Solar panel high-temperature-resistant anti-ultraviolet self-adhesive film

A solar panel and anti-ultraviolet technology, applied in the field of solar energy, can solve problems such as poor adhesion of self-adhesive film, poor high temperature resistance, accelerated aging, etc., achieve high temperature resistance and stretchability, and do not produce secondary pollution. Good effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

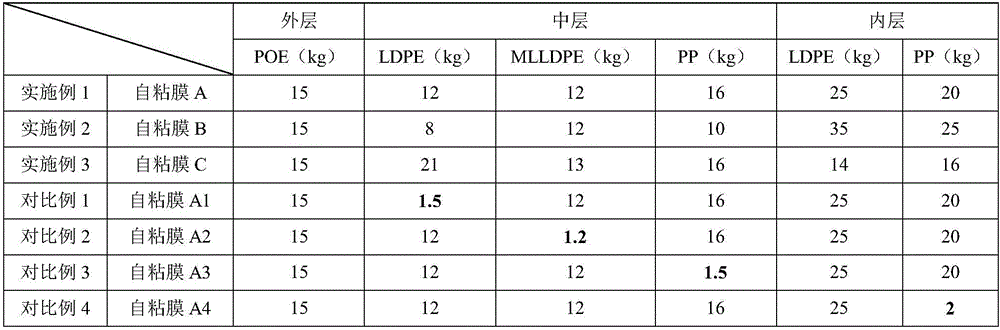

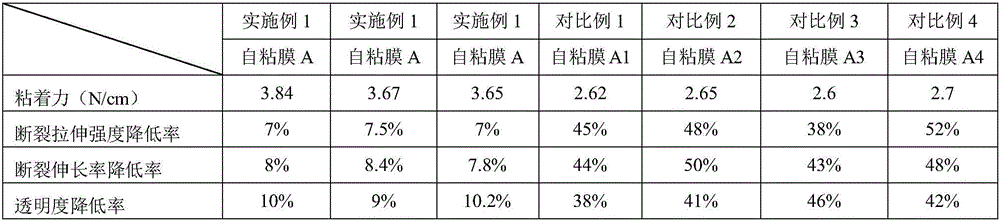

[0027] Example 1 Preparation of self-adhesive film

[0028] It is processed by a three-layer co-extrusion blown film machine. 15kgPOE is added to the outer hopper, 12kgLDPE, 12kg MLLDPE and 16kg PP are added to the middle hopper, and 25kgLDPE and 20kgPP are added to the inner hopper. The temperature of the layer screw is 180-190°C, the temperature of the middle layer screw is 175-185°C, the temperature of the inner layer screw is 165-175°C, the temperature of the die head is 190-200°C, the speed of the outer layer screw is 250rpm, and the temperature of the middle layer screw The rotating speed is 345rpm, and the rotating speed of the inner layer screw is 360rpm, extruded by a three-layer co-extrusion blown film machine, and blown into a tube film with a thickness of 130um by the outer, middle and inner three-layer co-extrusion through the die head; The self-adhesive film A with a thickness of 100 μm was obtained after cutting and winding separately.

Embodiment 2

[0030] It is processed by a three-layer co-extrusion blown film machine. Add 15kgPOE to the outer hopper, add 8kgLDPE, 12kg MLLDPE and 10kg PP to the middle hopper, add 35kgLDPE and 25kgPP to the inner hopper; The temperature of the layer screw is 180-190°C, the temperature of the middle layer screw is 175-185°C, the temperature of the inner layer screw is 165-175°C, the temperature of the die head is 190-200°C, the speed of the outer layer screw is 250rpm, and the temperature of the middle layer screw The rotating speed is 345rpm, and the rotating speed of the inner layer screw is 360rpm, extruded by a three-layer co-extrusion blown film machine, and blown into a tube film with a thickness of 132um by the outer, middle and inner three-layer co-extrusion through the die head; The self-adhesive film B with a thickness of 100 μm was obtained after cutting and winding separately.

Embodiment 3

[0032] It is processed by a three-layer co-extrusion blown film machine. Add 15kgPOE to the outer hopper, add 21kgLDPE, 13kg MLLDPE and 16kg PP to the middle hopper, add 14kgLDPE and 16kgPP to the inner hopper; The temperature of the layer screw is 180-190°C, the temperature of the middle layer screw is 175-185°C, the temperature of the inner layer screw is 165-175°C, the temperature of the die head is 190-200°C, the speed of the outer layer screw is 250rpm, and the temperature of the middle layer screw The rotating speed is 345rpm, and the rotating speed of the inner layer screw is 360rpm, extruded by a three-layer co-extrusion blown film machine, and blown into a tube film with a thickness of 128um by the outer, middle and inner three-layer co-extrusion through the die head; The self-adhesive film C with a thickness of 100 μm was obtained after cutting and winding separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com