Cleaning solution composition

A composition and cleaning liquid technology, applied in the direction of photosensitive material processing, etc., can solve the problems of water-insoluble residue or residue, surface pollution, affecting the development process, etc., and achieve the improvement of process qualification rate, stable surface quality, and improvement of cleaning procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039]

[0040] The following example is a test of the photoresist cleaning ability according to the cleaning solution composition shown in Table 1, wherein,

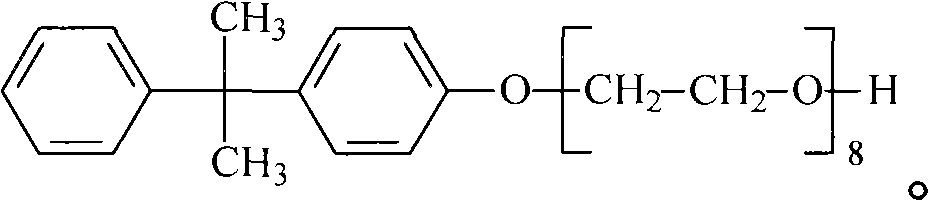

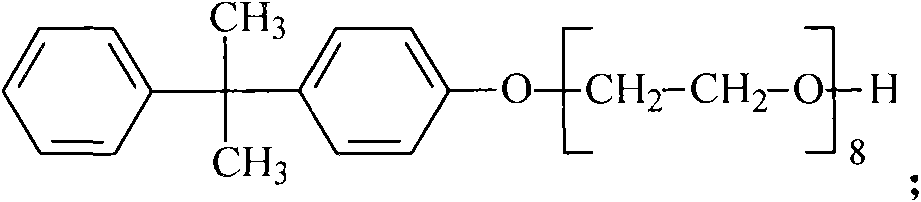

[0041] Surfactant CPE-208F has the following structure:

[0042]

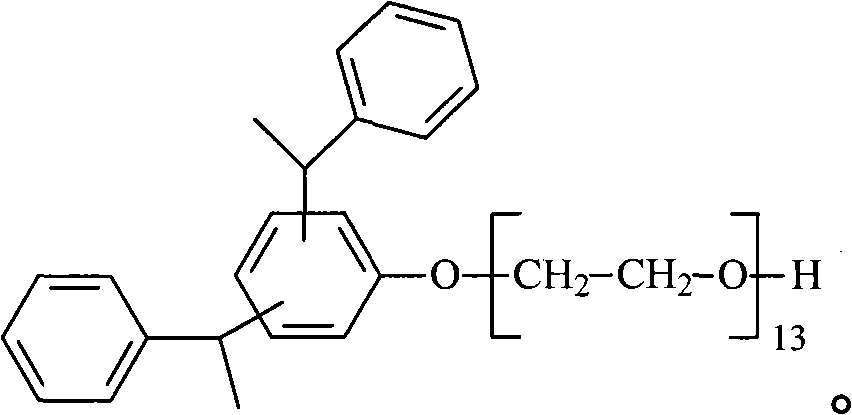

[0043] Surfactant DSP-213 has the following structure:

[0044]

[0045] Surfactant Hostapur SAS 60; C14-17 sodium alkylsulfonate (Sodium C14-17Alkylsulfonate, Clariant company) has the following formula structure:

[0046] m+n=11~14;

[0047] Surfactant Pelex SS-H (Kao company) has following formula structure:

[0048]

[0049] The chelating agent was tetrasodium ethylenediaminetetraacetic acid (EDTA4Na, Sigma Aldrich pharmaceutical grade); and,

[0050] The co-solvent was from sodium benzoate (p-TsONa, Sigma Aldrich reagent grade).

[0051] The composition of table 1 cleaning solution composition

[0052] Example 1

Example 2

Example 3

Comparative example 1

Comparative example 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com