Patents

Literature

38results about How to "Reduce intensity differences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

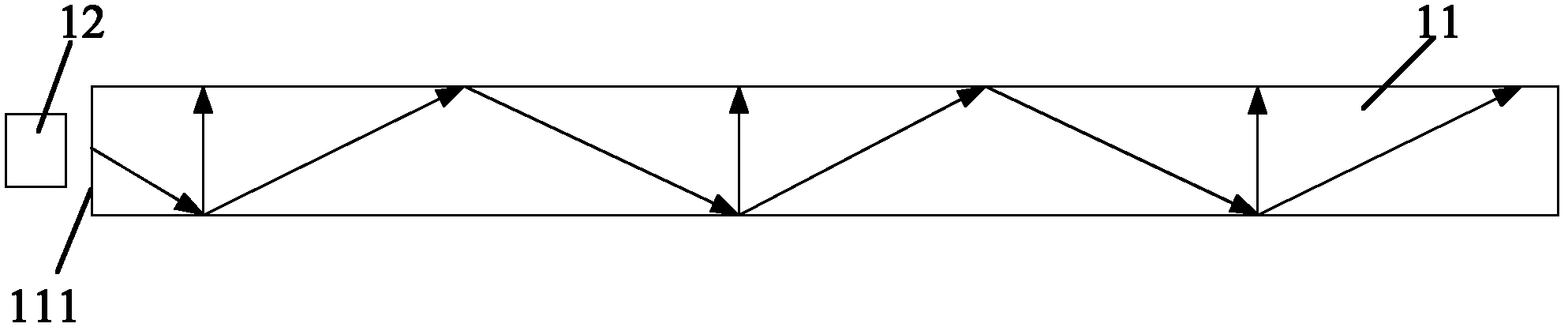

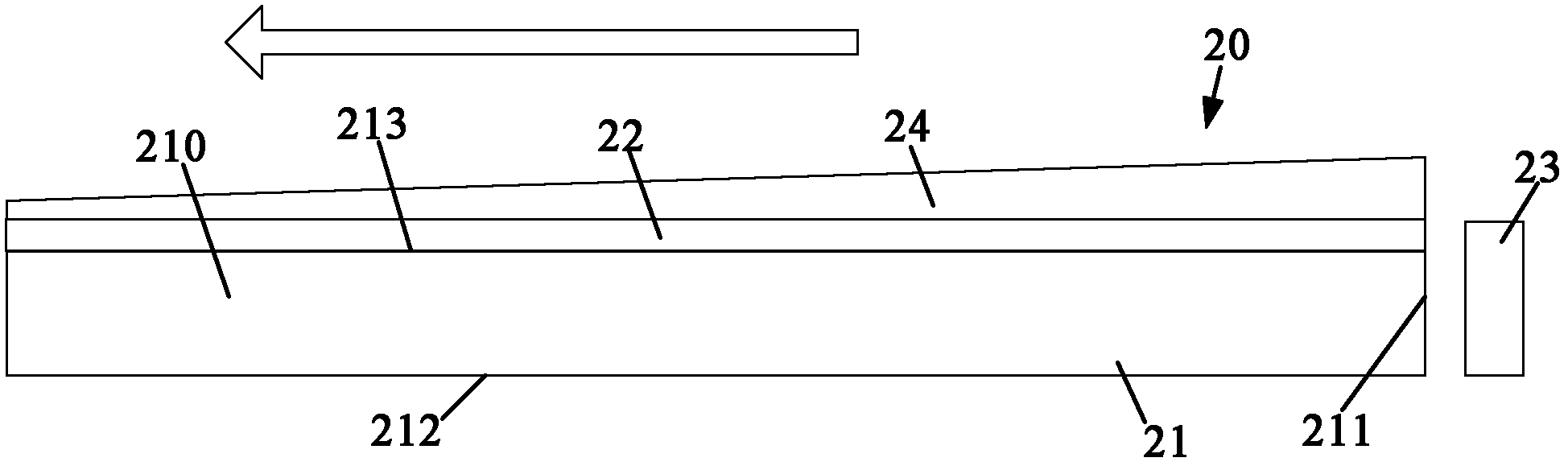

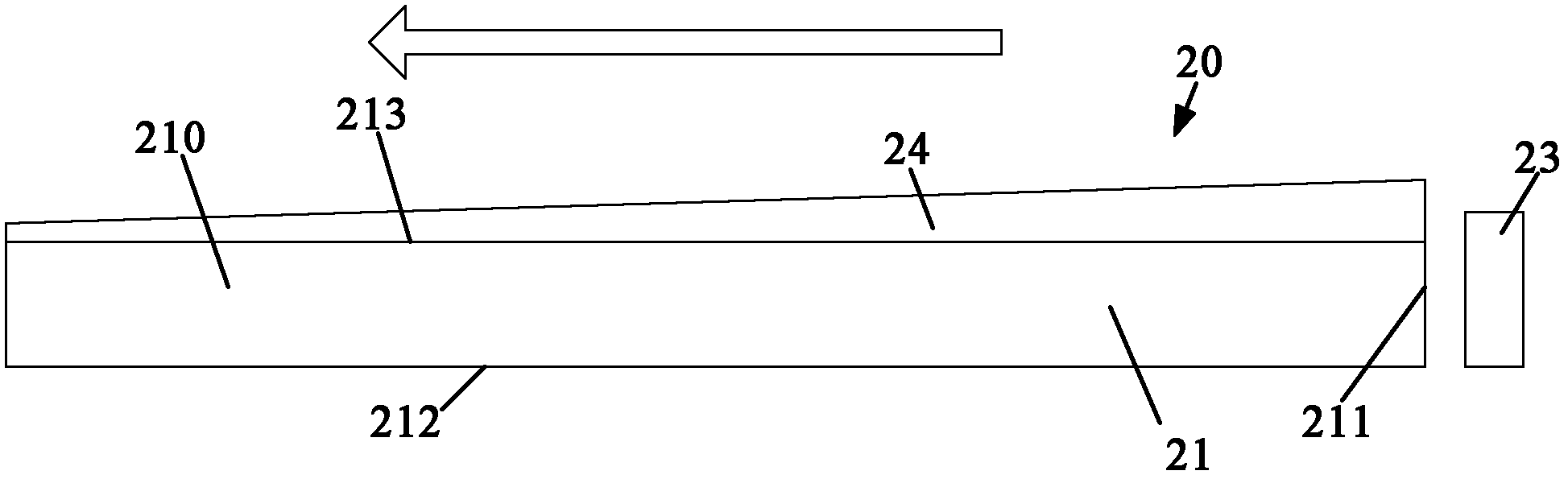

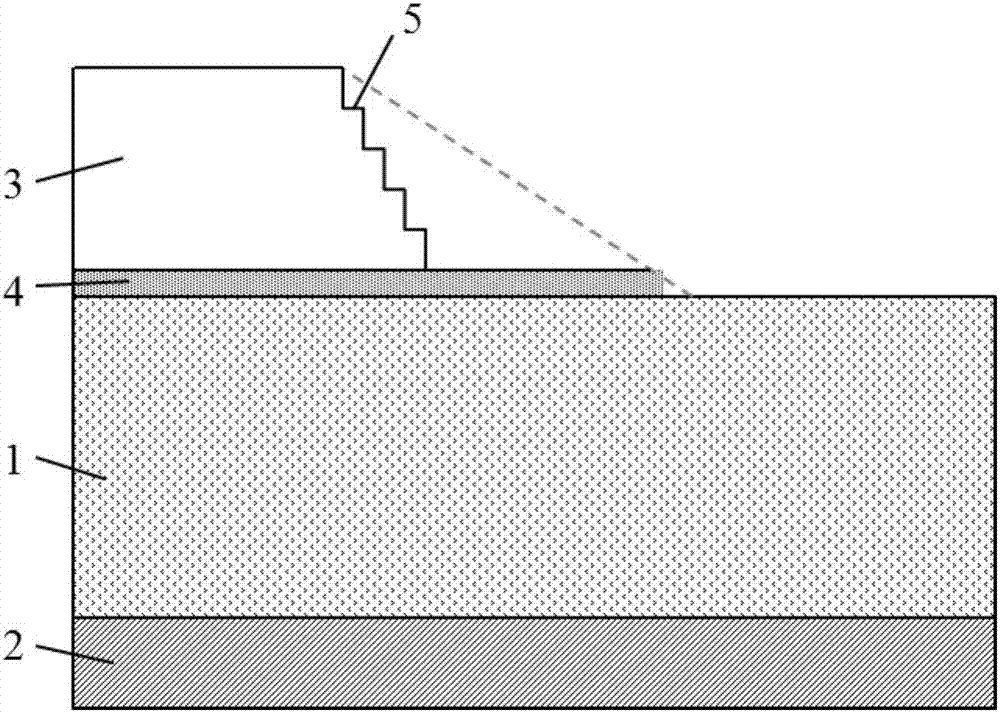

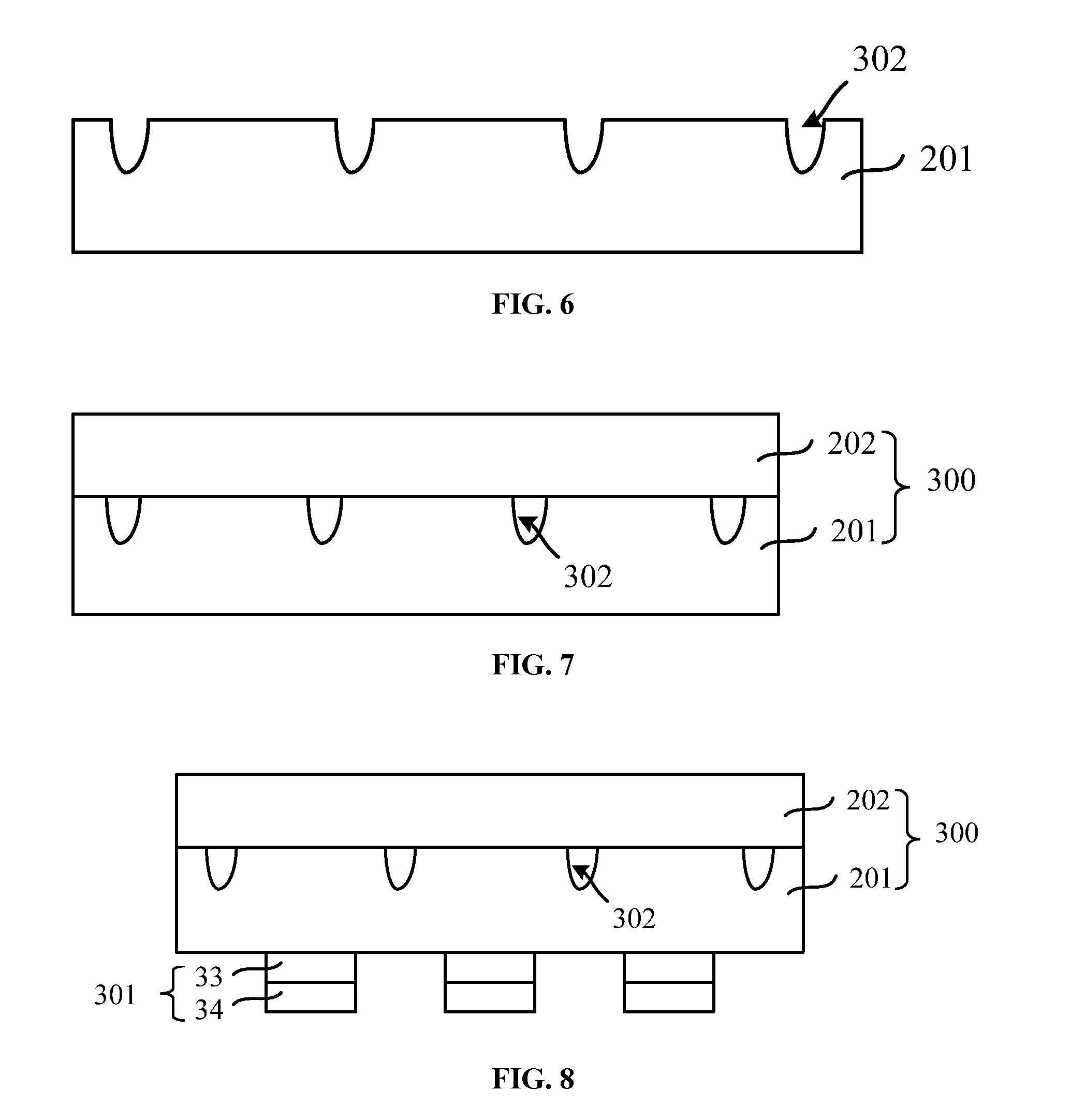

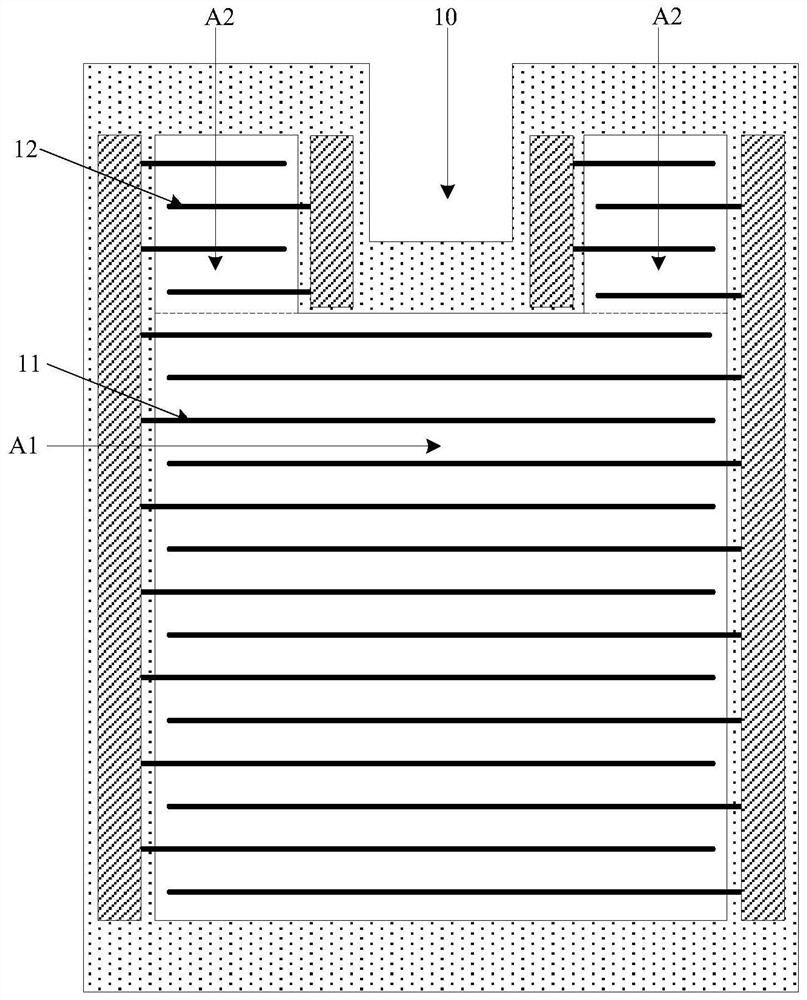

Color deviation balancing film, lateral incidence type backlight module and liquid crystal display device

InactiveCN102681049ALow absorbanceImprove the problem of chromaticity deviationPlanar/plate-like light guidesLighting device detailsLiquid-crystal displayEngineering

The invention provides a color deviation balancing film, a lateral incidence type backlight module and a liquid crystal display (LCD) device. The color deviation balancing film is applied to the lateral incidence type backlight module and the thickness of the color deviation balancing film is reduced progressively along the backlight irradiation direction. The color deviation balancing film is arranged in the lateral incidence type backlight module. The lateral incidence type backlight module with the color deviation balancing film is arranged in the LCD device. When the lateral incidence type backlight module with the color deviation balancing film is applied to the LCD device, the intensity difference of light at different positions along the backlight irradiation direction can be reduced, and the color deviation generated by the display picture can be effectively improved.

Owner:BOE TECH GRP CO LTD +1

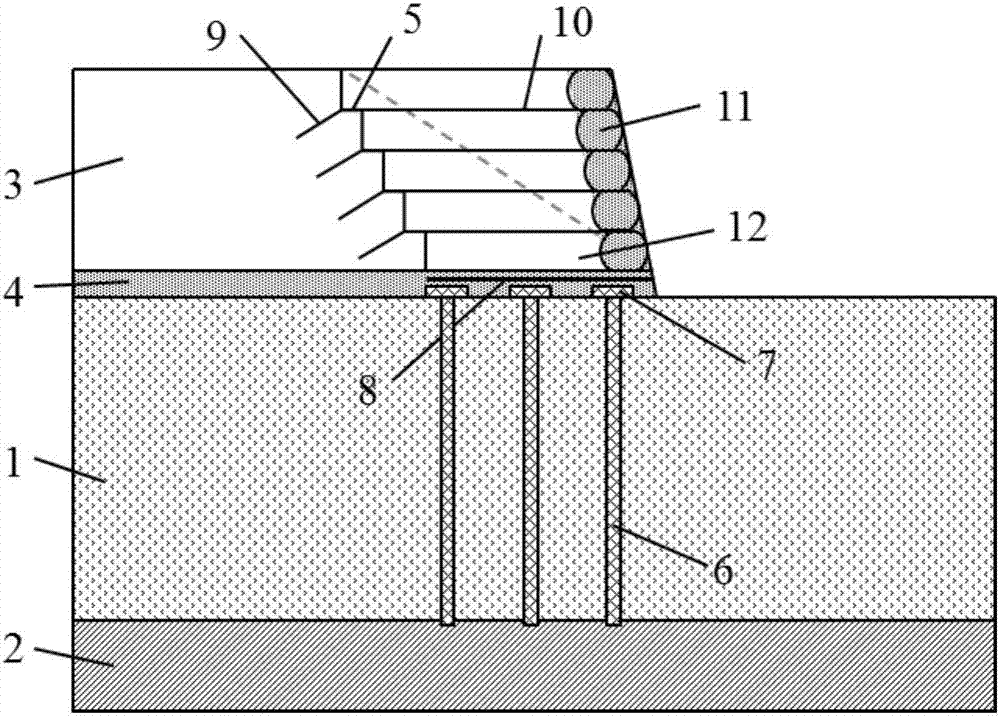

Soft soil area roadbed widening structure and construction method thereof

InactiveCN106988178AReduce processing widthReduce processing costsRoadwaysExcavationsCushionSmall footprint

The invention belongs to the technical field of roadbed widening and relates to a soft soil area roadbed widening structure and a construction method thereof. The soft soil area roadbed widening structure comprises an old roadbed, a gravel cushion layer, a soft soil stratum and a lower lying supporting layer which are arranged successively from top to bottom and further comprises vertical pile bodies, connecting pieces and reinforced retaining walls. The vertical pile bodies punch through the soft soil stratum and are supported on the lower lying supporting layer; the gravel cushion layer is laid on the tops of the vertical pile bodies; steps are arranged in the position, on a slide slope after substantial slope cutting, of the old roadbed; the slope ratio of the slide slope after slope cutting is (1:0.5)-(1:1); the reinforced retaining walls are arranged on the gravel cushion layer and are buckled with the steps of the slide slope of the old roadbed; and the connecting pieces are placed on the combination parts of the reinforced retaining walls and the old roadbed and are connected with the reinforced retaining walls and the old roadbed correspondingly. The invention provides the roadbed widening structure and the construction method thereof, the occupied area is small, the foundation treatment cost is low, the filler requirement is few, construction efficiency is high, the structure is stable, and the roadbed widening structure and the construction method thereof are especially suitable for roadbed widening engineering in coastal soft soil areas.

Owner:HUAZHONG UNIV OF SCI & TECH

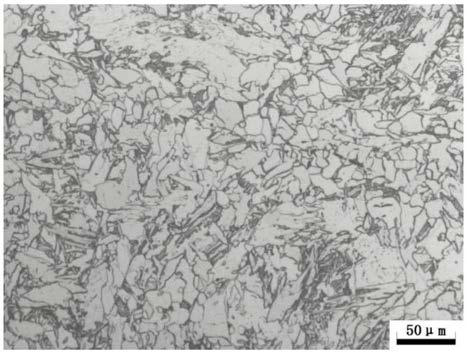

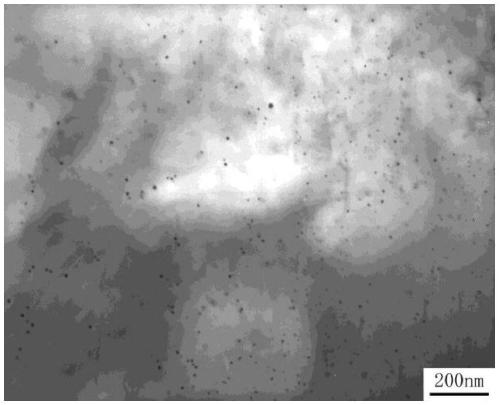

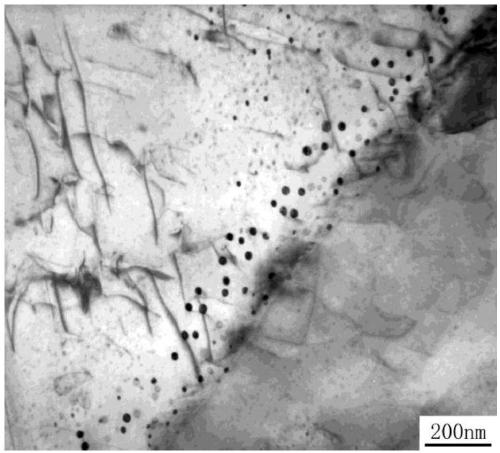

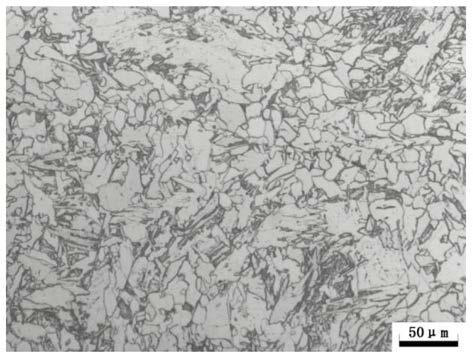

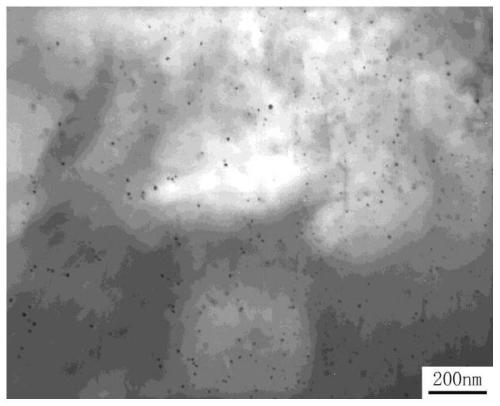

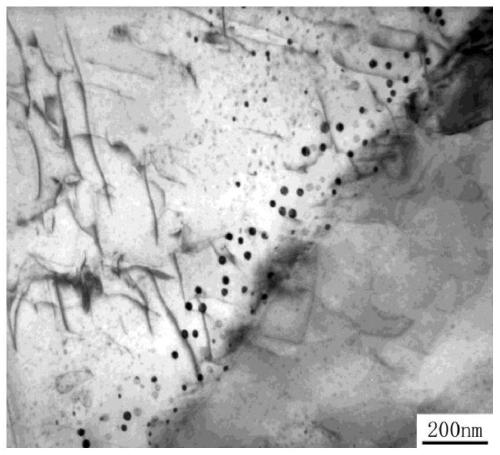

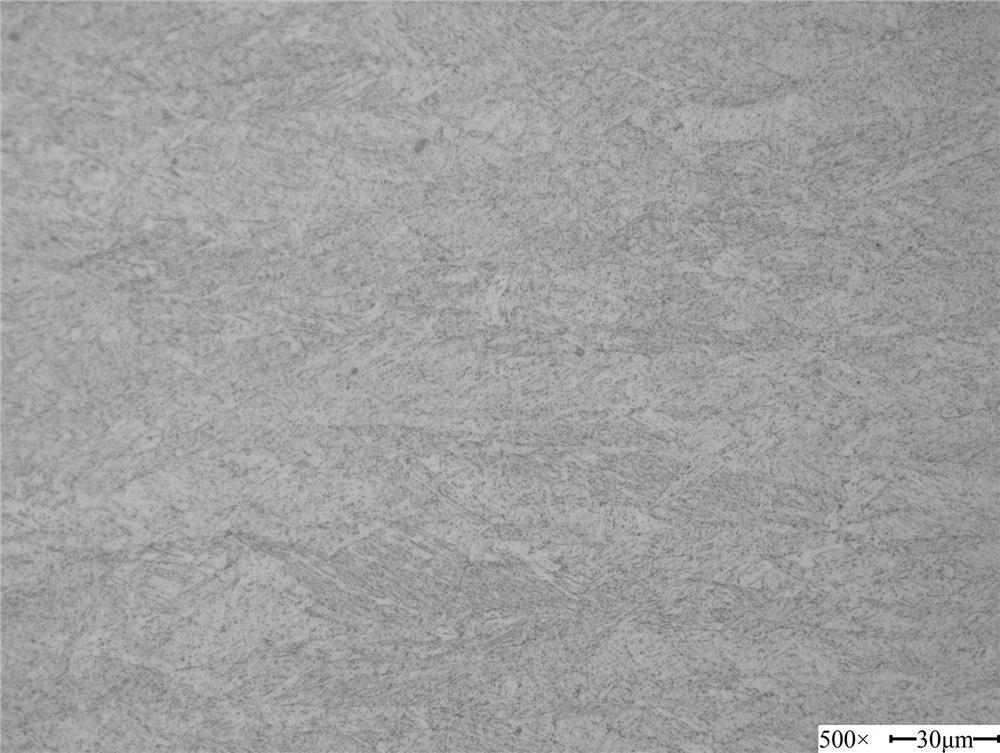

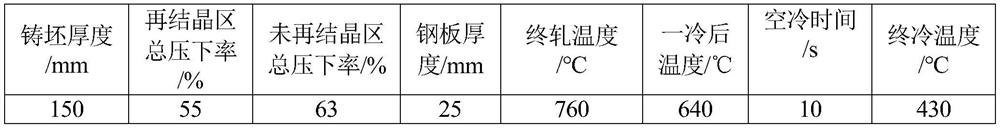

High-strength and high-plasticity 1000 Mpa grade hot rolled steel plate and preparation method thereof

The invention discloses a high-strength and high-plasticity 1000 Mpa grade hot rolled steel plate and a preparation method thereof. The high-strength and high-plasticity 1000 Mpa grade hot rolled steel plate is prepared from the following components by weight: 0.05%-0.40% of C, 1.00%-5.00% of Mn, 0.70%-1.60% of Si, 0.1%-1.00% of Al, 0.01%-0.10% of Nb, 0.01%-0.10% of V, 0.002%-0.005% of N and the balance Fe and inevitable impurities. The steel plate has high strength and high plasticity, and Nb and V microalloy elements are added to be combined with C and N to form nanoscale cluster precipitates, so that matrix structures are strengthened. Through chemical composition design, and combined with medium temperature coiling, the nanoscale cluster precipitates with small size, uniform distribution and high density can be obtained, the strength of ferrite is obviously strengthened, the strength difference between the two matrix structures (ferrite and martensite) is reduced, the ferrite grainsize is refined at the same time, and high reaming performance is obtained.

