Coolant injection process and suitable clamping fixture for same

A cooling liquid and process technology, which is applied in the field of cooling liquid injection process and fixtures suitable for this cooling liquid injection process, can solve the problem of labor time and labor cost consumption, reduced reliability of projection tubes, and affecting the cooling effect of cooling liquid on the optical properties of projection tubes and other issues to achieve the effect of improving the process qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

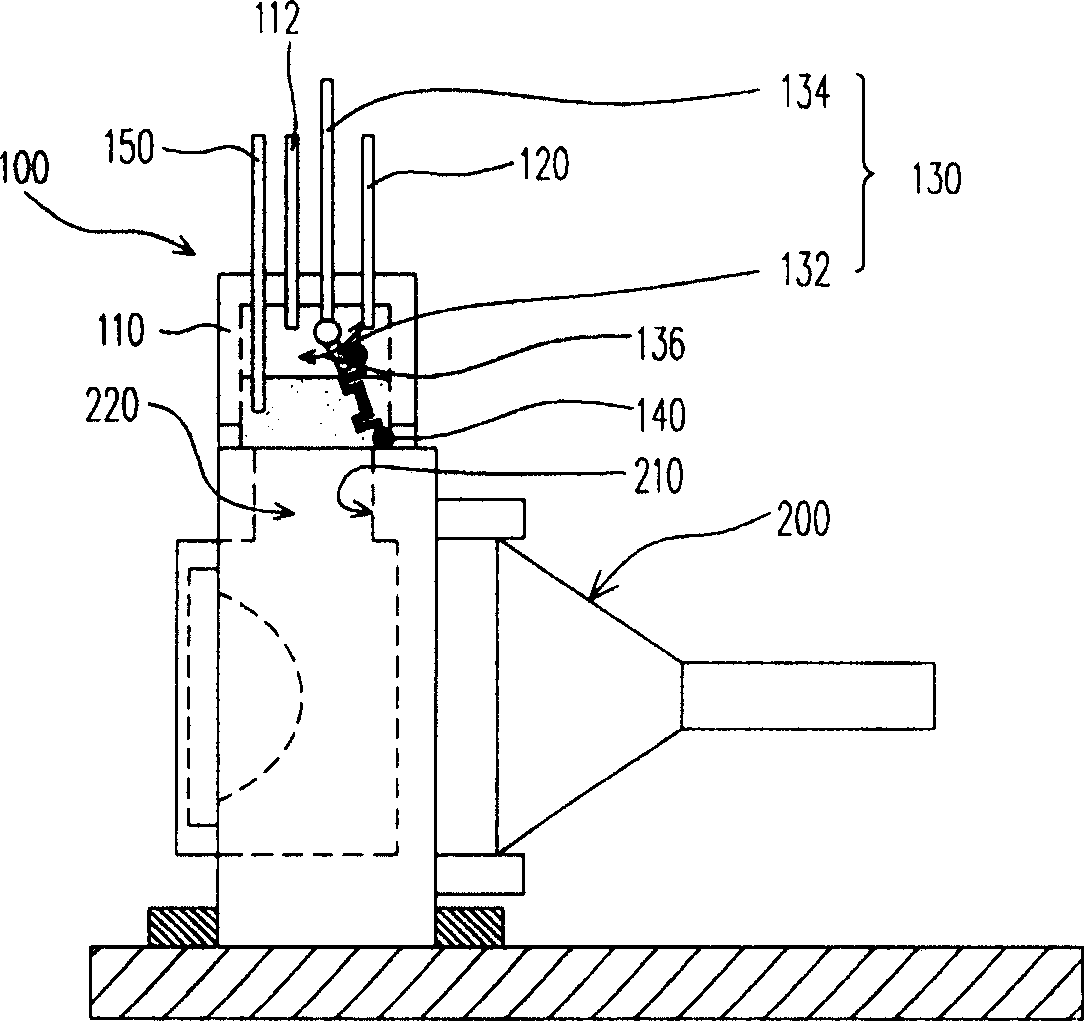

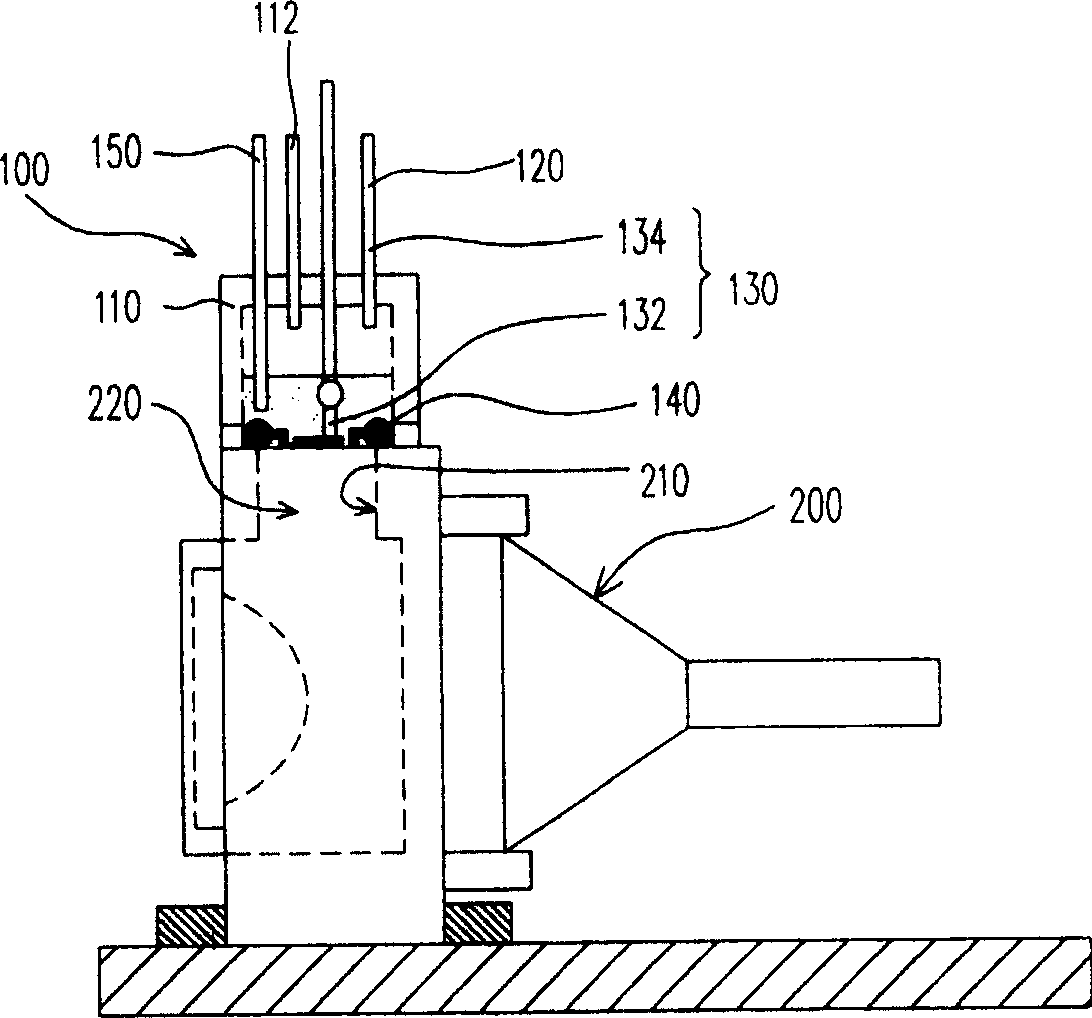

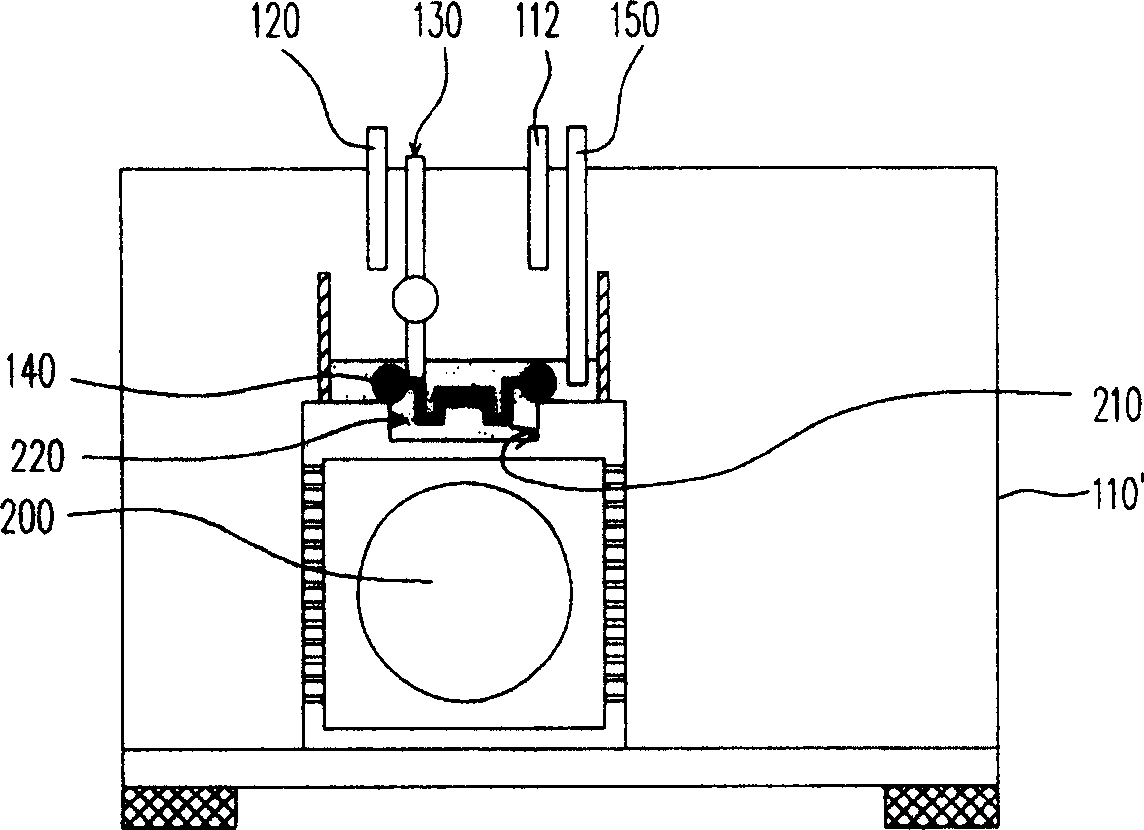

[0042] Figure 1A-1B It is a schematic diagram of a coolant injection process according to an embodiment of the present invention. Please refer to Figure 1A , the projection tube 200 has a cooling liquid injection port 210 and a chamber body 220 , and the cooling liquid injection port 210 and the chamber body 220 communicate with each other. In addition, the coolant injection fixture 100 includes a cover 110 , a liquid injection pipe 120 and a positioning device 130 . The cover 110 covers the coolant inlet 210 and is connected to a vacuum pump through a pipe 112 . In this way, a vacuum chamber can be formed in the cover body 110 through the suction of the vacuum pump, so that the chamber body 220 is in a negative pressure environment. In addition, the liquid injection pipe 120 is disposed in the cover body 110 for injecting cooling liquid into the chamber body 220 under a negative pressure environment.

[0043] Based on the above, the positioning device 130 is fixed inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com