Flexible mold used for profile stretch bending

A flexible mold and profile stretch bending technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of long production cycle and large quantity, reduce the occupied area, reduce the scale of investment, and speed up the development speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

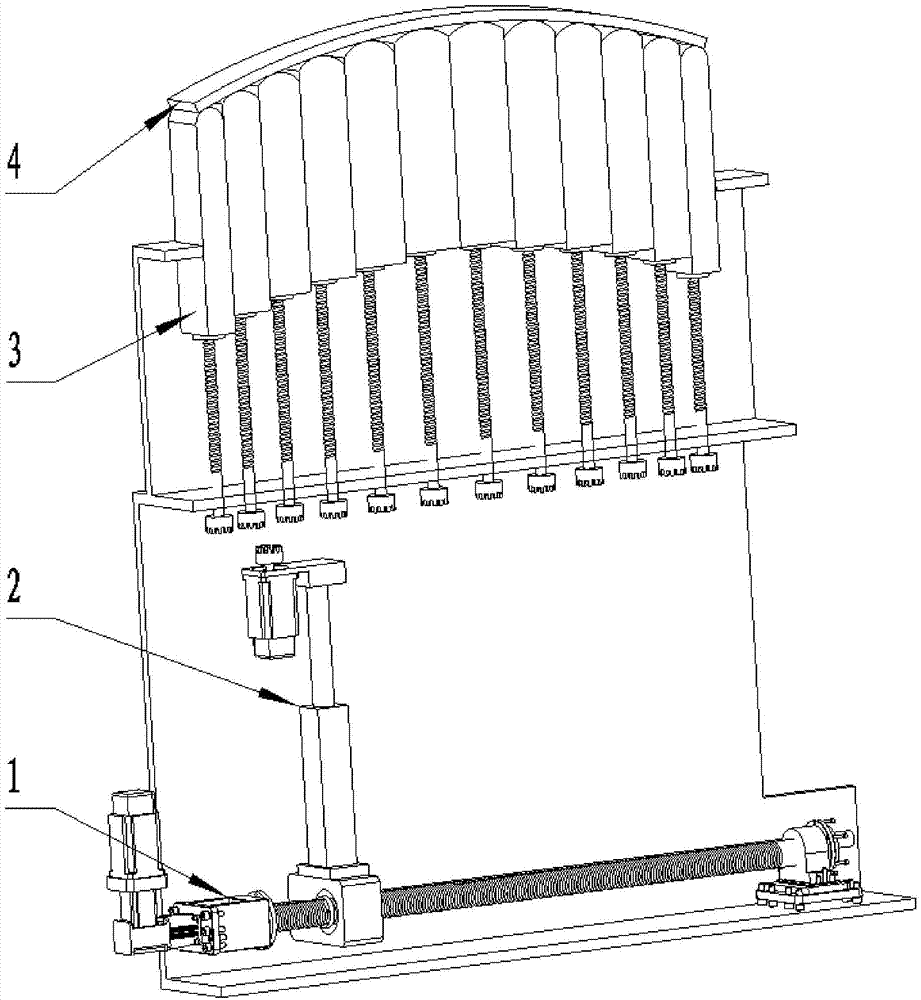

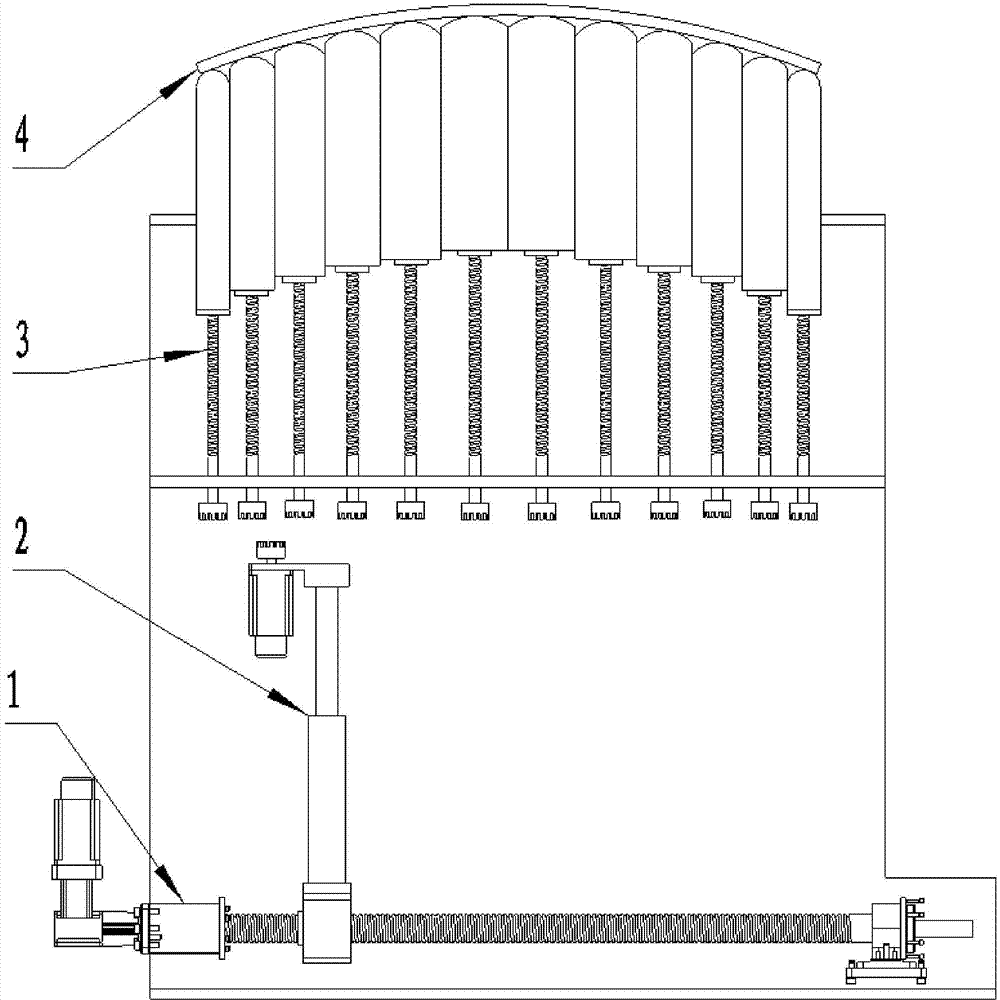

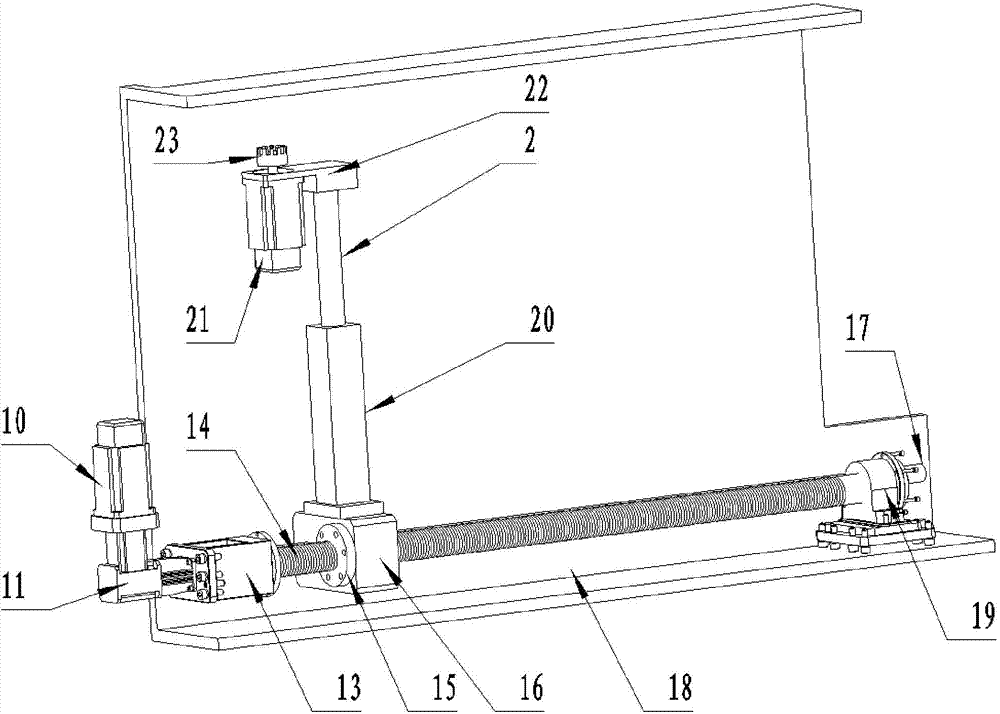

[0036] The flexible mold for profile stretch bending according to the present invention will be further described in detail below in conjunction with the accompanying drawings. A flexible mold for profile stretch bending, such as figure 1 and figure 2 As shown, it includes an X-direction positioning assembly 1, a Z-direction adjustment assembly 2 and a punch assembly 3. The X-direction positioning assembly 1 can adjust the position of the Z-direction adjustment assembly 2 in the X direction, that is, adjust the Z-direction adjustment assembly 2 in the X direction. figure 2 The position in the horizontal direction, the punch assembly 3 contains a plurality of height-adjustable punches 33, and the Z-direction adjustment assembly 2 can adjust the position of each punch 33 in the punch assembly 3 in the Z direction, that is, adjust the punch assembly 3 in each punch 33 in figure 2 position in the vertical direction.

[0037] The X-direction positioning assembly 1 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com