Optical film coated with adhesive

An optical film and adhesive layer technology, applied in the field of optical films, can solve the problems of uneven stress distribution and stress concentration, and achieve the effects of suppressing white tone, reducing local stress concentration, and preventing floating and peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

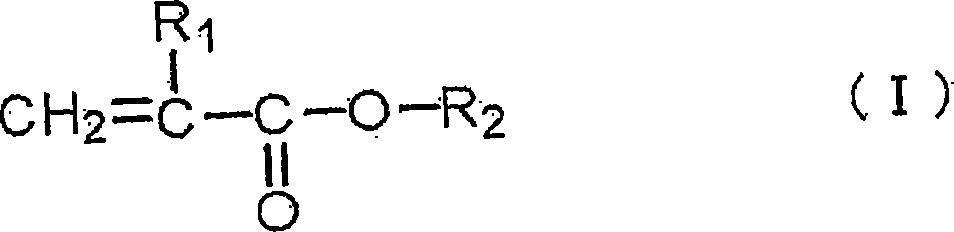

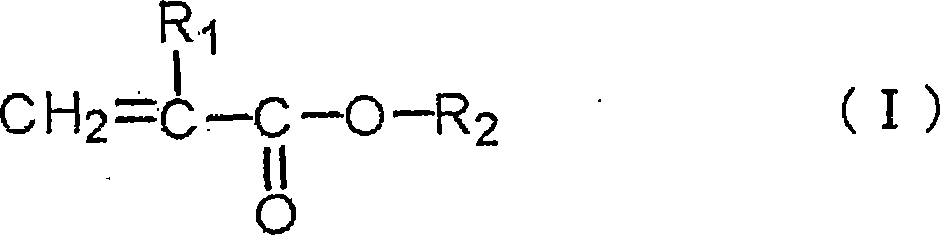

[0023] In the preparation of the first acrylic resin, as the (meth)acrylate represented by formula (I), one compound or two or more compounds may be used. In particular, it is preferable to use butyl acrylate as at least one monomer. The structural unit derived from (meth)acrylate of the first acrylic resin preferably contains a structural unit derived from butyl acrylate.

[0024] As the hydroxyl group-containing monomer used for another structural unit of the first acrylic resin, a compound having one ethylenic double bond and at least one hydroxyl group in the molecule is used, including, for example, 2-hydroxyethyl (meth)acrylate, ( 2-Hydroxypropyl meth)acrylate and 4-Hydroxybutyl (meth)acrylate. Such hydroxyl-containing monomers are preferably hydroxyalkyl (meth)acrylic acid esters wherein the alkyl group has about 1-10 carbon atoms, more preferably about 2-6 carbon atoms.

[0025] In addition, the first acrylic resin may contain a structural unit derived from a monomer...

Embodiment 1 to 3 and comparative example 1 to 3

[0107] (a) Preparation of adhesive

[0108] From the acrylic resin A1 itself obtained in Polymerization Example 1, or the acrylic resin A2 itself obtained in Polymerization Example 2, or in the A mixture of the acrylic resin A3 obtained in 3 and the acrylic resin A4 obtained in Example 4 was polymerized to prepare an ethyl acetate solution. Each of the ionic compounds 1 to 3, the crosslinkers "Colonate L", "Takenate D110N" and "TAZM", and the silane compound "X- 41-1805" were mixed in the ratios shown in Table 1 respectively to prepare adhesive compositions. Here, in Table 1, the mixing amount (part) of the crosslinking agent "Clonate L" or "Takenate D110N" is the amount of solid content.

[0109] Table 1

[0110] high molecular weight propane

low molecular weight propane

thing

crosslinking agent

Silane compound

X-41-1805

Type / quantity

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com