Aluminum alloy wall for building decoration and related building decoration

An aluminum alloy and wall technology, applied in construction, building structure, covering/lining, etc., can solve the problems of complex decoration process, unfavorable overall style, high housing cost, save material and labor cost, shorten construction period, The effect of reducing construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

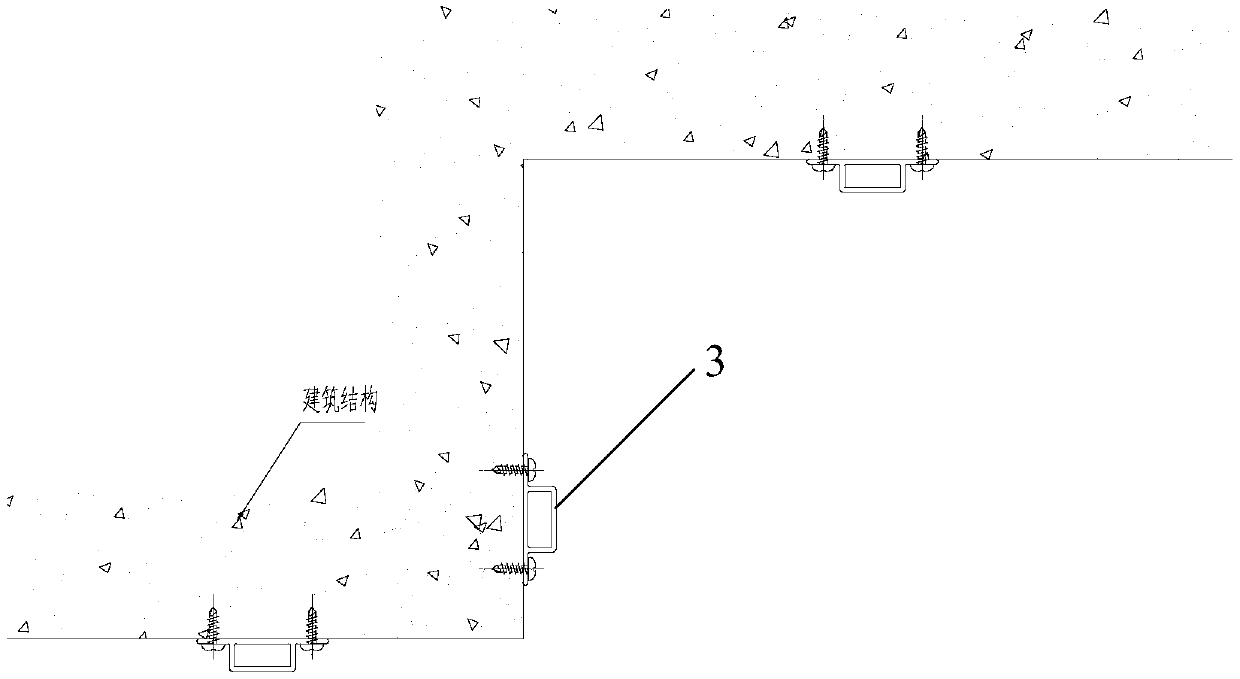

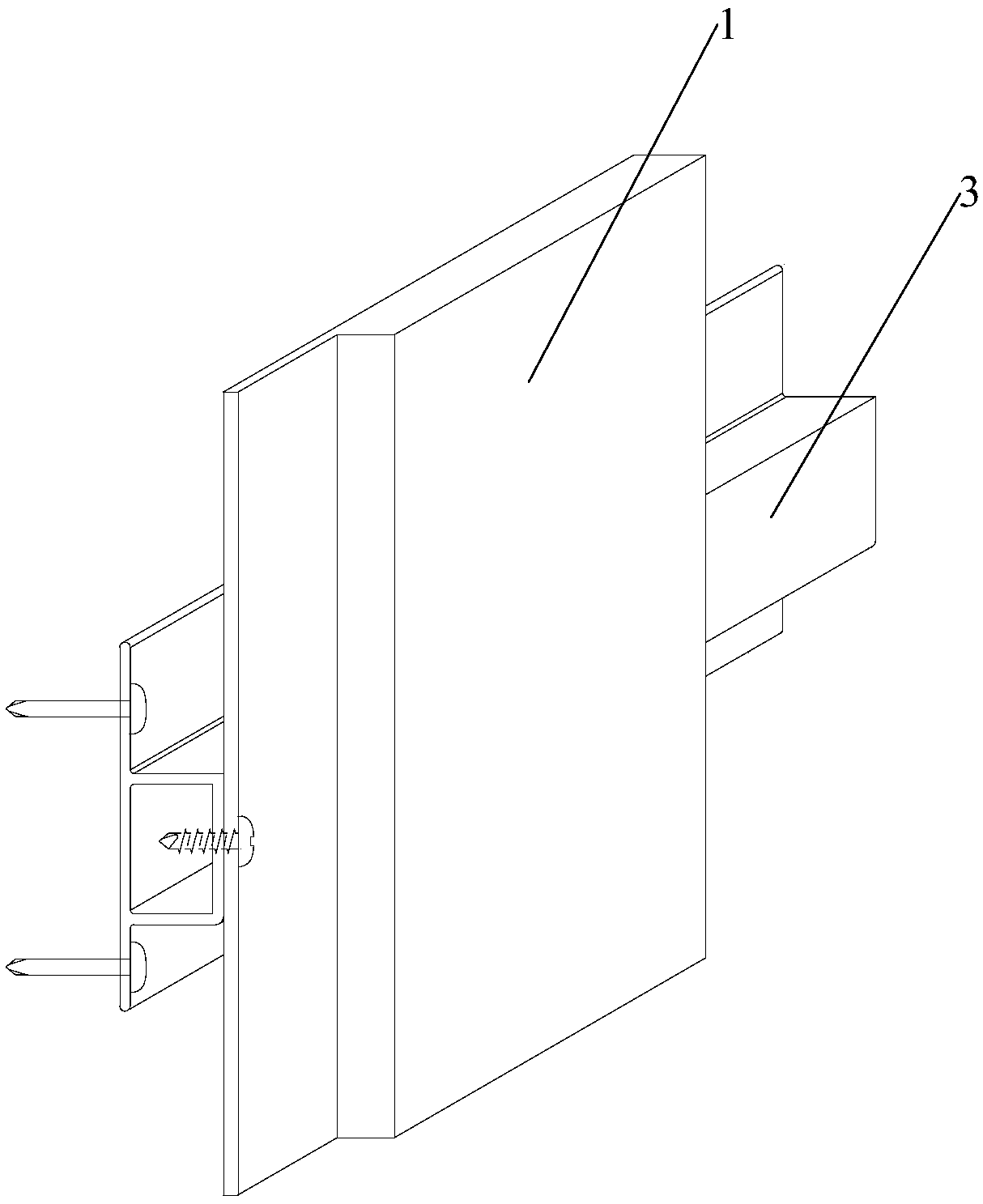

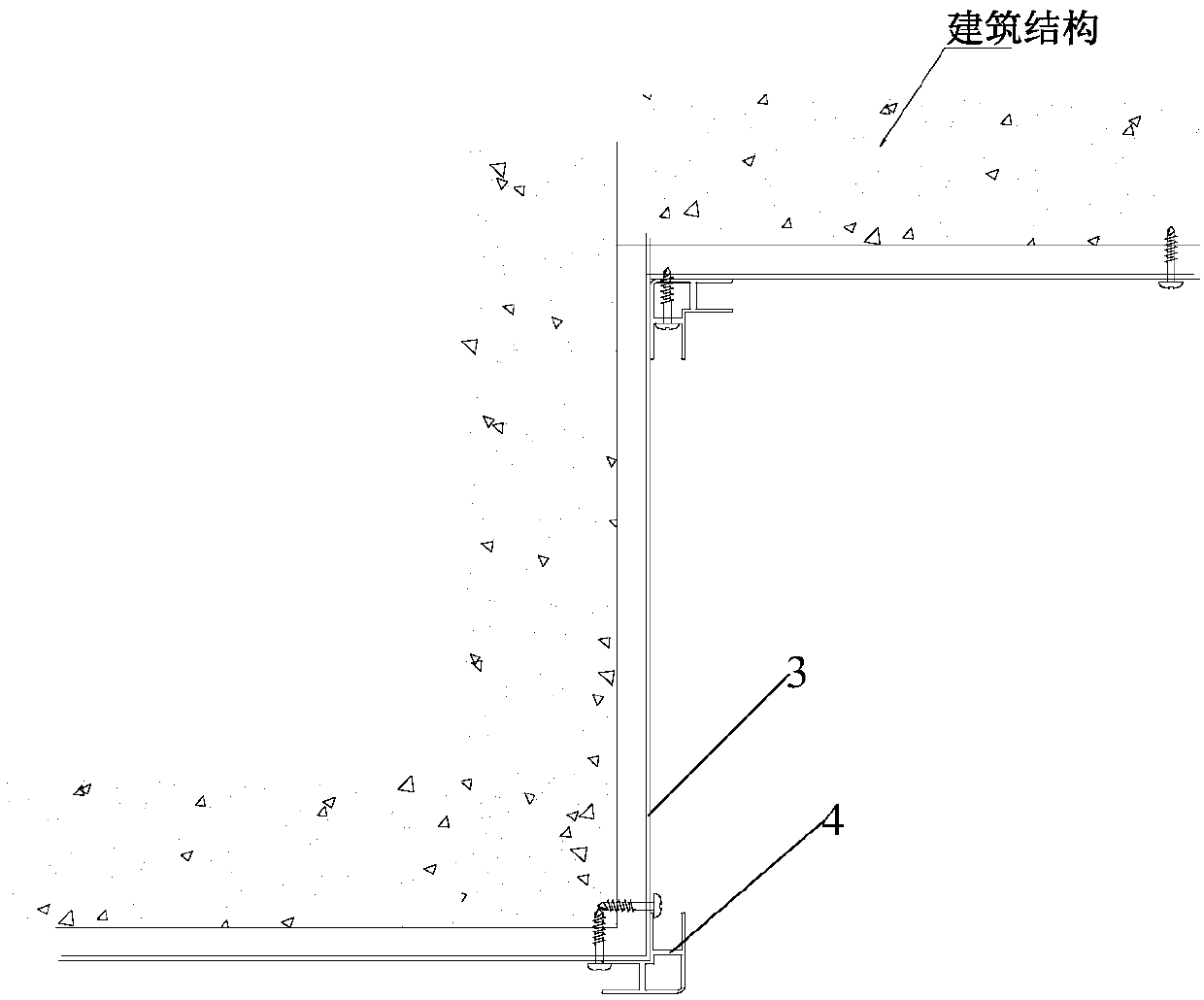

[0080] refer to Figure 1-Figure 23 , a kind of aluminum alloy wall body for architectural decoration provided by Embodiment 1 of the present invention, comprising:

[0081] The keel 3 fixed on the building structure and a plurality of spliced aluminum alloy profile plates have a corner unit 4 plugged with the aluminum alloy profile plate at the corner of the building structure;

[0082] The plurality of spliced aluminum alloy profile plates are plugged or clipped to each other;

[0083] The aluminum alloy profile plate is fixed on the keel 3 , the corner unit 4 is fixed on the building structure or the keel 3 , or the corner unit 4 is fastened to two vertical aluminum alloy profile plates.

