Method for testing ink-jet printing equipment

A test method and inkjet printing technology, applied in printing and other directions, can solve the problems of not reflecting the actual effect of inkjet printing, single test pattern, etc., and achieve the effect of improving the qualification rate of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0018] As mentioned above, many panel manufacturers are gradually using the new inkjet printing color filter technology to manufacture color filters for glass substrates, which not only simplifies the production process, but also shortens the production time. More importantly, the traditional color filter technology has to go through complicated exposure process and development process, which will generate a lot of waste. In contrast, inkjet printing color filter technology uses a relatively simple printing process and avoids the generation of various wastes.

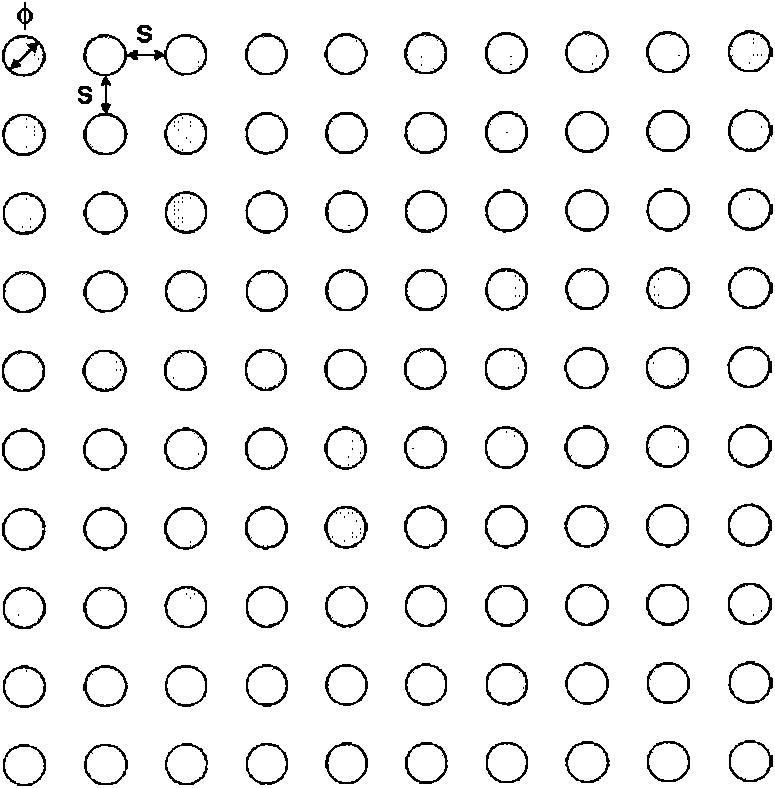

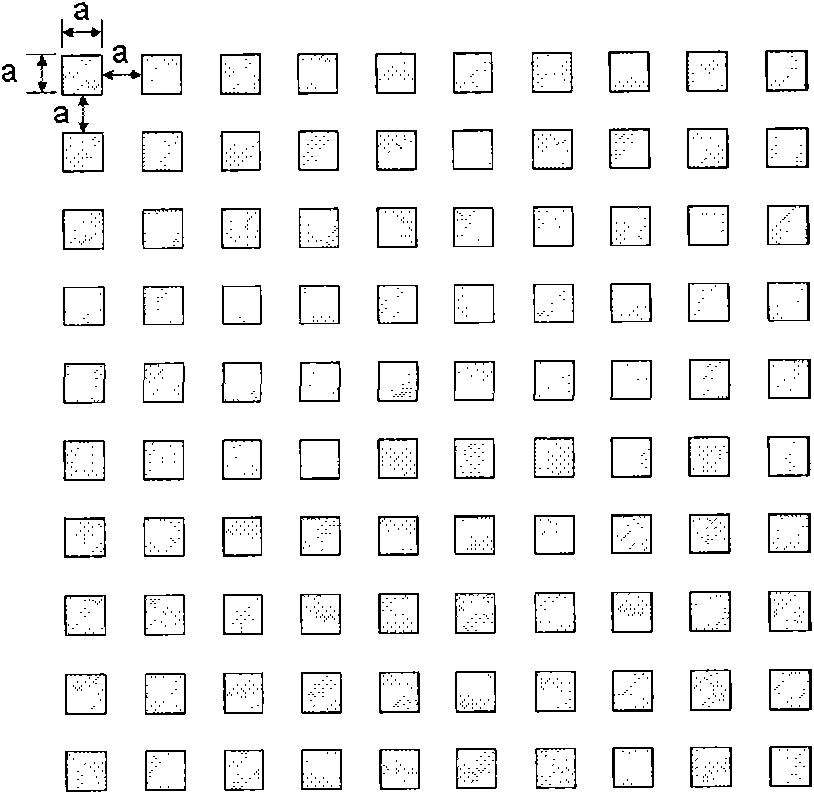

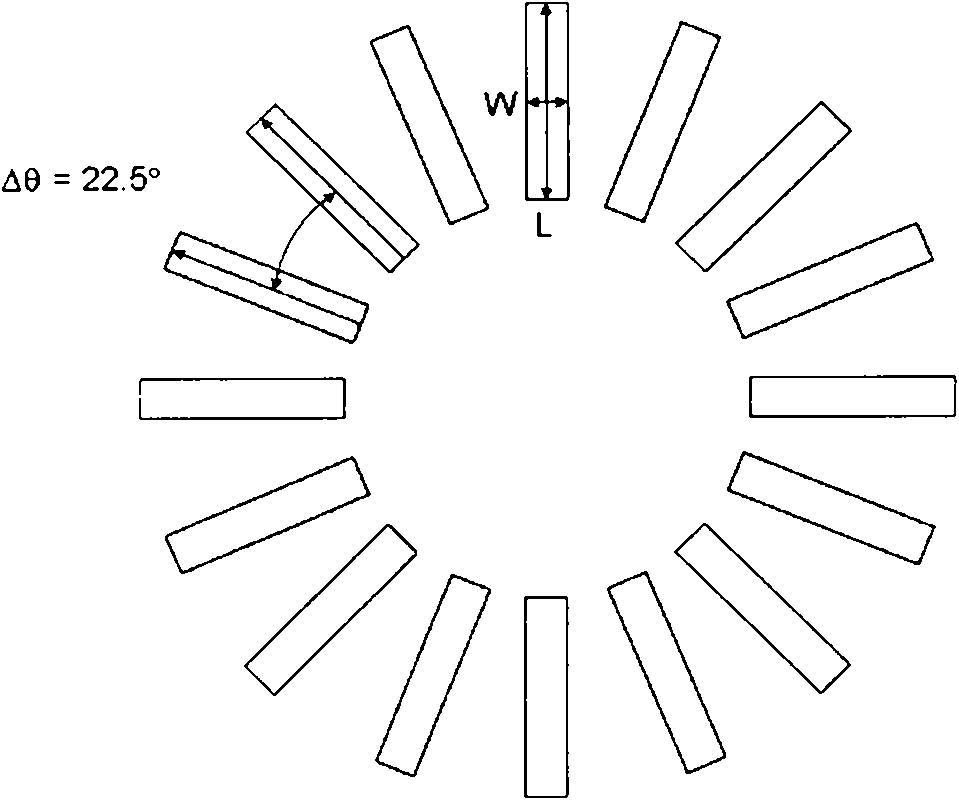

[0019] As far as the test method of the present invention is concerned, the inkjet printing equipment at least includes a machine platform and an inkjet head. During the test, a test pattern is first provided, and then the provided test pattern is used to evaluate and monitor the drawing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com