Photoresist removing machine station and photoresist removing process

A technology of photoresist and process, which is applied in the field of photoresist removal process, can solve problems such as wafer 20 photoresist bursting, and achieve the effect of improving process pass rate and avoiding bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

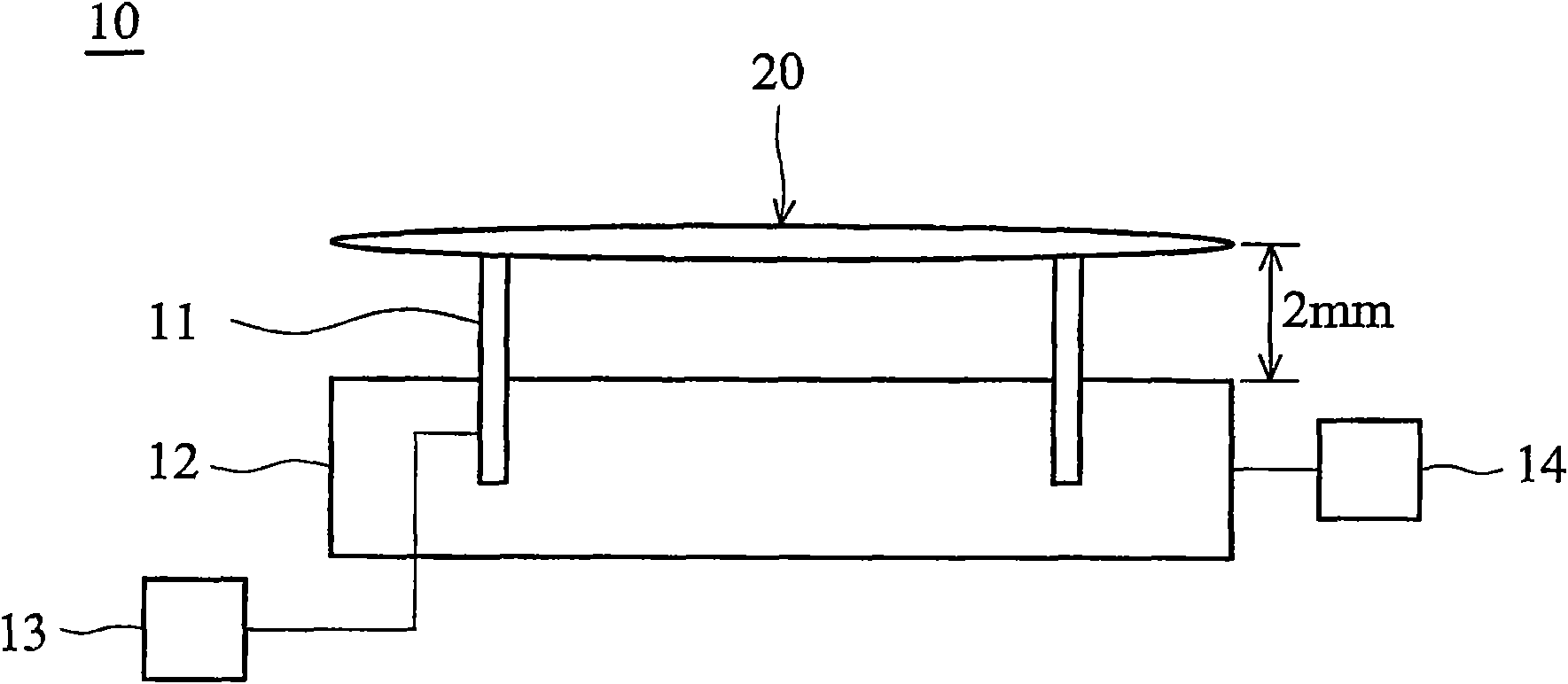

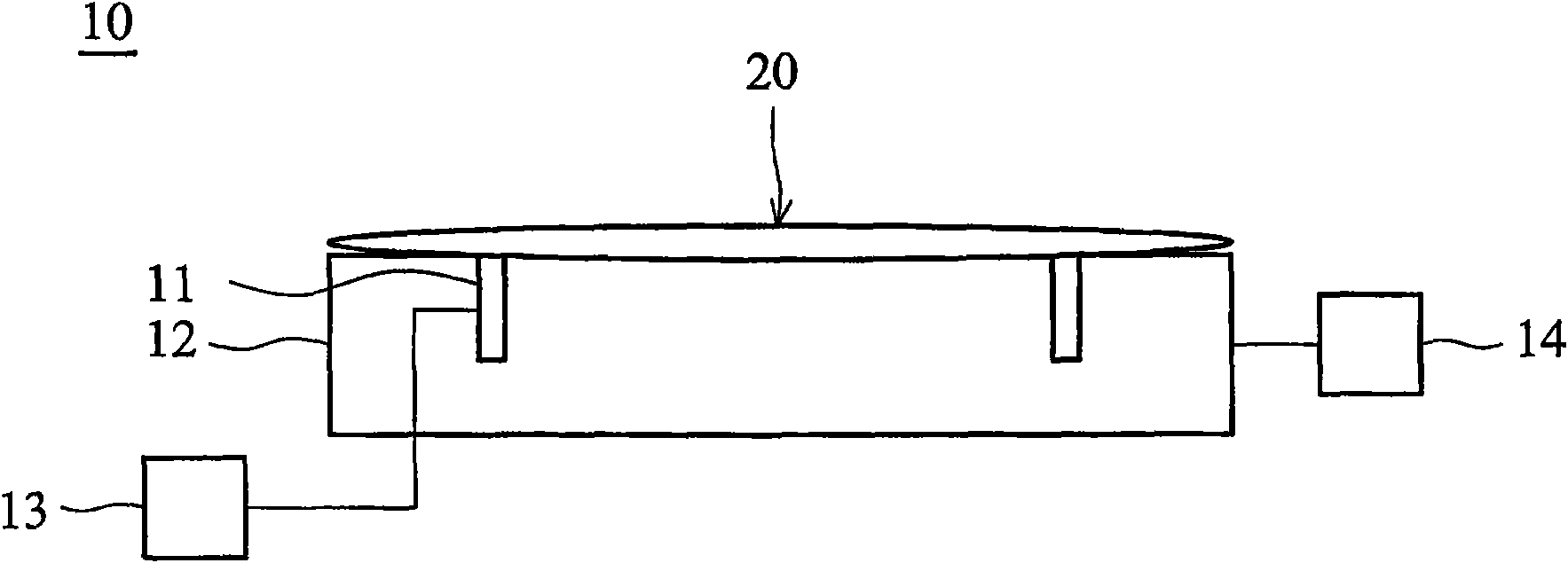

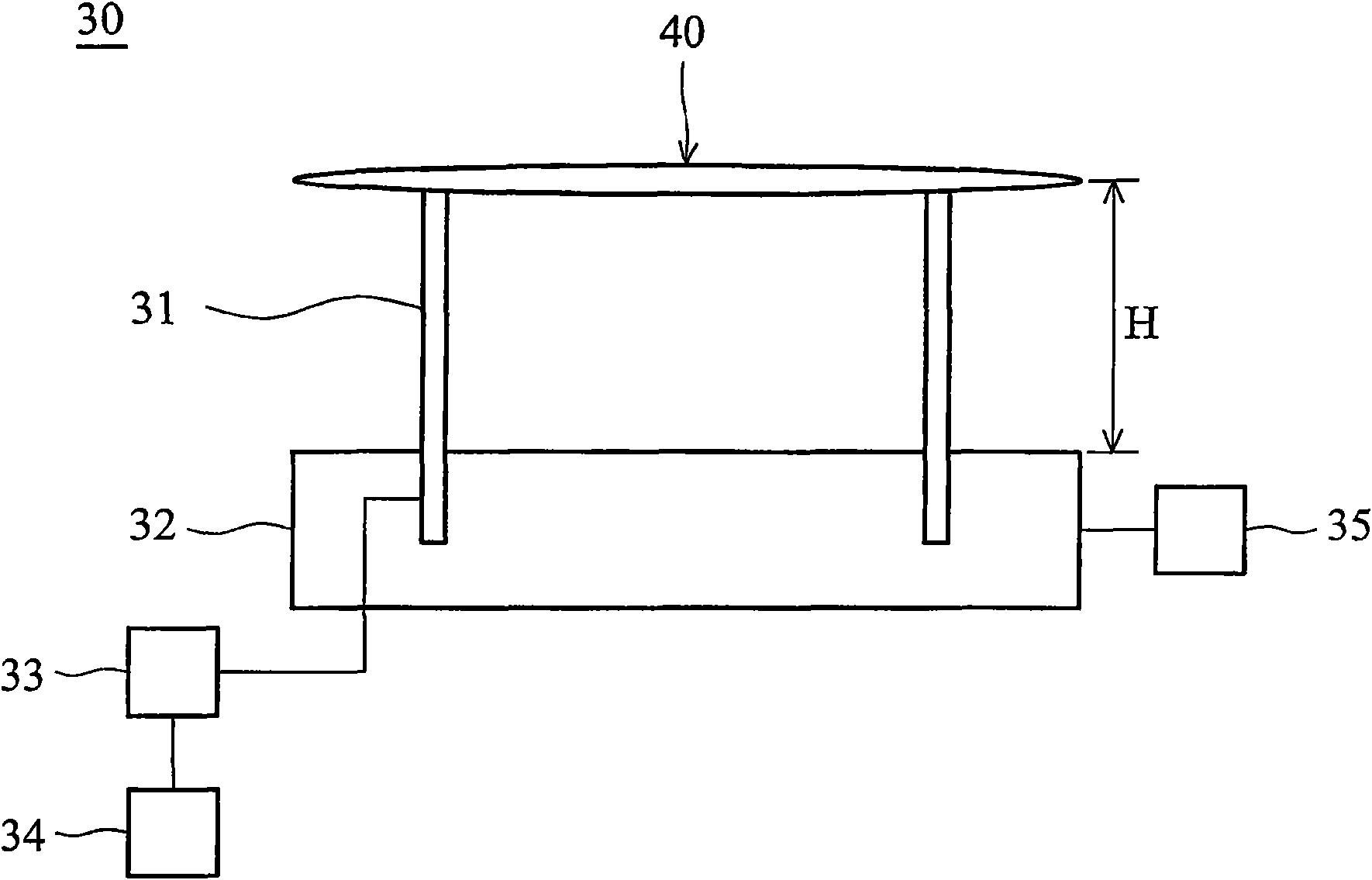

[0038] see Figure 2A-Figure 2C , Figure 2A It is a schematic diagram showing that the wafer carrier of the photoresist removal machine of the present invention is located at the carrying position, Figure 2B It is a schematic diagram that the wafer carrier of the photoresist removal machine of the present invention is located at the cooling position, and Figure 2C It is a schematic diagram of the wafer carrier located in the process position of the photoresist removal tool of the present invention. The photoresist removing machine 30 of the present invention is used to remove the photoresist on the wafer 40 , and includes a wafer carrier 31 , a heater 32 , a motor 33 , a height control unit 34 and a temperature controller 35 . The wafer carrier 31 supports the wafer 40 and makes the wafer 40 vertically displace relative to the heater 32. The motor 33 is electrically connected to the wafer carrier 31, and the height control unit 34 is electrically connected to the motor 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com