Germanium-doped crystalline silicon solar cell capable of suppressing light attenuation and preparation thereof

A technology of solar cells and crystalline silicon, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of incompatibility of cell structure and process, cost increase, etc., and achieve the effects of suppressing light attenuation, low cost, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

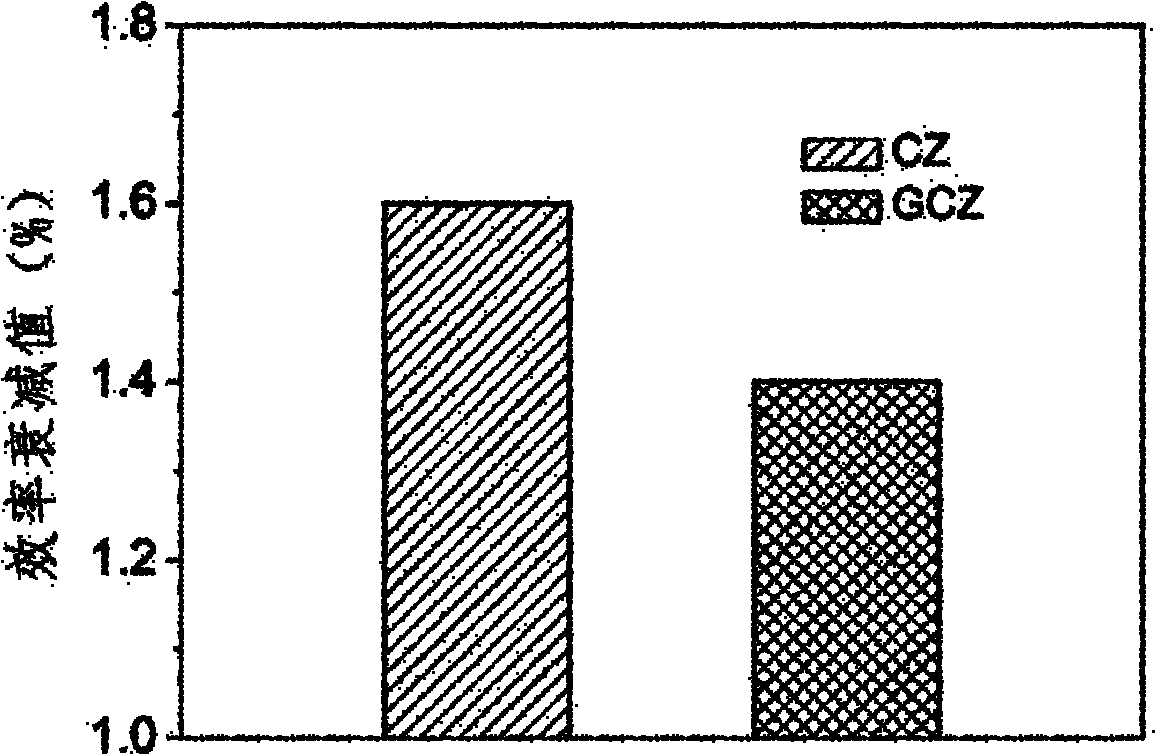

Embodiment 1

[0023] (1) Doping 69.8g germanium and 4.2×10 into 270Kg polysilicon raw material -2 g boron, the concentration of germanium is 5×10 18 cm -3 , The concentration of boron is 2×10 16 cm -3 , (Ie per cm 3 The number of atoms of germanium in the polysilicon raw material is 5×10 18 Per cm 3 The number of boron atoms in the polysilicon raw material is 2×10 16 A) Then in a polycrystalline ingot furnace, under an argon protective atmosphere, the pressure is 500 torr, and the furnace temperature is increased to 1480°C, germanium and boron are melted into the polycrystalline silicon solution to grow germanium-doped cast polycrystalline silicon.

[0024] (1') Using the same polycrystalline silicon raw material and doping amount of boron, in the same polycrystalline ingot furnace, the same growth parameters, growing ordinary cast polycrystalline silicon not doped with germanium as a control.

[0025] (2) After squared the germanium-doped cast polysilicon obtained in step (1) and the ordinary cas...

