Manufacturing method of appearance part

A production method and a technology of appearance parts, which are applied in the field of appearance parts production, can solve problems such as surface pattern erosion, product pass rate decline, damage, etc., and achieve the effects of increasing profits, improving process pass rate, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

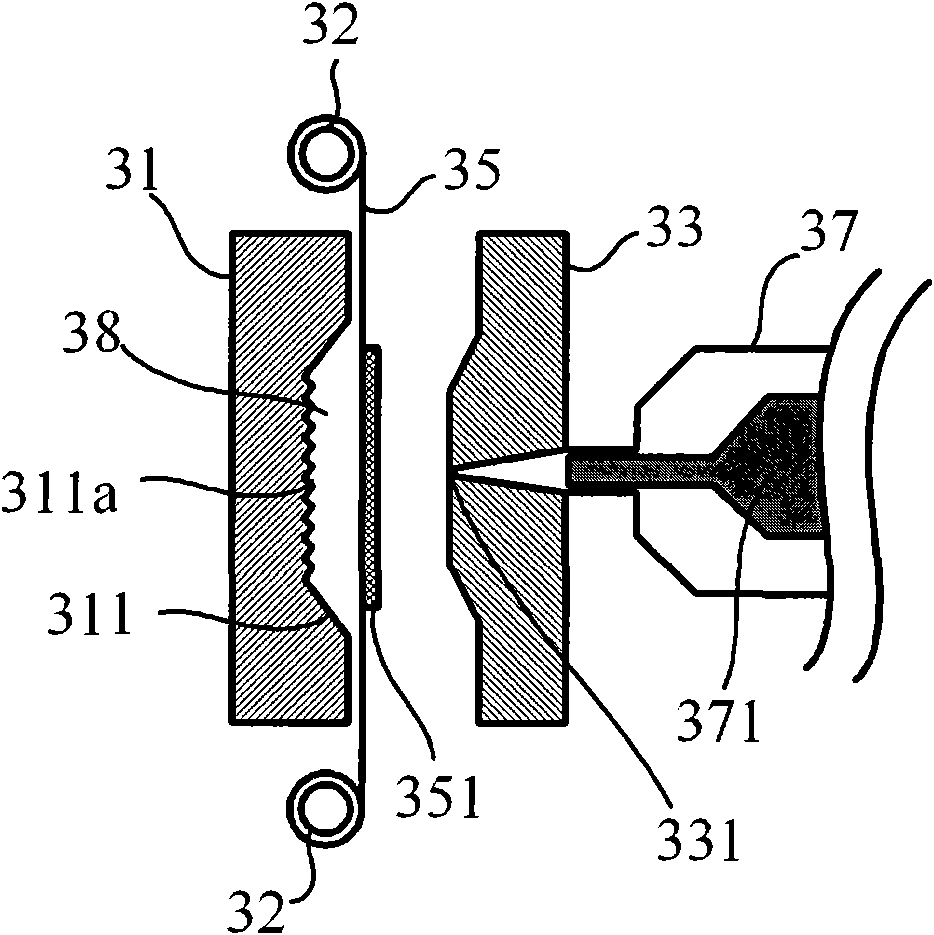

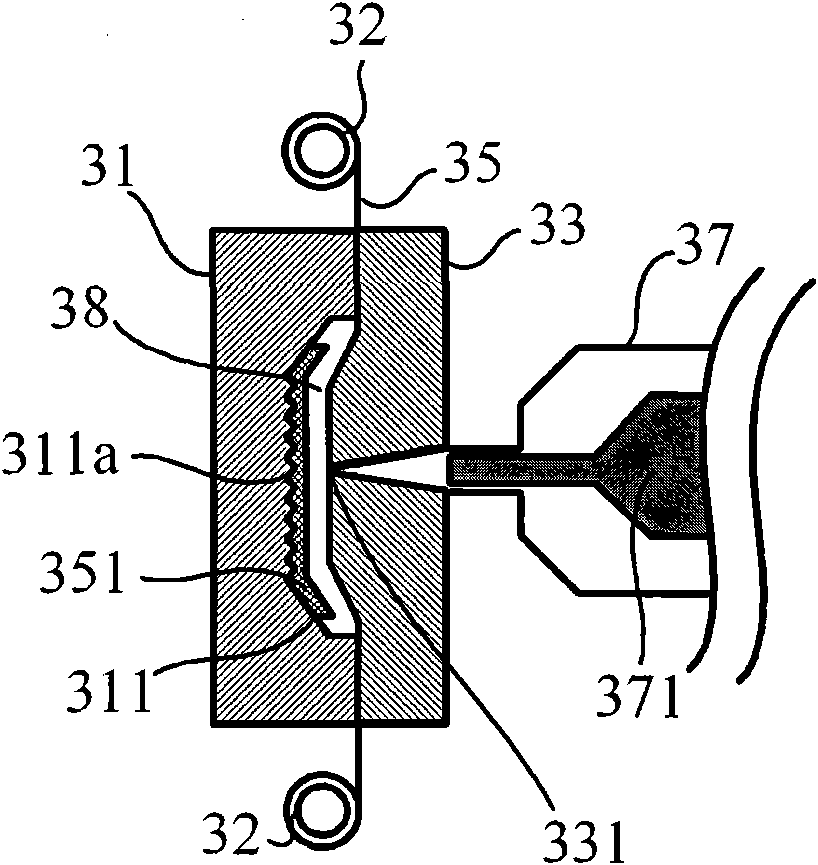

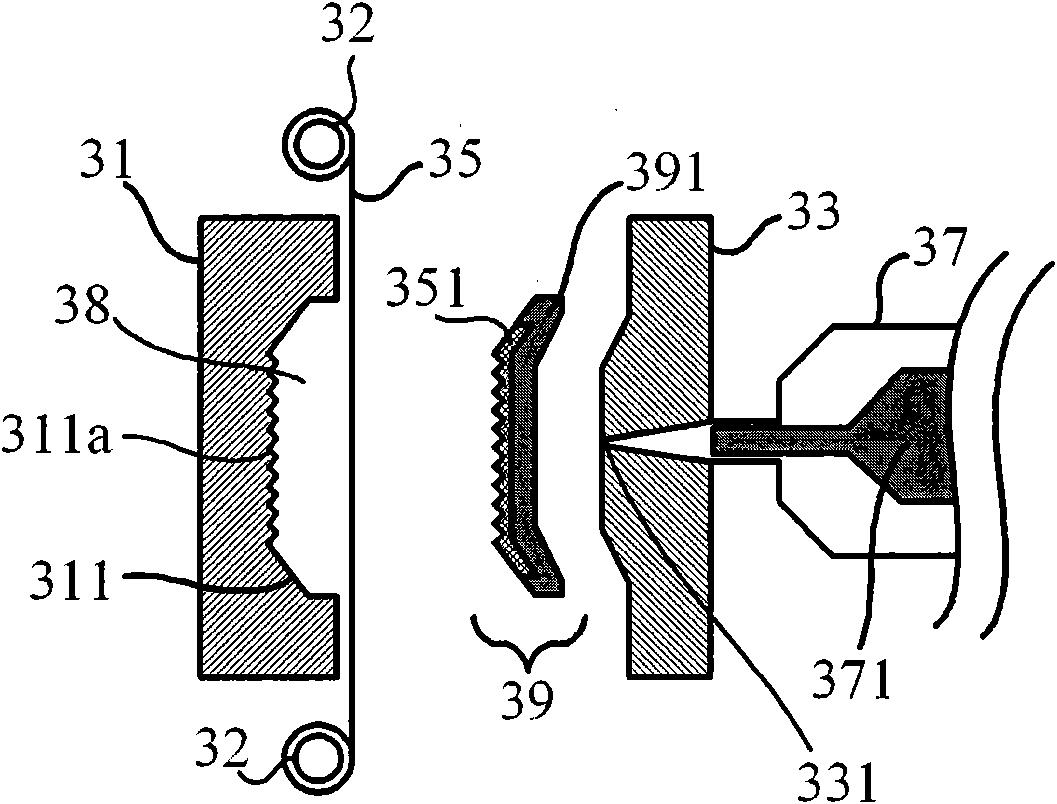

[0020] see figure 1 , figure 1 Shown is a schematic diagram of a specific embodiment of an in-mold transfer printing device applying the manufacturing method of the appearance part of the present invention. Such as figure 1 As shown, the in-mold transfer printing equipment includes a first mold 31 , a film feeding roller 32 , a second mold 33 , a transfer film 35 and an injection unit 37 .

[0021] The first mold 31 has a mold cavity 38, and the surface 311 of the mold cavity 38 has a texture 311a, and the texture 311a is a pattern. In particular, the texture 311a does not specifically limit the size, style, depth, pattern, etc., and is completely defined by the designer.

[0022] The transfer film 35 may include a base layer and a transfer pattern 351 . The base layer can generally be made of polymer materials such as PC / PBT, but not limited thereto. The transfer pattern 351 is generally a pattern or text printed on the base layer by using ink or paint. In particular, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com