Owner:武汉钢铁有限公司

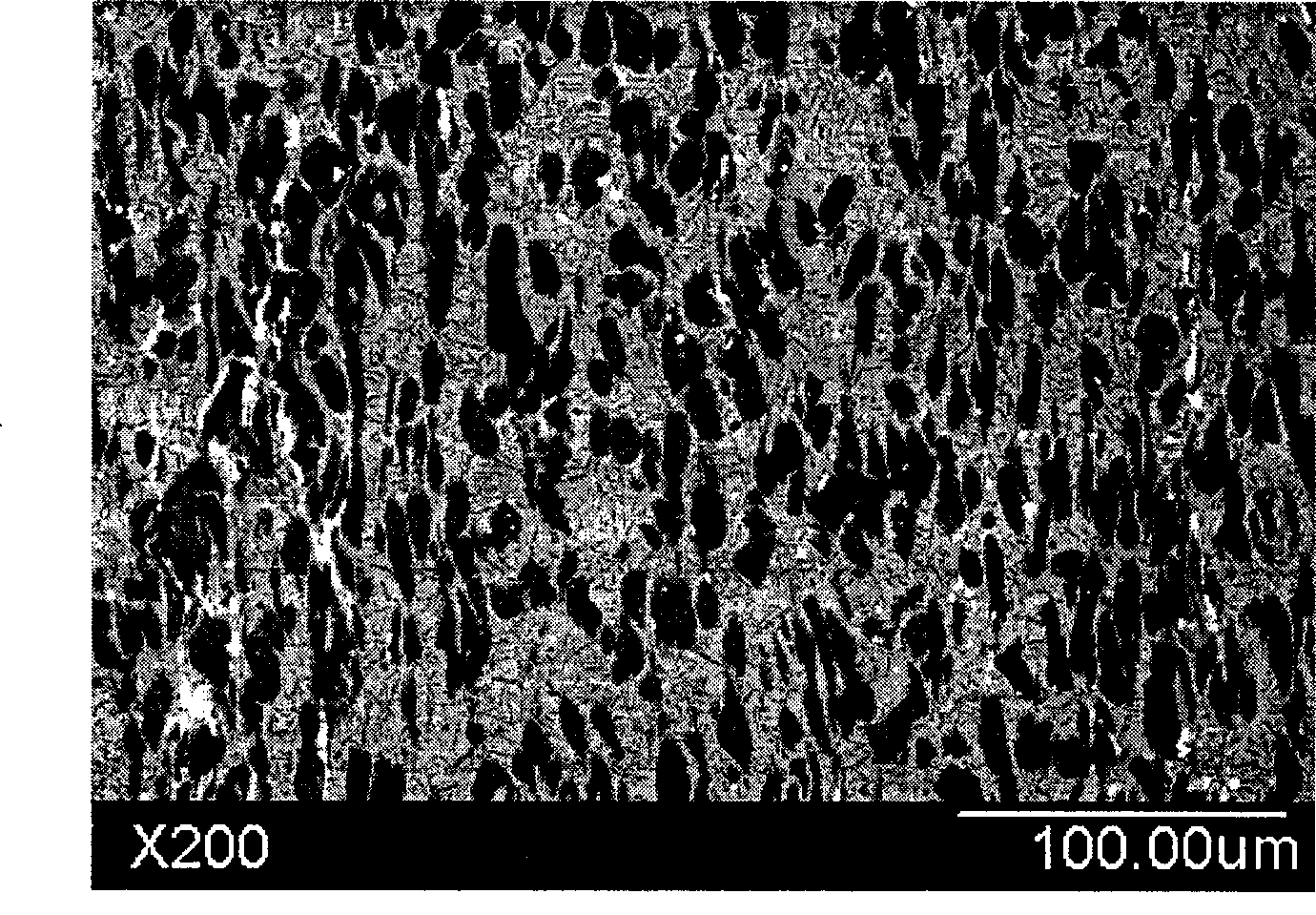

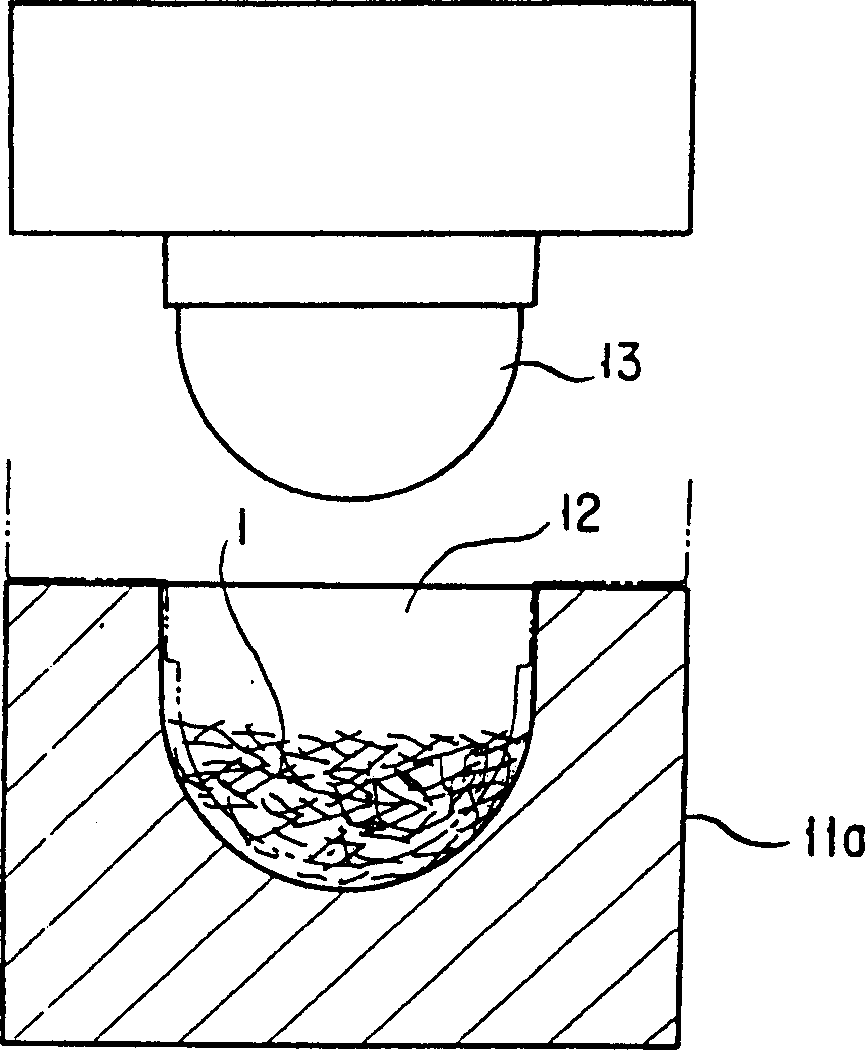

Production method for Gamma-TiAl alloy bar

InactiveCN101518794APrevent surface oxidationGood surface qualityExtrusion control devicesBase-materialsCrystalliteFiber

The invention relates to a production method for a bar, in particular to a production method for a Gamma-TiAl alloy bar. The production method solves the problems that a Gamma-TiAl alloy bar produced by the prior method has the defects of surface cracks, uneven diameter, uneven size of crystal grains and easy fusion caused by the reaction of Gamma-TiAl alloy and blank at high extrusion temperature. The production method comprises the steps: heating a cast ingot, keeping temperature and annealing; cutting a cylinder in the cast ingot, packaging aluminum silicate fibers, placing in the middle of a stainless steel pipe, and sealing both ends to obtain the blank; washing the sheathed blank, drying and heating the sheathed blank, keeping temperature, placing the sheathed blank in the air, putting the sheathed blank into a cup pre-pressured by glass lubricant, putting the sheathed blank into a mould to extrude to obtain the bar; annealing the bar, taking the bar out of a blast furnace for air cooling, and obtaining the Gamma-TiAl alloy bar. The obtained bar has the advantages of no surface cracks, even diameter, even size of crystal grains and no fusion caused by the reaction of the Gamma-TiAl alloy and the sheath.

Owner:HARBIN INST OF TECH

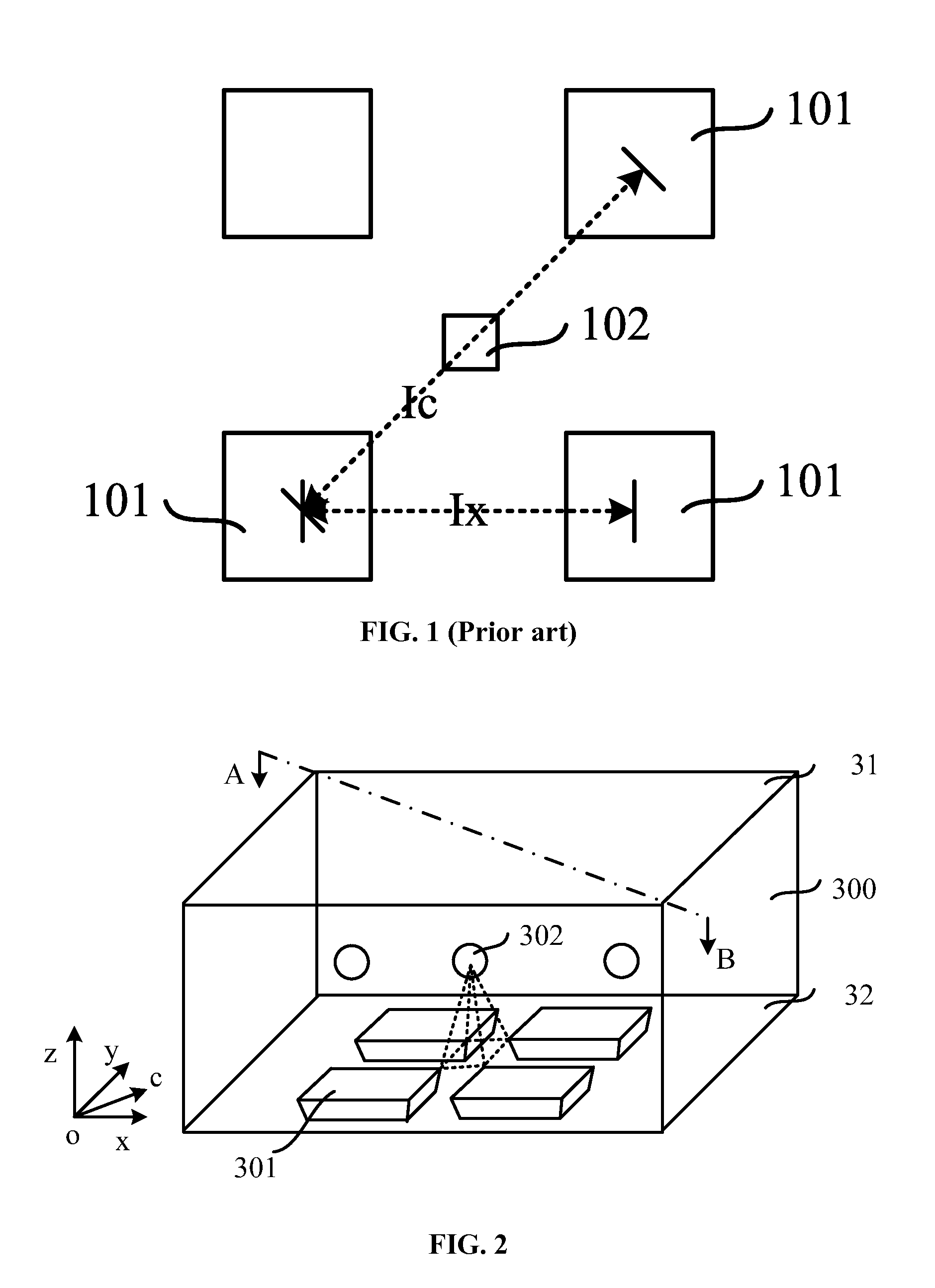

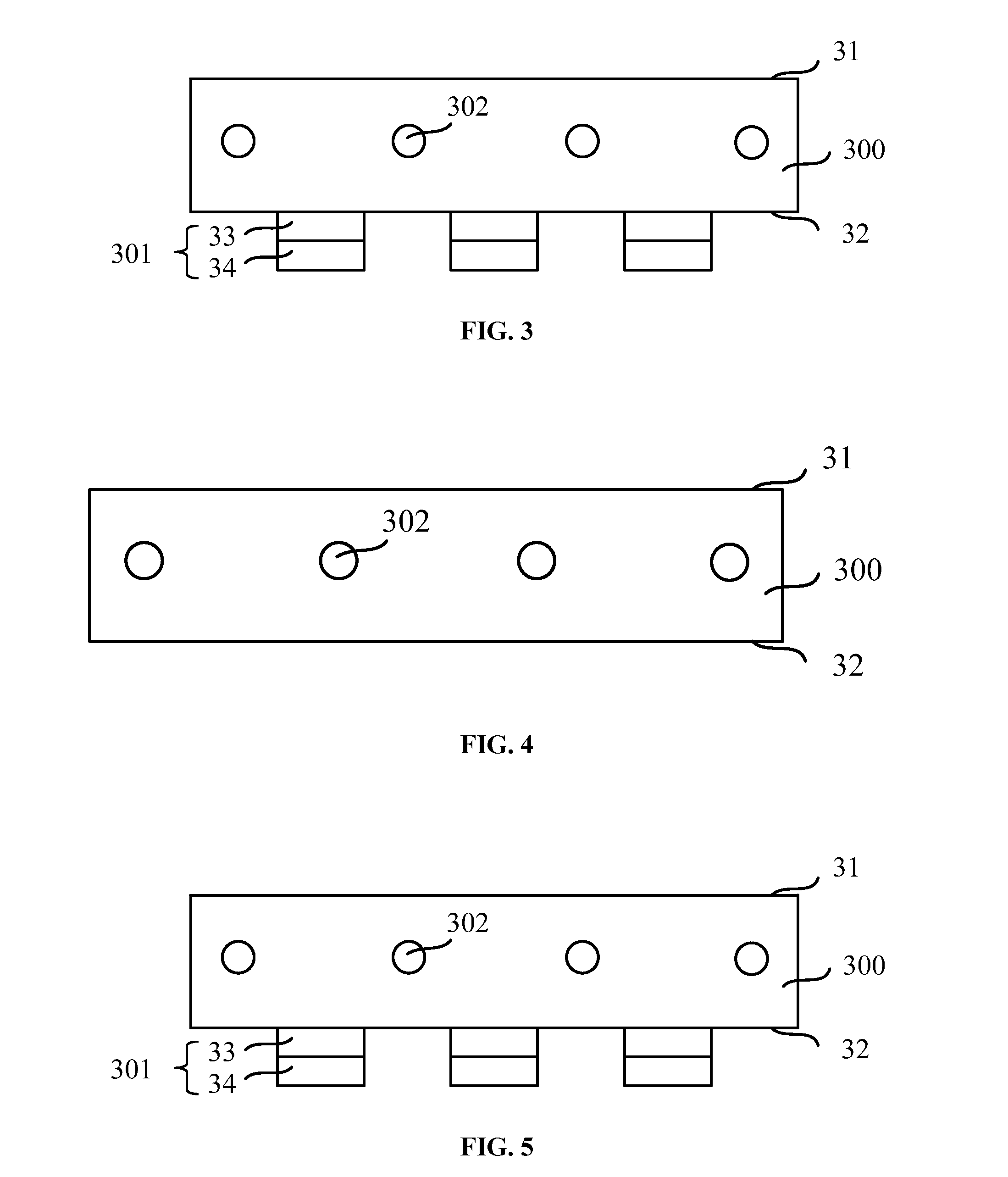

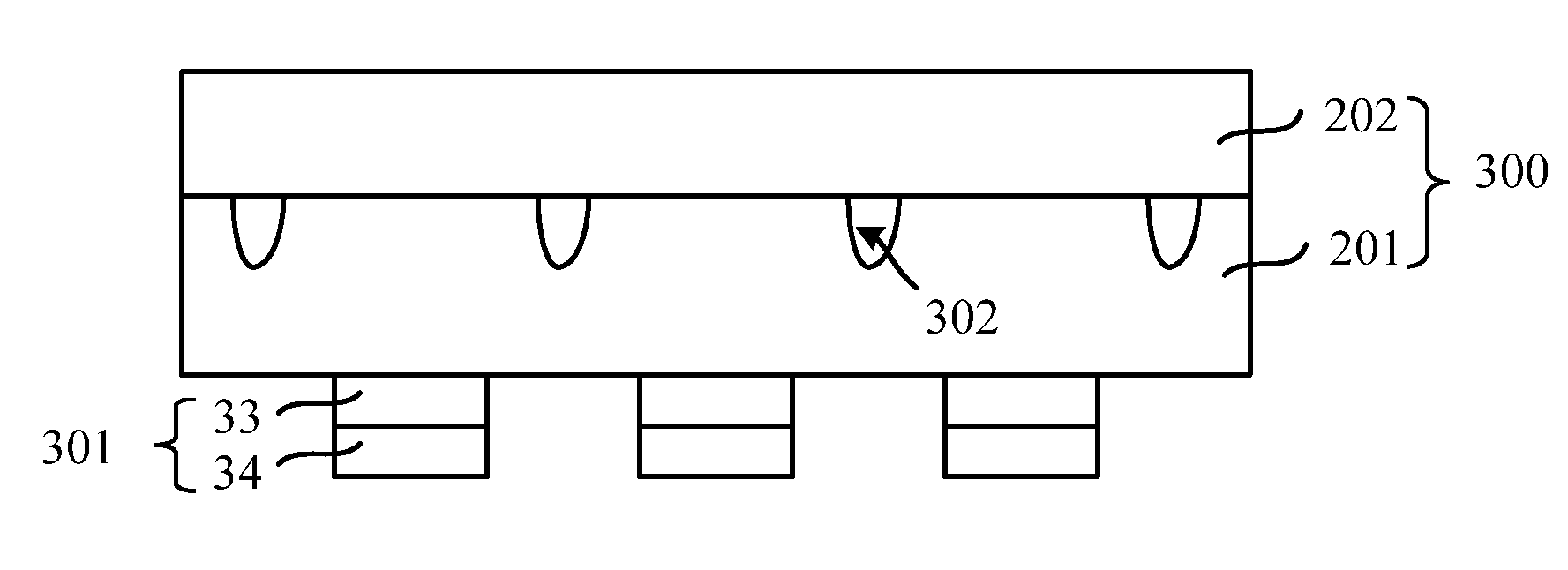

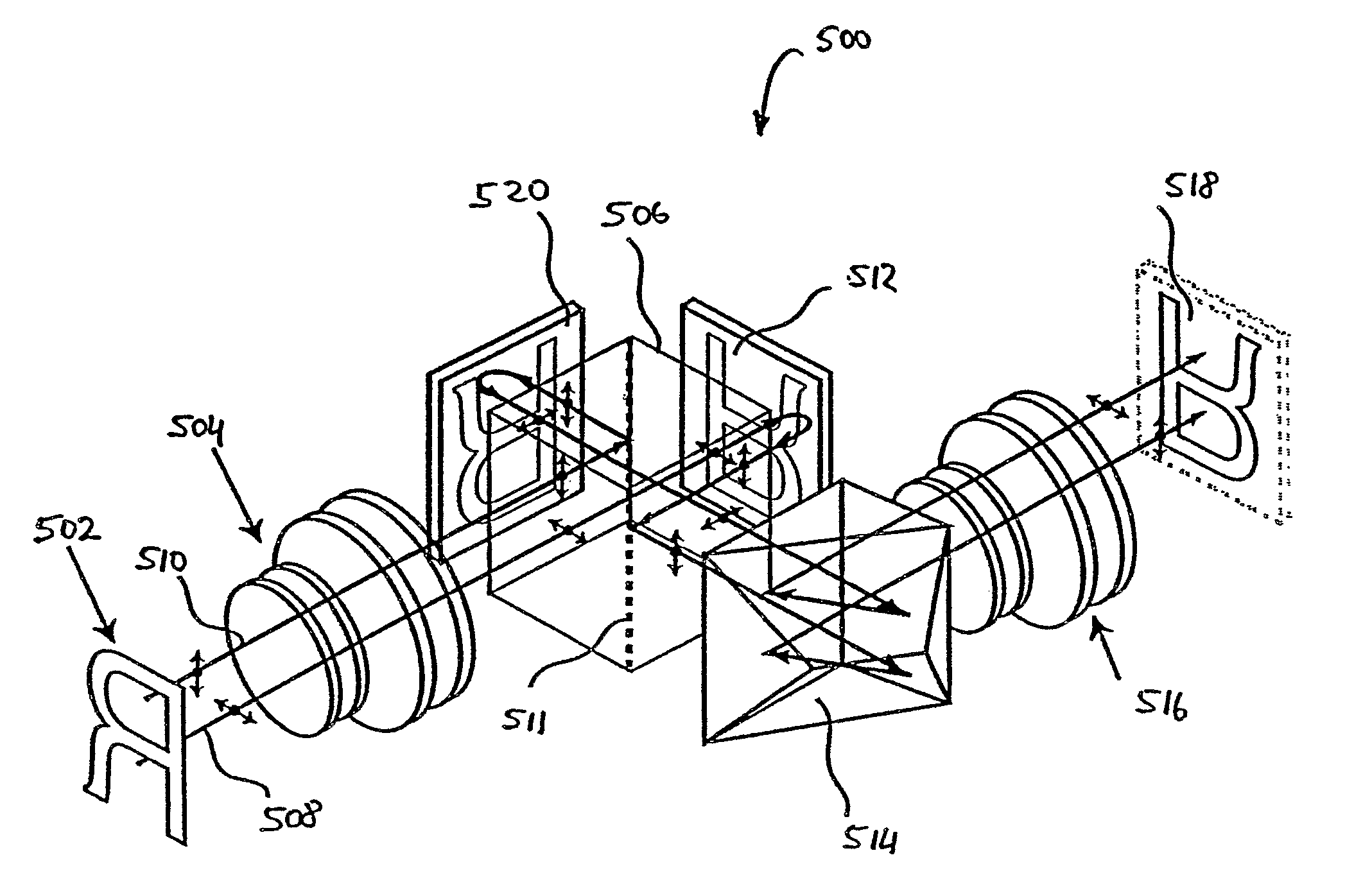

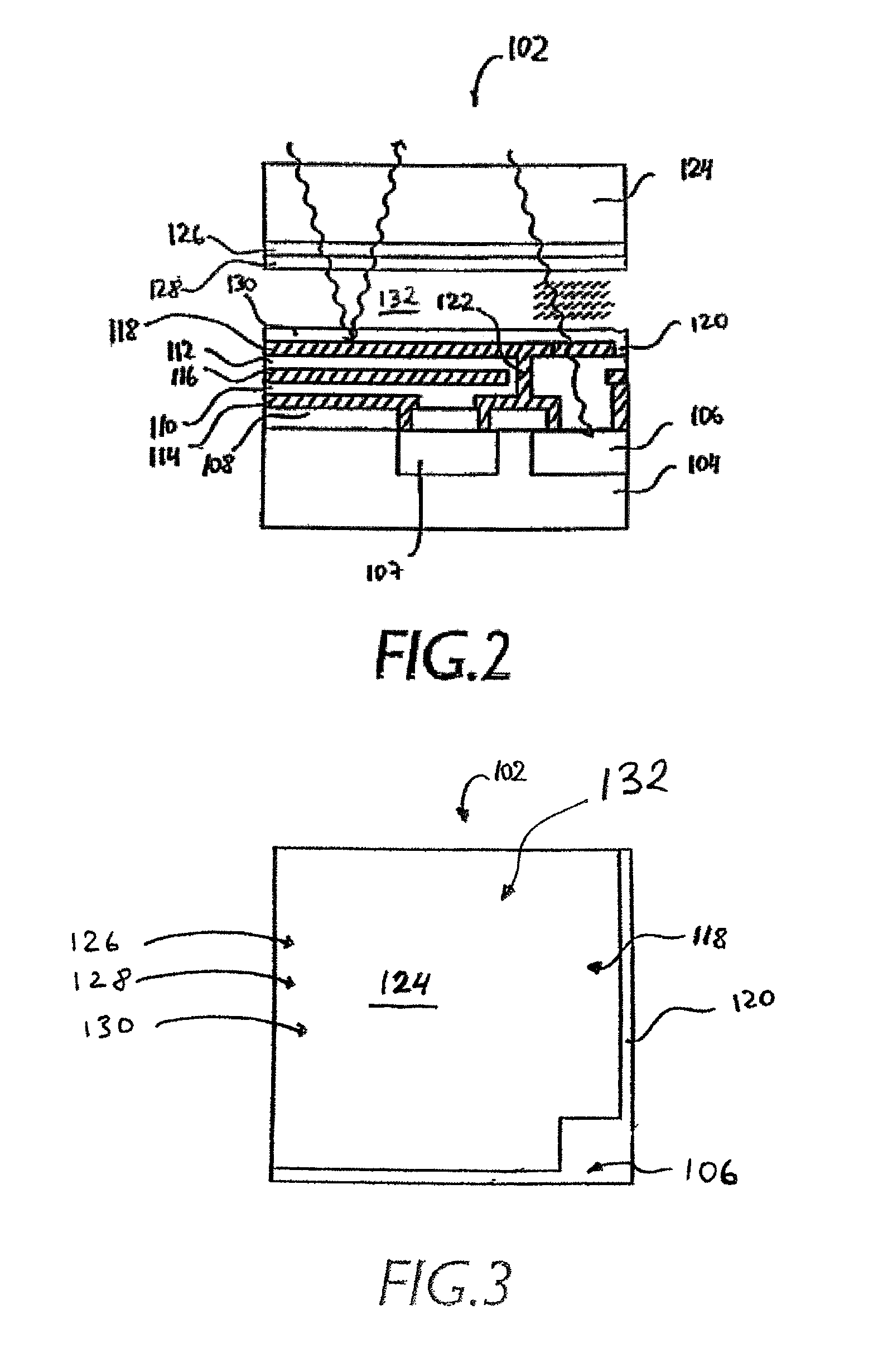

Photolithographic masks and fabrication method thereof

ActiveUS20150037714A1Reduce intensity differencesIncrease contrastOriginals for photomechanical treatmentRefractive index

A photolithographic mask is provided. The photolithographic mask includes a substrate having a first surface configured as a light incidence plane of an exposure light and a second surface. The photolithographic mask also includes a plurality of scattering centers functioning as a refractive index disturbance inside the substrate. Further, the photolithographic mask includes a plurality of mask patterns on the second surface of the substrate.

