Reactor with inner supporting structure

A technology of internal support and reactor, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve connection corner cracking, solutions that cannot meet high temperature and fatigue resistance, and affect safe production And economic benefits and other issues, to achieve the effect of reducing strength differences, low cost, and easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

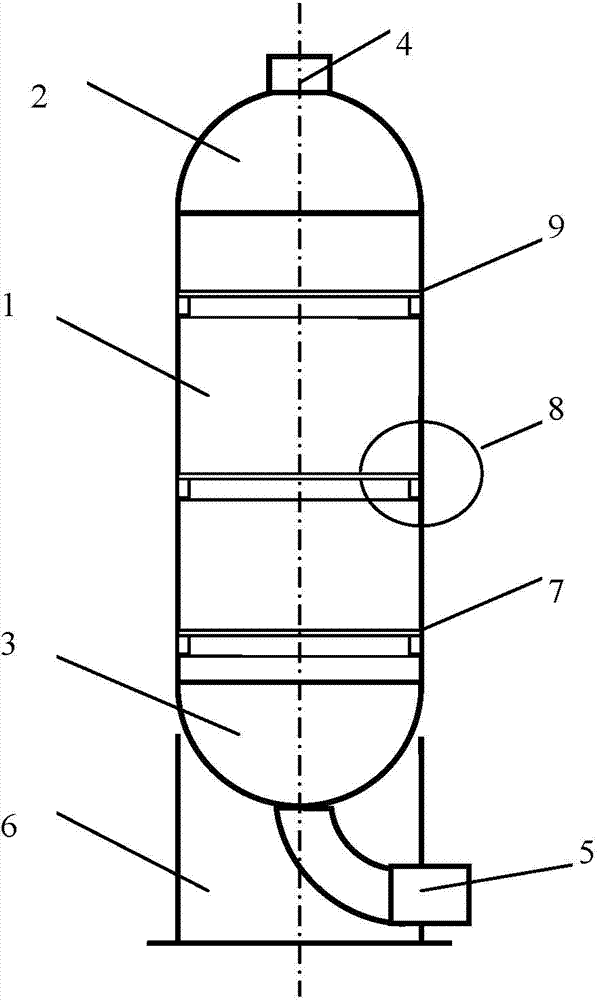

[0042] One of the specific implementations of a reactor with an internal support structure of the present application, see figure 1 As shown, its structure includes a cylinder body 1, an upper opening 4 and a lower opening 5 arranged on the cylinder body 1 for feeding in and out of materials, and an inner support structure disposed on the inner wall of the cylinder body 1. In addition, it also includes figure 1 The prior art features in the upper head 2, the lower head 3, the support 6, the inner support structure specifically includes the lower support structure 7, the middle support structure 8 and the upper support structure 9, the above technical features and the reaction in the prior art The structure of the reactor is basically the same, and the reactor with the inner support structure of the present application also has other basic structures of the reactor in the prior art.

