Technology of continuous producing polyurethane sponge bra cups

A polyurethane sponge, polyurethane technology, applied in bras, clothing, applications, etc., can solve the problems of polluting the fabric layer, polluting the appearance of the mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

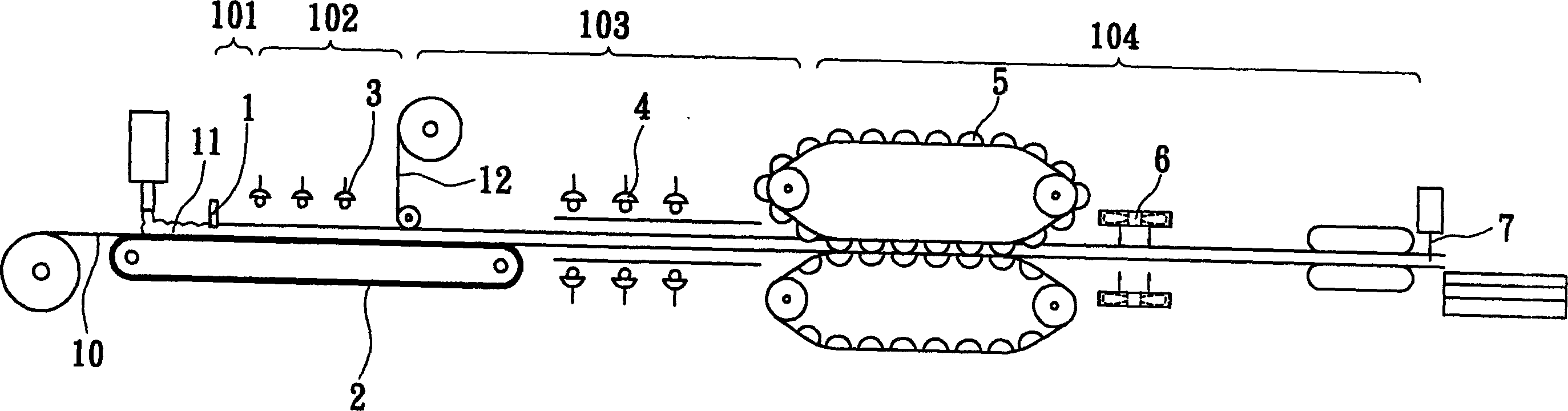

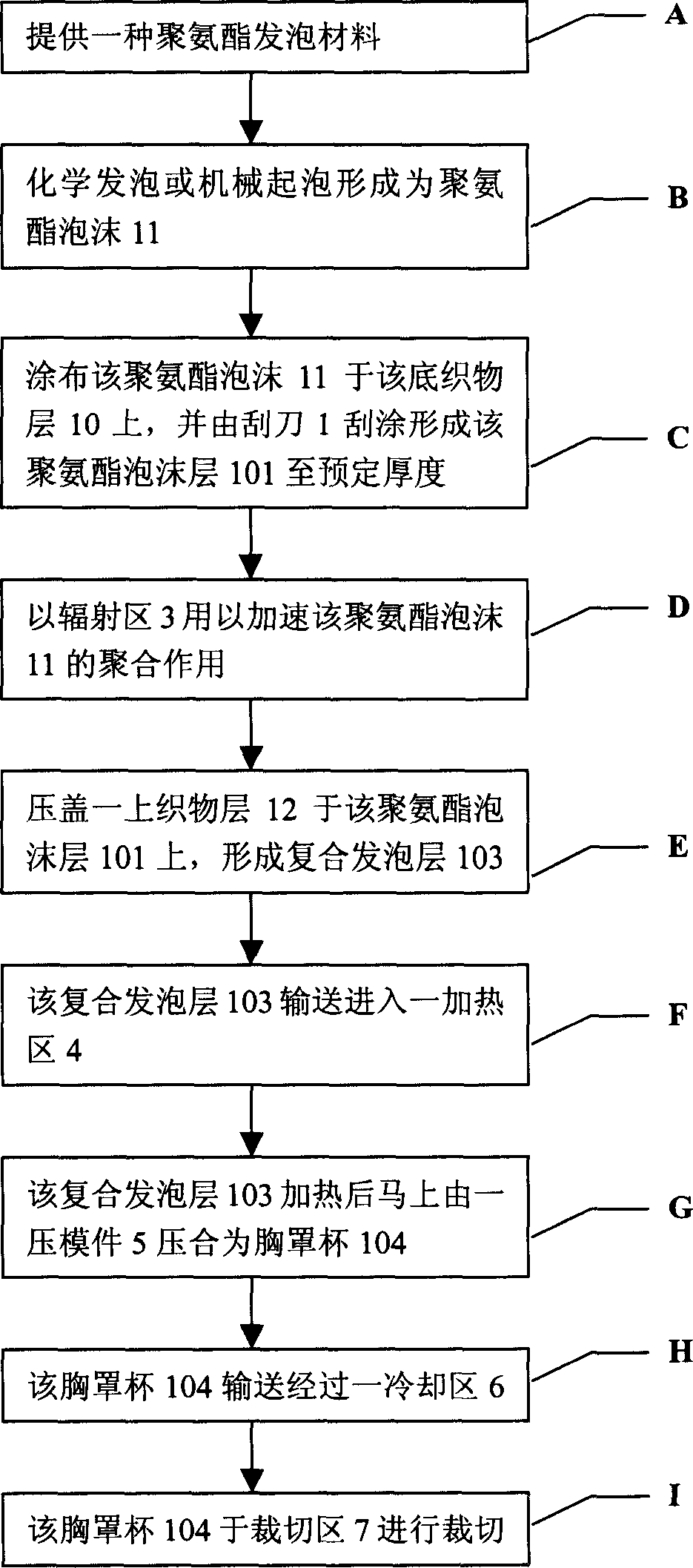

[0026] Please refer to figure 1 and figure 2 Shown, this process provides a kind of polyurethane foam material (step A), forms polyurethane foam (urethane frothmixture) 11 (step B) through chemical foaming or mechanical foaming, pours this polyurethane foam 11 to the conveyer belt of a moving state The bottom fabric layer 10 on the 2 is scraped and coated with the polyurethane foam 11 at a predetermined height with a suitable coating device 1 (such as a scraper), so that the thickness of the polyurethane foam 11 formed meets the polyurethane foam layer (urethane froth mixture) of design requirements. layer) 101 (step C); the polyurethane foam layer 101 covered on the bottom fabric layer 10 passes through the radiation zone 3, and the polyurethane foam layer 101 is heated by radiation to promote the generation of a solidified layer 102 on the surface of the polyurethane foam layer for Accelerate the polymerization of the polyurethane foam 11, and avoid surface bubbles and shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com