Owner:SEMICON MFG INT (SHANGHAI) CORP

High-strength polypropylene material and preparation method thereof

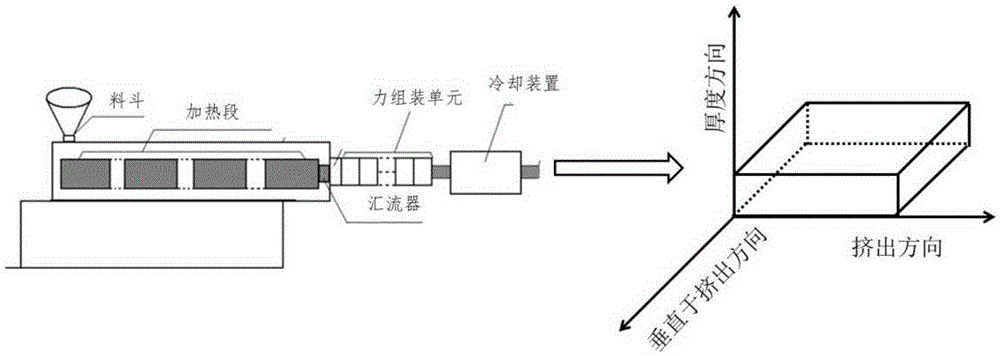

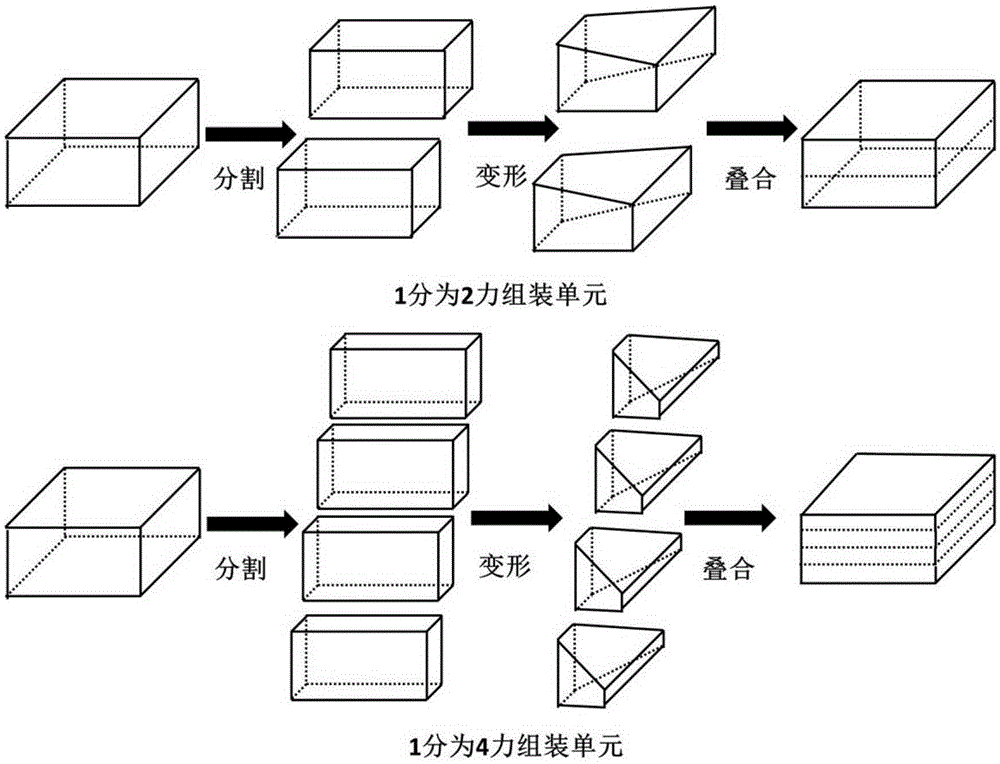

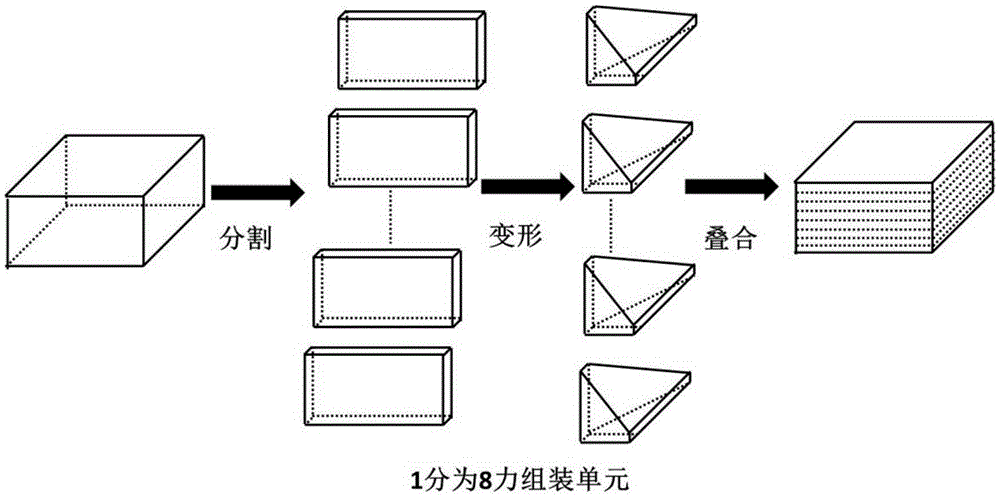

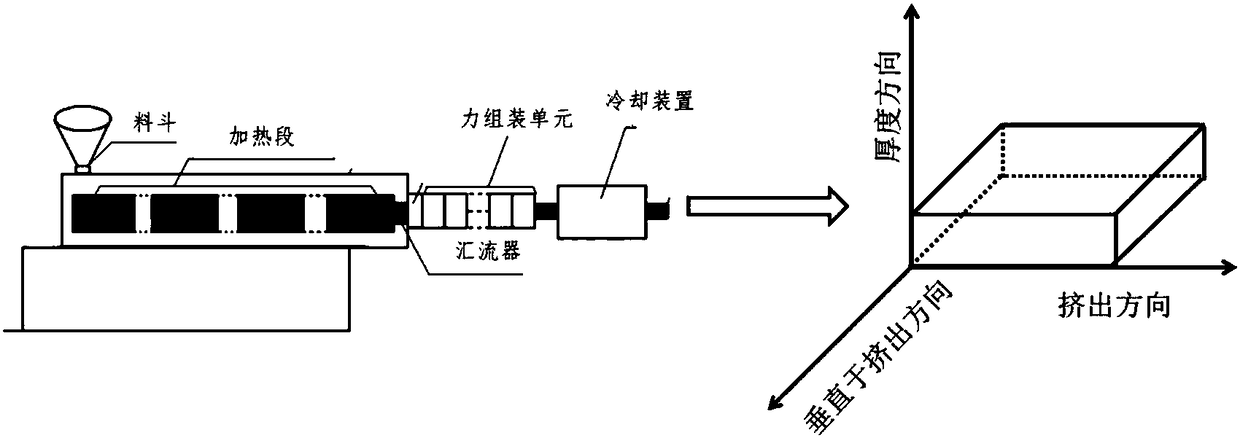

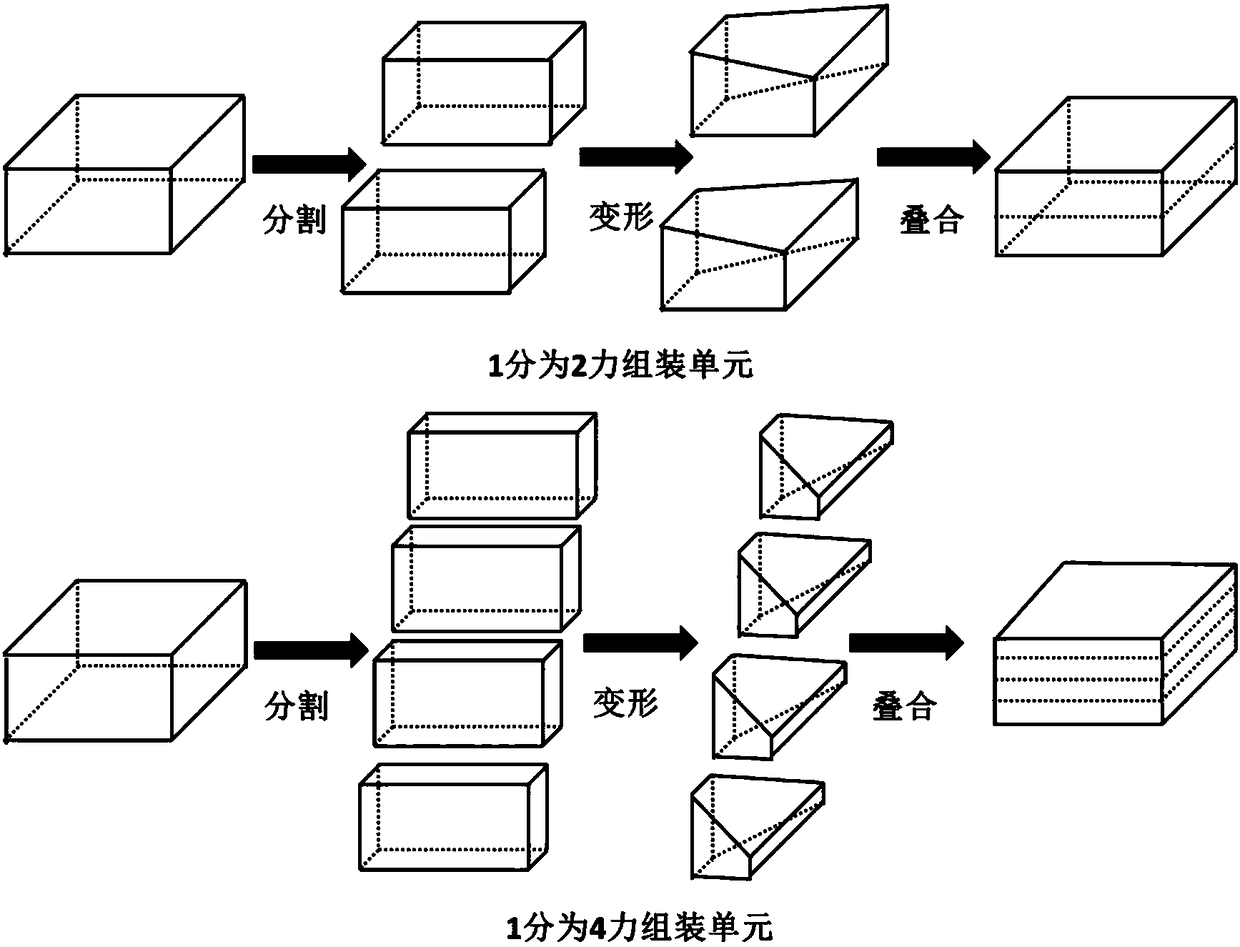

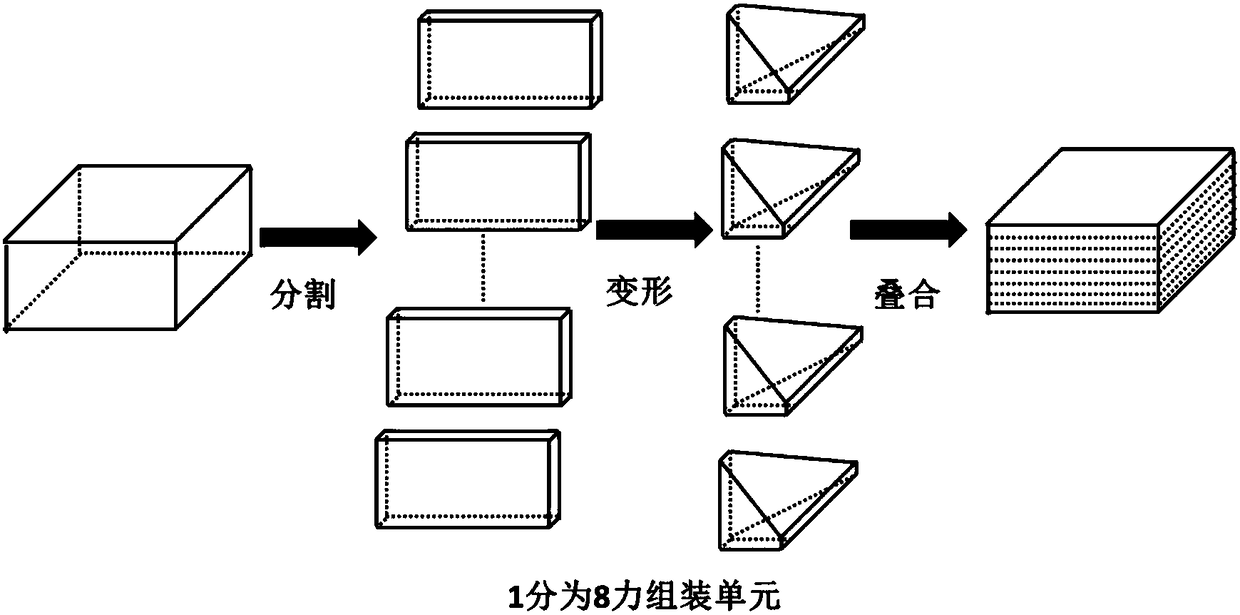

The invention discloses a preparation method of a high-strength polypropylene material. The preparation method is characterized in that in the machining process, the crystal habit of polypropylene is regulated and controlled, and therefore the mechanical performance of polypropylene is improved. In the machining process, a certain shear and two-way stretch force field is applied to polypropylene melt by regulating the number and type of force assembling units, under the action of the force field, the crystal habit of polypropylene is developed into shish-kebab structures orientated in different directions, the stretch strength of the polypropylene material can be remarkably improved, and the difference of the mechanical strength, in the extrusion direction, of the polypropylene product and the mechanical strength in the direction perpendicular to the extrusion direction, of the polypropylene product is weakened. The force assembling units are added to existing traditional extrusion equipment, operation is easy, continuous production can be achieved, control is convenient, quality is stable, production efficiency is high, and good industrial and market prospects are achieved; and the method can be widely applied to preparing high-strength polypropylene plate, sheet and film materials.

Owner:SICHUAN UNIV

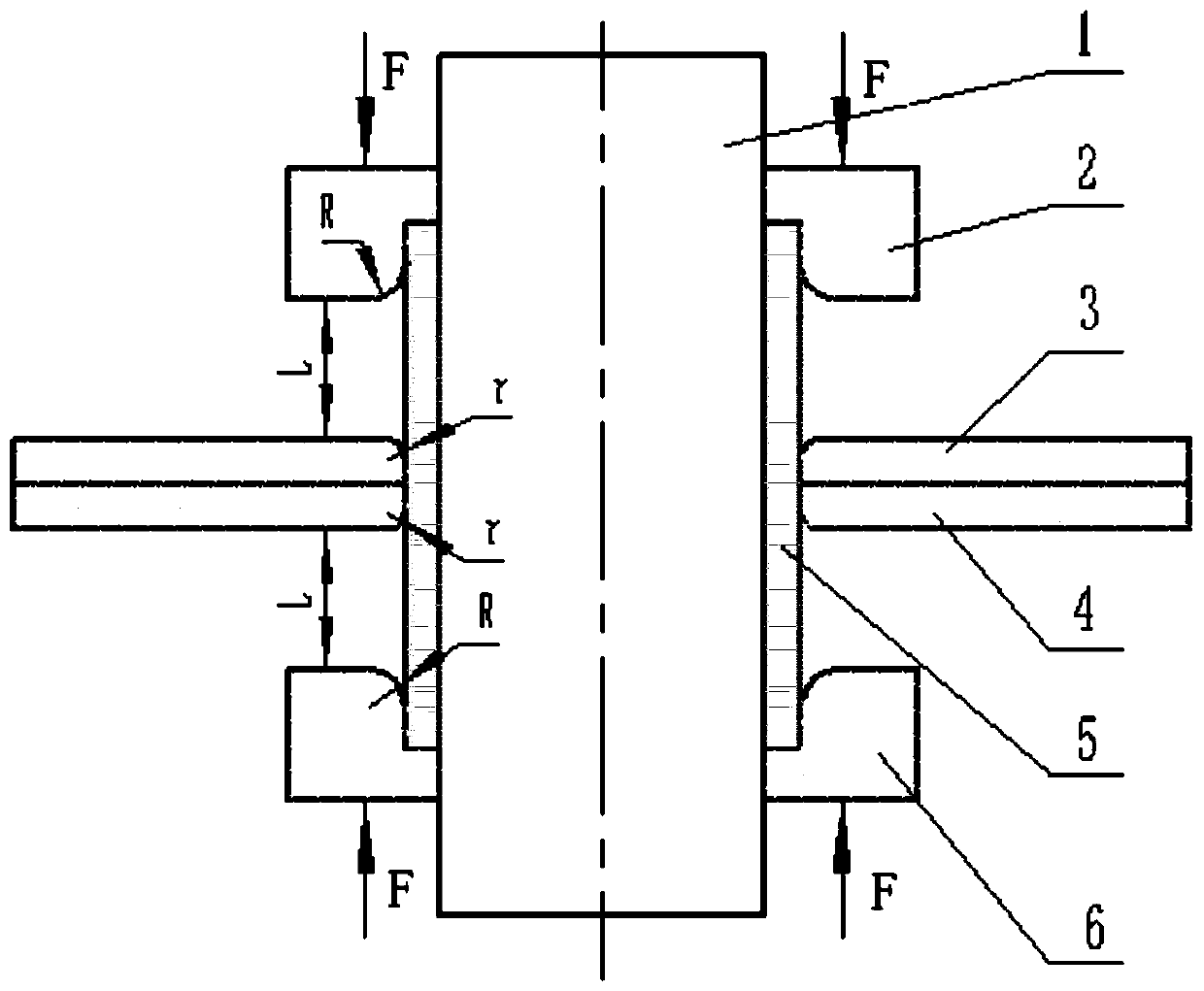

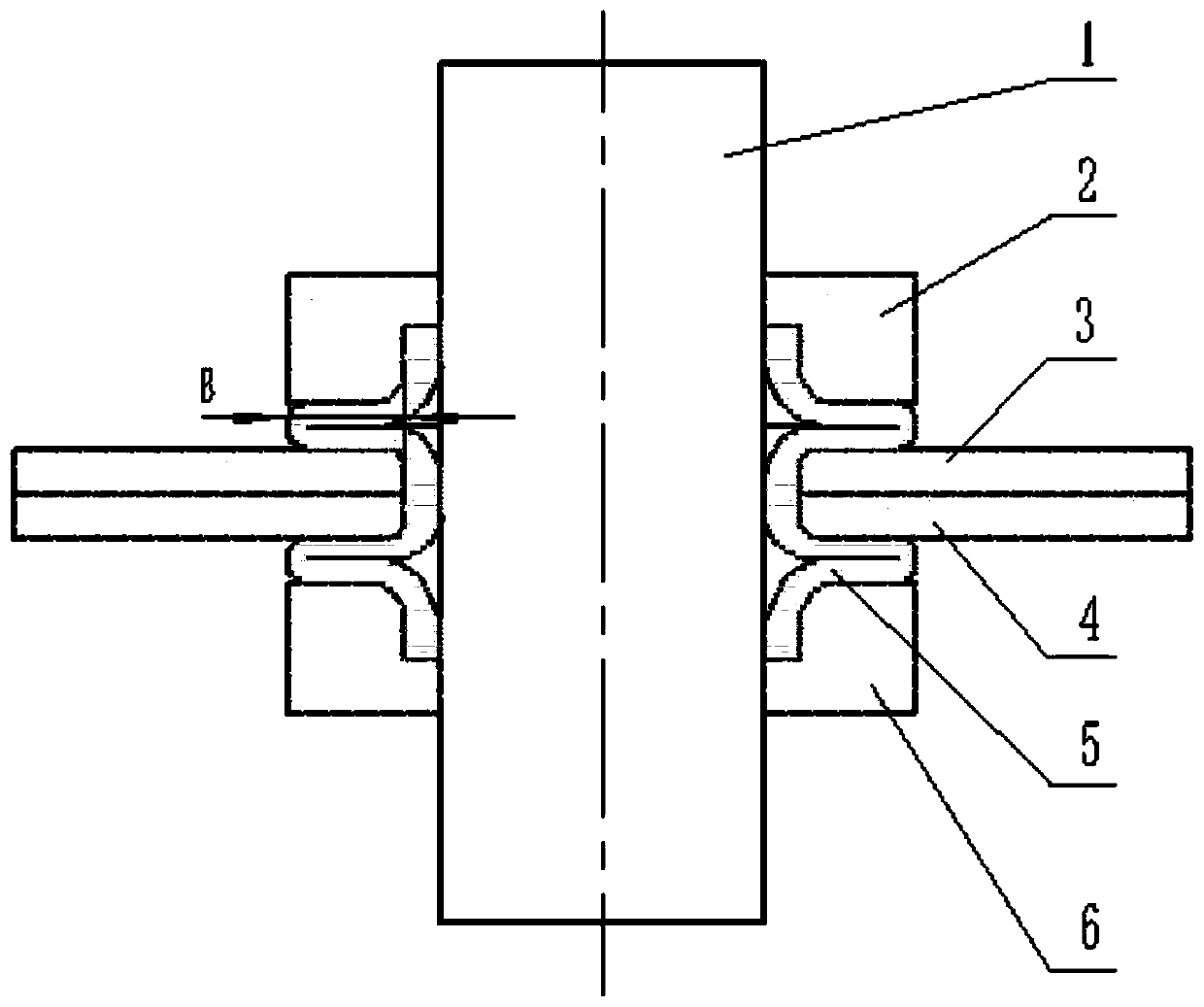

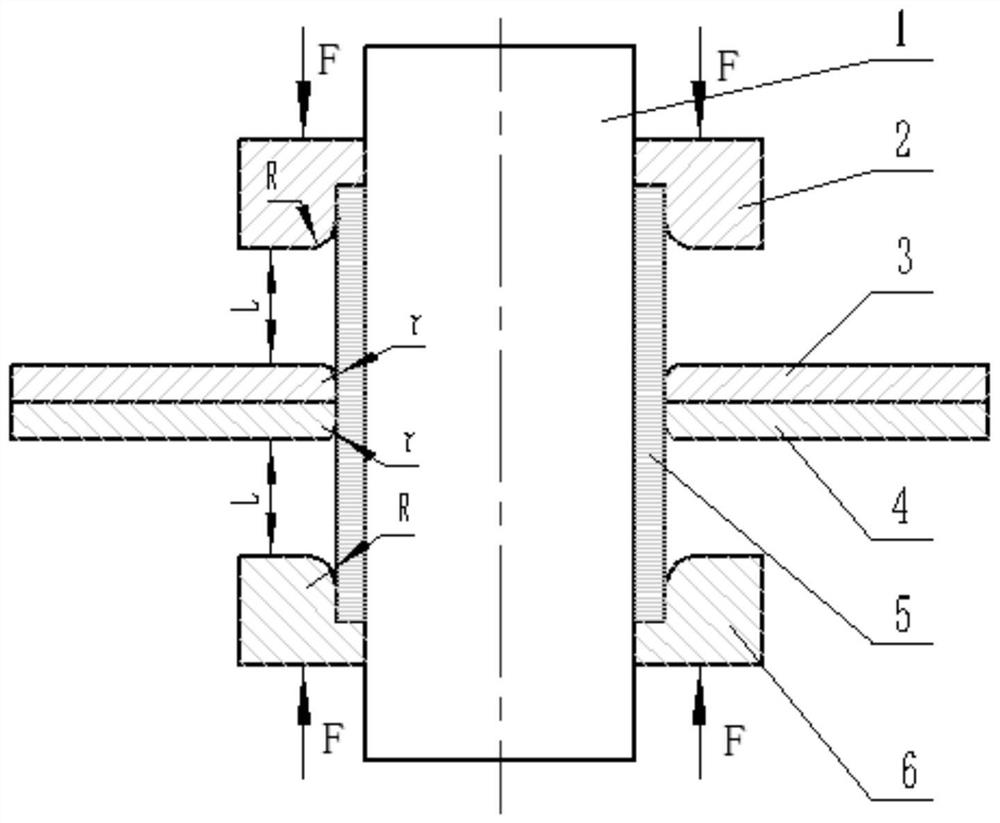

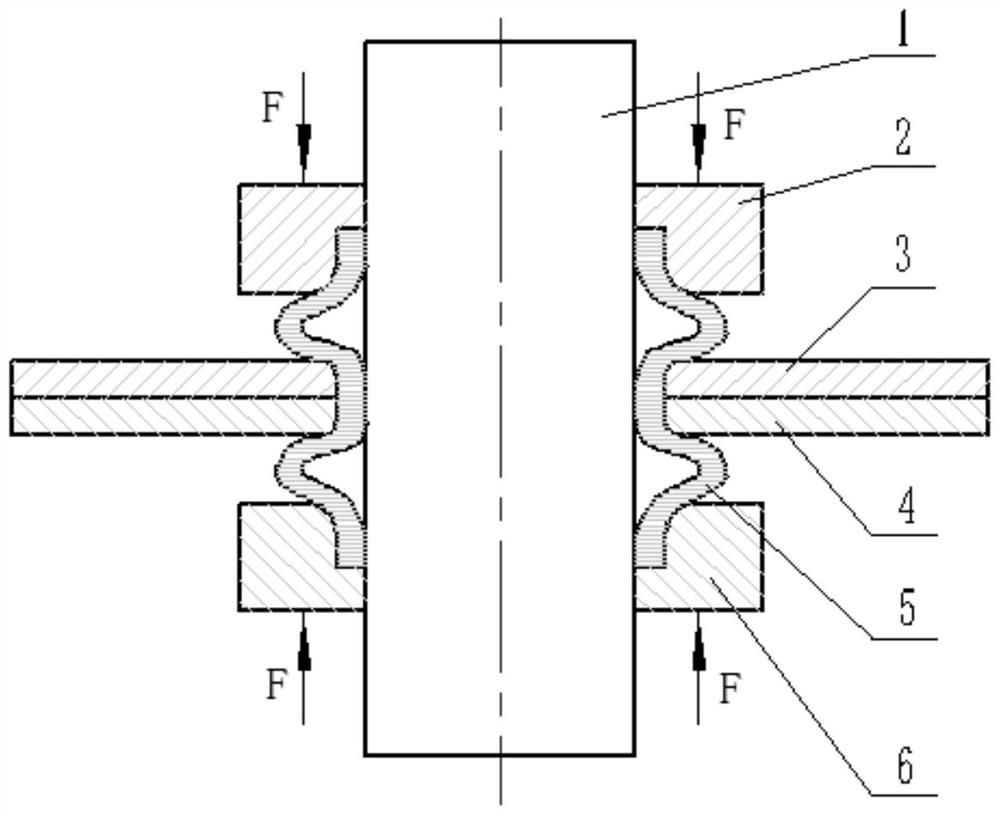

Method for achieving circular ring connection by utilizing wrinkling of metal pipes

ActiveCN110538931AHigh strengthSafe and reliable connectionShaping toolsEngineeringMechanical engineering

The invention discloses a method for achieving circular ring connection by utilizing wrinkling of metal pipes, and belongs to the technical field of material connection. The phenomenon that a connecting pipe deforms plastically under the action of force is utilized, so that the connecting pipe is wrinkled in a non-constraint area, the wrinkles are further compacted so as to achieve the plastic connection between two metal rings. After plastic deformation of the connecting pipe, the strength of the connection part can be enhanced due to deformation strengthening, so that the connection is safeand reliable; and the number of preparatory steps is few, the operation is simple and convenient, the whole connecting process is green and pollution-free, and the operation is simple, convenient andefficient.

