Optical athermalization, high-pixel, high-illumination and low-cost heat imaging system

A heat-absorbing, high-pixel technology, applied in the field of optical systems, can solve problems such as large temperature coefficient of refractive index, high processing cost, and large thermal difference of the lens, and achieve the effect of reducing complexity, reducing processing cost, and stabilizing resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

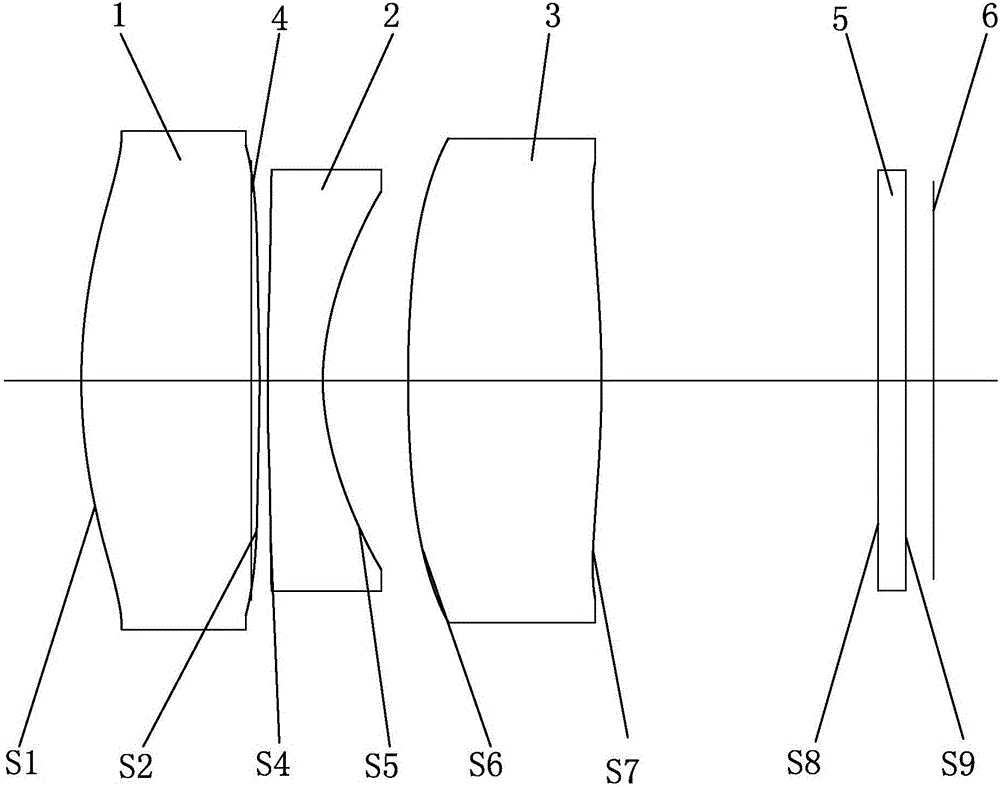

[0021] Such as figure 1 As shown, an optical athermalization, high pixel, high illuminance, low-cost infrared thermal imaging system, from the object side to the image side sequentially includes: a first lens 1, a diaphragm 4, a second lens 2, a third lens 3 And the photosensitive chip 6, the first lens 1, the second lens 2, and the third lens 3 are all aspheric lenses of chalcogenide glass, and a protective window glass 5 is arranged between the third lens 3 and the photosensitive chip 6.

[0022] Such as figure 1 As shown, in this embodiment, the focal lengths of the first lens 1 and the third lens 3 are positive, and the focal lengths of the second lens 2 are negative.

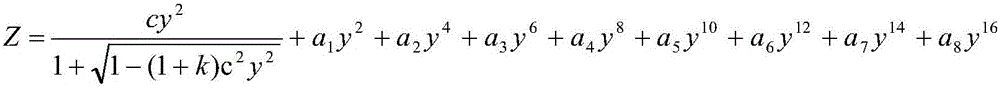

[0023] Such as figure 1 As shown, in this embodiment, the aspheric surface types of the first lens 1, the second lens 2 and the third lens 3 satisfy the equation:

[0024]

[0025] In the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com