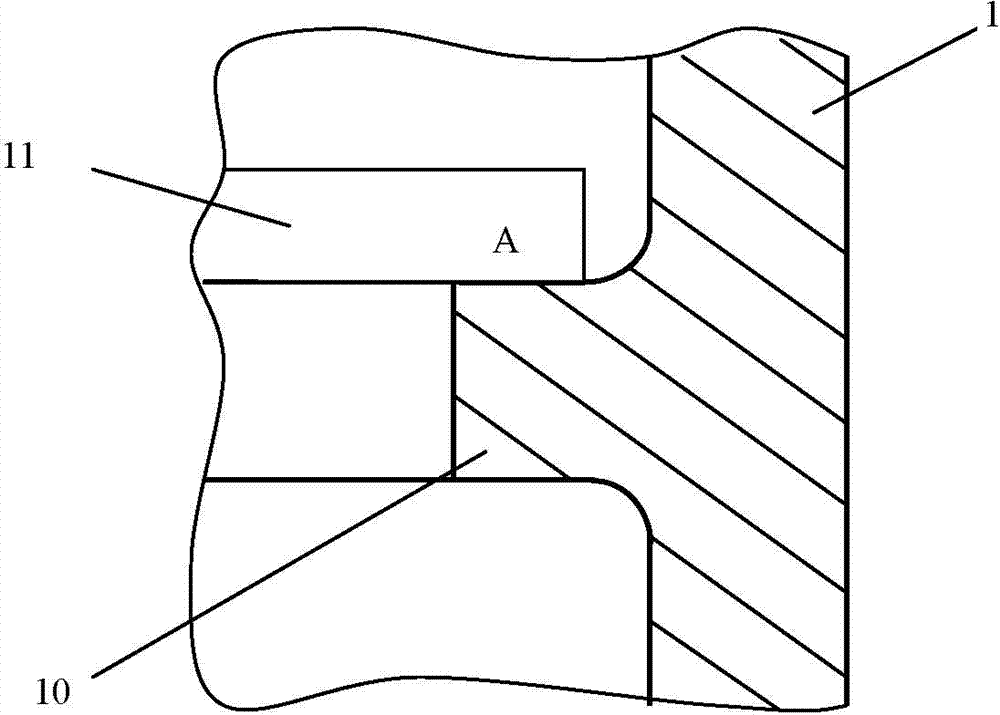

[0043] The improvement of the application is: see Figure 2 to Figure 7 ,as well as Figure ...

Embodiment 2

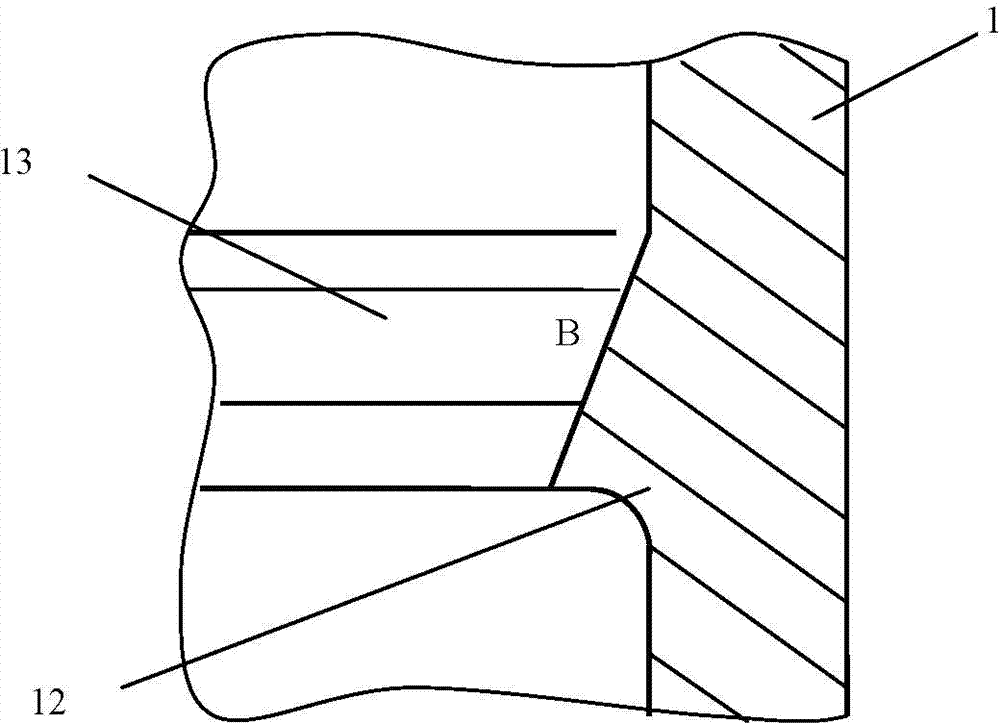

[0048] The second specific embodiment of a reactor with an internal support structure of the present application, the main technical scheme of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment adopt the explanation in embodiment 1, No further details will be given here. refer to Figure 3 to Figure 7 ,and Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the flange surface of the support flange is set as a streamlined annular smooth surface, and the support flange passes through the streamlined annular smooth surface. Fitted with the support frame for supporting the support frame. Compared with the planar support flange, the support flange with a streamlined annular smooth surface has one of its significant advantages in that it avoids the right-angled corner with the cylinder and reduces local stress. The second significant advantage is that It reduces the height of the flange by increas...

Embodiment 3

[0050] The third specific embodiment of a reactor with an internal support structure of the present application, the main technical scheme of this embodiment is the same as that of embodiment 2, and the features not explained in this embodiment adopt the explanation in embodiment 2, No further details will be given here. refer to Figure 3 to Figure 7 As shown, the difference between this embodiment and embodiment 2 is that the cross-sectional shape is streamlined, the annular smooth surface is an annular conical surface, or an annular double-cone surface formed by connecting two annular conical surfaces. That is, in Figure 3 to Figure 7 The outline of the bearing surface B of the flange on the section is straight, but there is an angle between it and the axis of the reactor. Compared with the flat support flange, one of the significant advantages of the support flange with a tapered surface is that it avoids the right-angled corner with the cylinder and reduces the local s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com