Owner:SHAANXI UNIV OF SCI & TECH

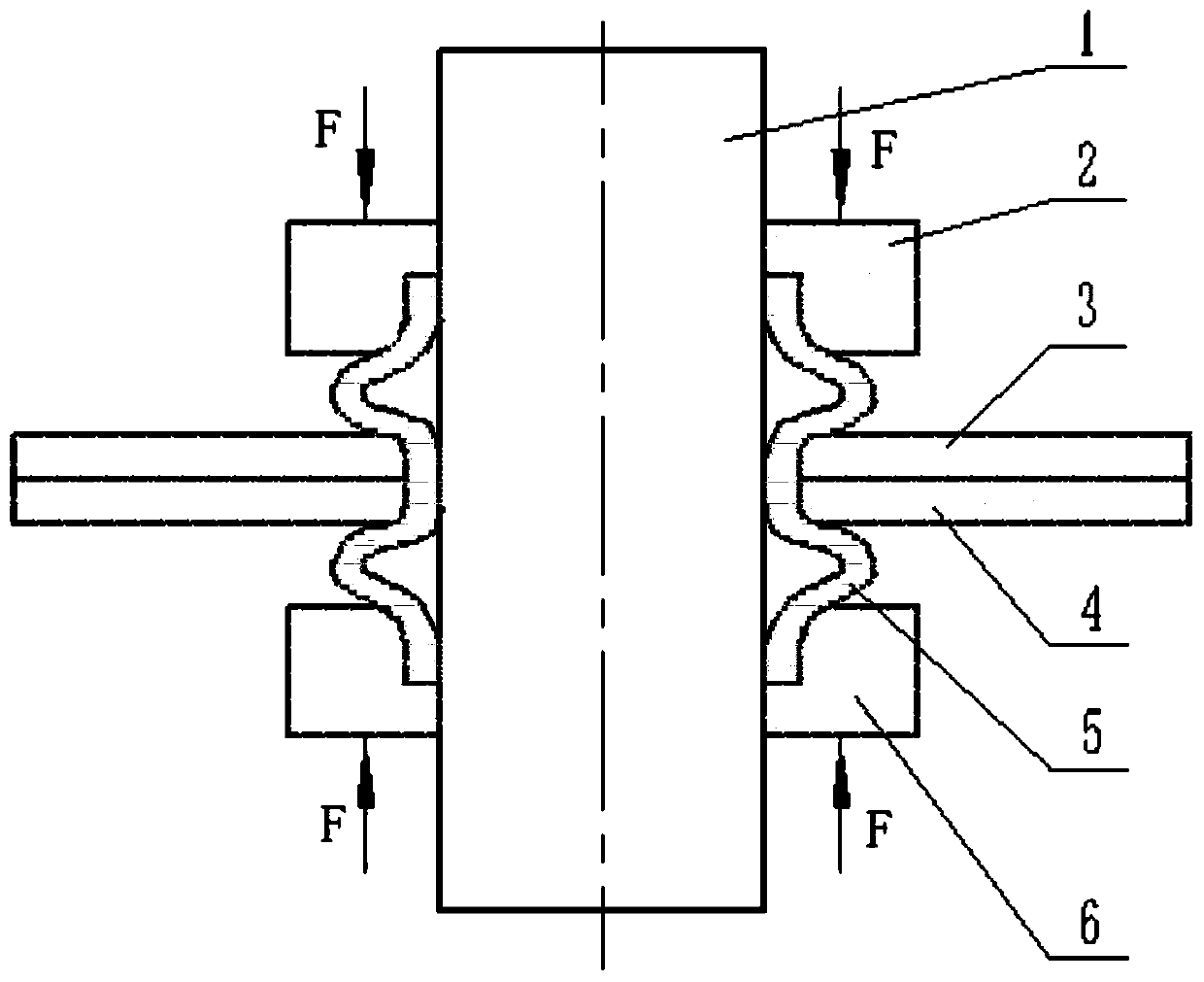

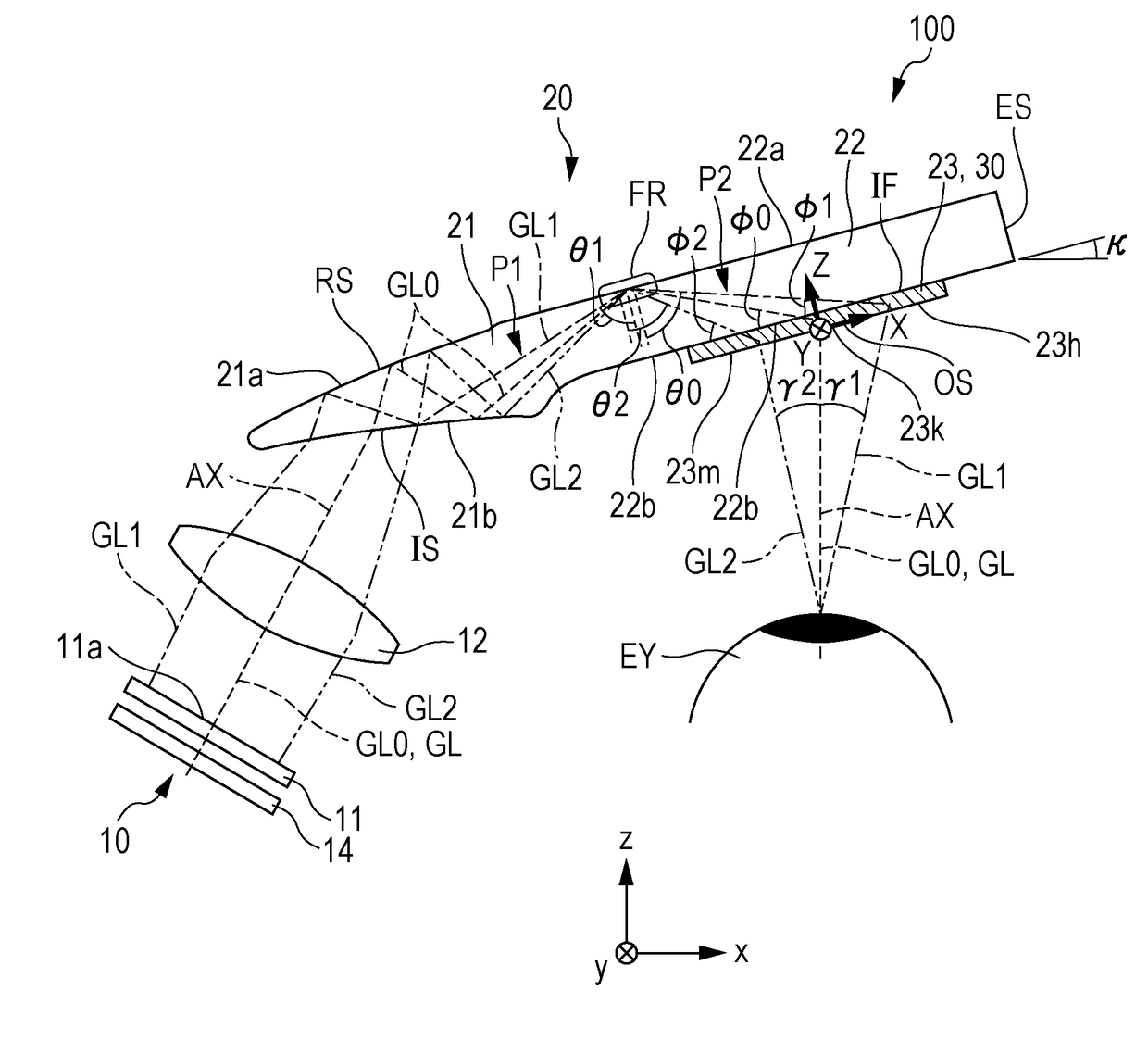

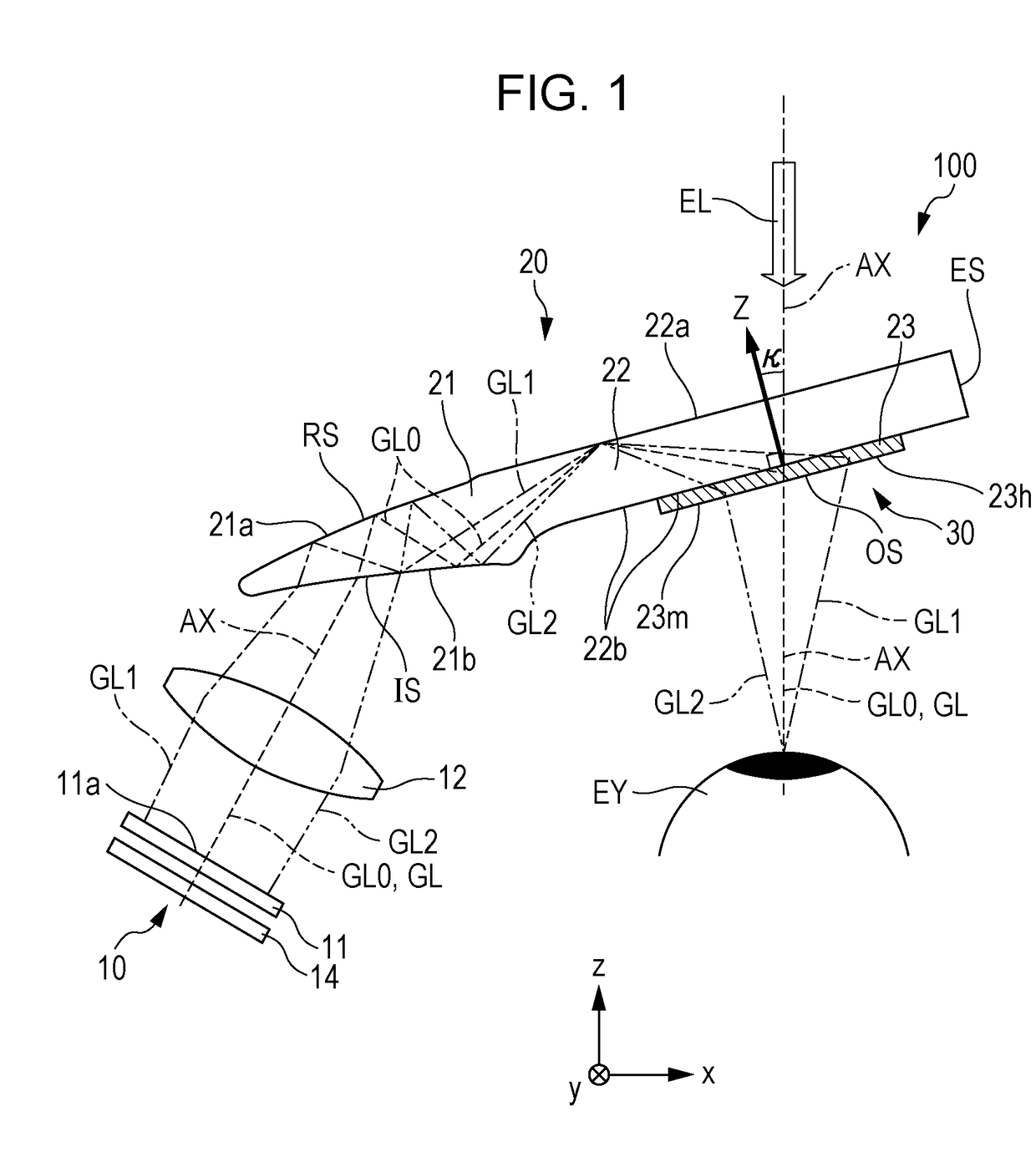

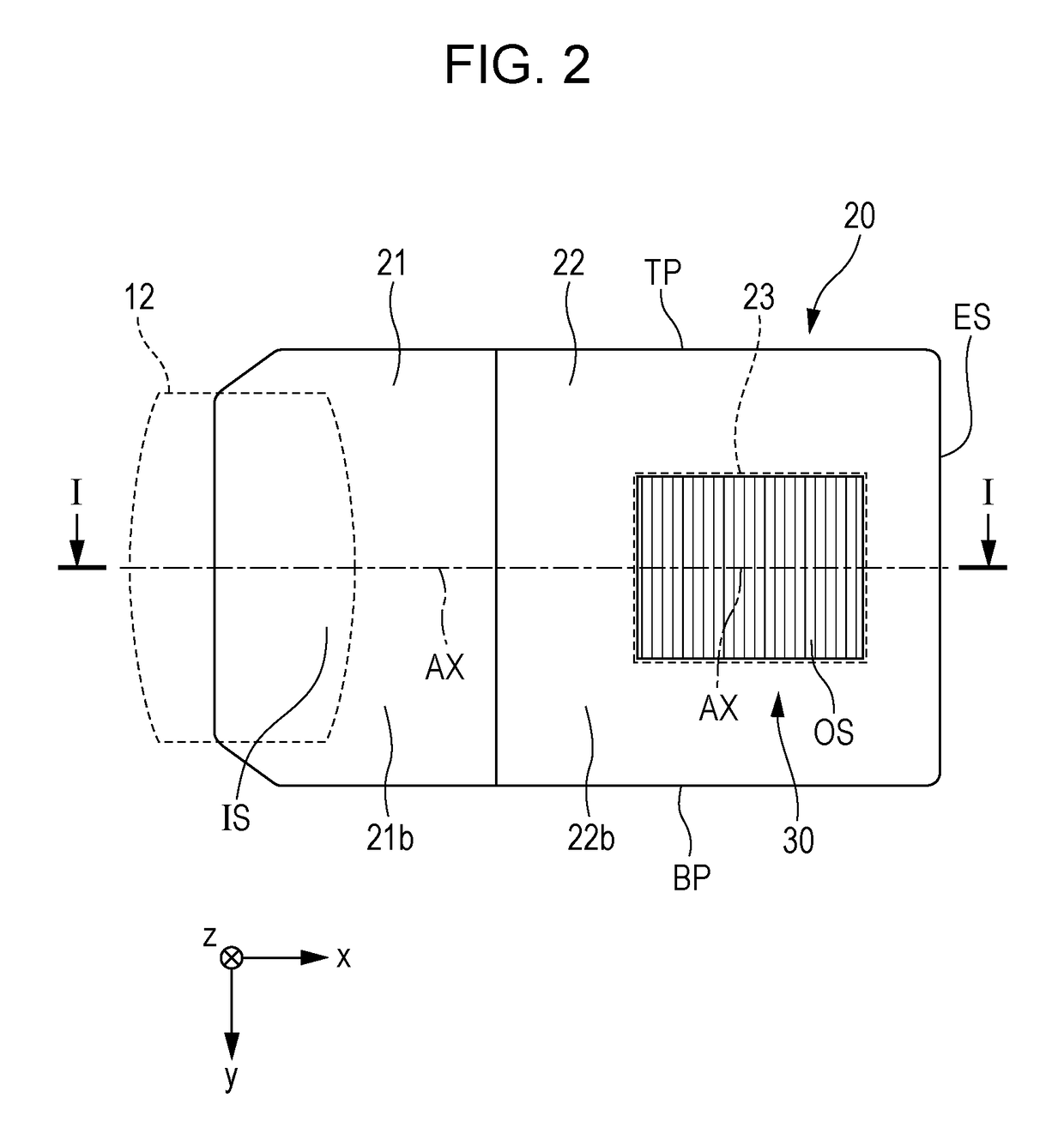

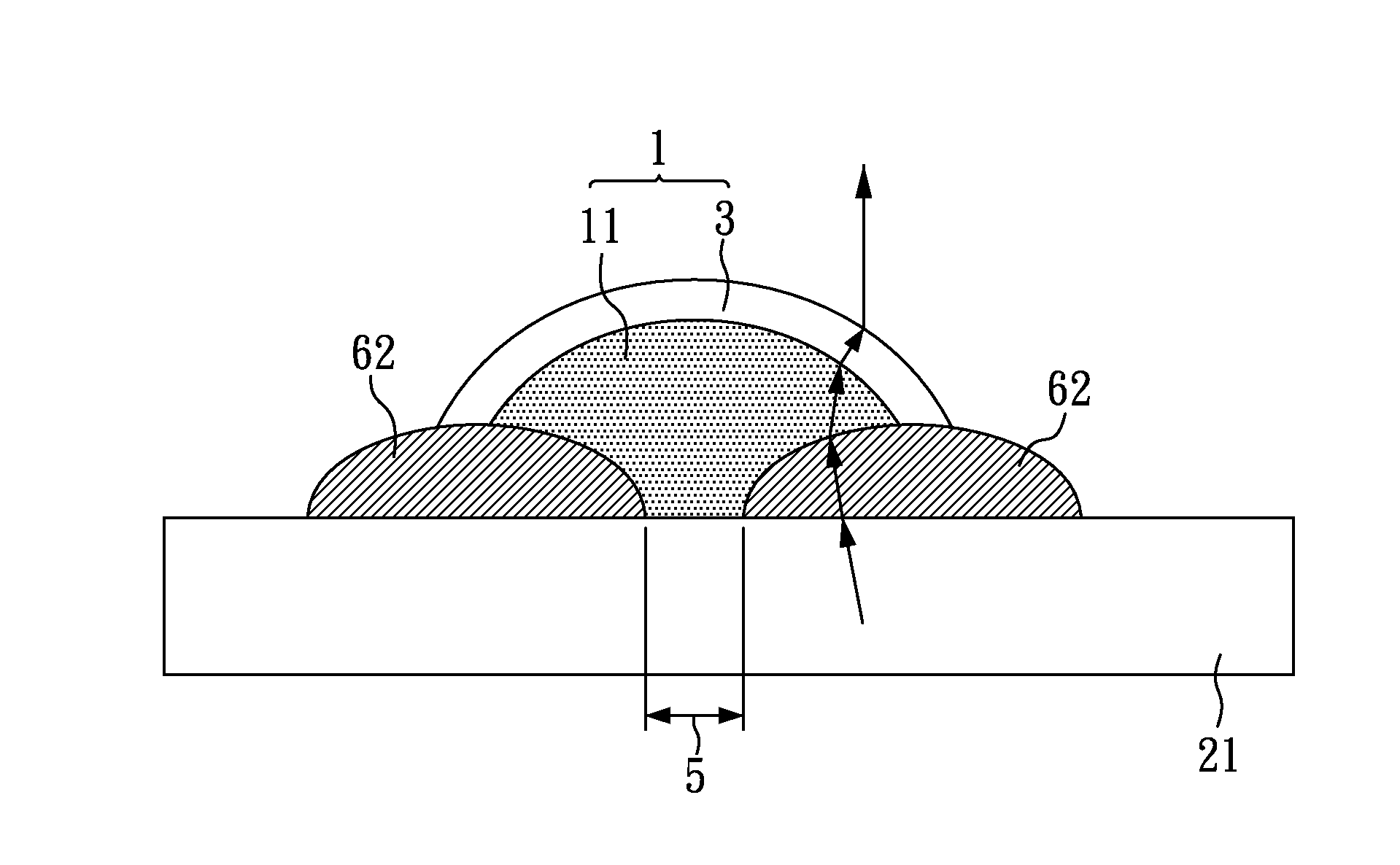

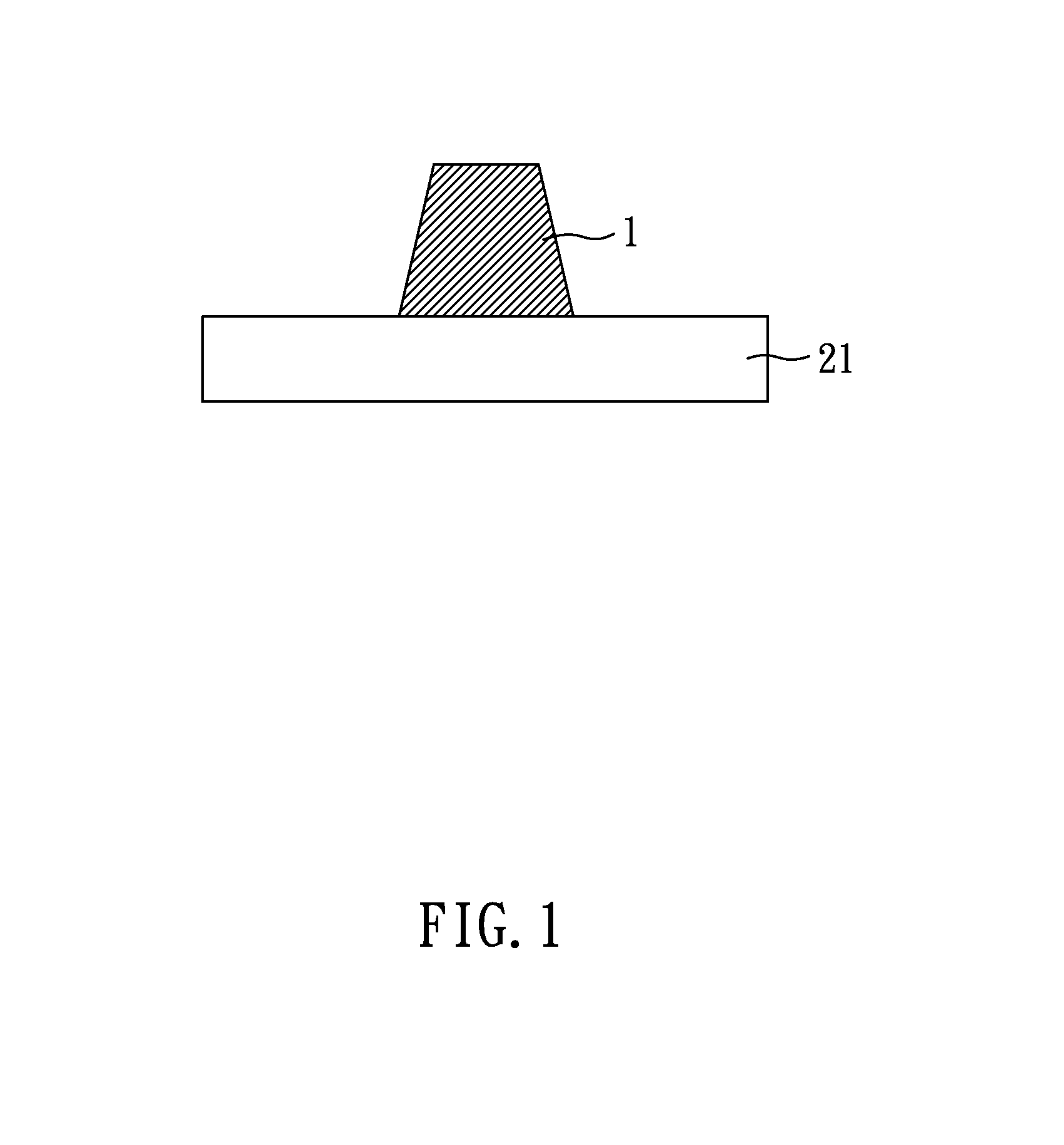

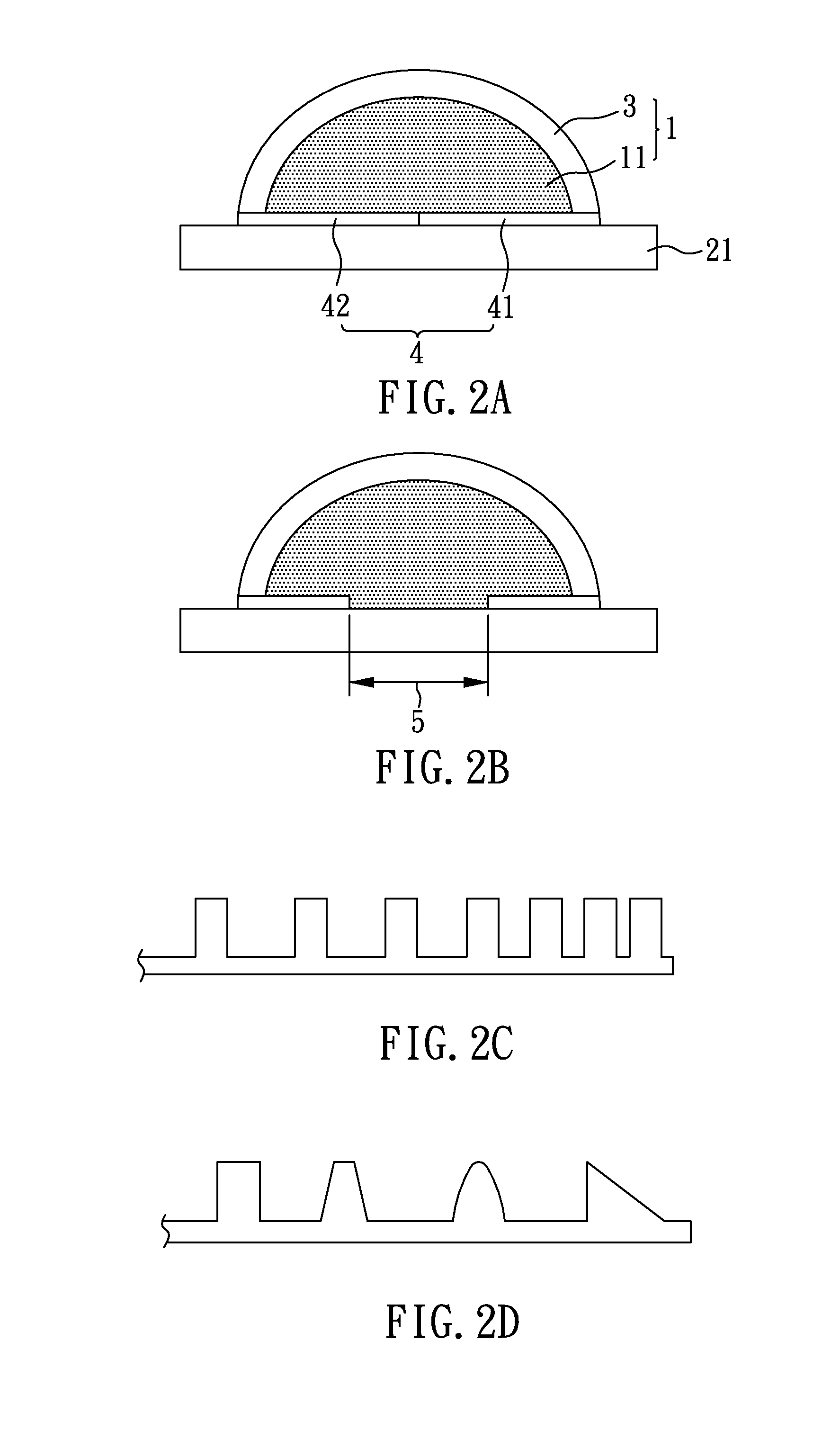

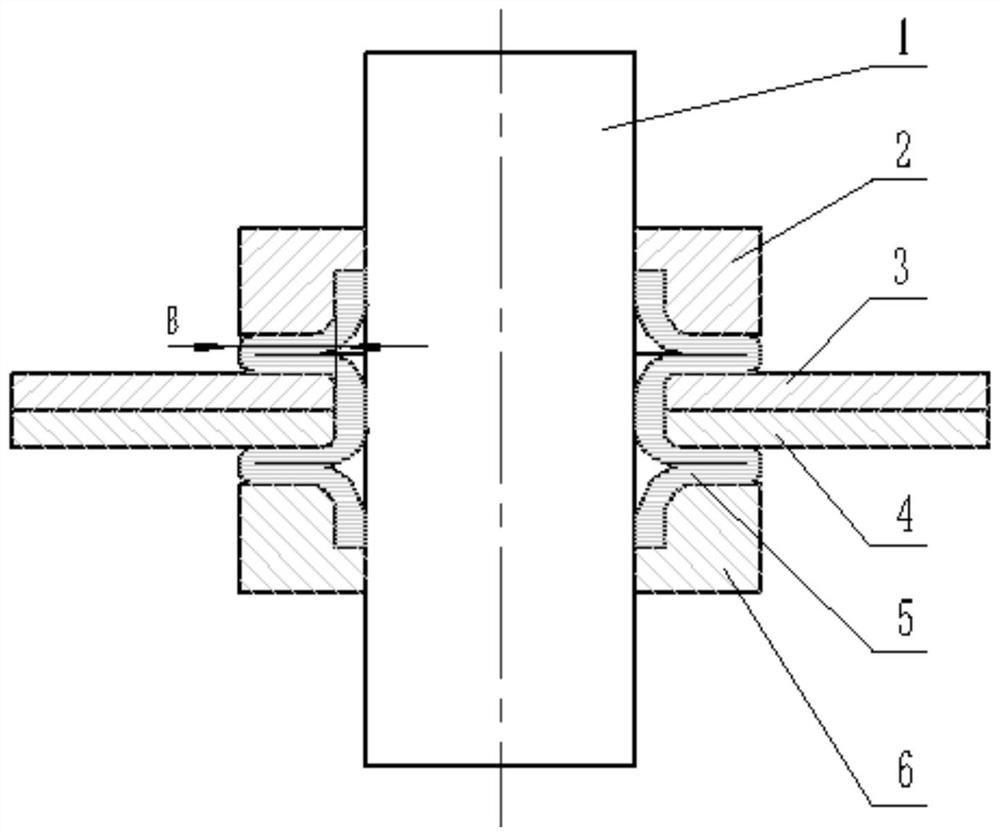

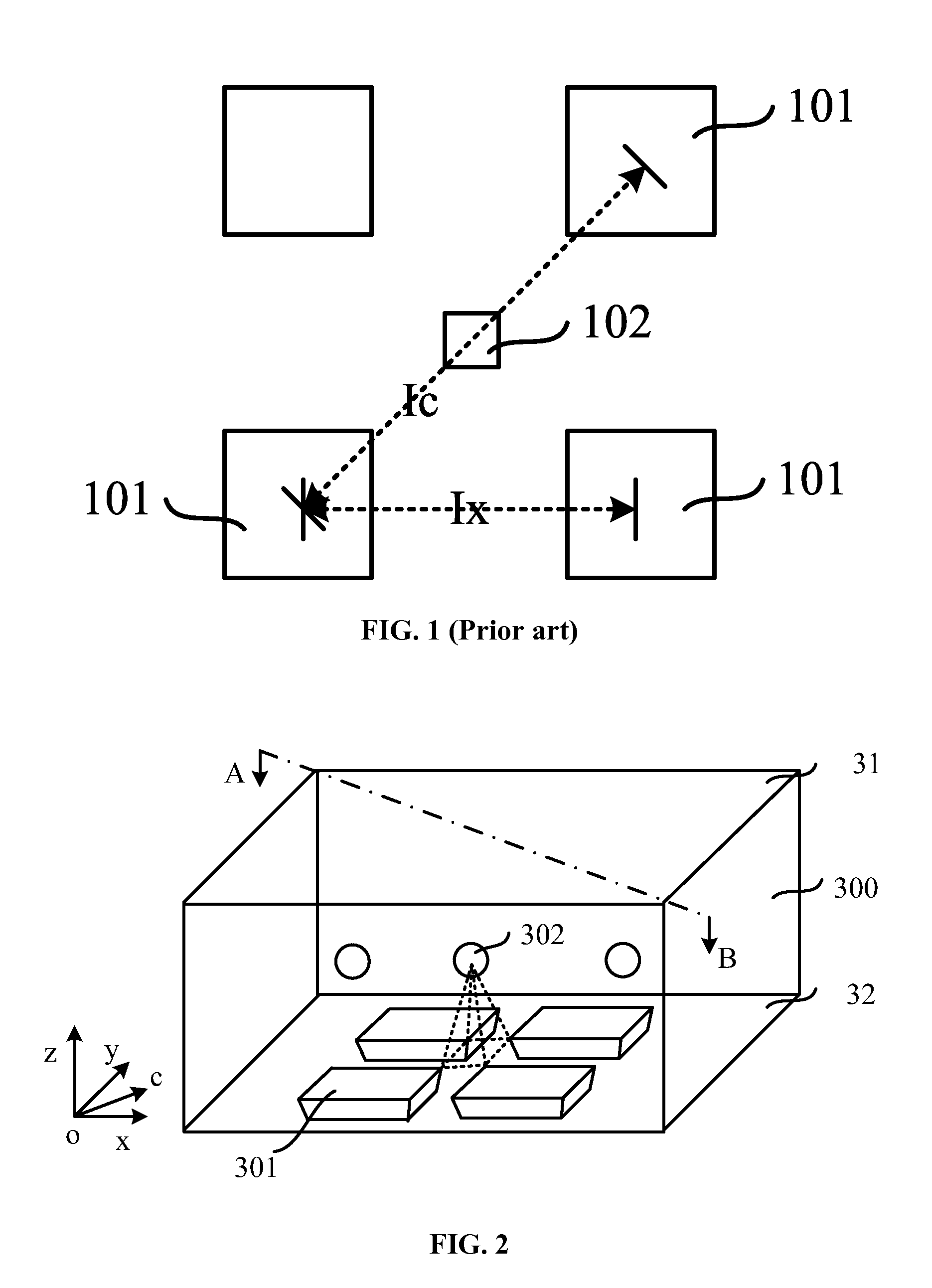

Optical element and display device

ActiveUS20180081177A1Reduce viewReduce intensity differenceOptical light guidesExit surfaceReflectivity

An optical element includes partially reflecting mirrors provided in parallel to each other with an interval therebetween, reflect a part of image light and external light, and transmit another part of the image light and the external light; and a transmitting member interposed between adjacent two partially reflecting mirrors of the partially reflecting mirrors. The light-transmissive member includes an incidence surface on which the image light and the external light are incident and an exit surface from which the image light and the external light are exited. Each of the partially reflecting mirrors is disposed to be inclined with respect to the incidence surface and the exit surface. The partially reflecting mirrors include at least one first partially reflecting mirror and at least one second partially reflecting mirror having different reflectances with respect to predetermined polarized light components included in the image light and the external light.

Owner:SEIKO EPSON CORP

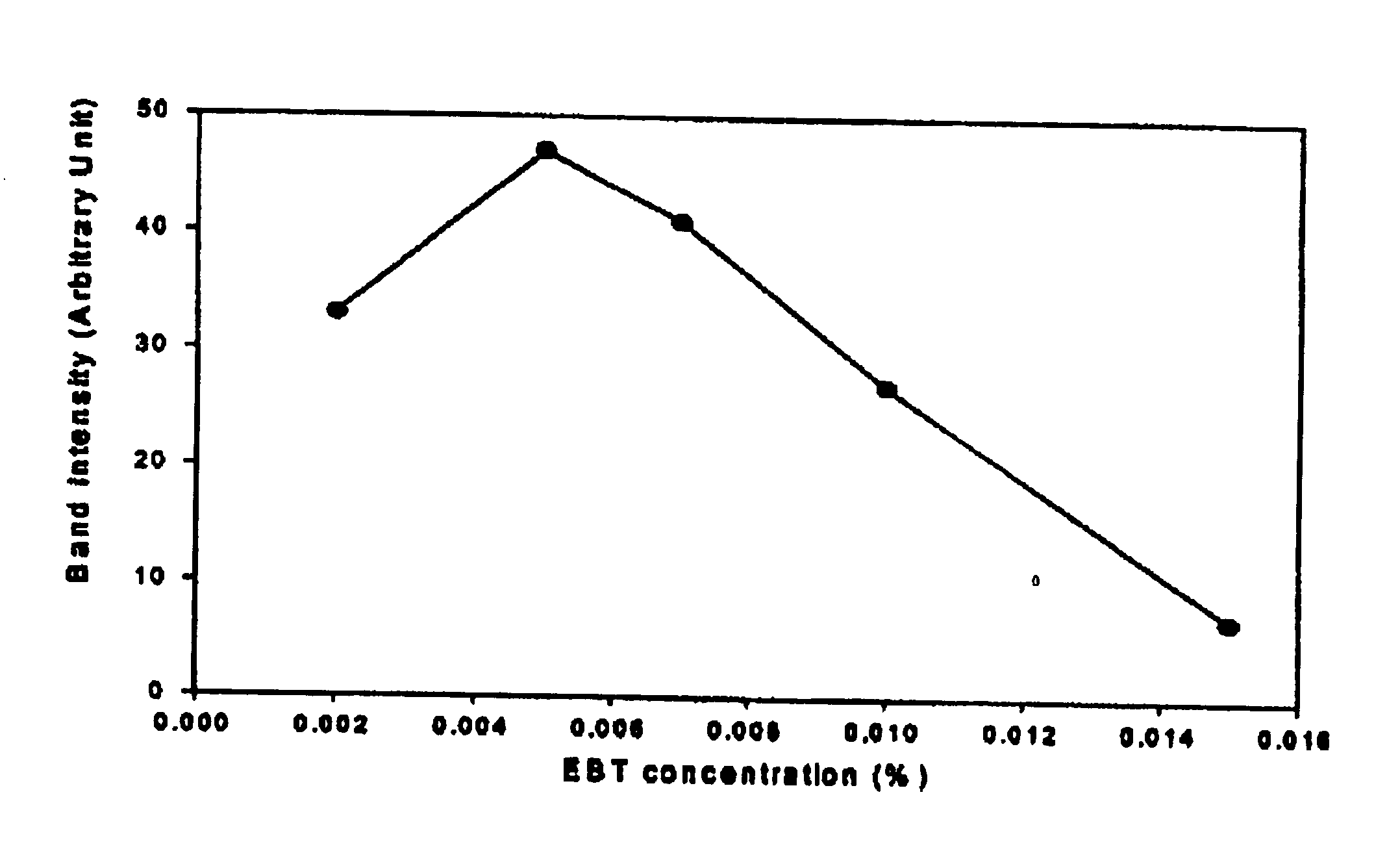

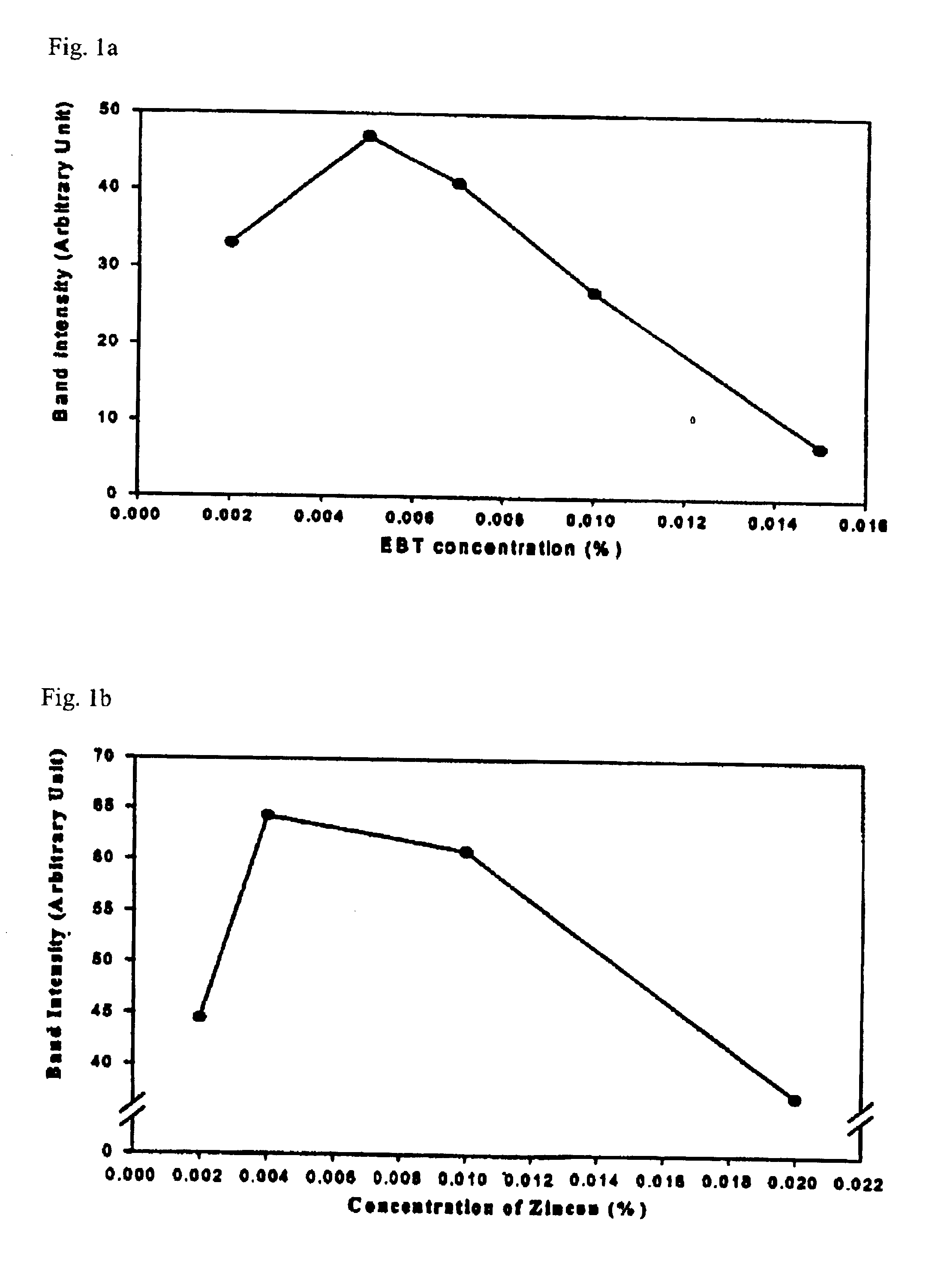

