Method and apparatus for manufacturing glass structure

A manufacturing method and technology for manufacturing equipment, applied in the direction of coating, etc., can solve the problems of increasing the cost of touch screens, increasing the difficulty of the process, and poor process qualification rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

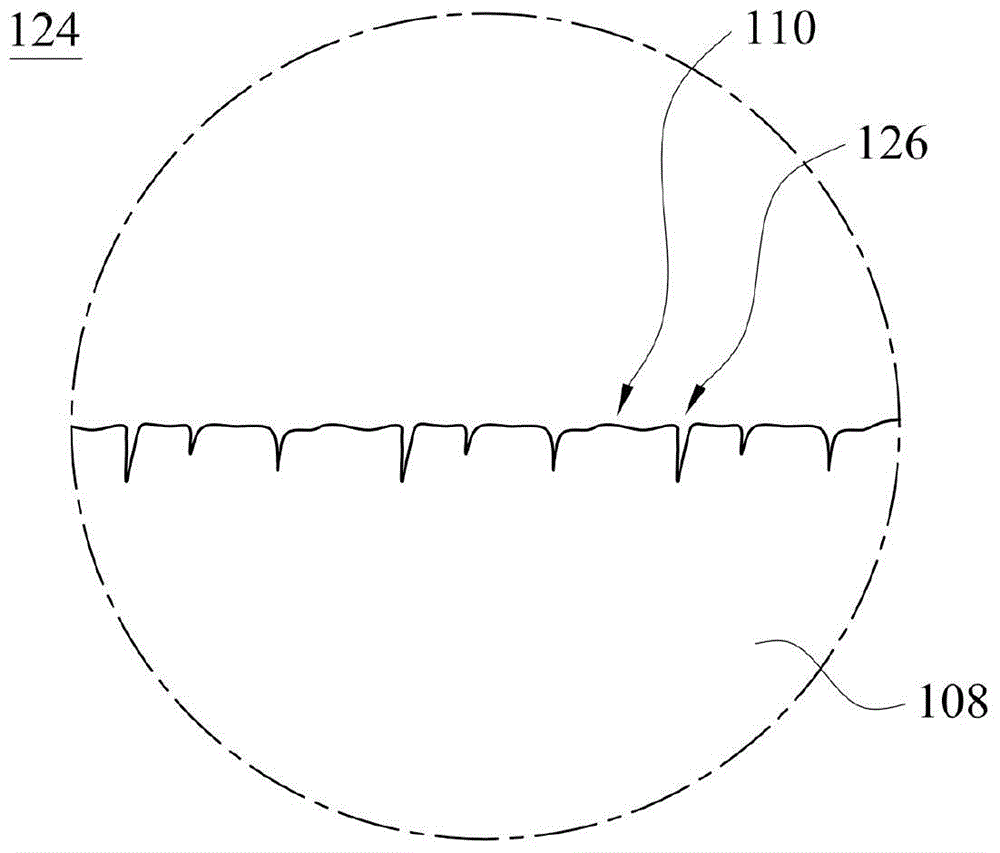

[0021] In view of the fact that the hardness and wear resistance of the surface of ordinary glass can no longer meet the requirements of today's touch screen, and the use of sapphire substrate will increase the difficulty and cost of manufacturing the touch screen. Therefore, the embodiment of the present case proposes a manufacturing method and method of the glass structure, which can produce a glass structure that meets the requirements of the touch screen in terms of hardness and wear resistance while taking into account the implementation of the manufacturing process and the cost.

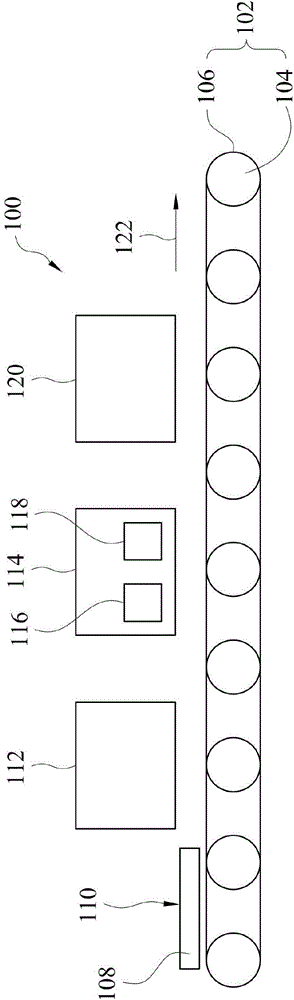

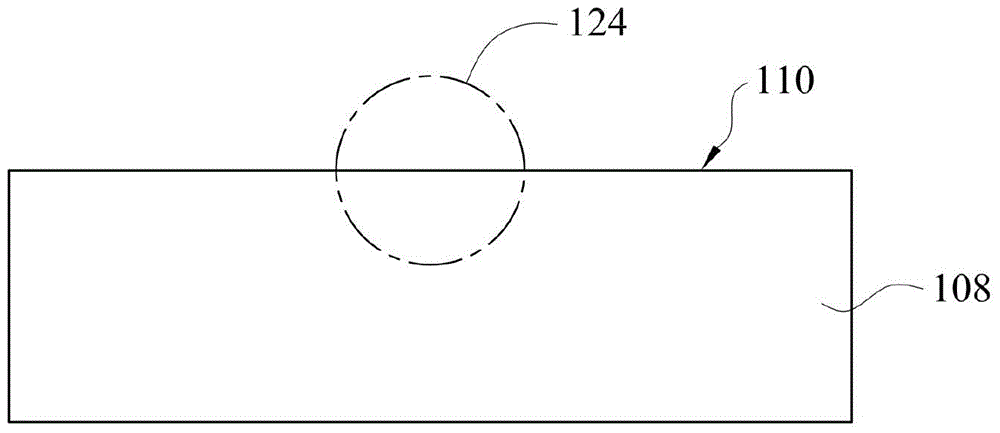

[0022] Please refer to figure 1 , which is a device diagram illustrating a glass structure manufacturing equipment according to an embodiment of the present invention. In this embodiment, the glass structure manufacturing equipment 100 mainly includes a conveying mechanism 102 , a coating device 114 and a laser tempering device 120 . The transfer mechanism 102 is adapted to transfer one or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com