Stator structure of molding electrical machine for washing machine

A stator structure, washing machine technology, applied in electromechanical devices, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc., can solve the problems of lower production efficiency, high cost, increased cost and process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

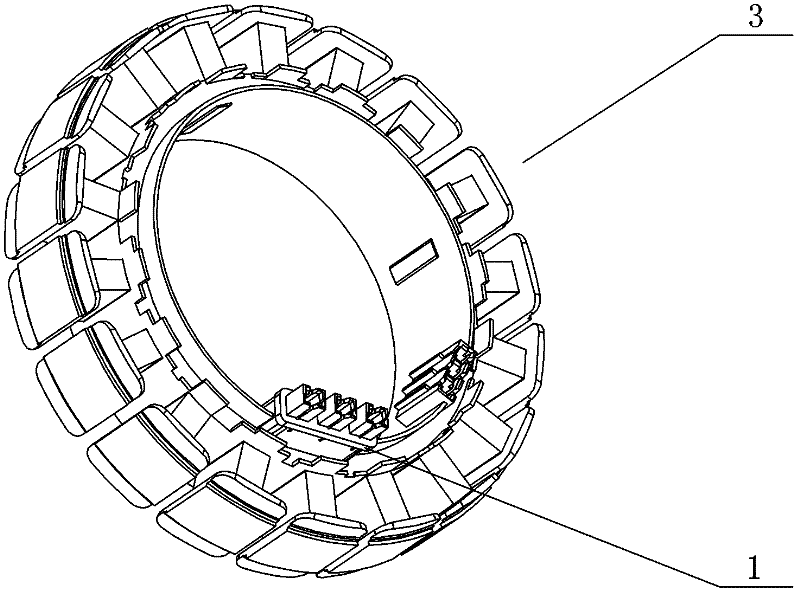

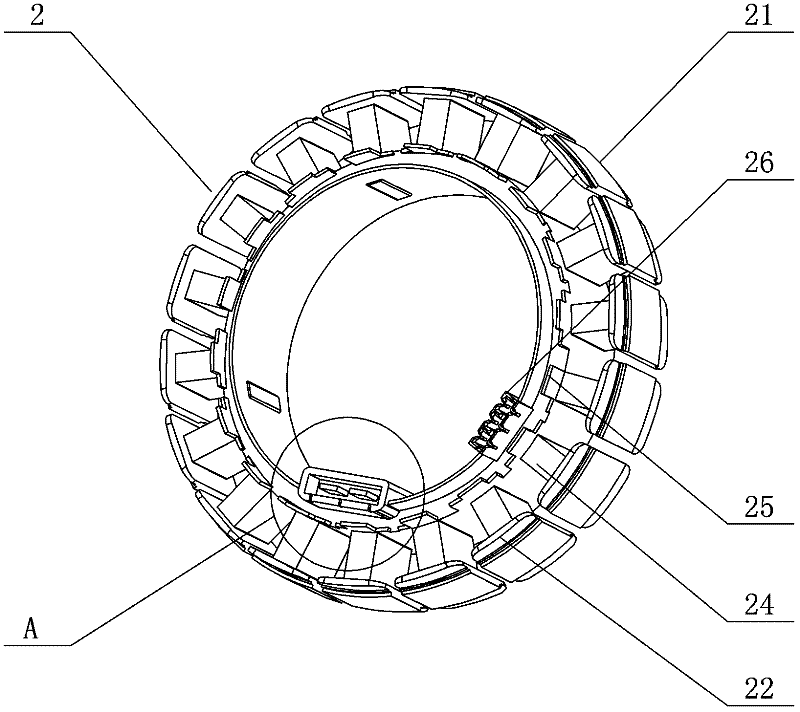

[0027] see Figure 1-Figure 6 , a stator structure of a molded motor for a washing machine, comprising a terminal part 1 and a stator core insulator 2 that are molded using the same material with different flame retardant grades or different materials. The terminal part 1 and the stator core insulator 2 are provided separately, and are connected and fixed together by plugging. The stator core insulator 2 is formed by molding the stator core 21 with an insulating material. The stator core insulator 2 with windings is formed by winding a coil on the insulating resin of the tooth portion of the stator core insulator 2 .

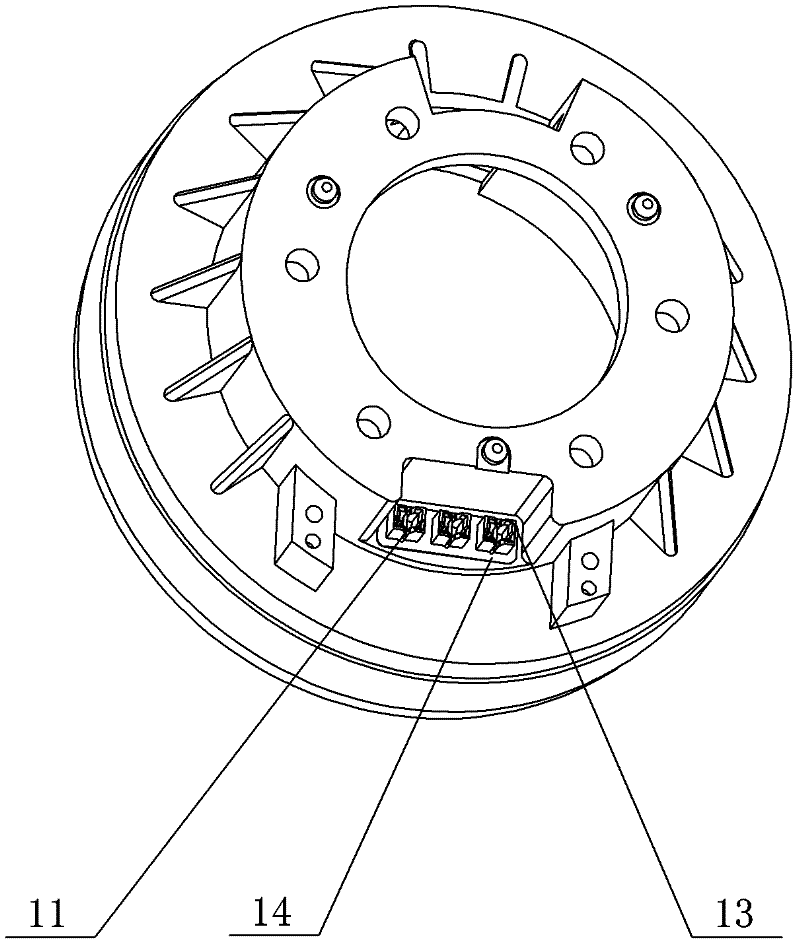

[0028] The end 13 of the electrical connection coil on the terminal part 1 is provided with a groove 11 for receiving the enameled wire, and there is a certain height difference between the groove and the middle plane 14 of the terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com