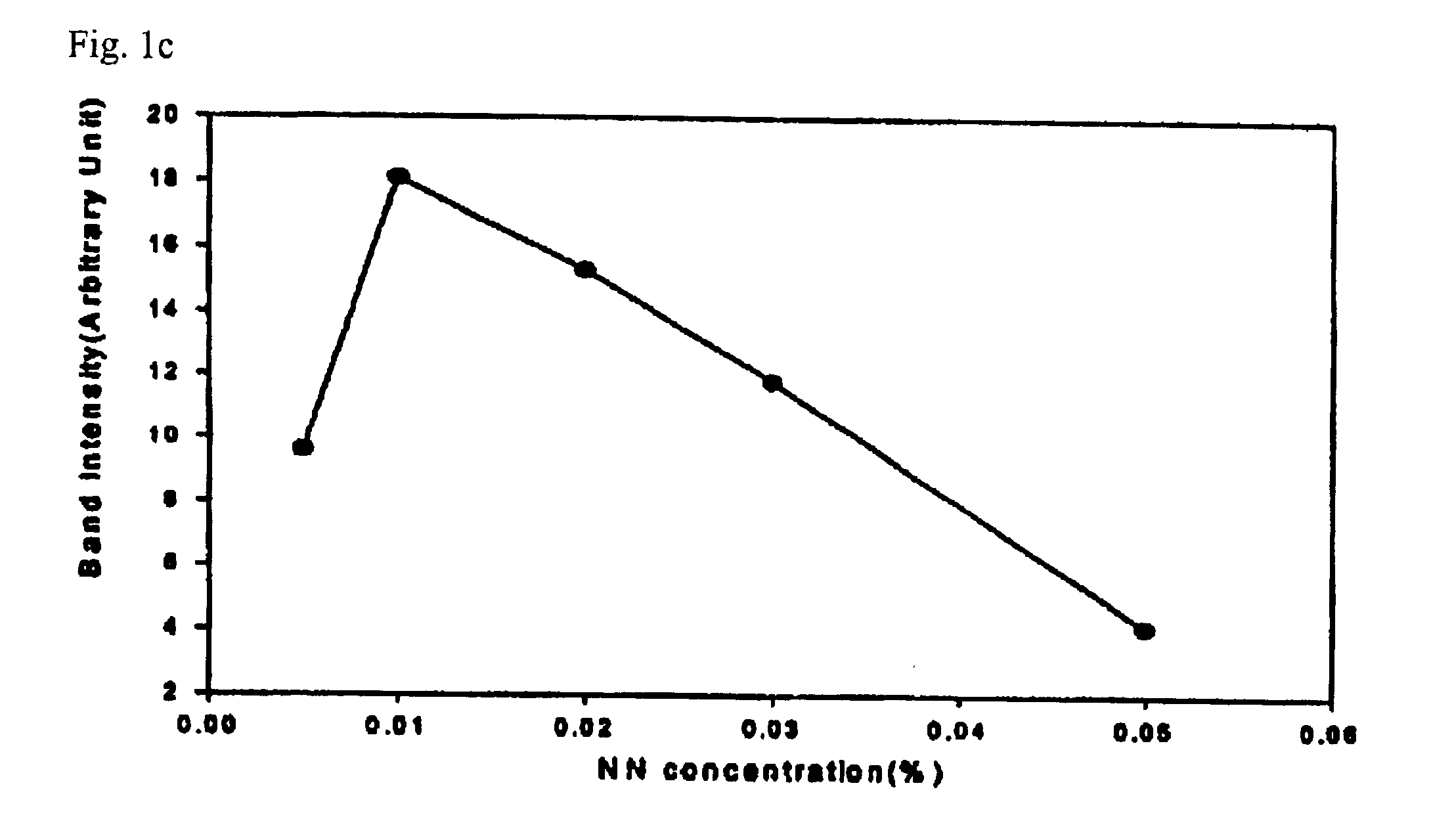

Detection method of proteins on polyacrylamide gels using a dye composition as a silver ion sensitizing agent and the dye composition for the same

InactiveUS6916663B2Reduce intensity differencesMaximize the effectStyryl dyesMethine/polymethine dyesOrganic dyeSilver ion

The present invention relates to a method for detecting proteins on polyacrylamide gels, comprising the steps of sensitizing the proteins with a dye composition comprising an acidic organic dye as a silver ion sensitizing agent, and optionally, a basic organic dye as an auxiliary agent, and washing them, and then silver staining complexes of the protein-dye, and to the dye composition for the same.

Owner:IND FOUND OF CHONNAM NAT UNIV

Liquid crystal display panel

InactiveUS20140063423A1Reduce the angle of incidenceImprove light leakageNon-linear opticsLiquid-crystal displayConductive materials

A liquid crystal display panel is disclosed, which comprises: a first substrate; a second substrate opposite to the first substrate; an optically isotropic liquid crystal layer disposed between the first substrate and the second substrate; and a protruding electrode layer composed of a polymer conductive material and disposed on the first substrate. Besides, when a protruding part is composed of a non-conductive organic material, the liquid crystal display panel further comprises: an electrode layer disposed on the protruding electrode layer; and a submicron structure layer, a multilayer film, or a micro-reflection layer is disposed between the protruding electrode layer and the first substrate.

