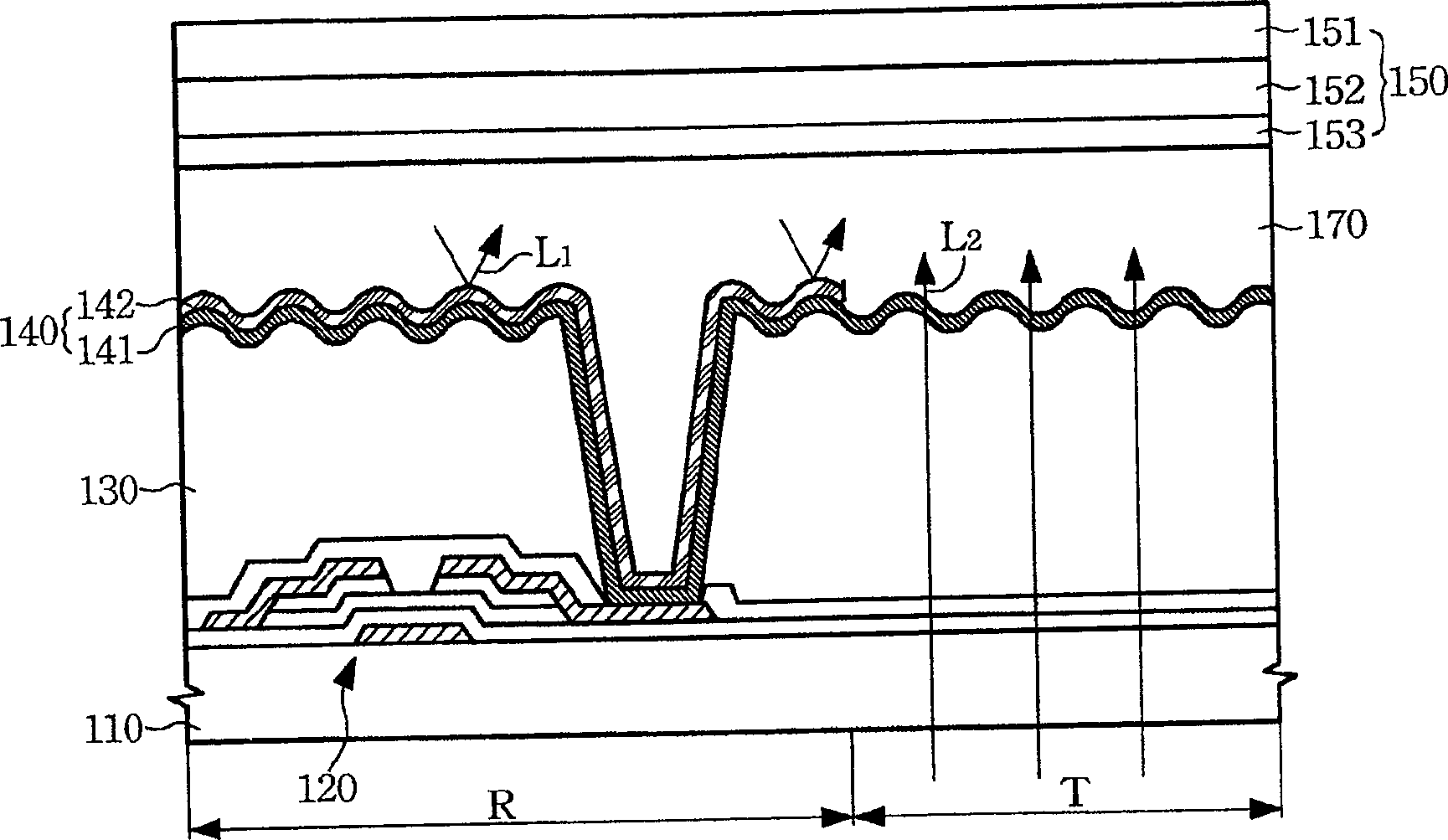

[0056] Please refer to Figure 3A , which is a structural form of the display substrate of the present invention. As shown in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com