Crystal, and method and device for casting same

A technology of crystal and single crystal, applied in the field of crystal and its casting and device, can solve the problems of difficult control of temperature gradient, difficult to achieve, no silicon single crystal, etc., to reduce manufacturing difficulty and manufacturing cost, low cost, and increase heat The effect of spreading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

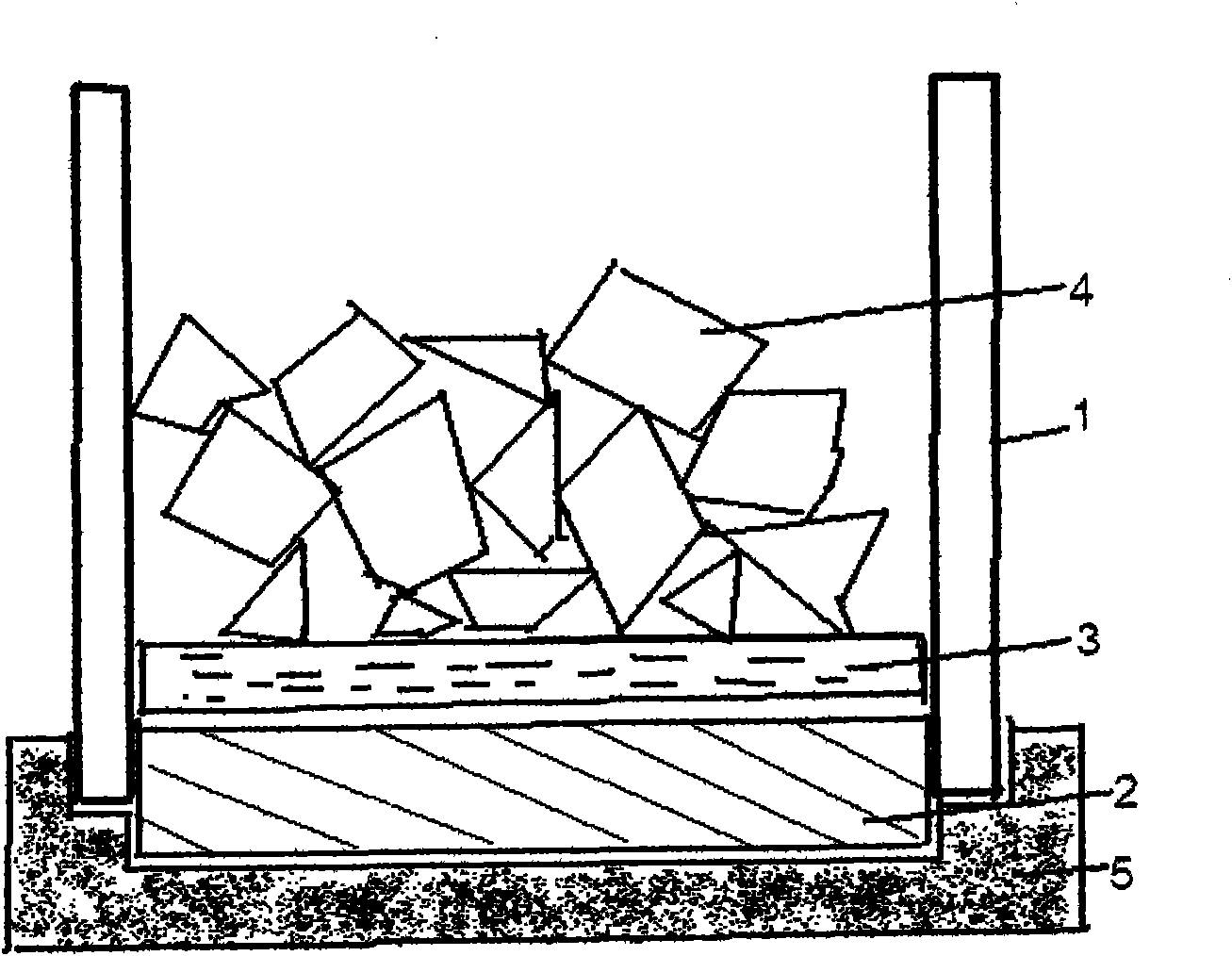

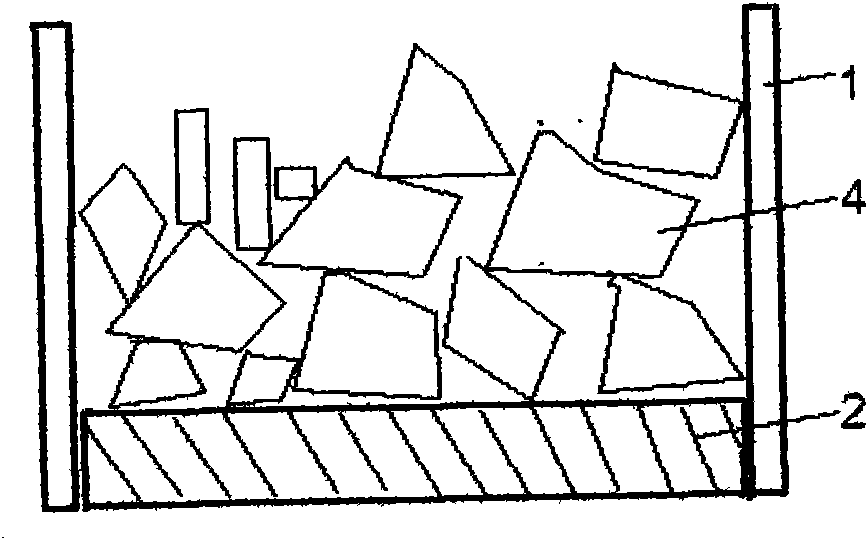

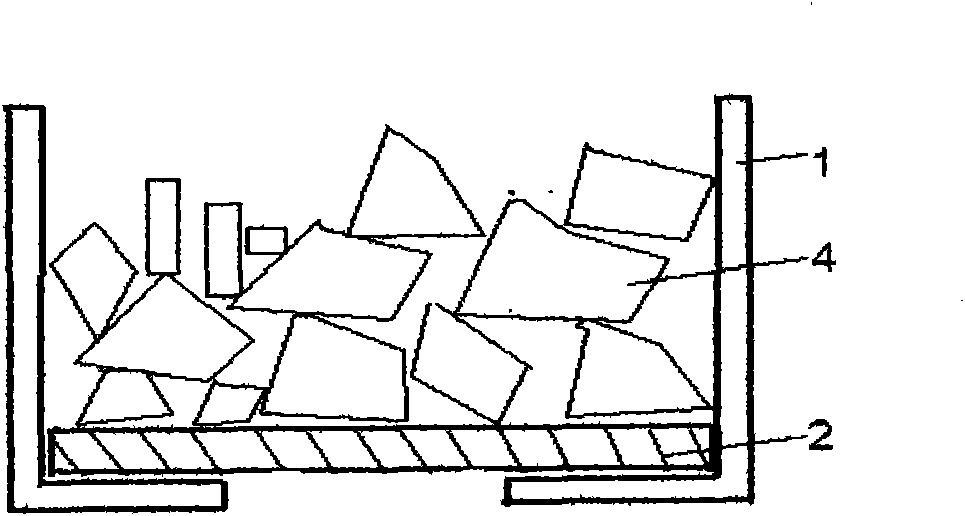

[0056] figure 1 In a preferred embodiment of the present invention, the positional relationship of the melt-solidified bottomless crucible sleeve, the seed crystal, the thermally insulating region, the crystal raw material and the heat sink is shown. figure 1 Among them, a seed crystal 2 is placed at the bottom of the bottomless crucible sleeve 1, and the seed crystal basically covers the bottom of the whole crucible sleeve, constitutes the bottom wall of the crucible sleeve, and together with the crucible sleeve forms a crucible for accommodating the melt. An optional thermally insulating region 3 placed in the crucible separates the seed crystal 2 and the crystal feedstock 4 or a melt of feedstock and consists of a thermal insulator. Wherein, between the thermally insulating region and the seed crystal, a part of granular crystal raw material 41 is optionally included to form a part of the crystal raw material separating region separating the thermally insulating region and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com