Owner:INNOLUX CORP

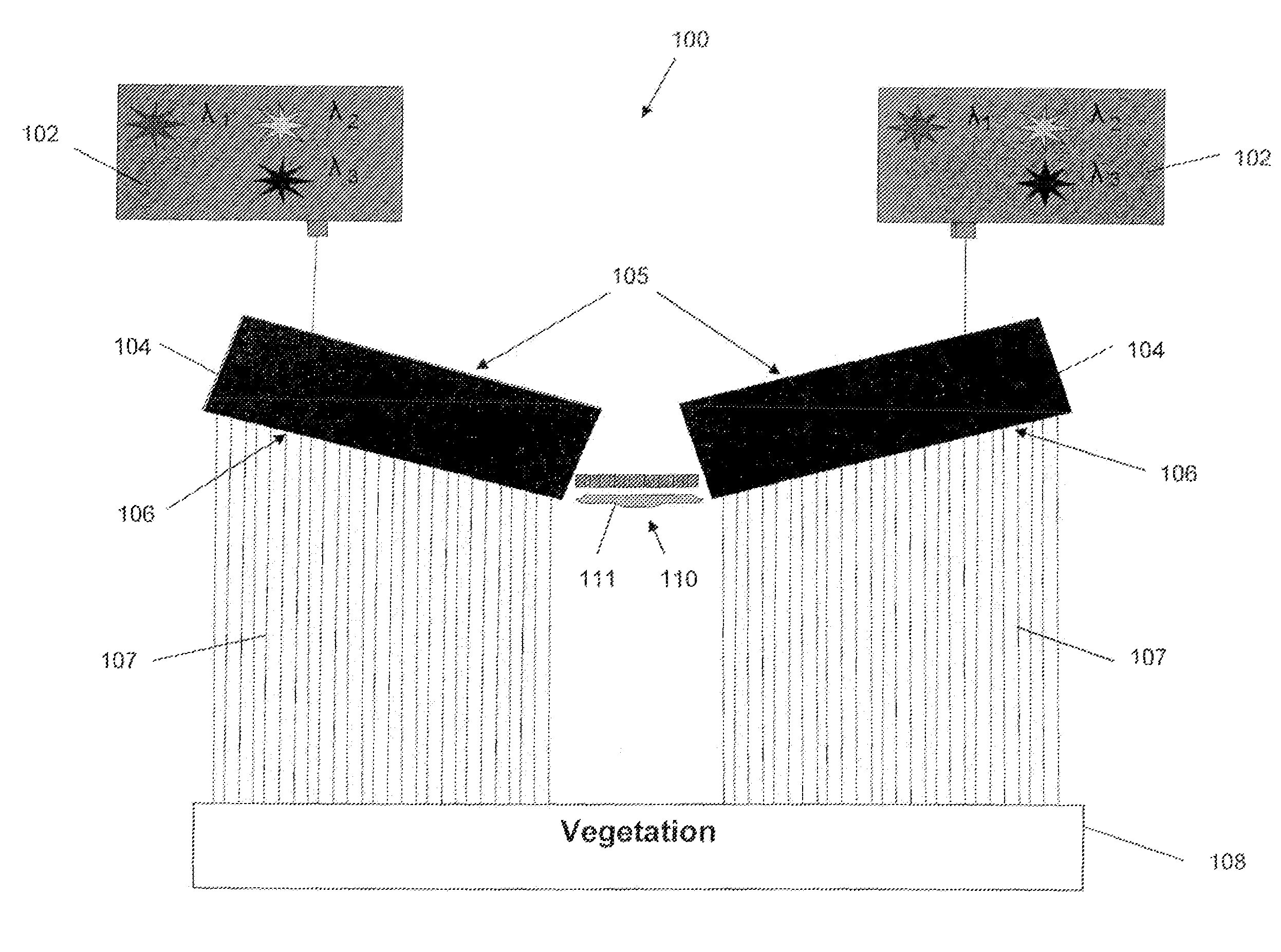

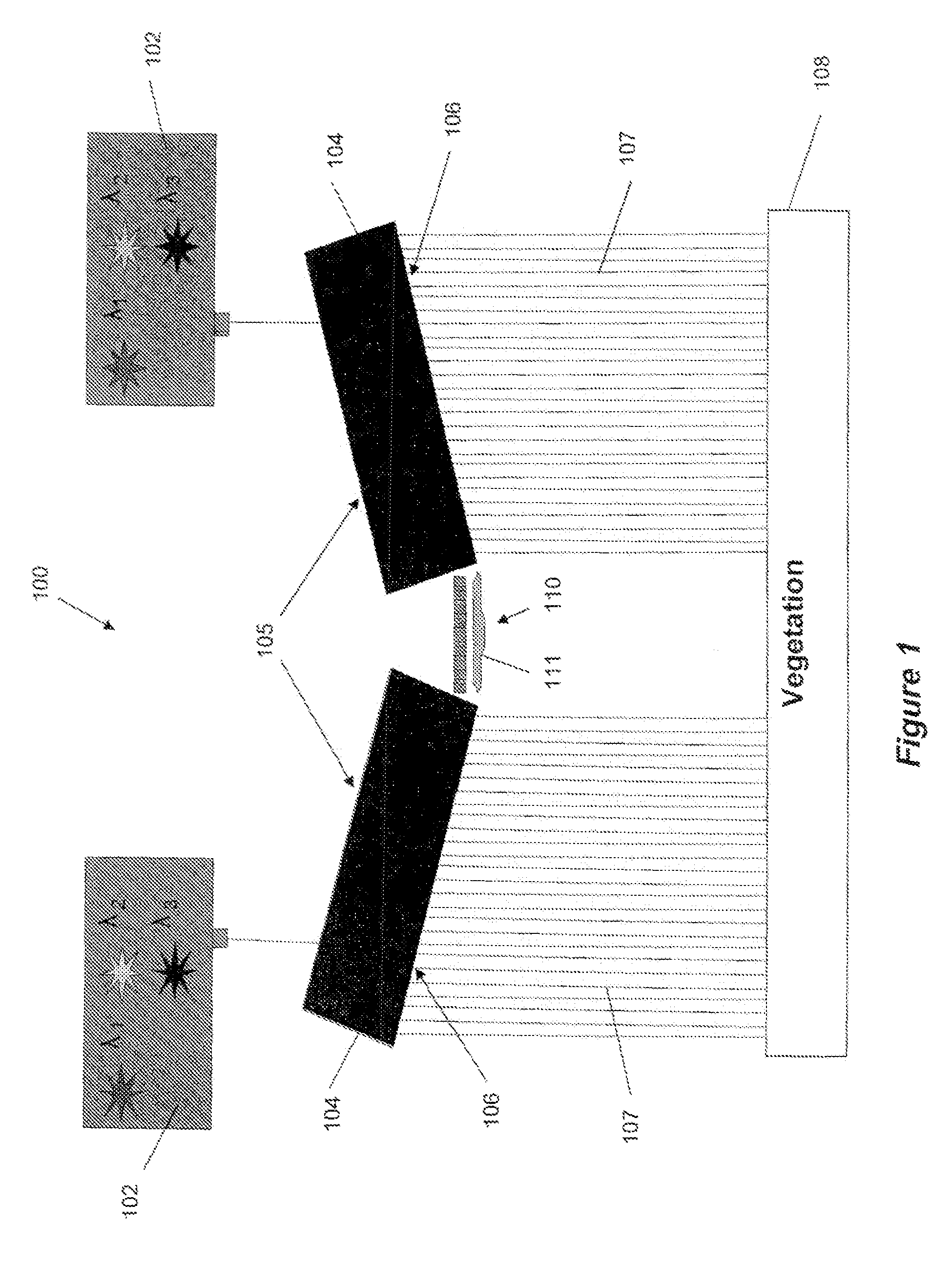

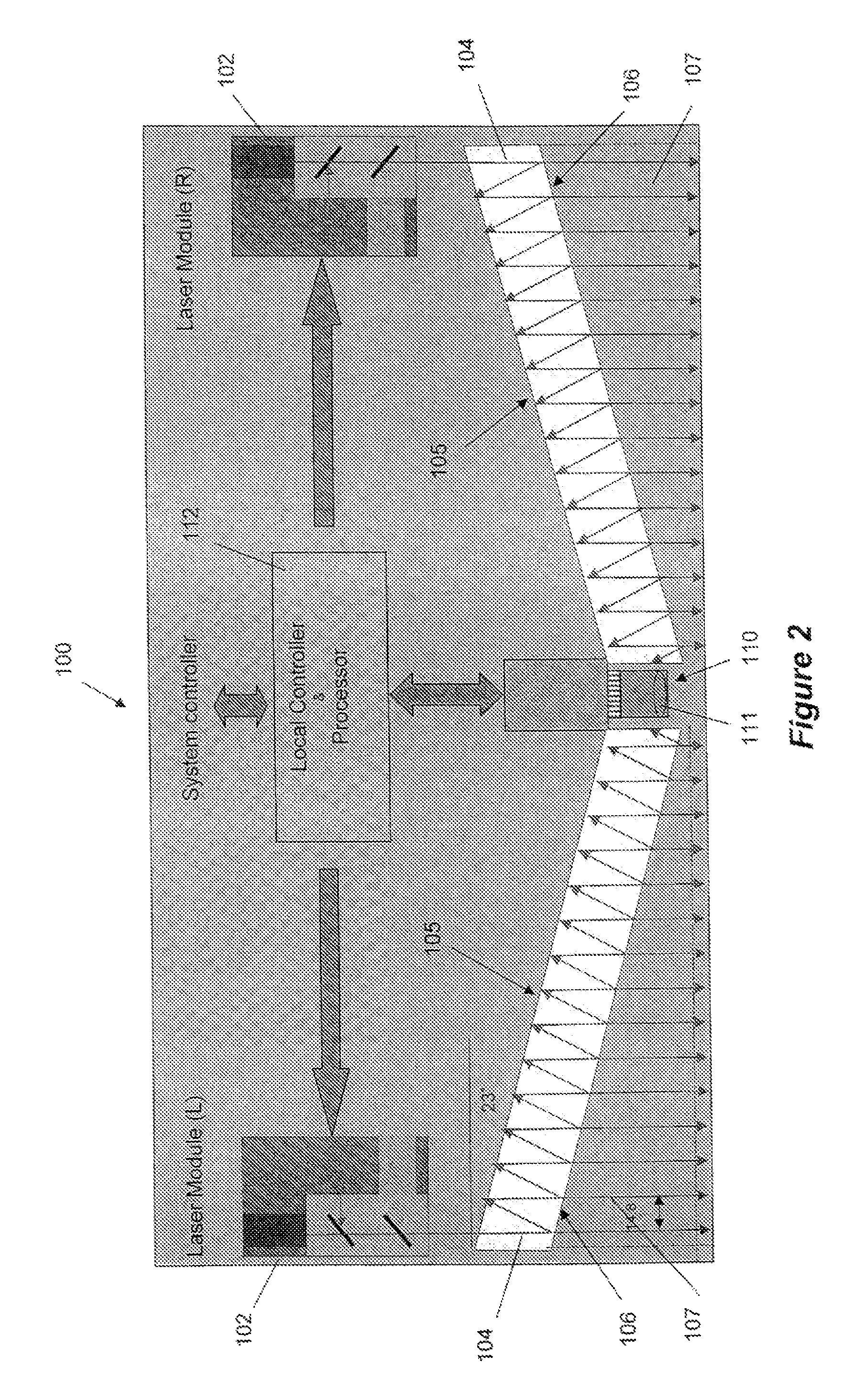

Device for selecting a specific matter

ActiveUS9025154B2Increase rangeHigh sensitivityRadiation pyrometryScattering properties measurementsOptical propertyLight beam

The present disclosure provides an optical device for selecting specific matter, such as plant matter. The device comprises a light source for emitting light having at least (3) wavelengths and for generating a combined beam of light having the at least 3 wavelengths. The device further comprises an optical element for directing a plurality of light beams towards matter including the specific matter. The optical element has first surface portions through which in use the plurality of component light beams are directed to the matter including the specific matter. Each component light beam is directed through a respective first surface portion that has an optical property that is selected so that light intensity differences between the component light beams are reduced. The optical device also comprises an optical filter for filtering reflected component light beams such that an intensity of light is reduced in a wavelengths range outside one or more wavelengths ranges that include the at least three wavelengths. Further, the optical device comprises a detector for detecting the reflected component light beams.

Owner:PHOTONIC DETECTION SYST

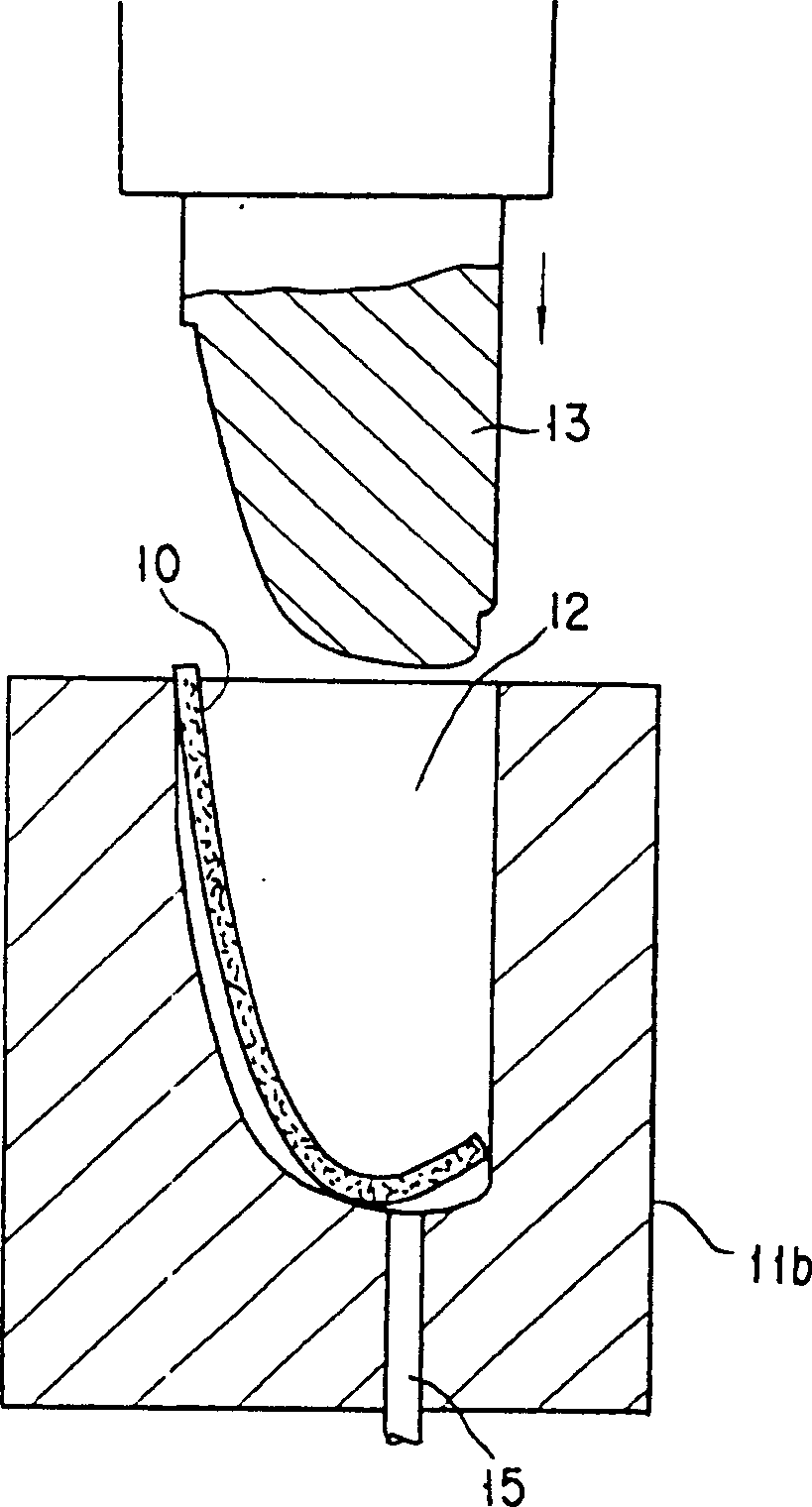

Protective shoe toecap made of long fiber reinforced thermoplastic resin and manufacture thereof

InactiveCN1406534ALow costImprove effectivenessWear-resisting attachmentsDomestic footwearLong-fiber-reinforced thermoplasticBiomedical engineering

A method for the production of a toe cap for a safety shoe comprises placing a fibrous pellet material of a long fiber-reinforced thermoplastic resin in a pseudo-forming mold, compressing the fibrous pellet material therein under application of heat to primarily form a pseudo-toe cap, setting the resultant pseudo-toe cap in position in a mold for forming a toe cap for a safety shoe, and applying pressure and heat to the pseudo-toe cap to compression mold a toe cap for a safety shoe. By this method, there is obtained the toe cap made of a long fiber-reinforced thermoplastic resin in which the proportion of the content of reinforcing fibers in a skirt part to that in a main body part is in the range of 70 to 100%.

Owner:YKK CORP

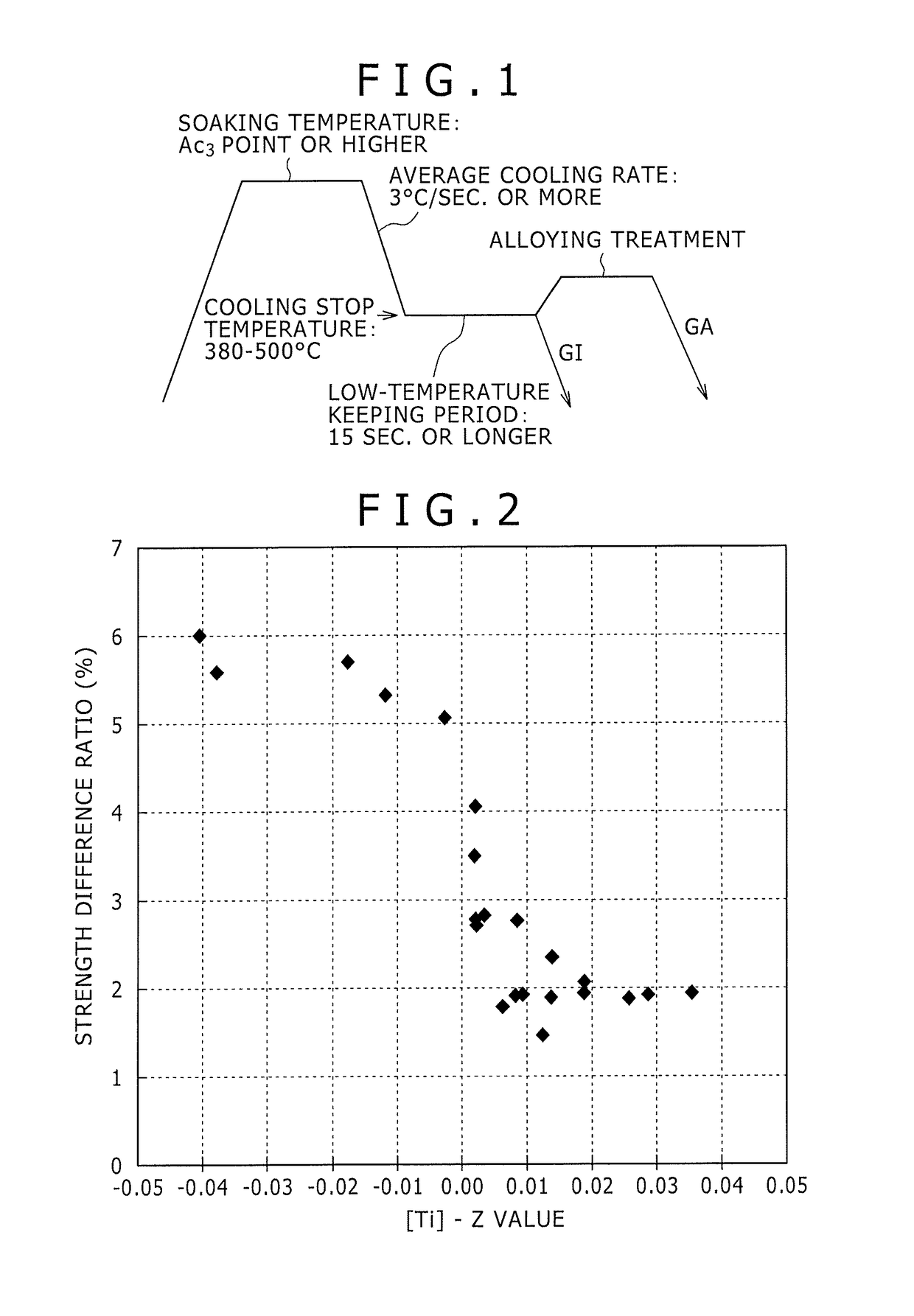

High-strength hot-dip galvanized steel sheet and high-strength alloyed hot-dip galvanized steel sheet having excellent bending workability and minimal strength difference between center part and end parts in sheet width direction, and method for manufacturing same

InactiveUS20190078188A1Reduce the ratioReduce intensity differencesHot-dipping/immersion processesFurnace typesAlloyUltimate tensile strength

A high-strength hot-dip galvanized steel sheet with improved bending workability and reduced strength difference between a center part and end parts in the sheet width direction is provided. A method for manufacturing the high-strength hot-dip galvanized steel sheet is also provided. The hot-dip galvanized steel sheet has a hot-dip galvanizing layer on a surface of a base steel sheet containing: C, Mn, P, S, and Al; Ti and B in amounts satisfying expression (1): 0.005×[Mn]+0.02×[B]1 / 2+0.025≤[Ti]≤0.15; N; and Si as needed; the remainder being iron and unavoidable impurities. The base steel sheet has 50 area % or more of the martensite, 15-50 area % of the bainite, and 5 area % or less of the ferrite, with respect to the overall metallographic structure.

Owner:KOBE STEEL LTD

High-strength refractory cement mortar in petroleum industry and construction process thereof

The invention discloses high-strength refractory cement mortar in a petroleum industry and a construction process thereof. The high-strength refractory cement mortar is prepared from the following technical formula (weight percentage): 10-18% of silicate cement, 8-16% of powdered refractory cement, 5% of silica powder, 12-20% of corundum, 3-6% of alumina micro powder, 5-10% of high-alumina bauxite, 1-5% of sodium nitrate, 30-50% of river sand and proper amount of water. Firewalls constructed with the refractory cement mortar have high stability and safety; the high-strength refractory cement mortar is simple in production and low in production cost; the construction process of the high-strength refractory cement mortar is simple to operate; the high-strength refractory cement mortar is applicable to high temperature of up to about 1,700 degrees centigrade and can be widely applied to the firewalls in the petroleum industry and independent chimney flues and small kilns in the other industries.

Owner:JIANGSU JIANSHEN BIOLOGY AGROCHEM

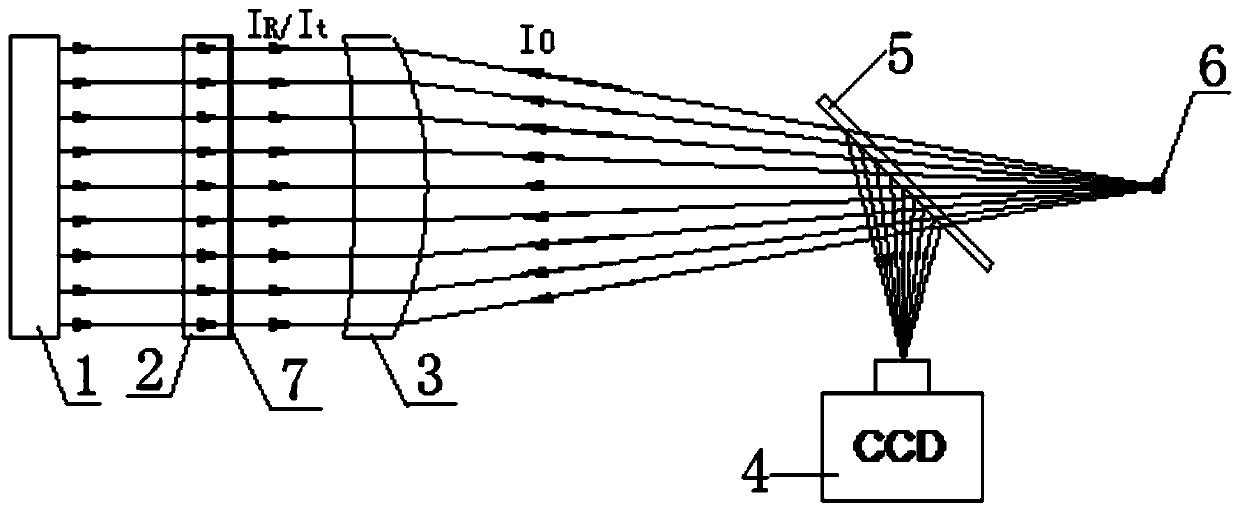

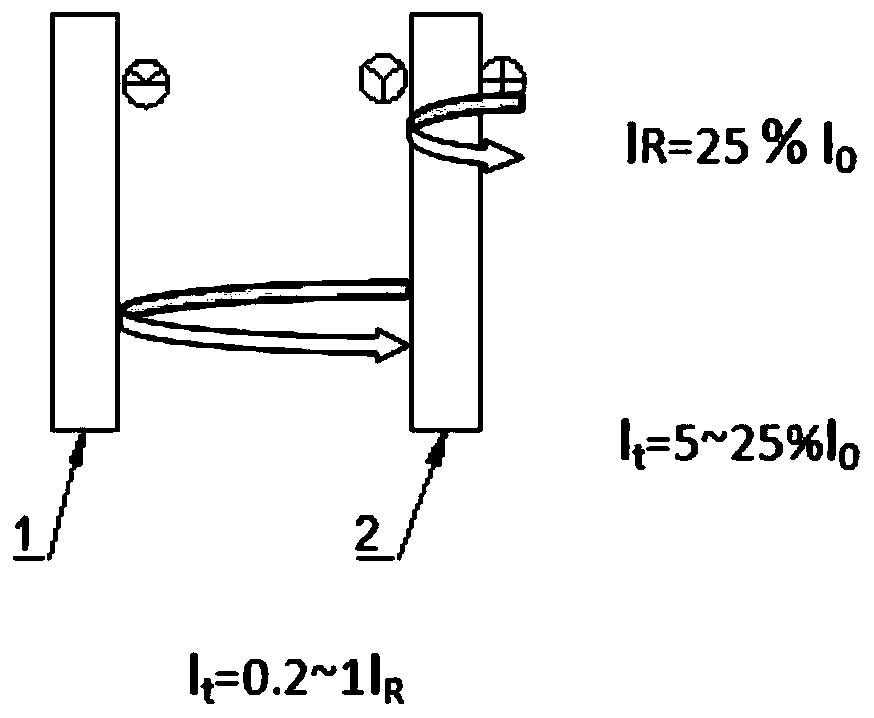

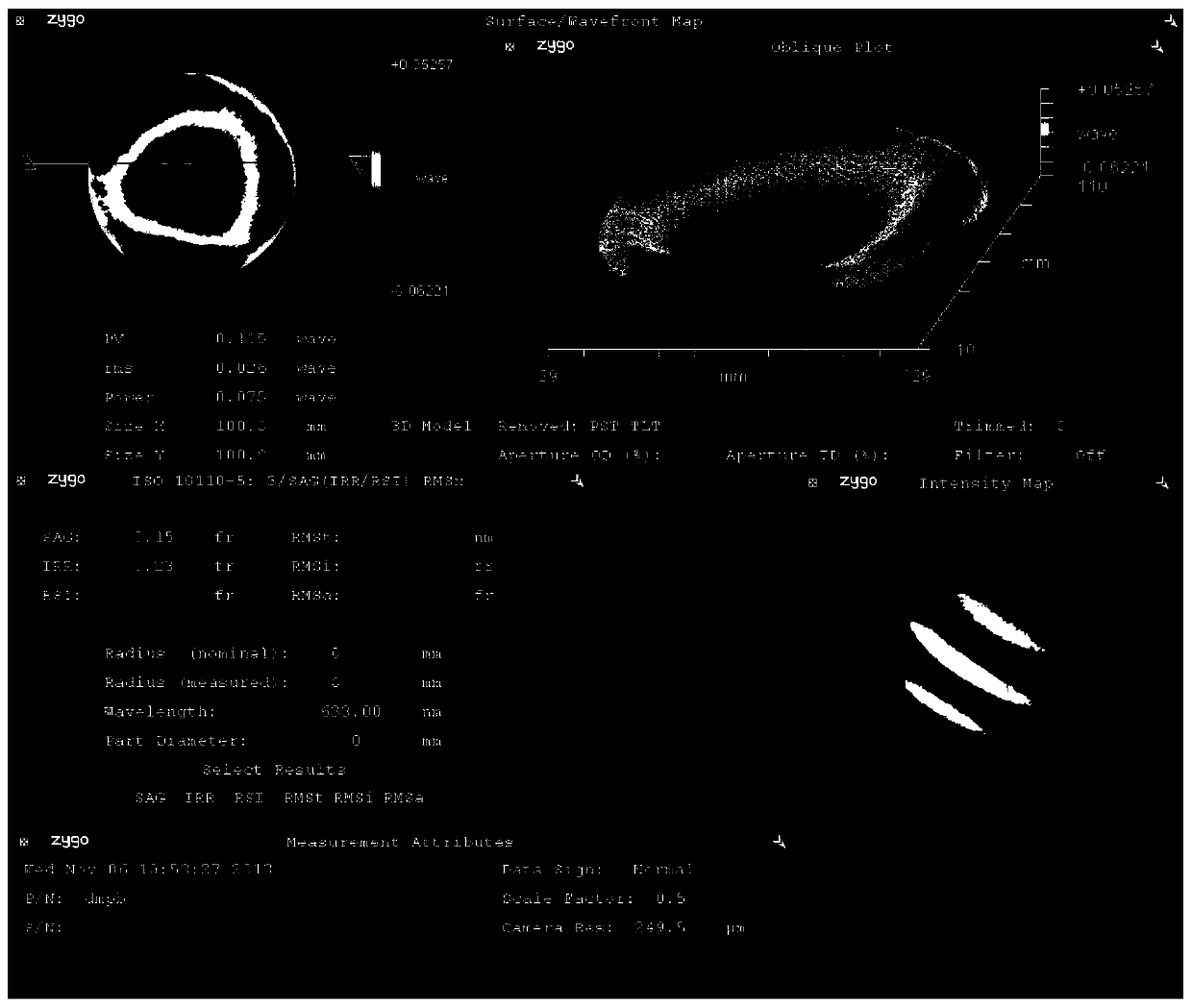

Device for measuring surface shape of high-reflection mirror

InactiveCN110455501AClear faceReduce intensity differencesReflective surface testingUsing optical meansMeasurement deviceBeam splitter

The invention discloses a device for measuring the surface shape of a high-reflection mirror. The device comprises a light source, a beam splitter, a collimator, a standard lens and a CCD imaging system. The front surface of the standard lens is plated with a light splitting film, a light beam emitted by the light source passes through the beam splitter and then is converted into parallel light bythe collimator, when the parallel incident light Io passes through the standard lens, part of the light is emitted is reflected and returned by the standard lens plated with the light splitting film,the other part of the light passes through the standard lens to arrive at the surface of the measured lens and is reflected by the surface of the measured lens, the light IR reflected and returned bythe standard lens plated with the light splitting film and light It reflected by the surface of the measured lens after passing through the standard lens form interference light and return the interference light to the beam splitter, the interference the light enters the CCD imaging system after being reflected by the beam splitter, and the intensity ratio It / IR of the two paths of coherent lightis 0.2-1.

