Method and device for growing germanium crystal

A crystal and single crystal growth technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as unfeasible, germanium single crystal arsenic-doped process limitations, restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

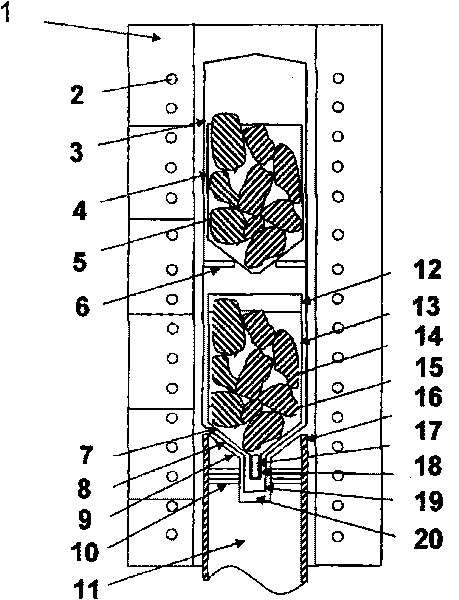

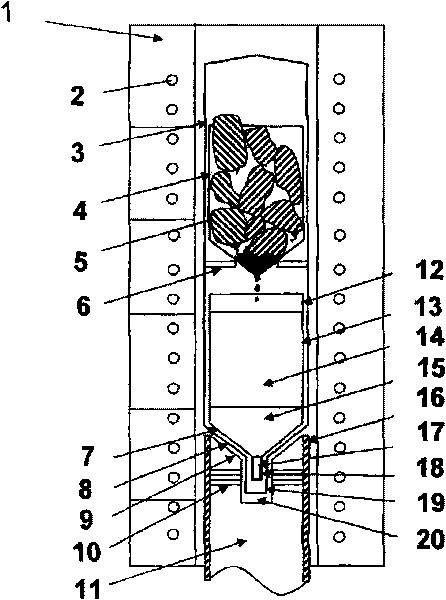

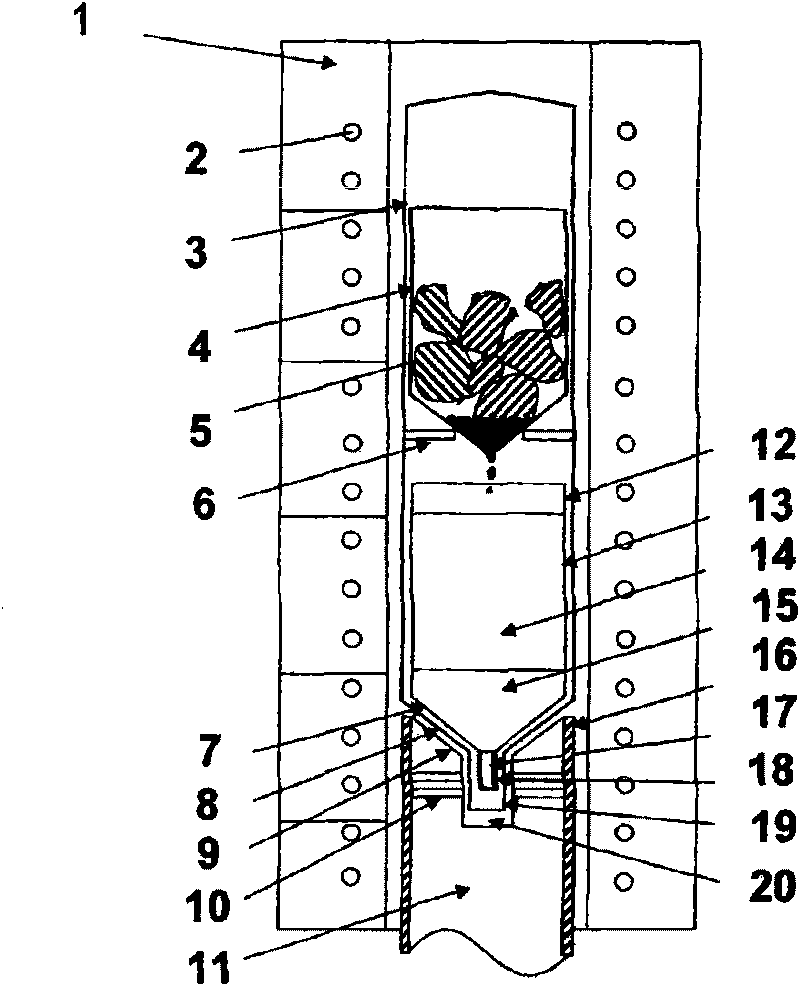

[0035] The method for growing single crystal germanium (Ge) crystal of the present invention comprises:

[0036] loading the first Ge feedstock into a crucible with a seed well in which the seed crystals are placed;

[0037] Fill the second Ge material into a loading container that will be placed in the ampoule to supplement the Ge material;

[0038] sealing the crucible and loading container within an ampoule;

[0039] placing the ampoule sealed with the crucible and loading vessel into a crystal growth furnace having a movable ampoule holder supporting the ampoule;

[0040] Melting the first raw material in the crucible to produce a melt;

[0041] Melting the second raw material in the vessel and adding the second raw material to the melt;

[0042] Controlling the crystallization temperature gradient of the melt so that the melt crystallizes to form a single crystal germanium rod when it contacts with the seed crystal; and

[0043] Cool the single crystal germanium ingot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com