[0084] In one embodiment, it may be that the plurality of spliced aluminum alloy profile plates are the first aluminum alloy profile plates 1 connected end to end; or,

[0085] A plurality of profile plate unit groups that are clamped end to end; each profile plate unit group incl...

Embodiment 2

[0142] Based on the same inventive concept, an embodiment of the present invention also provides an aluminum alloy wall having a structure similar to that of the aluminum alloy wall in Embodiment 1, and the same structure will not be repeated here.

[0143] refer to Figure 5C The aluminum alloy profile plate of the aluminum alloy wall provided by the second embodiment of the present invention includes: an upper plate 101 and a lower plate 102 parallel to each other, and a first side plate 103 and a second side connecting the upper plate 101 and the lower plate 102 Plate 104, a cavity is formed between the upper plate 101, the lower plate 102, the first side plate 103 and the second side plate 104;

[0144] The outer wall of the first side plate 103 has an insertion slot 105, and the insertion slot 105 includes an upper terminal plate 1051 and a lower terminal plate 1052 parallel to the upper plate 101 and the lower plate 102; the upper terminal plate 1051 extending outward a...

Embodiment 3

[0160] Based on the same inventive concept, the embodiment of the present invention also provides an aluminum alloy wall having a structure similar to that of the aluminum alloy wall in embodiment 1 or embodiment 2, and the same structure will not be repeated here.

[0161] refer to Figure 21 or Figure 22 , the aluminum alloy wall provided by the embodiment of the present invention includes a plurality of profile plate unit groups that are clamped end to end; each profile plate unit group includes: a first aluminum alloy profile plate 1 and a second aluminum alloy profile plate that are clamped at one end 2. in, Figure 21 The shown first aluminum alloy profile plate 1 and the second aluminum alloy profile plate 2 respectively correspond to Figure 5D and Figure 6A The first aluminum alloy profile plate 1 and the second aluminum alloy profile plate 2 shown; Figure 22 The shown first aluminum alloy profile plate 1 and the second aluminum alloy profile plate 2 respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com