Systems, methods and substrates for single crystal germanium crystal growth

A technology for crystal growth and single crystal germanium, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., and can solve the problems of limitation and unusability of arsenic doping methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

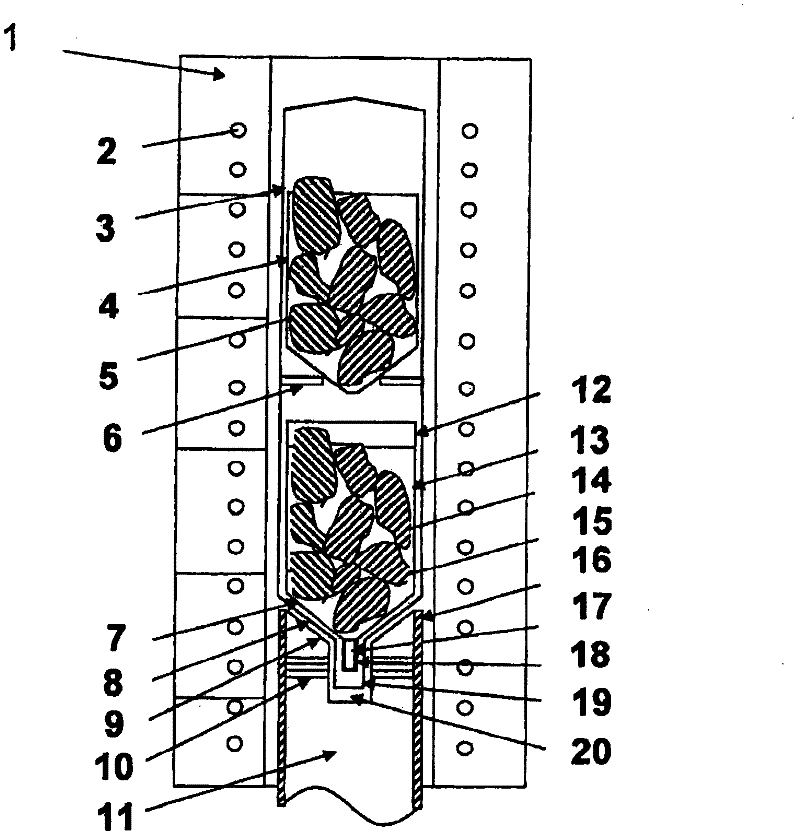

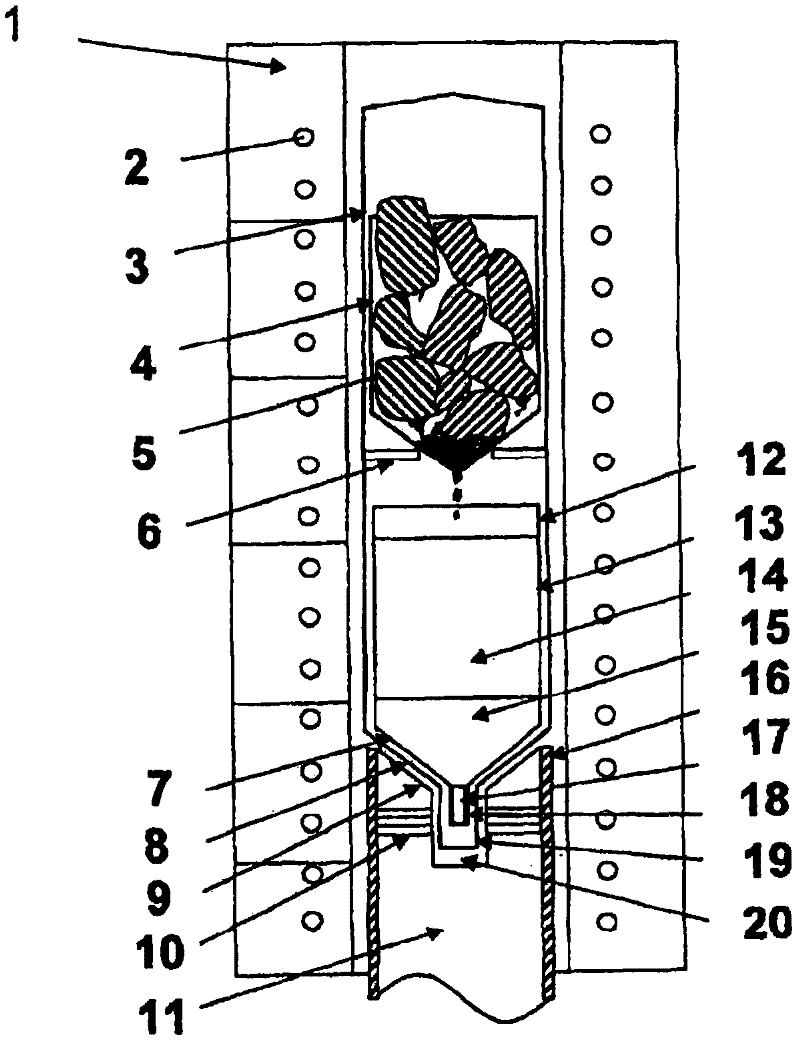

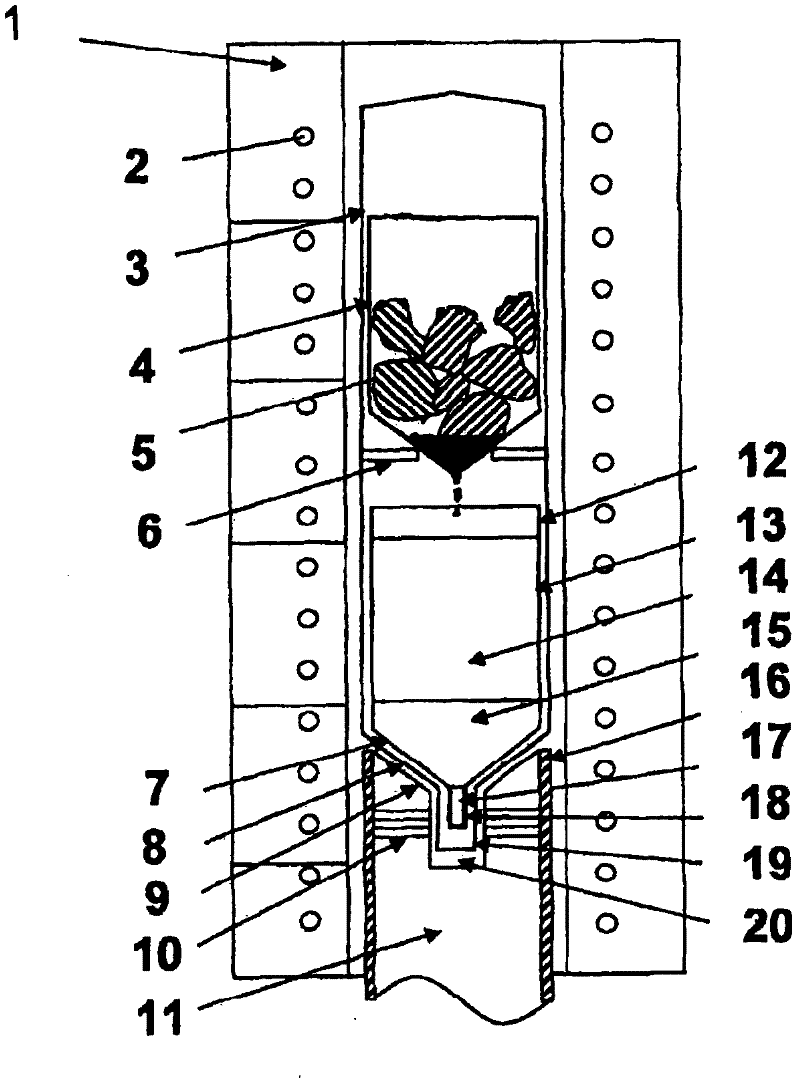

[0018] The invention will now be described in detail, examples of which are illustrated in the accompanying drawings. The embodiments given in the following specification do not represent all embodiments consistent with the claimed invention. Rather, they are merely some examples consistent with certain aspects of the invention. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0019] Aspects of the present invention are particularly suited for the apparatus and methods for growing germanium ingot crystals having a diameter of 150 mm (6 inches), which are described herein. However, it should be understood that some aspects of the present invention have greater utility, such as the use of related apparatus and methods to produce germanium (Ge) ingots with diameters greater than 50 mm (2 inches), such as diameters of 100 mm (4 inches) and 200mm (8 inches) boule.

[0020] and Figure 1A-Figure 2 Consistent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com