Lead frame for leadless encapsulation, encapsulation construction and manufacture method thereof

A technology of packaging structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., and can solve problems such as area limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

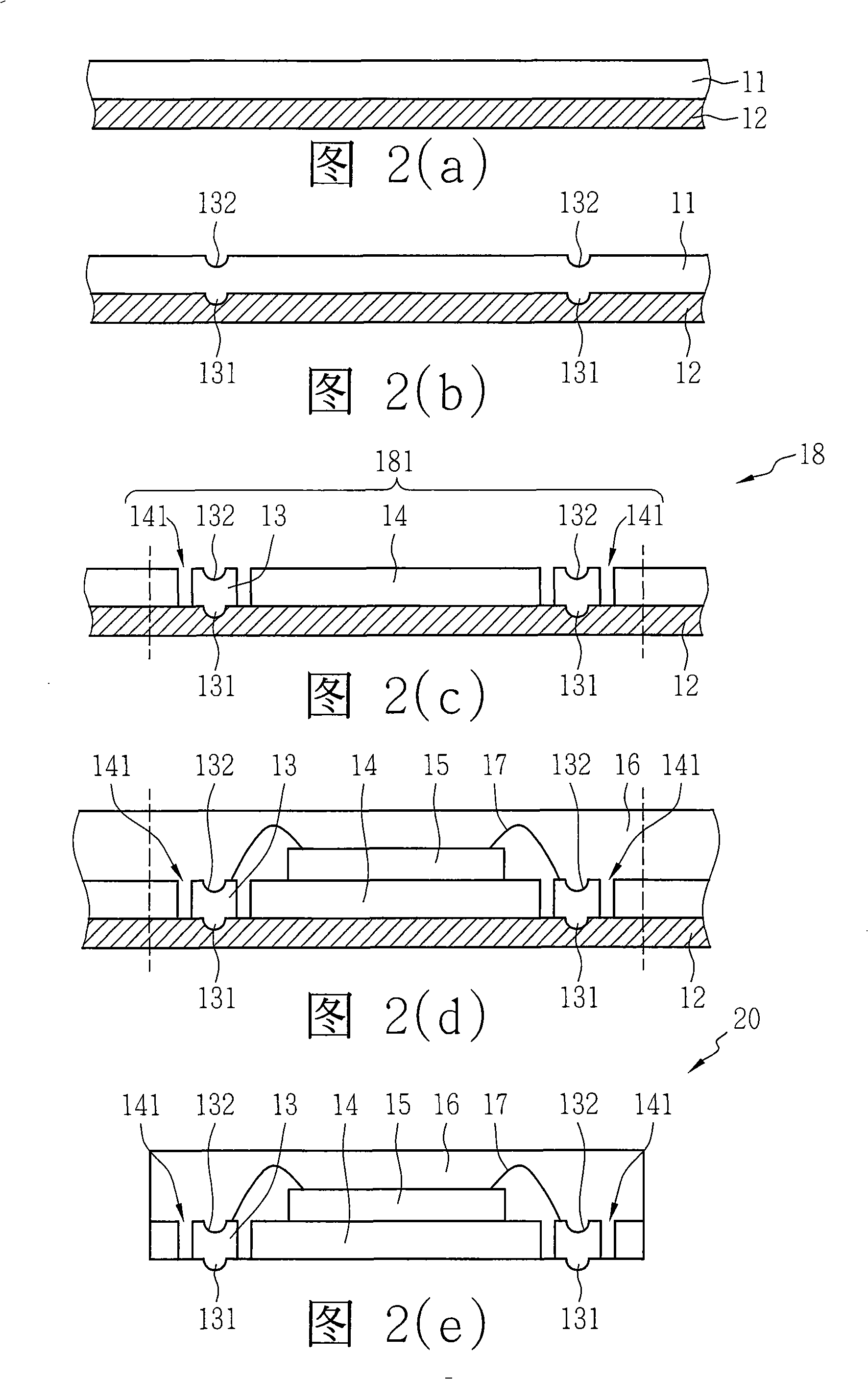

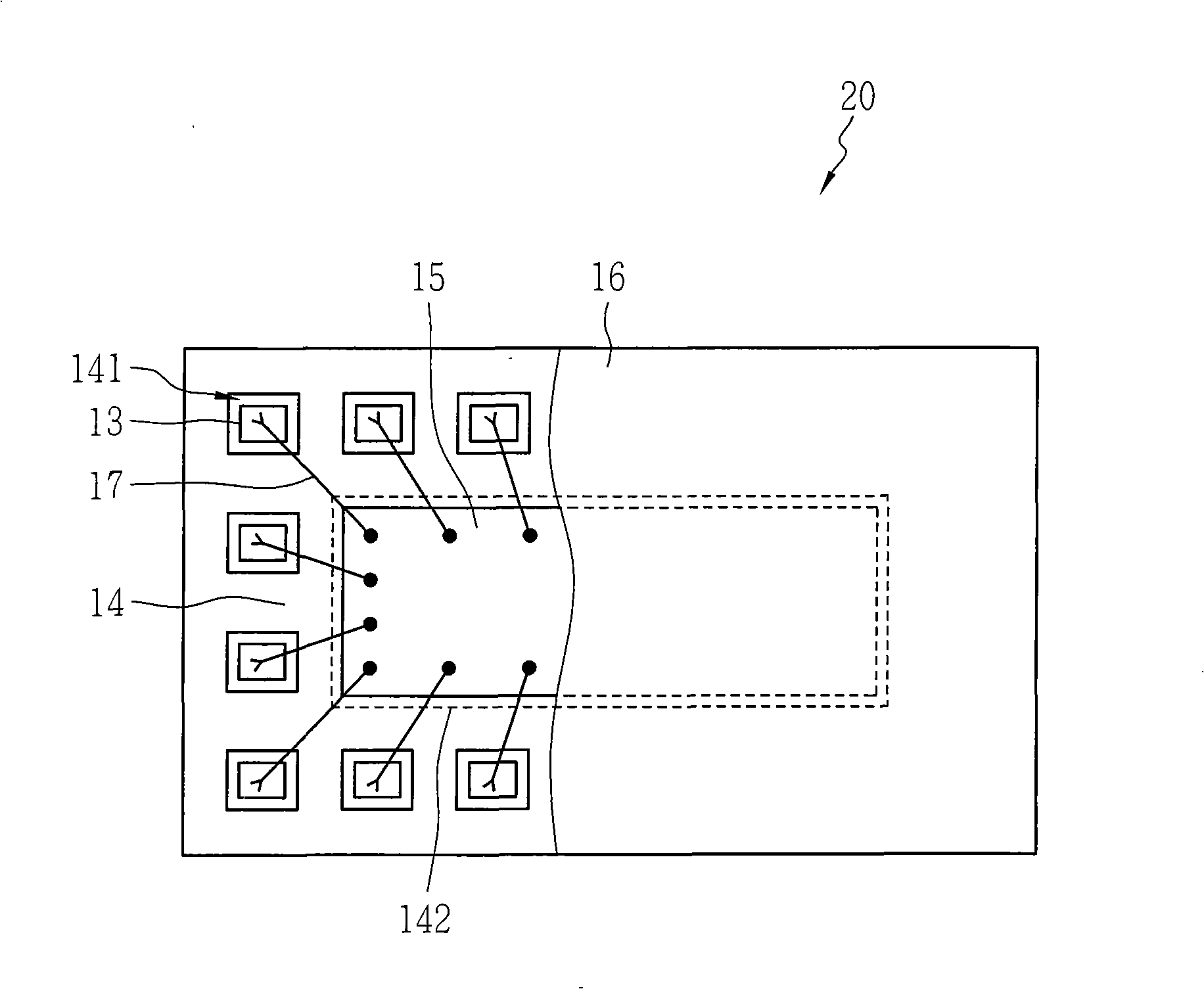

[0016] 2( a ) to 2 ( e ) are schematic diagrams of various manufacturing steps of the leadless package structure of the present invention. First, the metal plate 11 covered with the adhesive tape 12 is provided, and the metal plate 11 can be selected from the group consisting of copper, aluminum, copper-aluminum alloy, aluminum alloy and mixtures thereof. As shown in FIG. 2( b ), multiple depressions 132 are formed by stamping on the upper surface of the metal sheet 11 , and a plurality of protrusions 131 are produced on the lower surface of the metal sheet 11 bonded with the adhesive tape 12 . Then, the metal plate 11 is formed into a plurality of connected chip holders 14 and a plurality of separated pins 13 by photolithography, and the plurality of pins 13 are respectively arranged in a plurality of through holes 141 around each chip holder 14, As shown in Figure 2(c). Each die pad 14 and surrounding pins 13 are regarded as a package unit 181 on the lead frame 18 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com