Growth method of germanium substrate and germanium substrate

A growth method and technology of germanium substrate, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of poor crystal quality and inability to obtain Ge single crystal layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

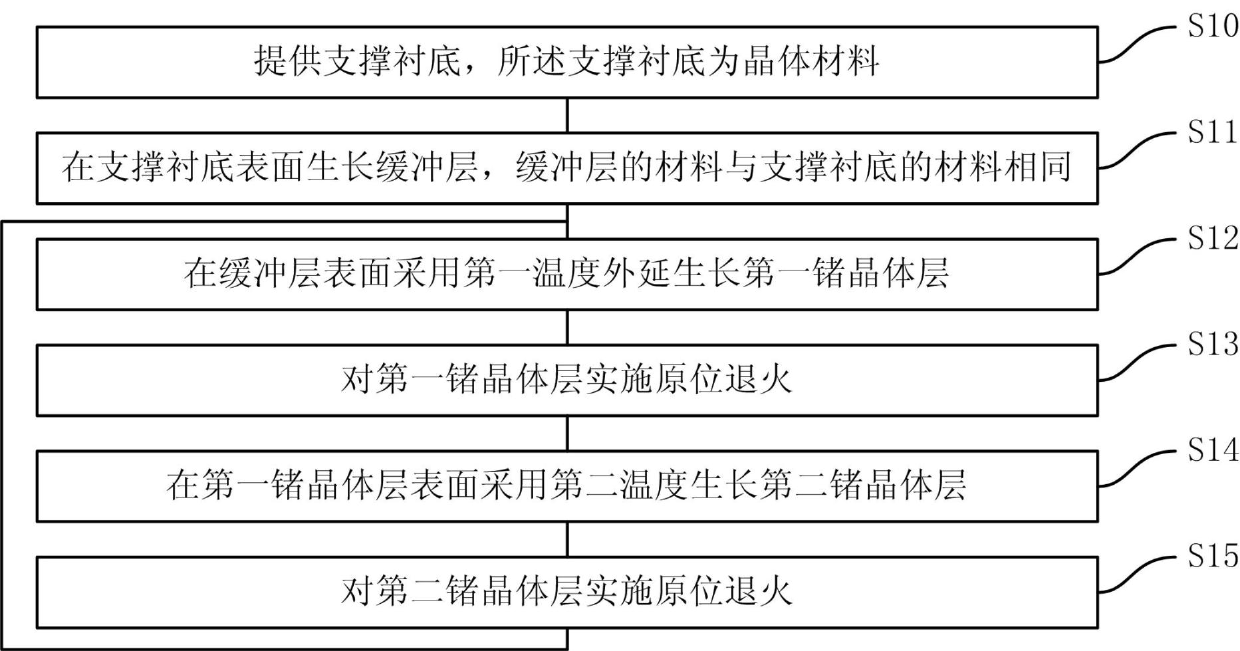

[0021] attached figure 1 Shown is a schematic diagram of the implementation steps of the first embodiment of the present invention, including: step S10, providing a support substrate, the support substrate is a crystal material; step S11, growing a buffer layer on the surface of the support substrate, the material of the buffer layer The same material as the supporting substrate; step S12, epitaxially growing the first germanium crystal layer on the surface of the buffer layer at the first temperature; step S13, implementing in-situ annealing on the first germanium crystal layer; step S14, growing the first germanium crystal layer on the first germanium crystal layer A second germanium crystal layer is grown on the surface at a second temperature, and the first temperature is lower than the second temperature; step S15 , performing in-situ annealing on the second germanium crystal layer.

[0022] attached Figure 2A to attach Figure 2D Shown is the process schematic diagram...

no. 2 Embodiment approach

[0032] attached image 3 Shown is a schematic diagram of the implementation steps of the second embodiment of the present invention, including: step S30, providing a support substrate, the support substrate is a crystal material; step S31, growing a buffer layer on the surface of the support substrate, the material of the buffer layer The same material as the supporting substrate; step S32, epitaxially growing the first germanium crystal layer on the surface of the buffer layer at the first temperature; step S33, implementing in-situ annealing on the first germanium crystal layer; step S34, growing the first germanium crystal layer on the first germanium crystal layer A second germanium crystal layer is grown on the surface at a second temperature, and the first temperature is lower than the second temperature; step S35, performing in-situ annealing on the second germanium crystal layer; step S36, using the second germanium crystal layer on the surface of the second germanium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com