Connection method of cathode carbon blocks and cathode steel bars of aluminum electrolytic cells and construction thereof

A technology of cathode carbon block and cathode steel rod, which is applied in the field of aluminum production, can solve the problems of electrolytic cell cathode damage, increase equipment investment, increase environmental protection investment, etc., and achieve the effect of improving utilization rate, reducing environmental protection investment, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

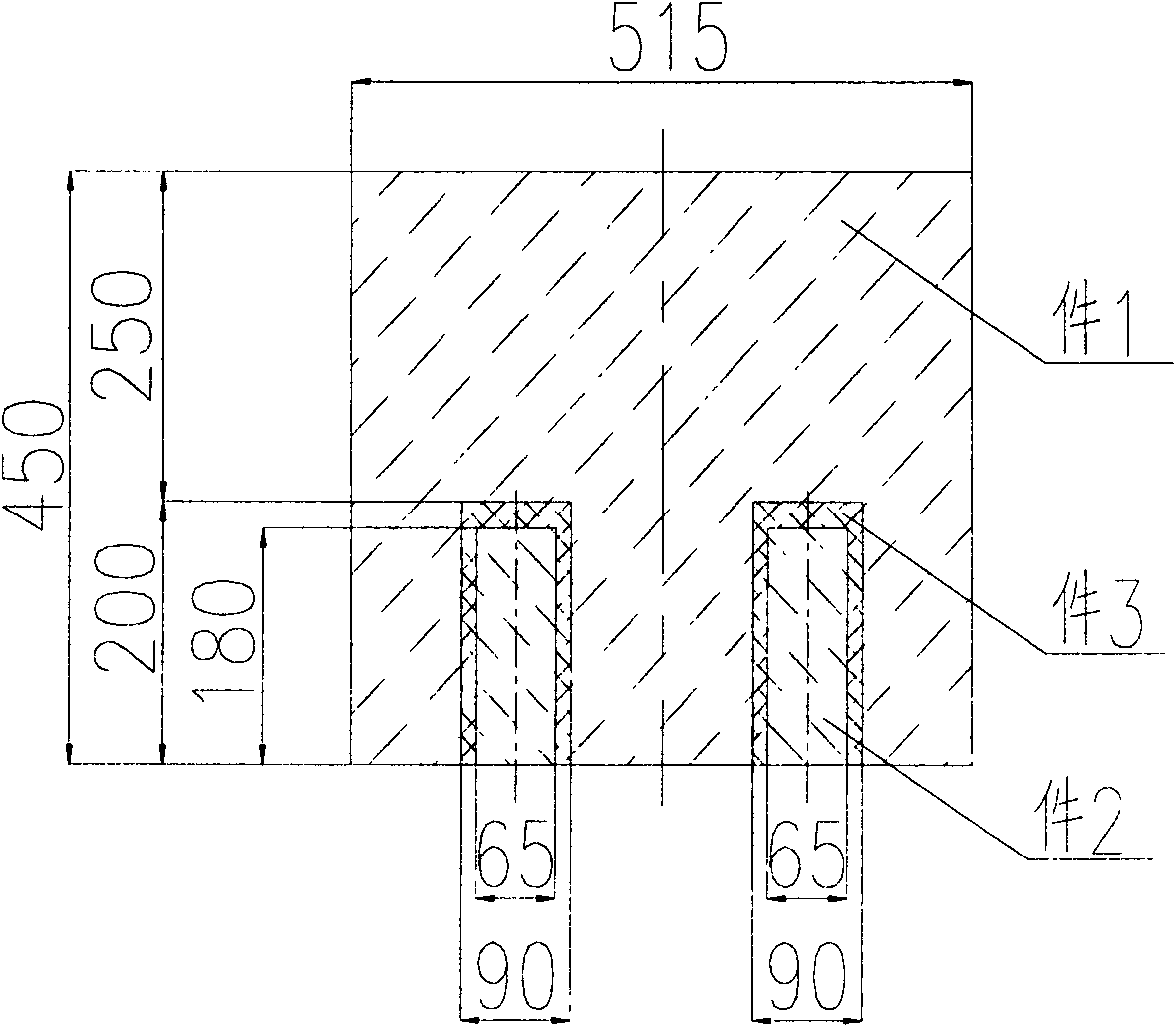