Embodiment 2

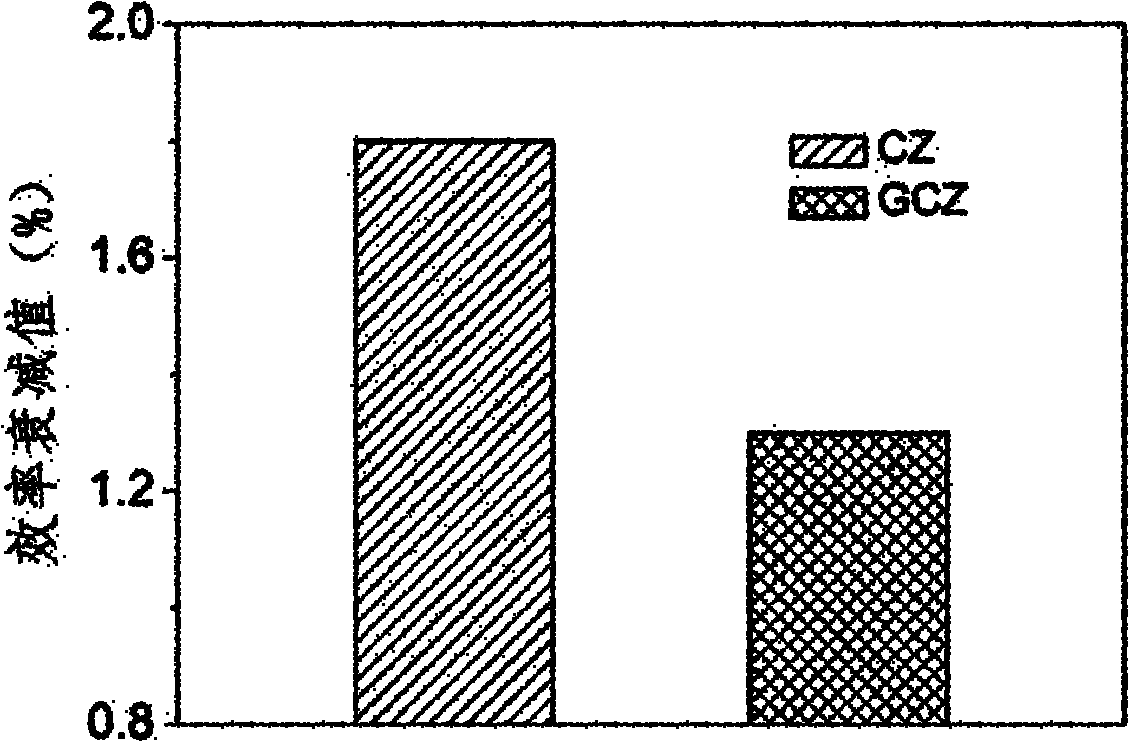

[0033] (1) Doping 2.33Kg germanium and 1.7×10 into 450Kg polysilicon raw material -2 g boron, the concentration of germanium is 1×10 20 cm -3 , The concentration of boron is 5×10 15 cm -3 Then, in a polycrystalline ingot furnace, under an argon protective atmosphere, the pressure is 600torr, the furnace temperature is increased to 1440°C, germanium and boron are melted into the polycrystalline silicon solution to grow germanium-doped cast polycrystalline silicon.

[0034] (1') Using the same polycrystalline silicon raw material and doping amount of boron, in the same polycrystalline ingot furnace, the same growth parameters, growing ordinary cast polycrystalline silicon not doped with germanium as a control.

[0035] (2) After squared the germanium-doped cast polysilicon obtained in step (1) and the ordinary cast polysilicon ingot obtained in step (1'), cut into 160 micron silicon wafers by wire cutting. After cleaning, the germanium-doped cast polysilicon Silicon wafers are package...

Embodiment 3

[0043] (1) Add 56.9g germanium and 2.1×10 into 55Kg polysilicon raw material -3 g boron, the concentration of germanium is 2×10 19 cm -3 , The concentration of boron is 5×10 15 cm -3 Then, in a single crystal furnace, under an argon protective atmosphere, the pressure is 10torr, the furnace temperature is increased to 1420°C, germanium and boron are melted into the polysilicon solution to grow germanium-doped Czochralski single crystal silicon.

[0044] (1') Using the same polycrystalline silicon raw material and boron doping amount, in the same single crystal furnace, the same growth parameters, and growing ordinary Czochralski single crystal silicon without germanium as a control.

[0045] (2) After slicing the germanium-doped Czochralski single crystal silicon obtained in step (1) and the ordinary Czochralski single crystal silicon ingot obtained in step (1′), cut into 180 micron silicon wafers by wire cutting. After cleaning , Germanium-doped Czochralski silicon wafers are packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com