High-precision involute spline broach and design method thereof

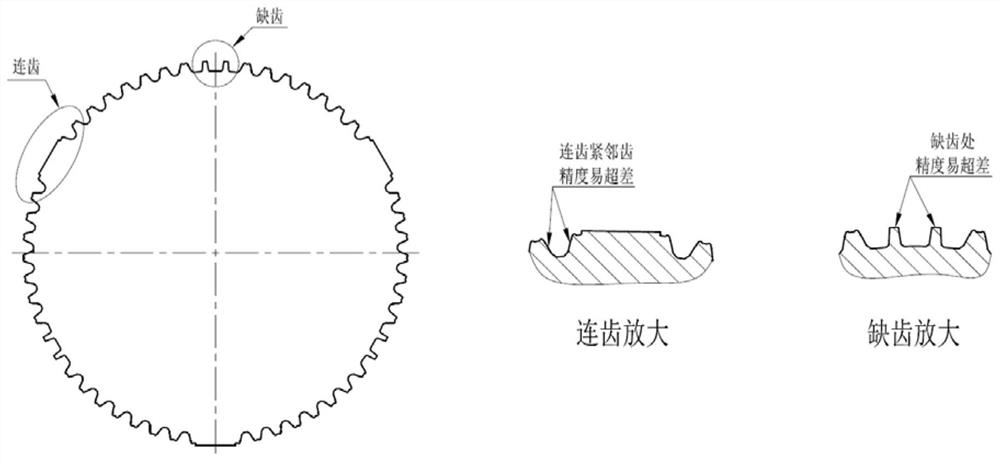

An involute spline, high-precision technology, applied in the direction of broaching tools, broaching machines, metal processing equipment, etc., can solve the problems of large accumulation of spline tooth profile, large outer diameter runout, processing quality problems, etc., to achieve lifting and pulling Cutting accuracy, broaching force reduction, and the effect of reducing workpiece deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] The involute spline broach of this embodiment and the related parameters of the spline to be processed are shown in Table 5. In combination with the exemplary content of the parameters shown in Table 1 in Tables 2 to 4, the method of the present invention is used to determine the broach Related parameters.

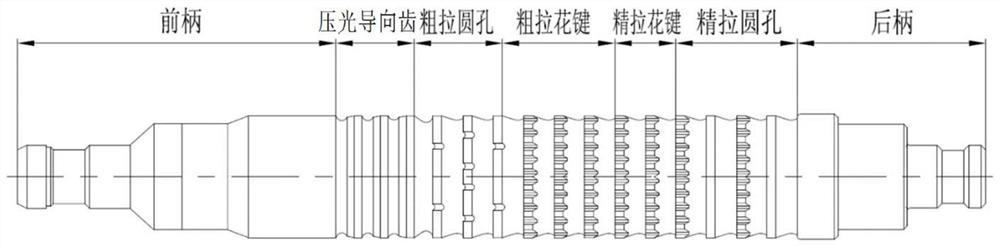

[0070] like Figure 1-2 As shown, the structure of the type 2 broach in this embodiment consists of a rear shank, a finish-drawing round hole, a finish-drawing spline, a rough-drawing spline, a rough-drawing round hole, a calendering guide tooth and a front Handle composition.

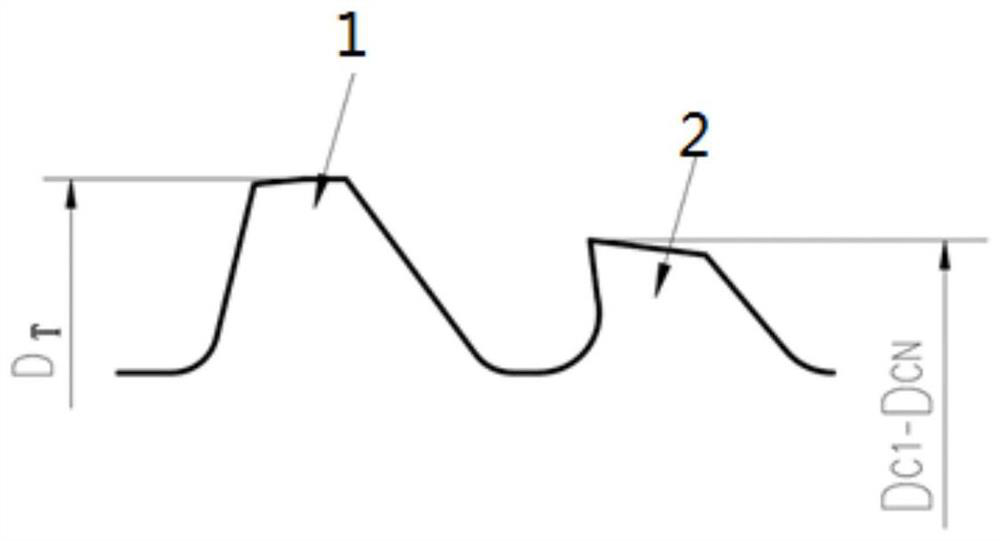

[0071] The difference between model 1 broaches and model 2 broaches is that model 1 broaches have no corresponding structure of calendered guide teeth, f R is the tooth lift of the rough-drawn circular hole tooth, and the corresponding structure of the rough-drawn circular hole tooth, f SR The tooth lift of fine-drawn spline teeth is 0.06-0.12mm, f C The tooth lift of the round hole toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com