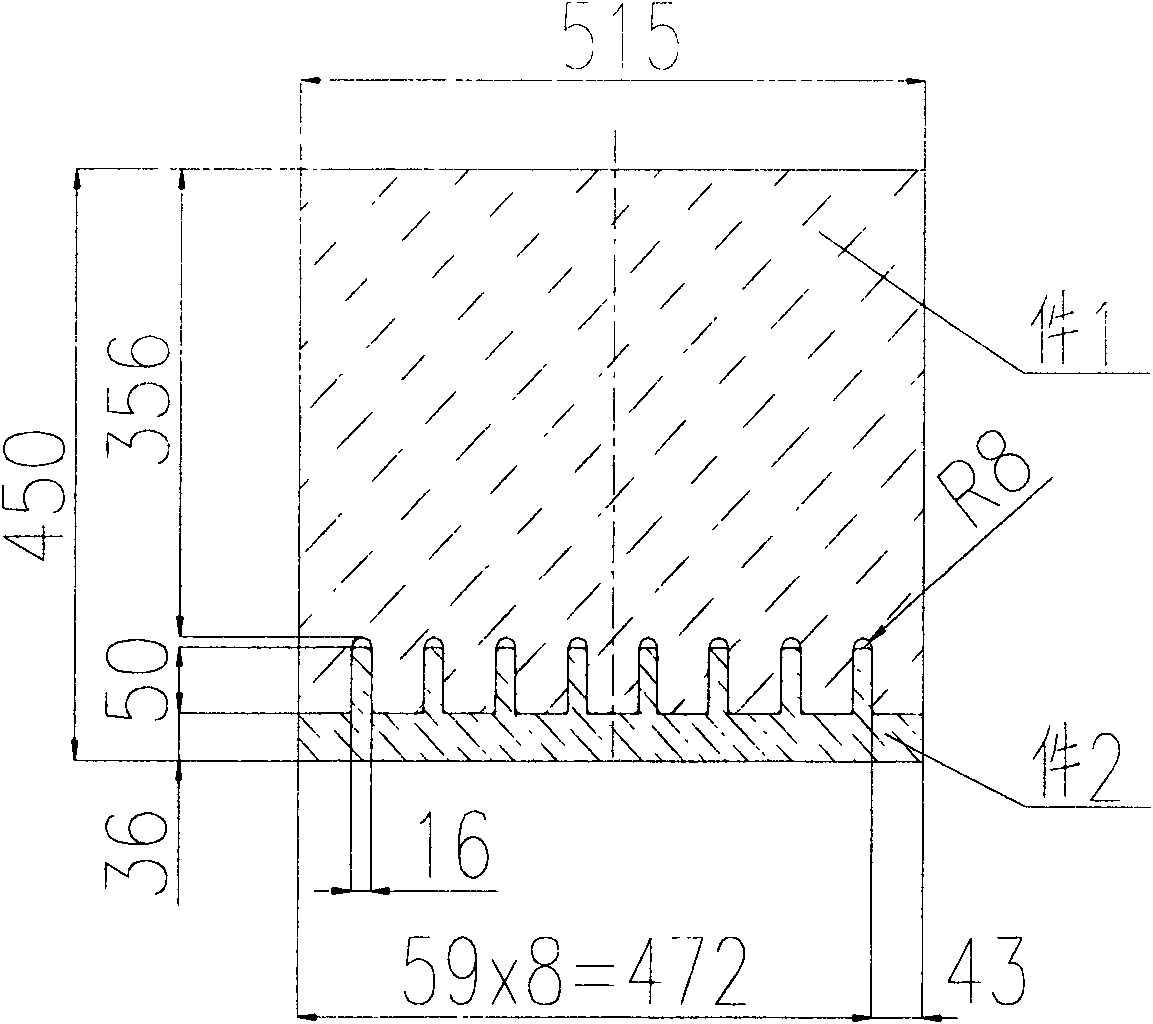

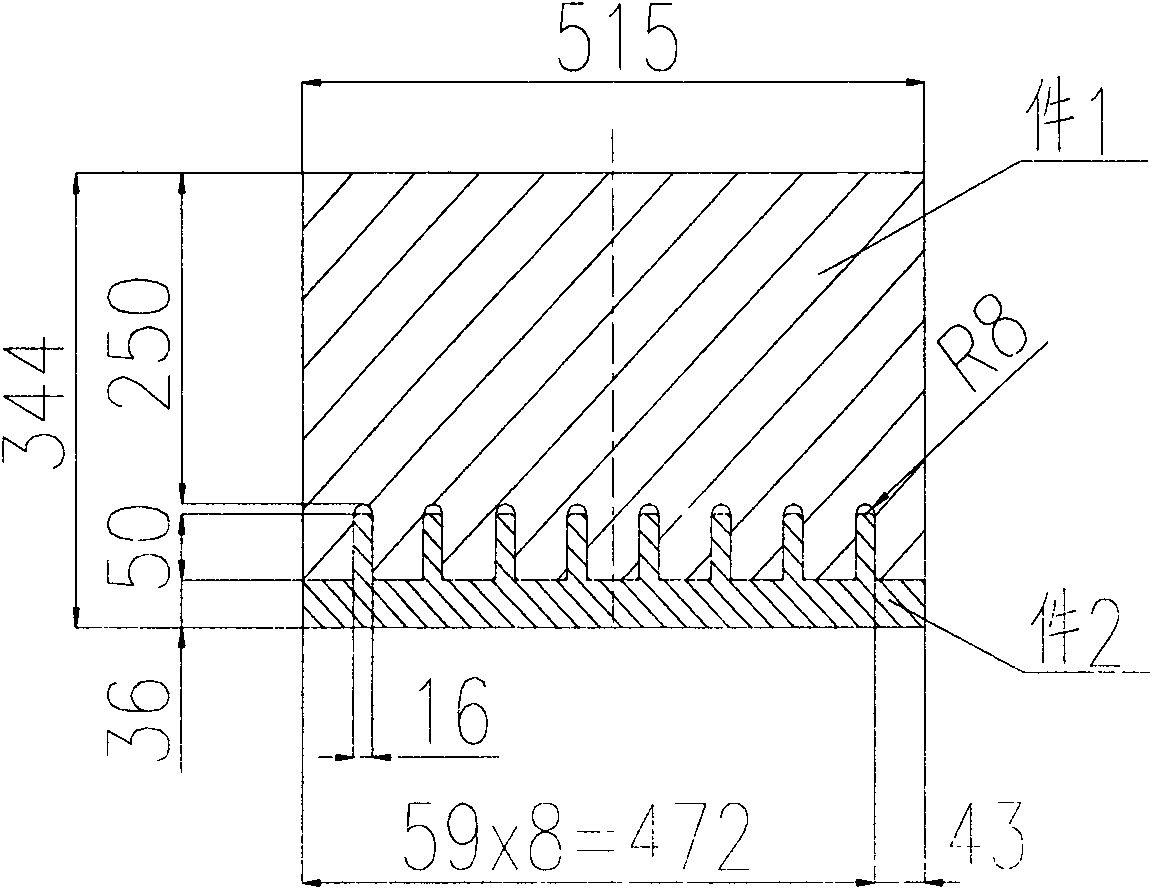

[0081] The cathode carbon block group of the present invention only involves two parts, the cathode carbon block (part 1) and the cathode steel rod (part 2). Still taking the cathode carbon block group with a cross-sectional size of 515mm×450mm as an example, the procurement, processing and assembly of the two parts are as follows:

[0082] ① Cathode carbon block

[0083] For the electrolytic cells that have been put into production, since the height of the original cathode carbon block group needs to be kept unchanged at 450mm, the cross-sectional size of the purchased cathode carbon block should be 515mm×414mm.

[0084] For newly built electrolyzers, cathode carbon blocks with a cross-sectional size of 515mm×308mm can be purchased. The cathode carbon block of this specification can be designed according to the design of the electrolytic cell, which can reduce investment.

[0085] After the cathode carbon block is purchased, use a milling cutter with a width of 16mm and arcs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com