Owner:MLOPTIC CORP

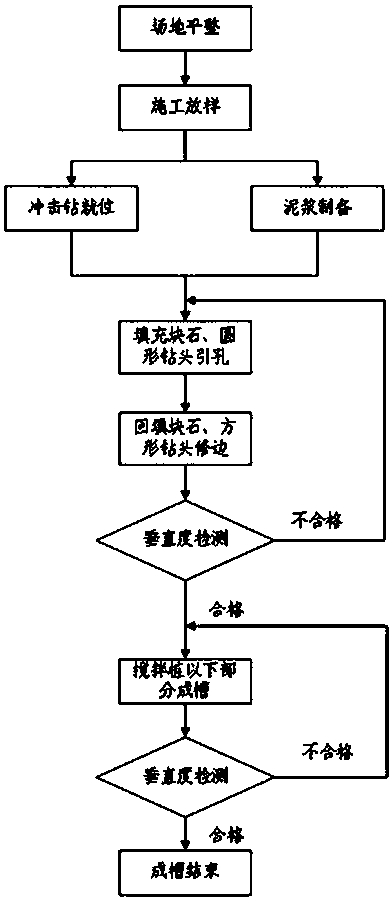

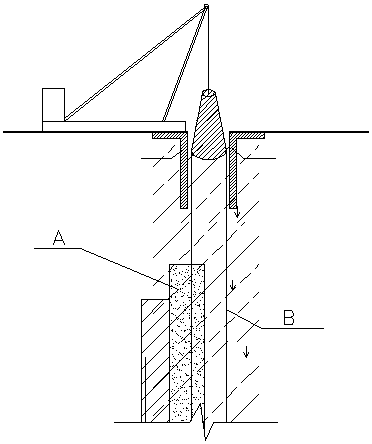

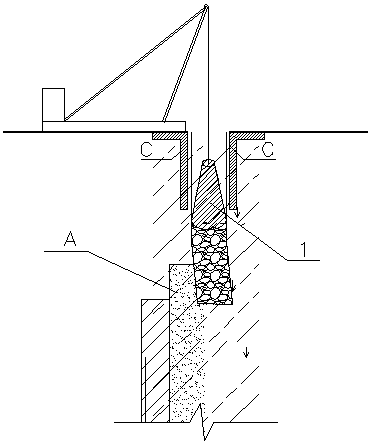

Treatment and construction method for grooving underground diaphragm wall encountering with underground stirring pile

InactiveCN110159190ASolve the speed problemSolve quality problemsFlushingExcavationsSlurry wallHardness

The invention discloses a treatment and construction method for grooving an underground diaphragm wall encountering with an underground stirring pile. The construction method comprises the following steps: (1) judging a beyond-limit range and a hole guiding position of the stirring pile; (2) putting a percussion hammer in position and preparing slurry; (3) guiding a hole by a round drill bit and filling the hole with rock blocks; (4) trimming the hole by a square drill bit and filling the hole with the rock blocks; and (5) grooving a groove section below the depth range of the stirring pile. By means of a method which comprises the steps of backfilling gravels, using the round percussion drill to impact the beyond-limit stirring pile in advance, brushing a wall by the square percussion drill to control the perpendicularity and then grooving by using a grooving machine, the construction method solves the problem that the grooving speed of the grooving machine is slow and the grooving quality is hard to control as the strata in the grooving range are not uniform in hardness as a result of beyond-limit of the stirring pile in a construction process of the underground diaphragm wall, so that the progress of station construction is completed on schedule while the cost is saved, and a good economical benefit is obtained.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

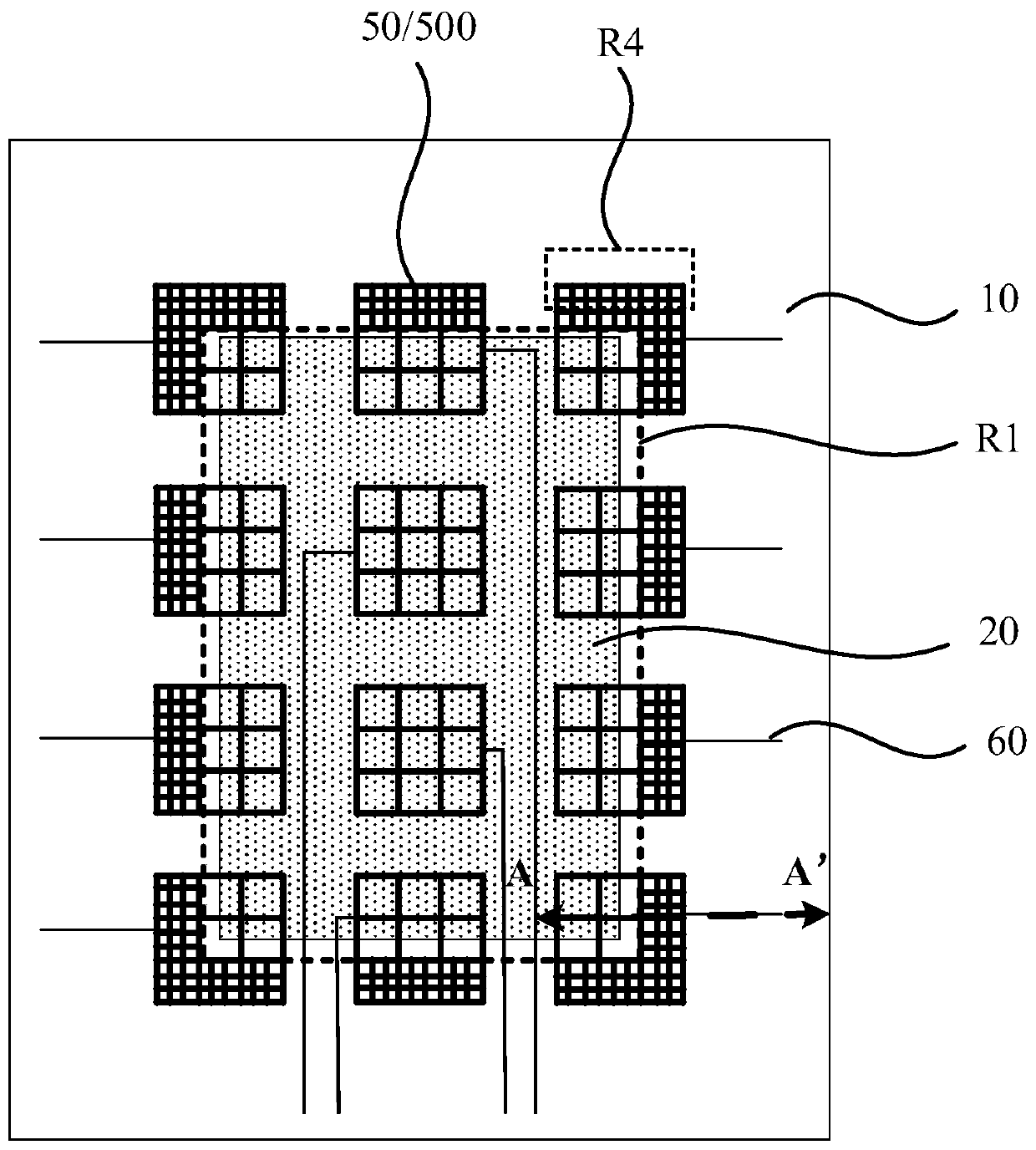

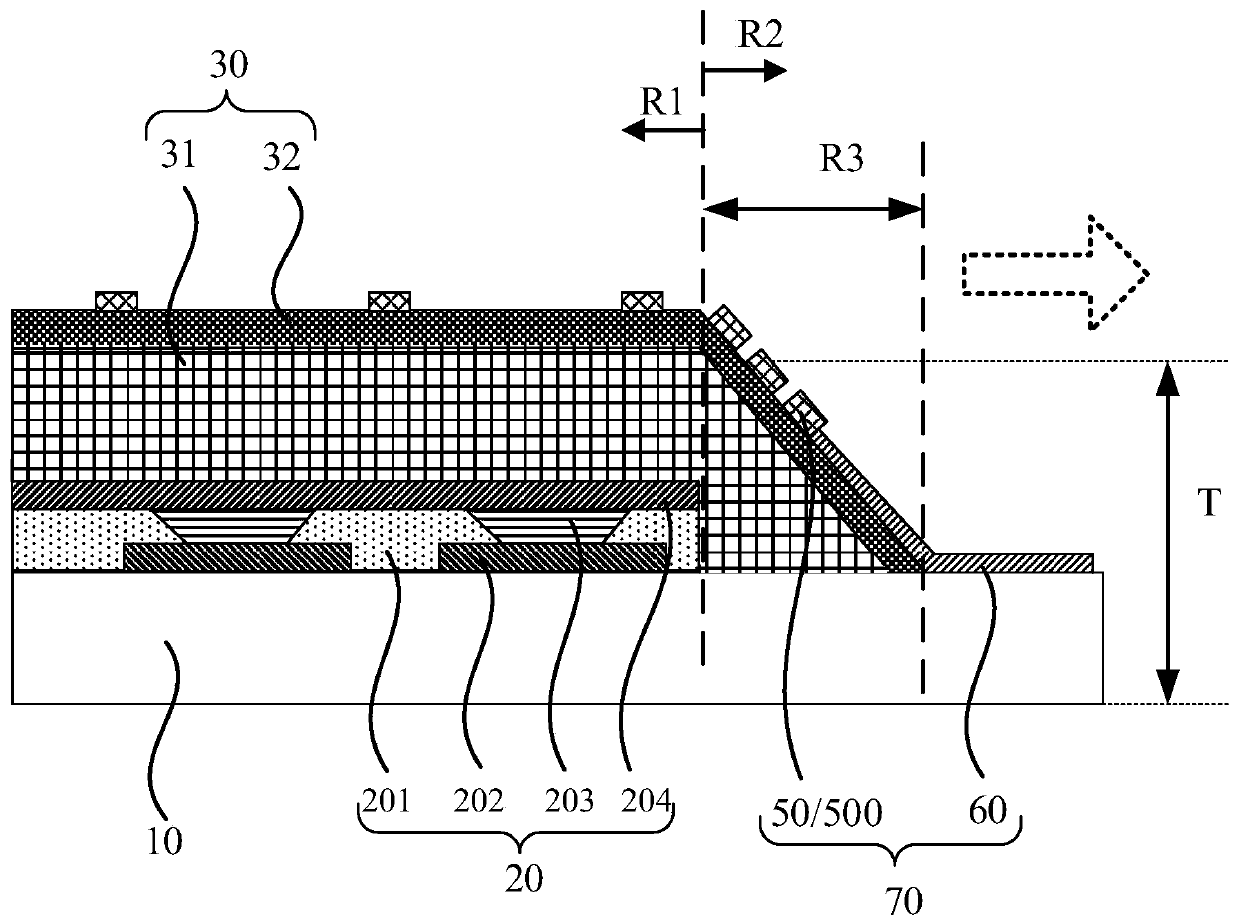

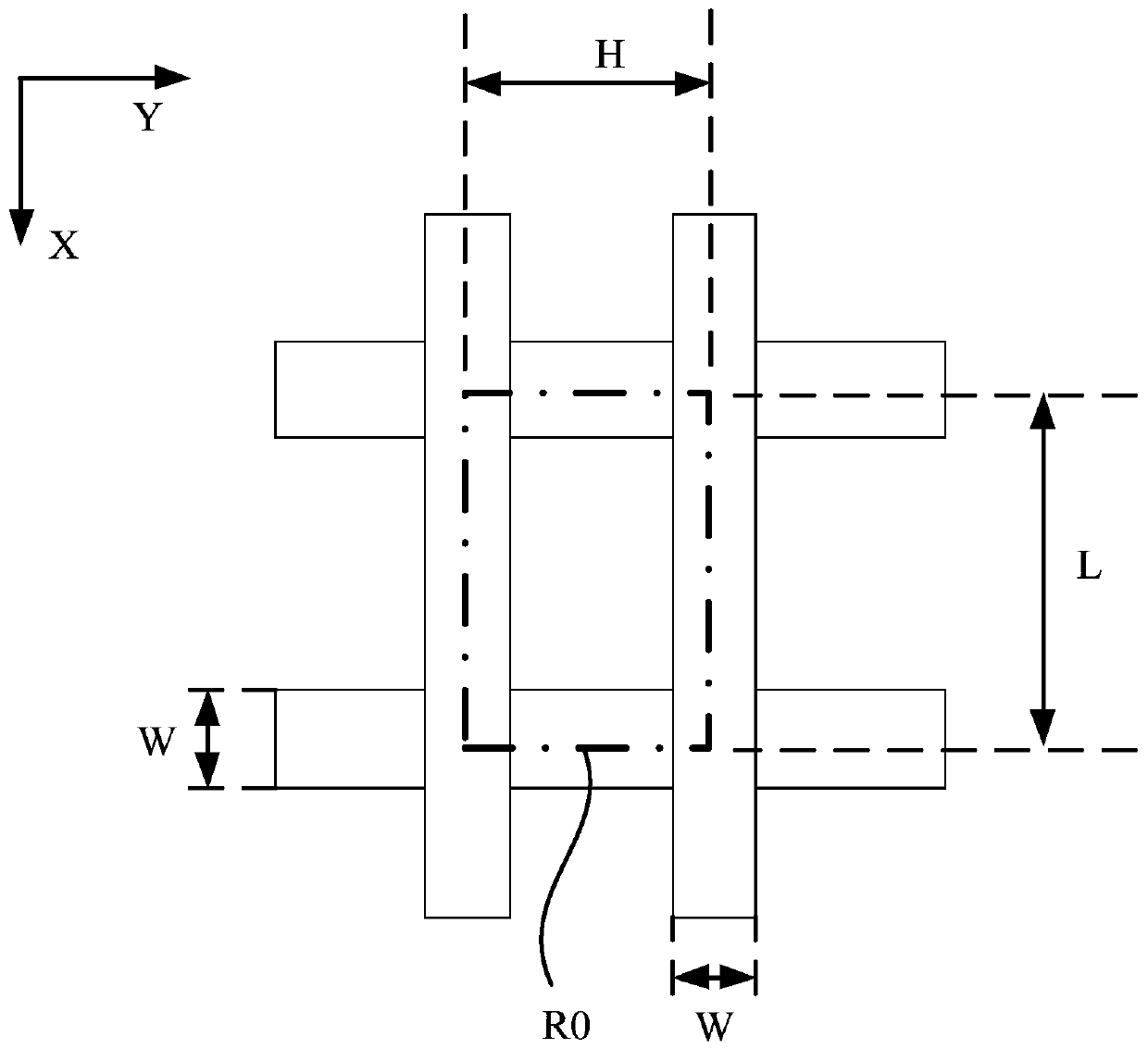

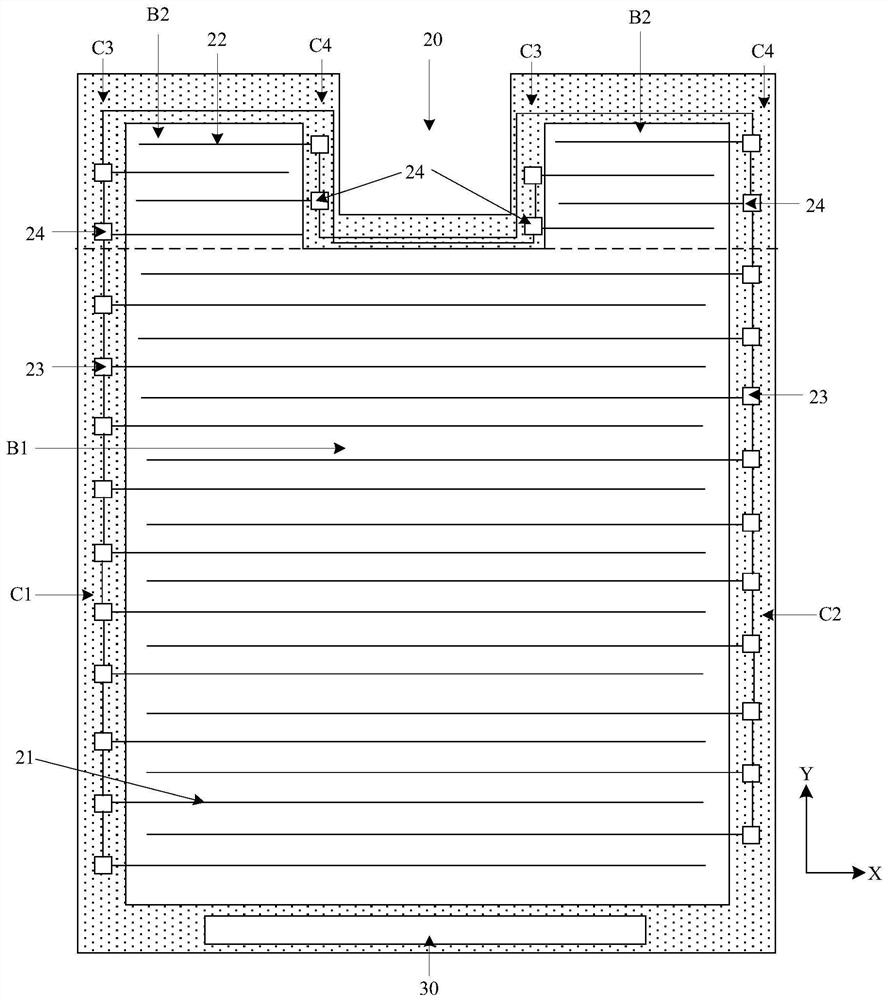

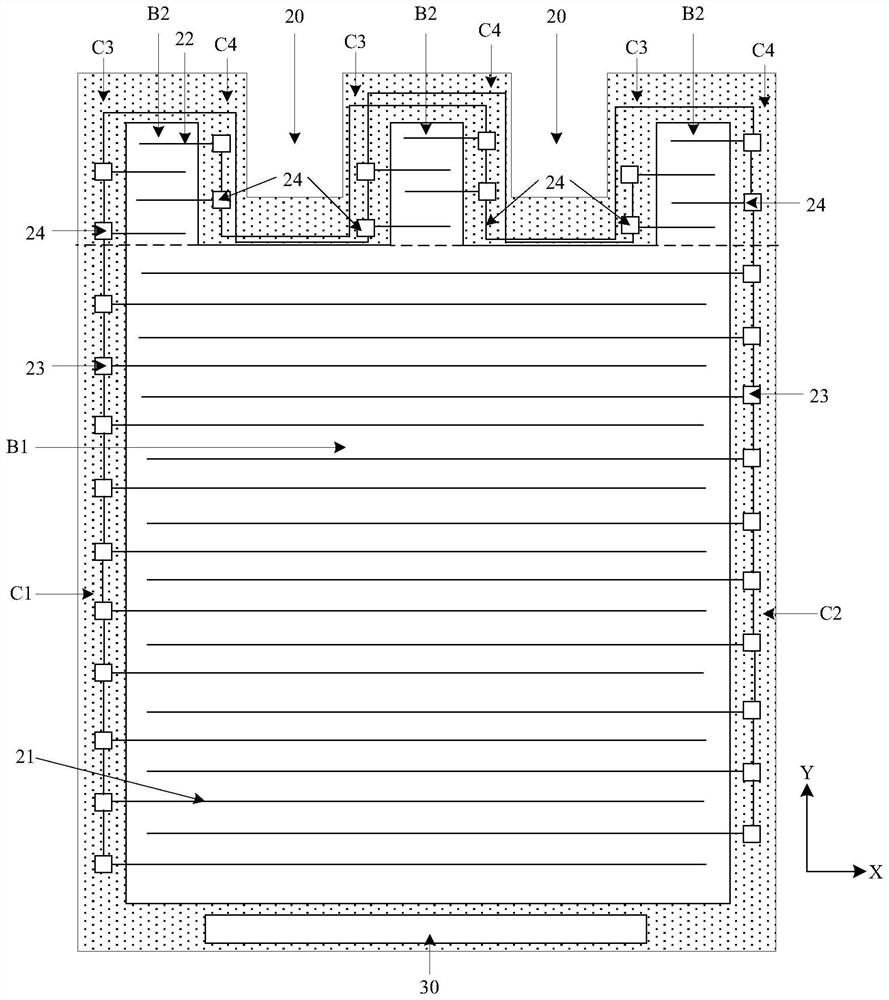

A touch display device

ActiveCN107122077BReduce intensity differencesIncrease capacitanceInput/output processes for data processingDisplay deviceMaterials science

A touch display apparatus with a display region and a frame region is provided. The touch display apparatus includes a base substrate, a display function layer and a thin film encapsulation layer which are sequentially stacked. The display function layer is located in the display region. A touch electrode layer is arranged at a side, facing away from the base substrate, of the display function layer. The frame region includes a slope region adjacent to the display region. The thickness of the touch display apparatus in the slope region is gradually decreased outward from the display region. The touch electrode layer includes touch electrodes which form a grid of metallic wires. The grid density of the touch electrodes in the slope region is higher than that in the display region.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

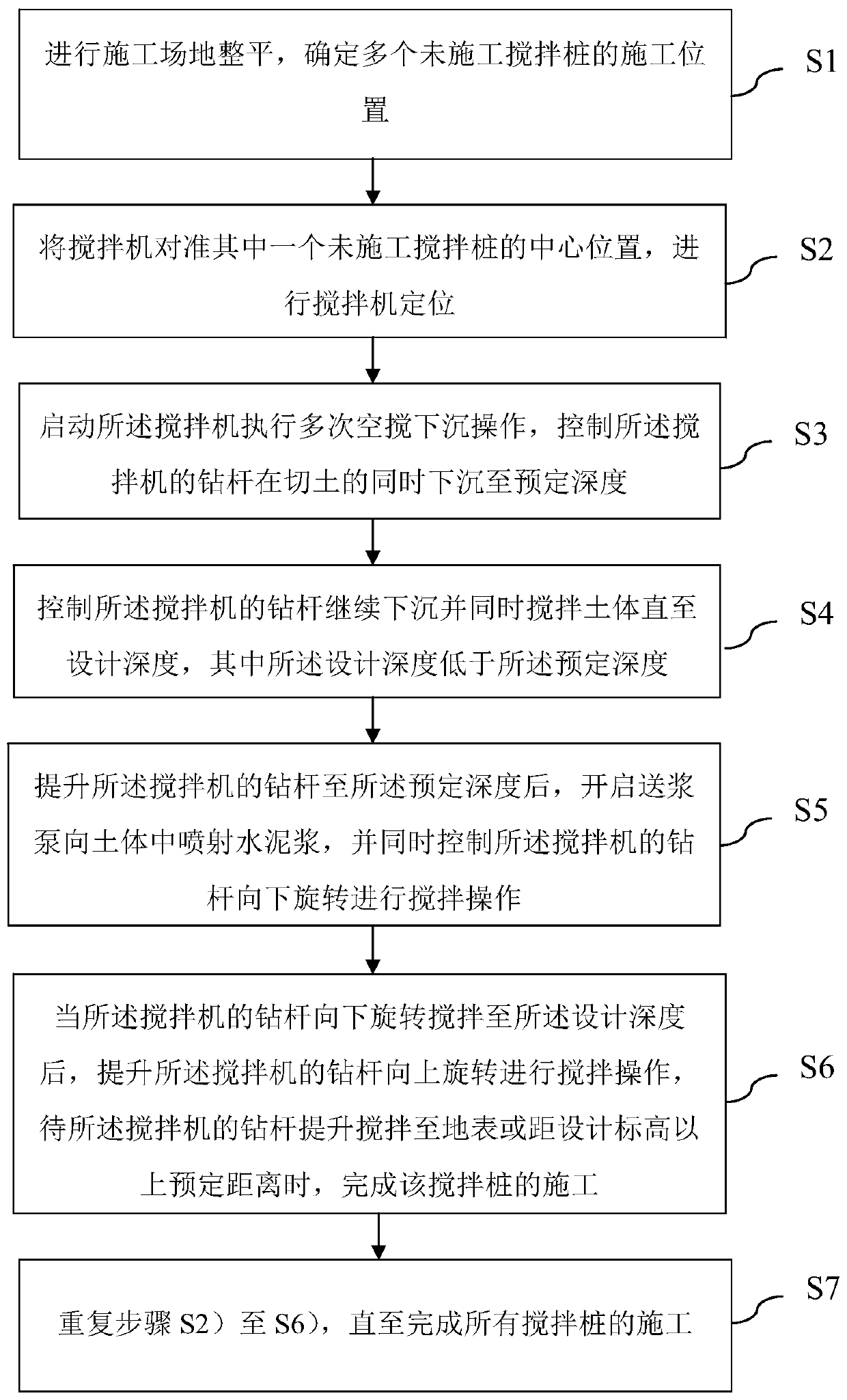

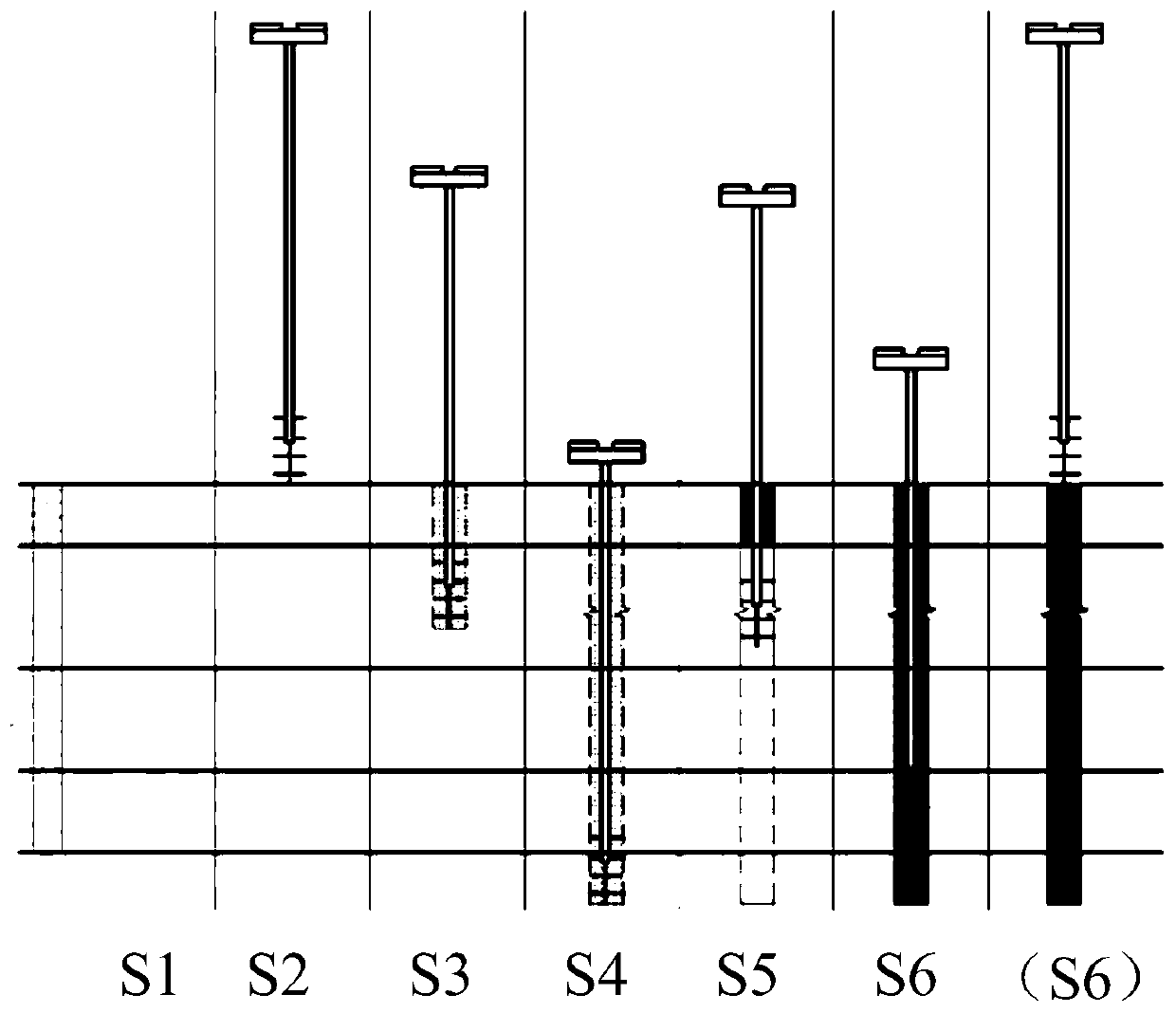

Cement soil mixing pile construction method considering intensity uniformity

InactiveCN109868811AImprove soil strength differencesGuaranteed uniformityBulkheads/pilesEngineeringDrill pipe

The invention provides a cement soil mixing pile construction method considering intensity uniformity, which comprises the following steps that a construction site is levelled, and construction positions of a plurality of unconstructed mixing piles are determined; a mixer aligns with the center position of one of the unconstructed mixing piles, and positioning of the mixer is carried out; the mixer is started to perform empty agitation sinking operation, and a drill pipe of the mixer is controlled to sink to a predetermined depth while cutting soil; the drill pipe of the mixer is controlled tocontinue to sink and simultaneously stir the soil until a design depth is reached; after the drill pipe of the mixer is lifted to the predetermined depth, a slurry sending pump is turned on to spraycement slurry into a soil body, and the drill pipe of the mixer is controlled to rotate downwards to perform stirring operation; when the drill pipe of the mixer rotates downwards to the design depth,the drill pipe of the mixer is lifted to rotate upwards to perform stirring operation, and when the drill pipe of the mixer is lifted to the earth surface or a predetermined distance above design elevation, the construction of the mixing pile is completed; and the steps are repeated until the construction of all the mixing piles is completed.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

