Pad Pattern Repair Equipment

A welding pad and equipment technology, applied in the field of welding pad pattern repair equipment, can solve problems such as reducing the process qualification rate, and achieve the effect of improving the process qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

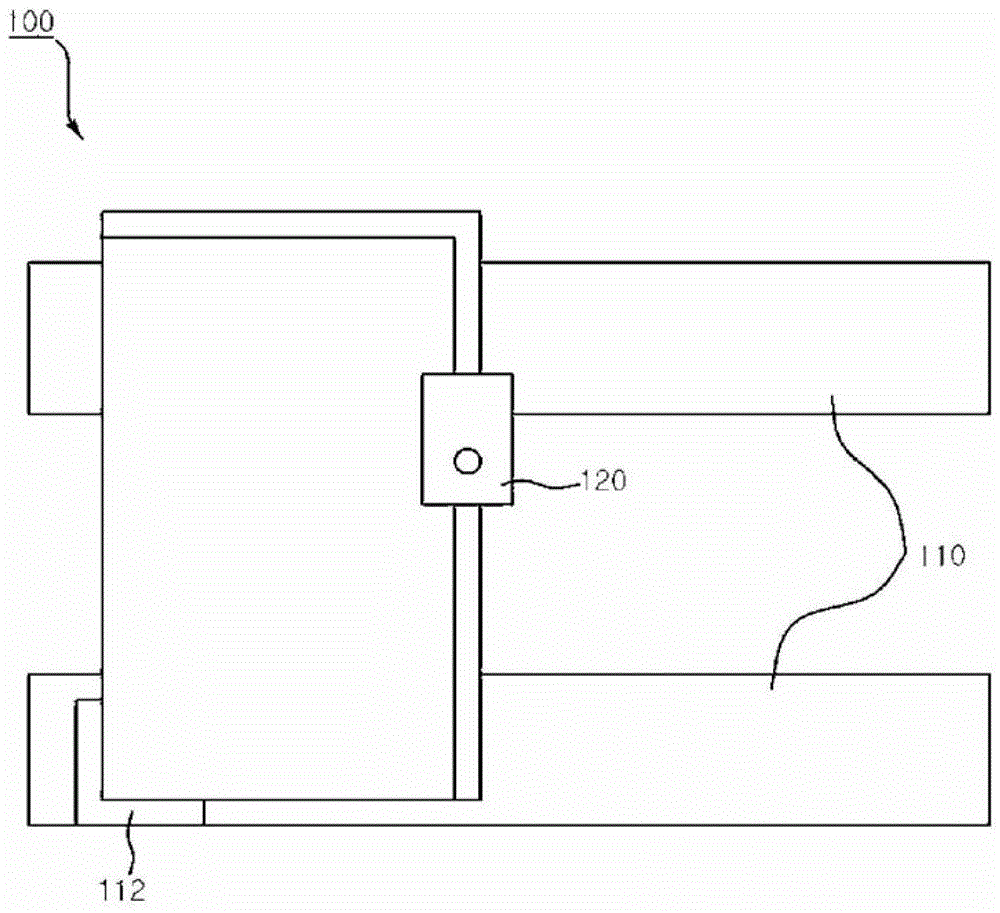

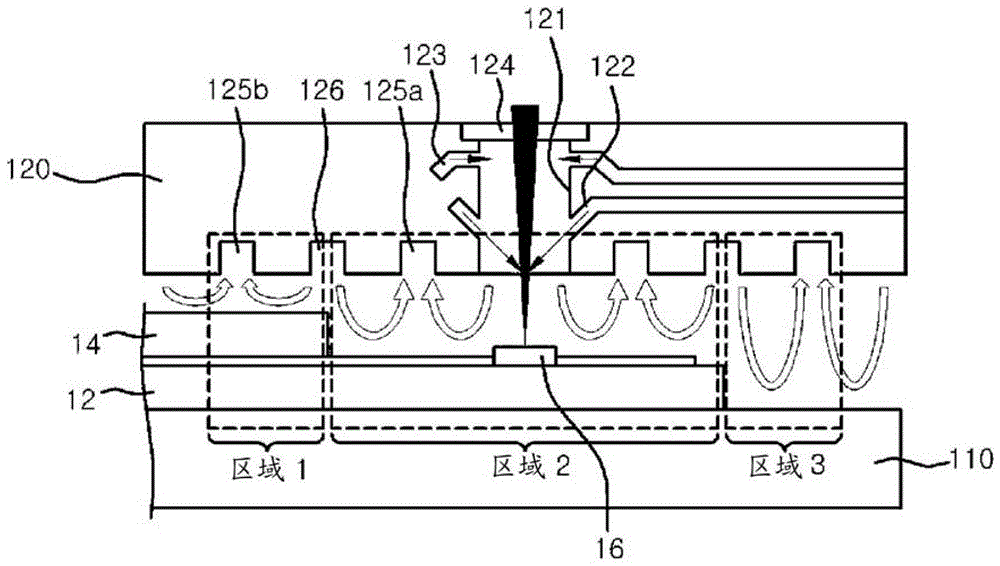

[0038] An embodiment of the pad pattern repairing device according to the present invention will be described below with reference to the accompanying drawings.

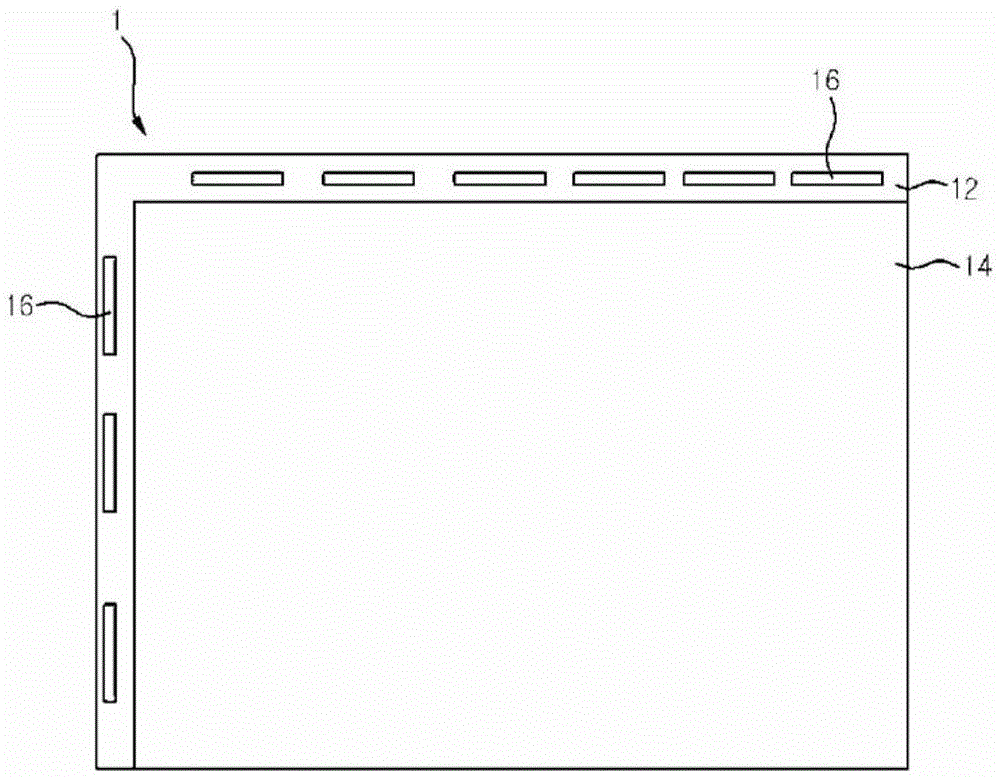

[0039] Such as figure 2 and image 3 As shown, a pad pattern repairing device 100 according to a preferred embodiment of the present invention includes a step 110, a chamber 120, and a driving part and a clamp 130, providing a signal that will be applied to a TFT substrate 12 and a color filter substrate 14 has the function of repairing defects in the electrodes of the bonding pads 16 of the non-overlapping TFT substrate 12 .

[0040] In particular, the pad pattern repairing apparatus 100 relates to a pad 16 that connects an LCD or OLED substrate (hereinafter referred to as "substrate") with a driving printed circuit board (PCB) and relates to an application for repairing a metal electrode that occurs in the pad 16. Open or short defect laser chemical vapor deposition (CVD) repair equipment.

[0041] The substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com