Preparation method for growing germanium sulfide single crystal film on SiO2 substrate

A technology of single crystal thin film and germanium sulfide, which is applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, final product manufacturing, etc., can solve the problems of long growth time, unfavorable processing and preparation of devices, etc., to reduce the growth temperature and promote The effect of cryolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

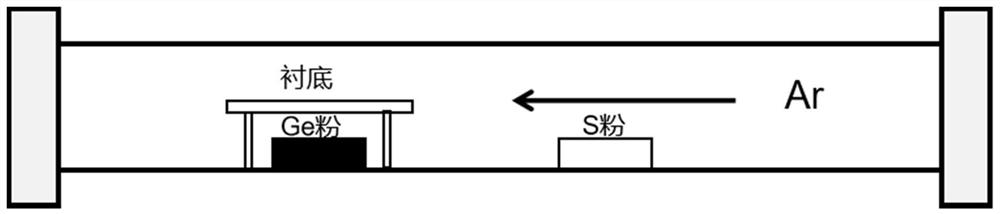

[0037] The SiO provided in this example 2 The preparation method for growing a germanium sulfide single crystal film on a substrate can obtain a high-quality germanium sulfide single crystal film with a thickness of about 1 micron on an amorphous substrate. The prepared single crystal thin film has good crystal quality, flat surface and roughness of only a few tenths of a nanometer. After the photoluminescence spectrum test, there are two luminescence peaks at the wavelengths of 410nm and 445nm in the blue-violet light band, indicating that it has the potential to be used in the field of visible light detection.

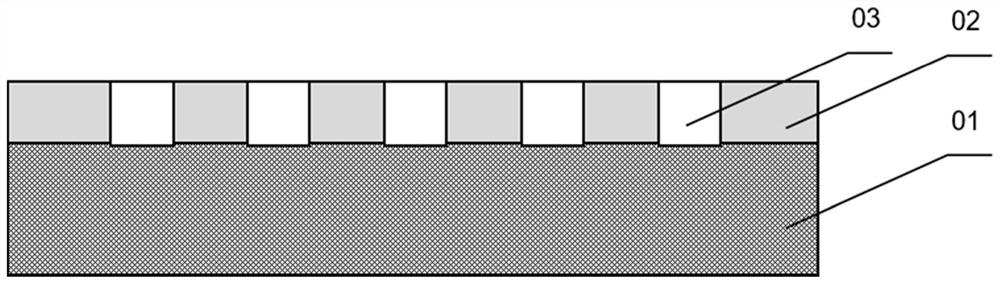

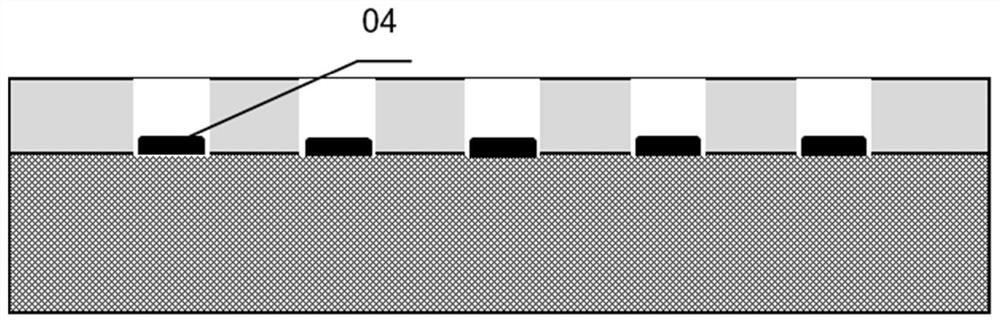

[0038] This embodiment provides a SiO 2 A preparation method for growing a germanium sulfide single crystal thin film on a substrate, comprising the following steps:

[0039] (1) Preferably, the substrate is Si / SiO with a p-(100) crystal orientation and a thickness of 300nm 2 substrate.

[0040] (2) Clean the surface of the substrate with acetone, ethanol and dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com