Automatic equal diameter controlling method for germanium single crystal straight-pull growth method

A control method and germanium single crystal technology, applied in the field of diameter control, can solve the problems of uneven shape of germanium crystals, the inability of equal diameters to meet the requirements for use, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

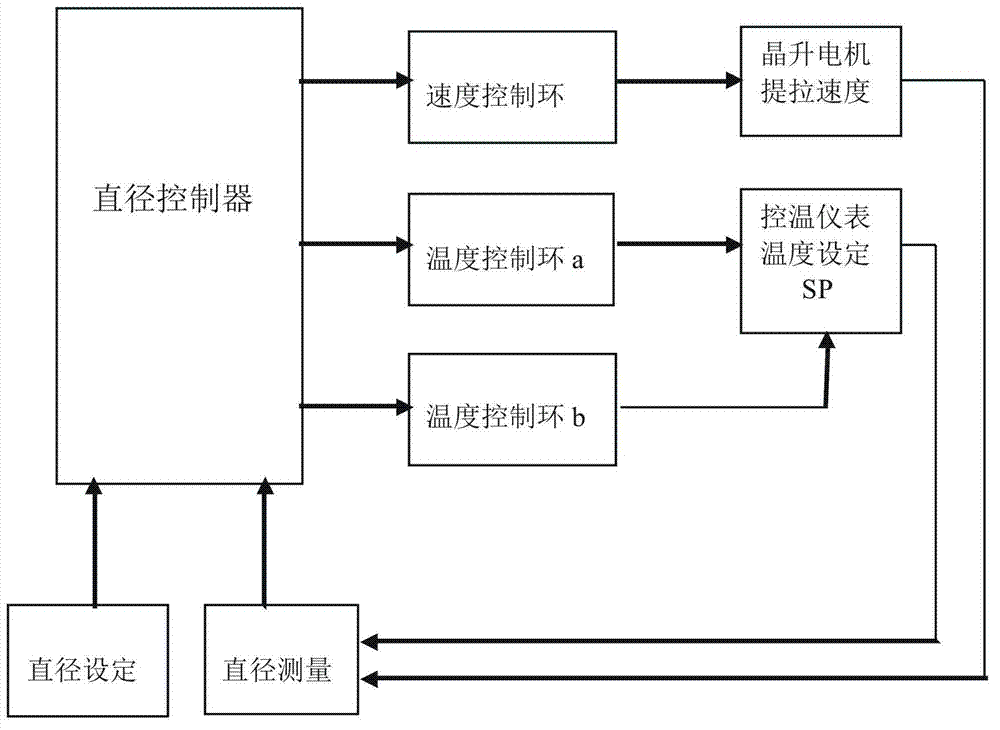

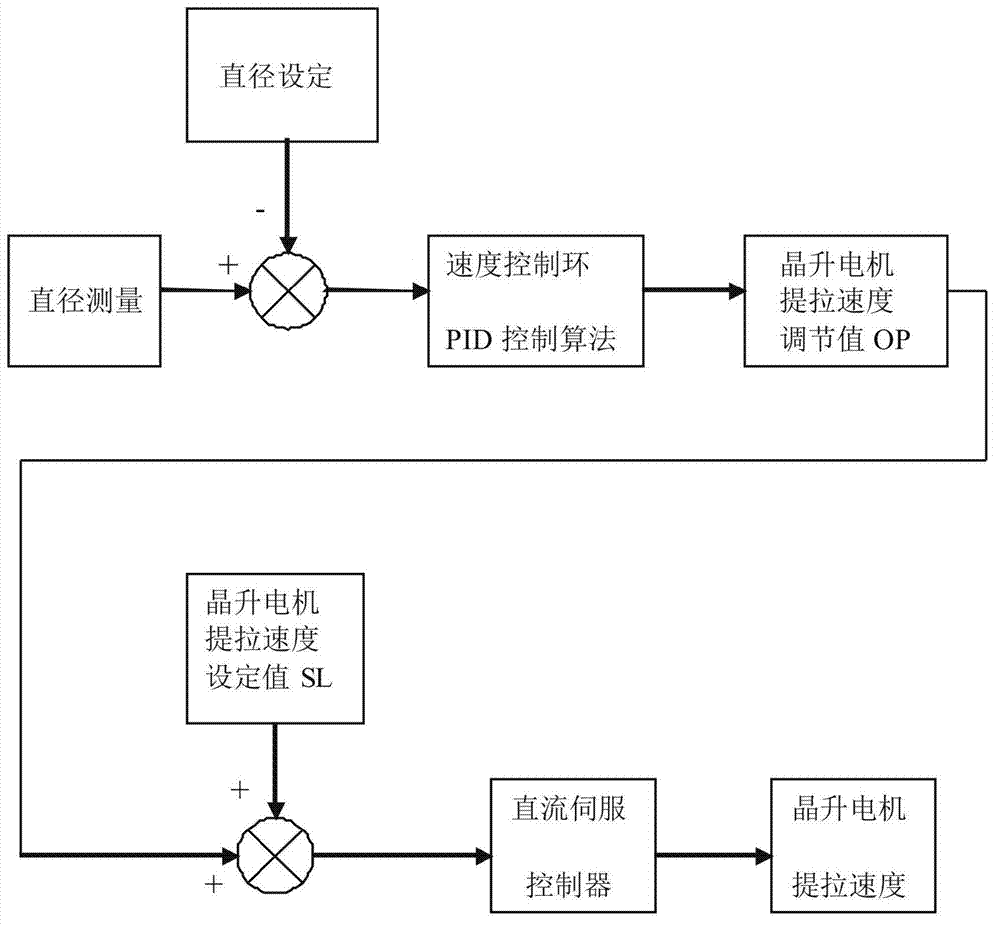

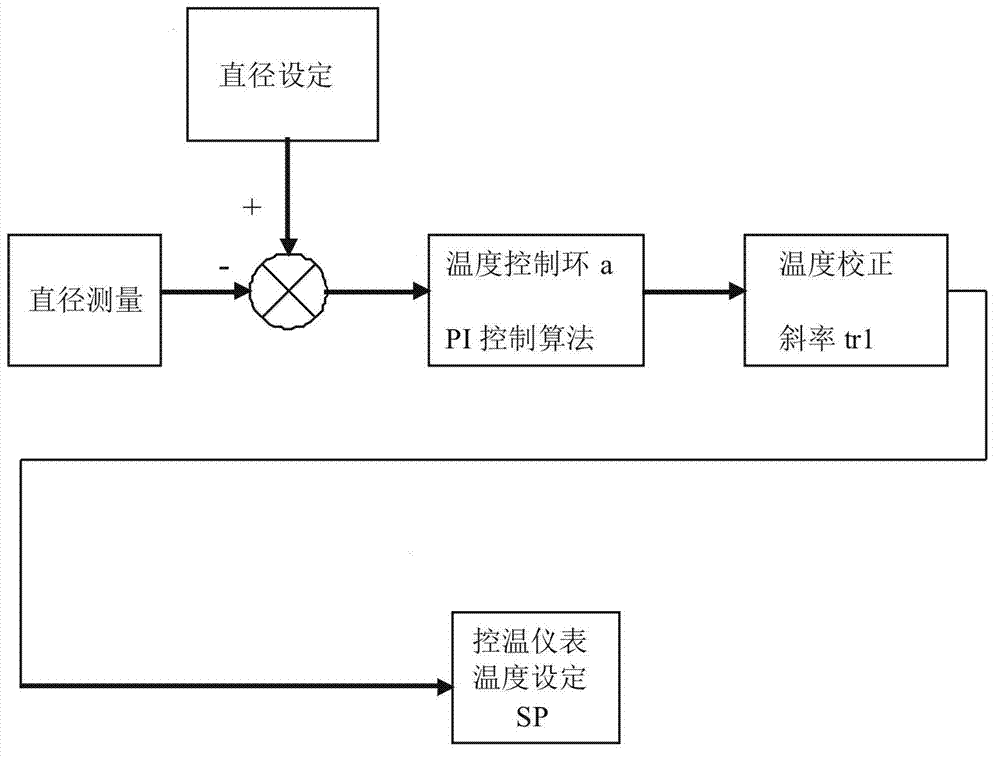

[0034] The invention provides an automatic equal-diameter control method of a germanium single crystal Czochralski growth method, such as figure 1 As shown, follow the steps below to implement:

[0035] 1) Set the diameter of the germanium crystal to be prepared, and set the initial crystal lift motor pulling speed SL;

[0036] 2) Establish speed control loop, temperature control loop a and temperature control loop b, among them,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com