Method and device for casting crystal material by using crystal selector

A crystal selector and crystal technology, applied in the field of polycrystalline and single crystal materials, to achieve the effects of low cost, high photoelectric efficiency, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

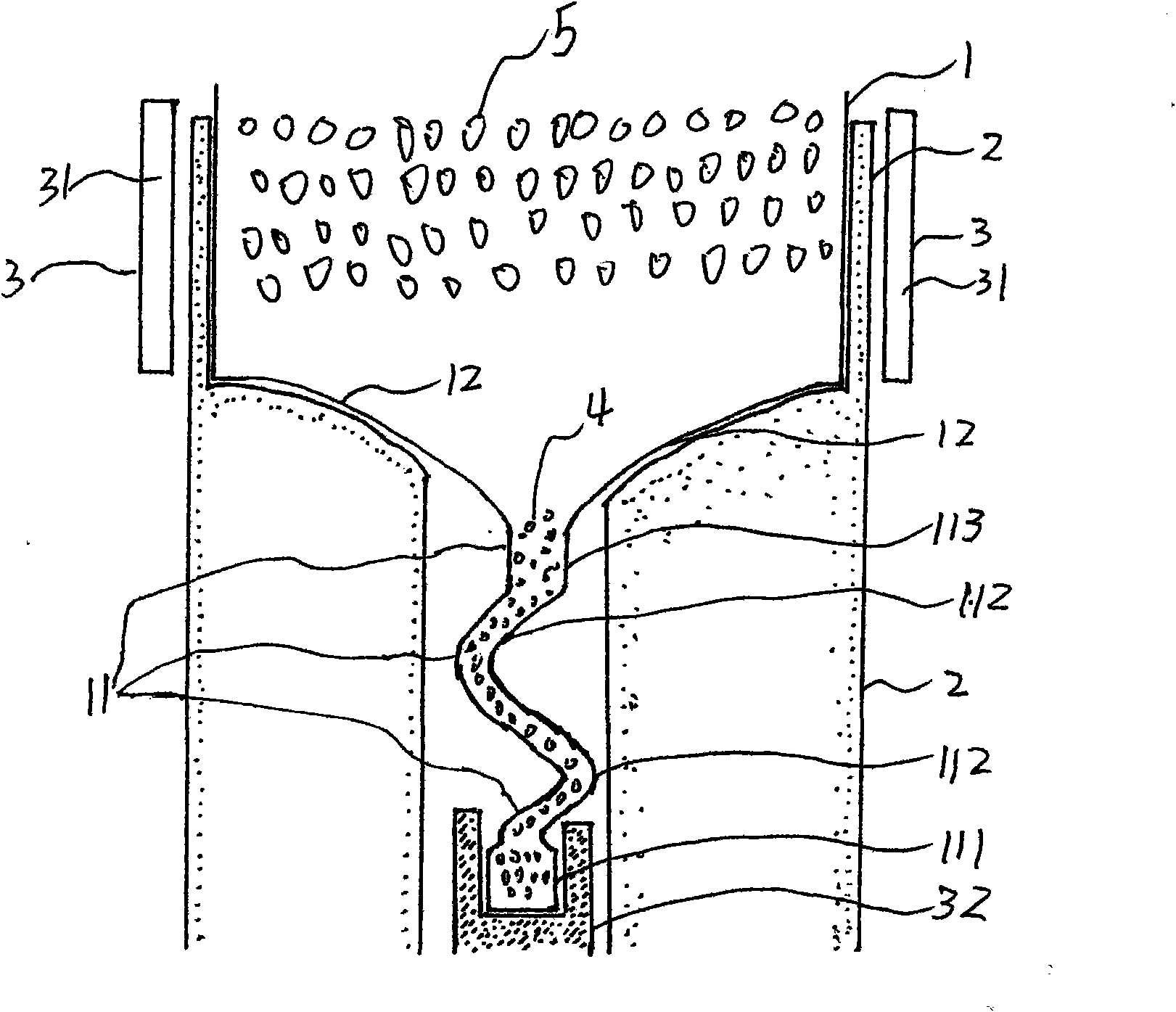

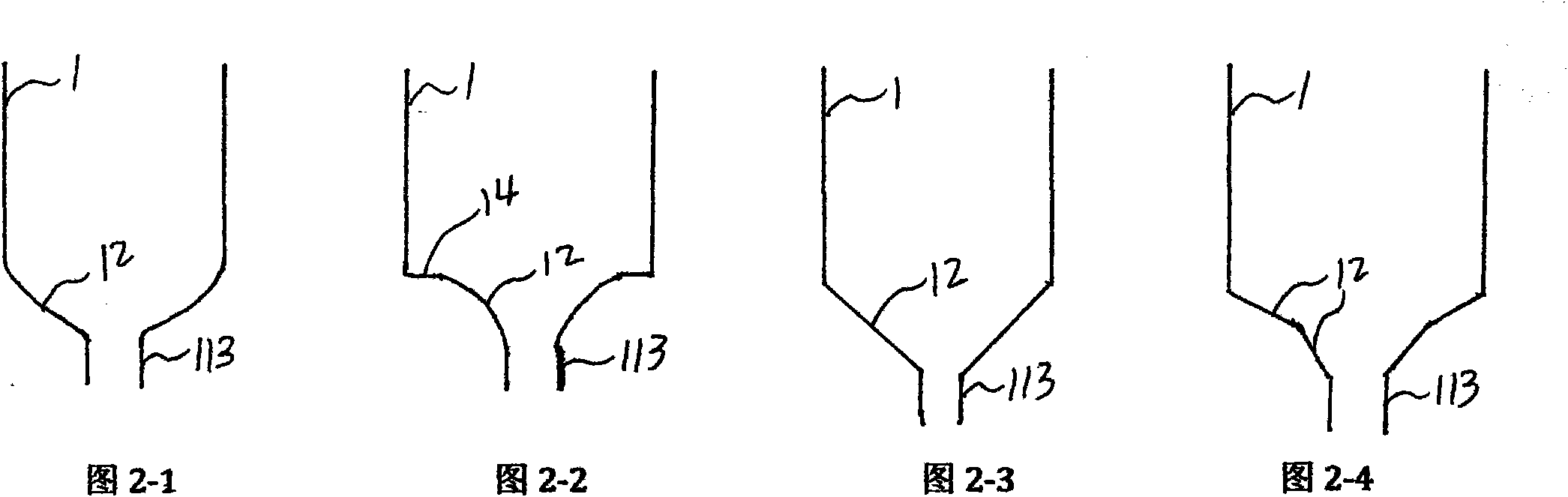

[0083] figure 1 Show the silicon crystal manufacturing device that adopts the silicon crystal growth process of VGF method, for clearly showing the feature of the present invention, only provide the schematic diagram that comprises crucible 1, crucible supporting device 2 and heating device 3 that comprise crystal selector among the figure, and each Only the relative positions are shown between the parts, and do not represent the real scale. according to figure 1 , The crucible 1 is formed by a quartz crucible, and the middle part of its bottom wall is provided with a spiral crystal selector 11, and the crystal selector is an initial section 111, a crystal selection section (helix) 112 and a single crystal section 113 from bottom to top. The crystal selector is located at the upper opening of the single crystal segment, and is connected to the side wall by the arc-shaped bottom wall 12 recessed into the crucible, which is the gradual transition area of the bottom wall. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com