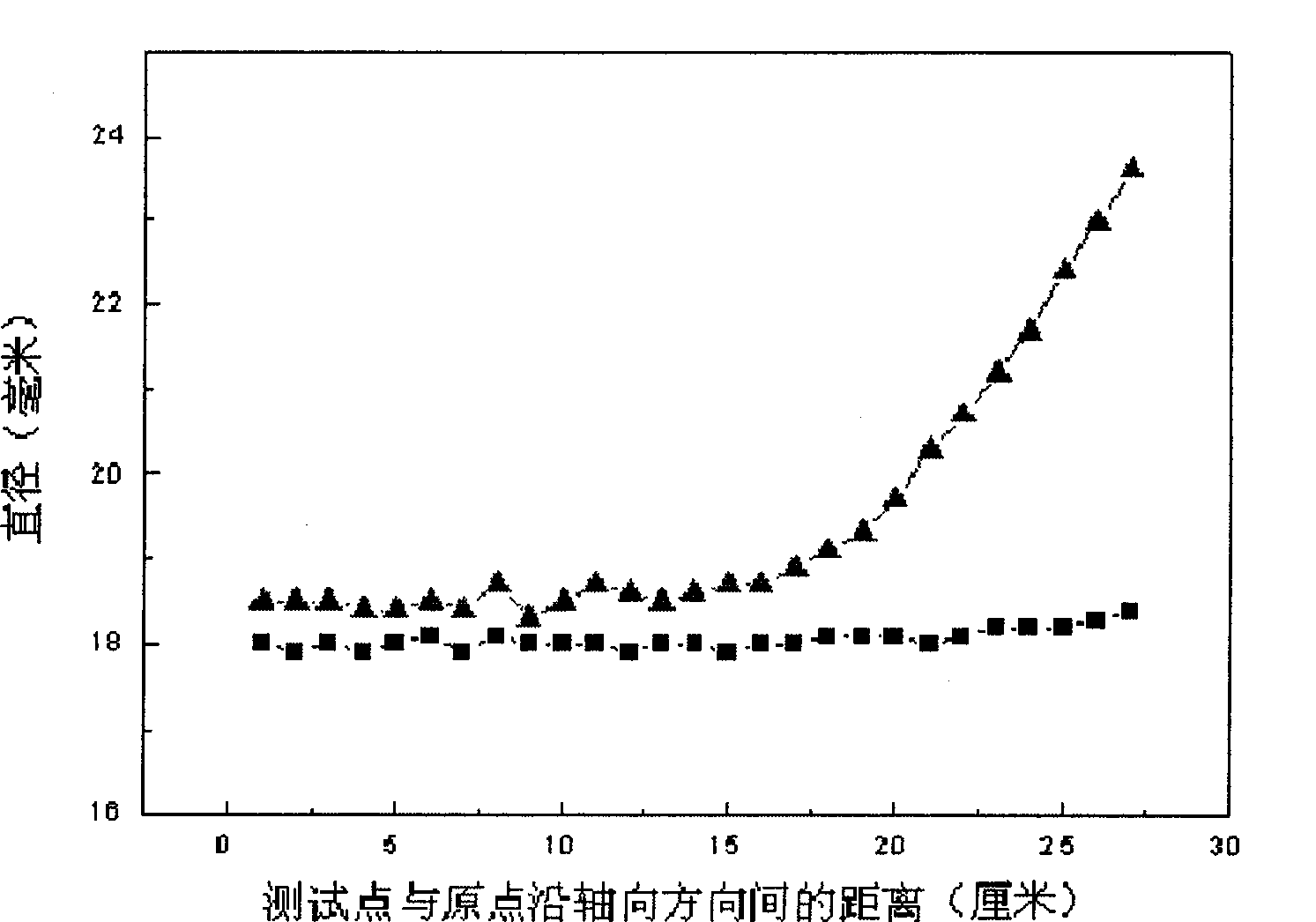

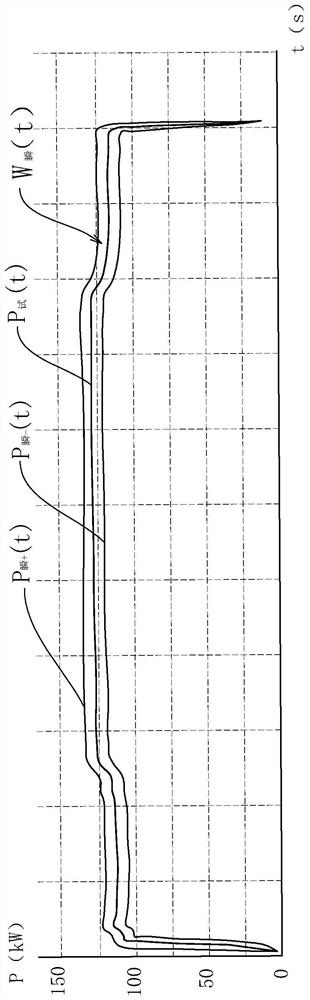

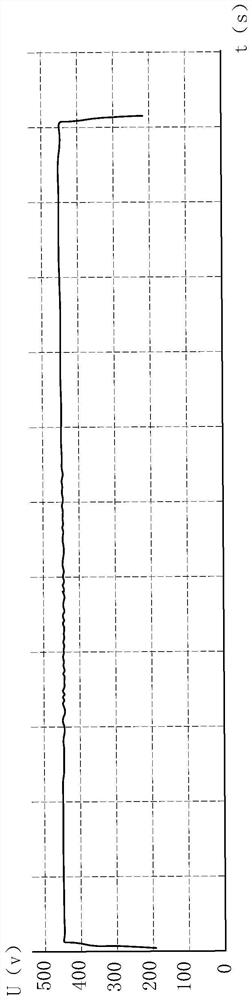

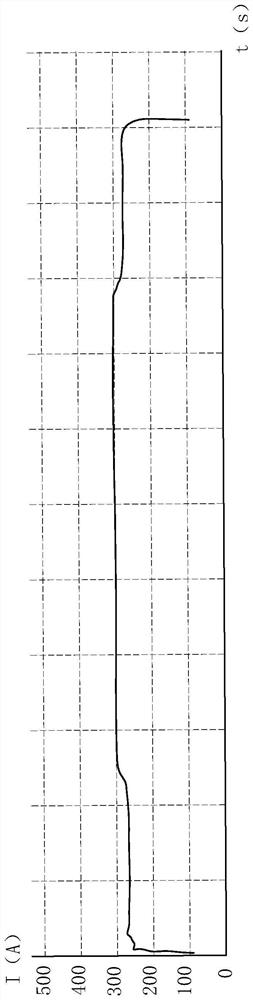

Production, calculation, heating and verification method for reducing strength difference of mandrel

ActiveCN114250343AImprove yield rateReduce intensity differencesIncreasing energy efficiencyFurnace typesThermodynamicsEngineering

The invention relates to a production, calculation, heating and verification method for reducing the strength difference of a mandrel. The production, calculation, heating and verification method comprises the steps that the depth of a quenching hardening layer needed by the mandrel is calculated according to the design strength; and calculating the output power of the induction heating equipment, calibrating the curve interval W instantaneous (t) of the instantaneous power value when the depth of the quenching hardening layer of the workpiece meets the required depth, carrying out induction heating on the workpiece by utilizing the induction heating equipment, controlling the instantaneous power to be in the curve interval W instantaneous (t), and detecting whether the instantaneous power is in the curve interval W instantaneous (t) or not so as to judge whether the workpiece is qualified or not. And S4, checking the depth of a quenching hardening layer of the workpiece. The device has the effects that the workpieces are fully inspected, and the strength difference between the workpieces in the same batch is reduced.

Owner:ZHEJIANG ODM TRANSMISSION TECH

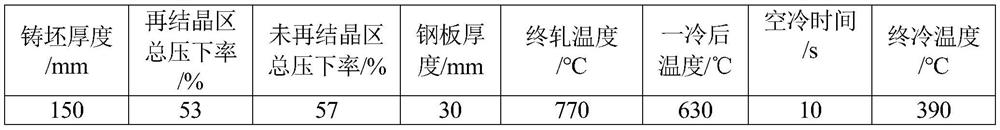

High-strength and high-plasticity 1000mpa grade hot-rolled steel plate and preparation method thereof

The invention discloses a high-strength and high-plasticity 1000 Mpa grade hot rolled steel plate and a preparation method thereof. The high-strength and high-plasticity 1000 Mpa grade hot rolled steel plate is prepared from the following components by weight: 0.05%-0.40% of C, 1.00%-5.00% of Mn, 0.70%-1.60% of Si, 0.1%-1.00% of Al, 0.01%-0.10% of Nb, 0.01%-0.10% of V, 0.002%-0.005% of N and the balance Fe and inevitable impurities. The steel plate has high strength and high plasticity, and Nb and V microalloy elements are added to be combined with C and N to form nanoscale cluster precipitates, so that matrix structures are strengthened. Through chemical composition design, and combined with medium temperature coiling, the nanoscale cluster precipitates with small size, uniform distribution and high density can be obtained, the strength of ferrite is obviously strengthened, the strength difference between the two matrix structures (ferrite and martensite) is reduced, the ferrite grainsize is refined at the same time, and high reaming performance is obtained.

Owner:武汉钢铁有限公司

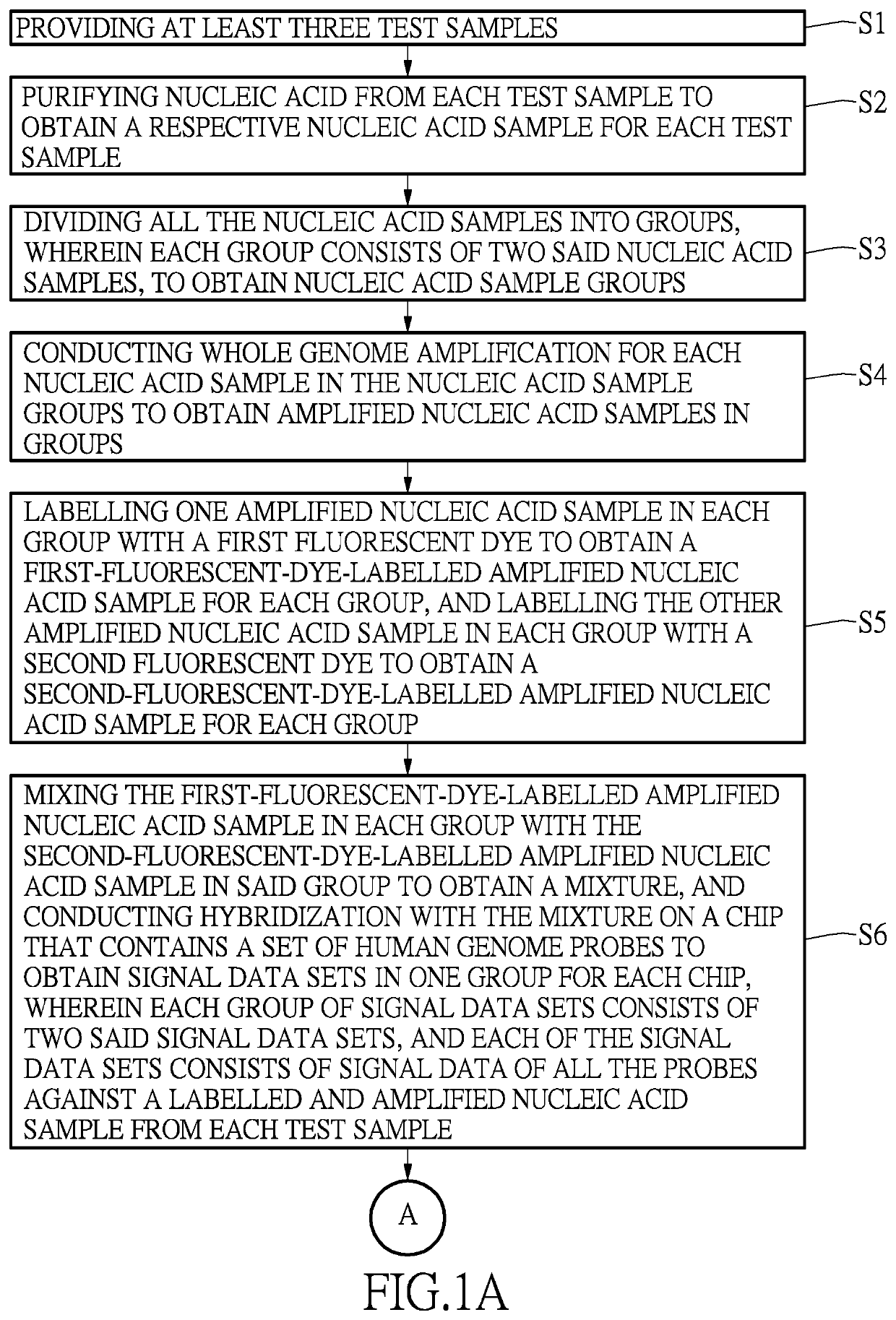

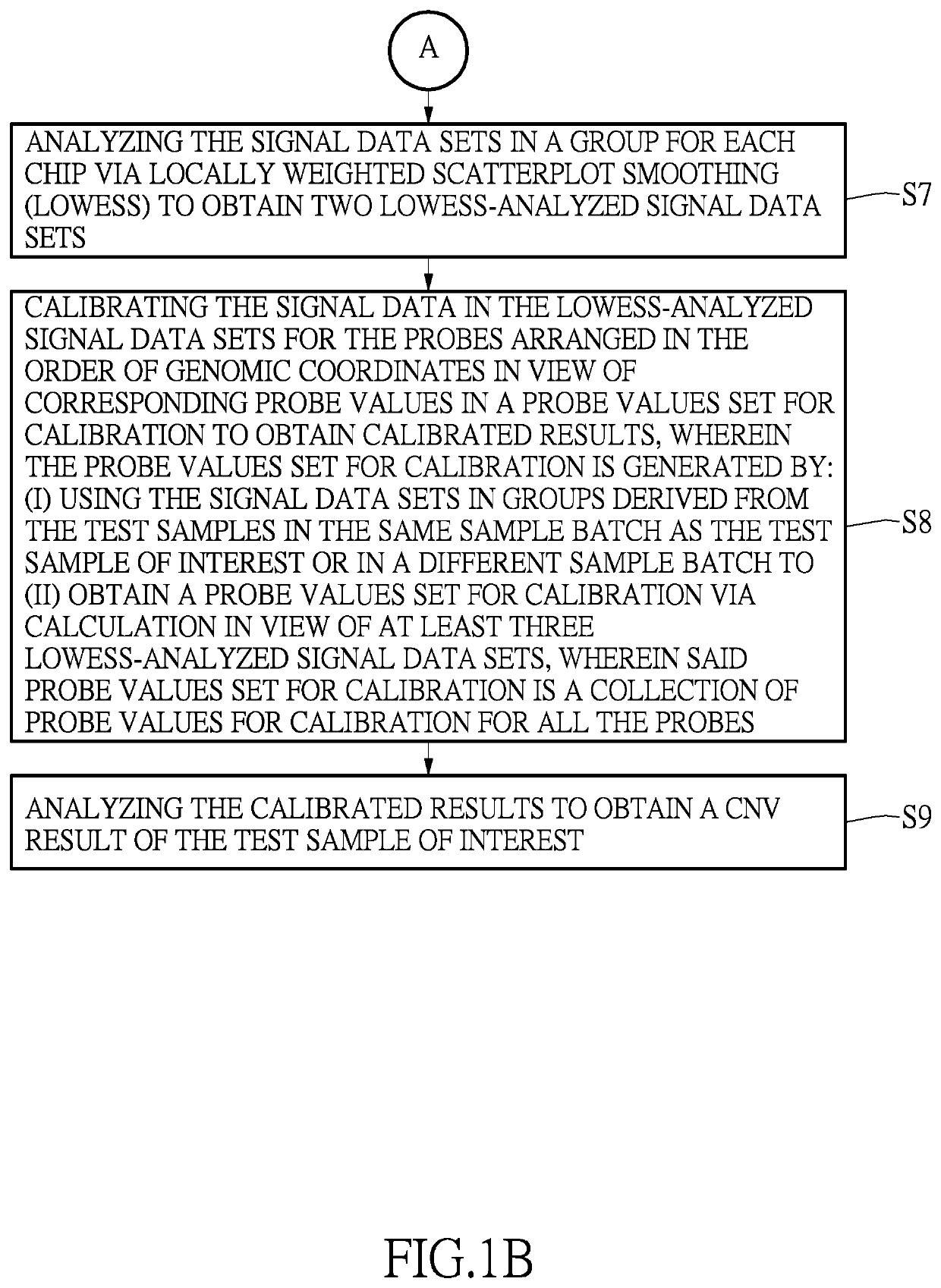

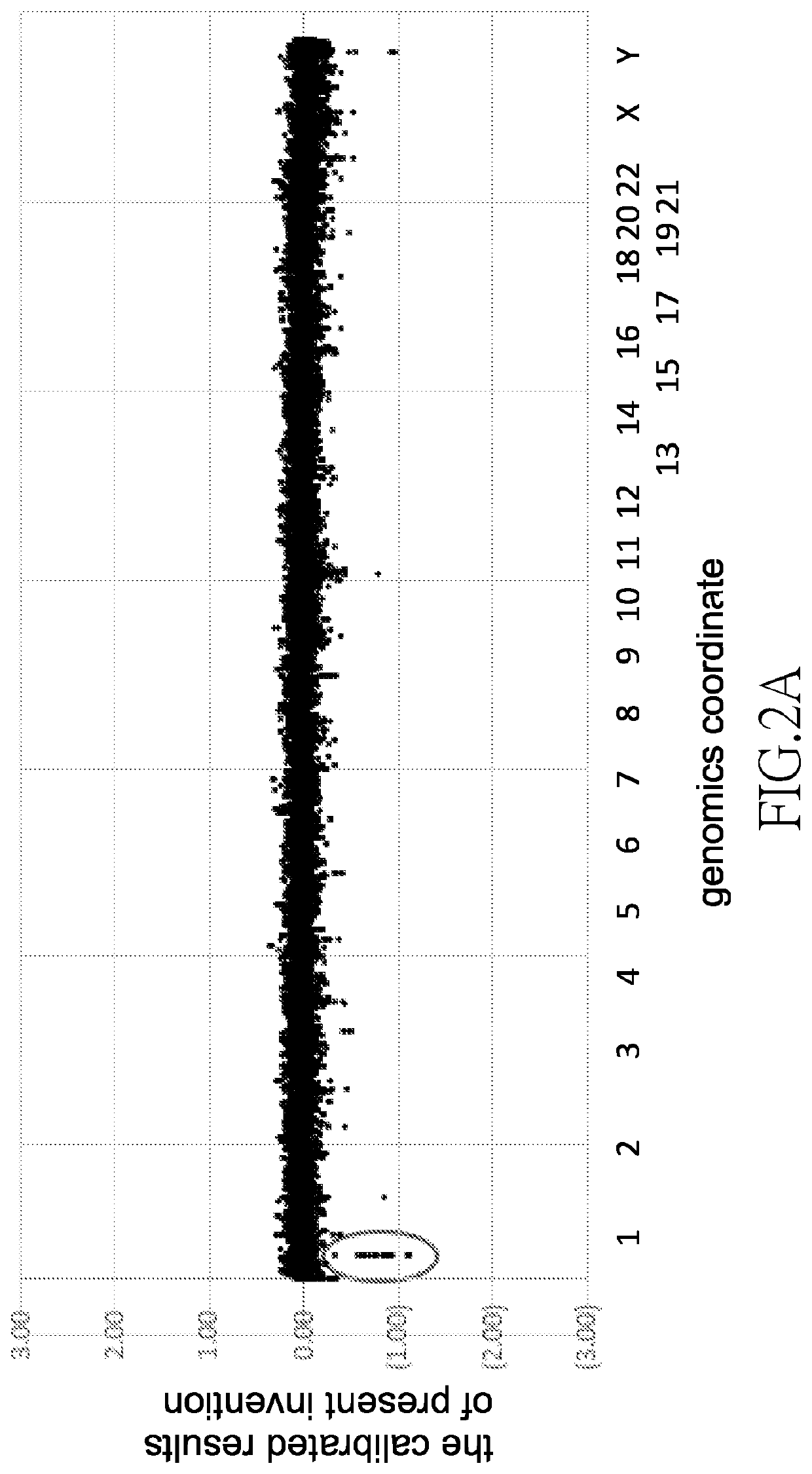

Method for detecting copy number variation

InactiveUS20200190562A1Reducing human resourceLow benefitMicrobiological testing/measurementBiostatisticsHuman DNA sequencingReference sample

Provided is a method for detecting CNV including: (A) providing at least three test samples; (B) purifying nucleic acid from each test sample; (C) dividing all the nucleic acid samples into groups; (D) conducting whole genome amplification for each nucleic acid sample in the nucleic acid sample groups; (E) labelling the amplified nucleic acid samples with two fluorescent dyes; (F) performing hybridization on a chip that contains a set of specific human genome probes; (G) analyzing the signal data sets via locally weighted scatterplot smoothing (Lowess); (H) calibrating the signal data in view of corresponding probe values in a probe values set for calibration; (I) analyzing the calibrated results to obtain the CNV result of the test sample of interest. The detection method saves the reference sample and is beneficial for high-throughput detection.

Owner:PHALANX BIOTECH GROUP

A Method of Using Metal Pipe Wrinkles to Realize Circular Connection

Owner:SHAANXI UNIV OF SCI & TECH

Photolithographic masks and fabrication method thereof

ActiveUS9348215B2Reduce intensity differencesIncrease contrastOriginals for photomechanical treatmentRefractive index

A photolithographic mask is provided. The photolithographic mask includes a substrate having a first surface configured as a light incidence plane of an exposure light and a second surface. The photolithographic mask also includes a plurality of scattering centers functioning as a refractive index disturbance inside the substrate. Further, the photolithographic mask includes a plurality of mask patterns on the second surface of the substrate.

Owner:SEMICON MFG INT (SHANGHAI) CORP

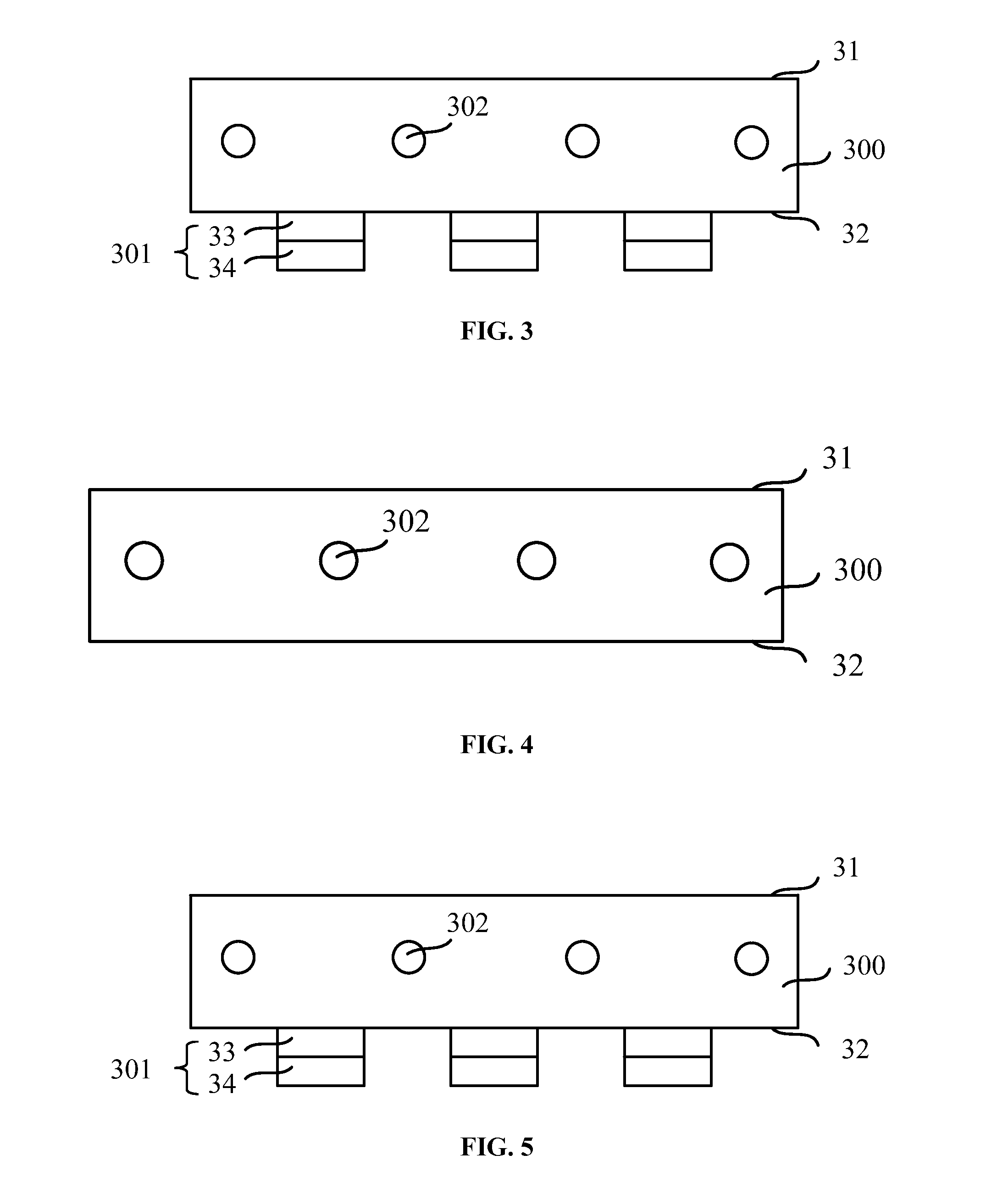

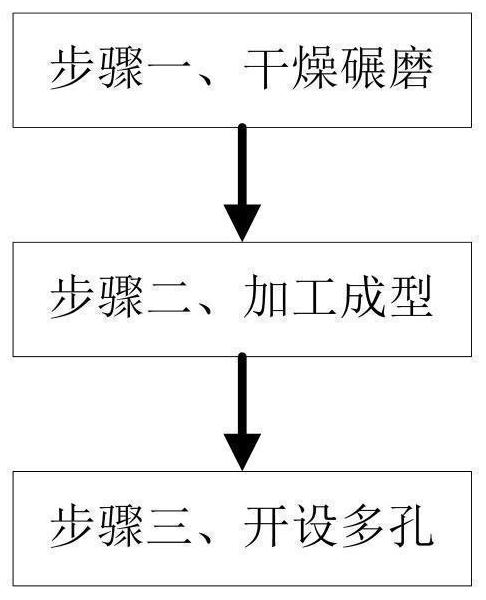

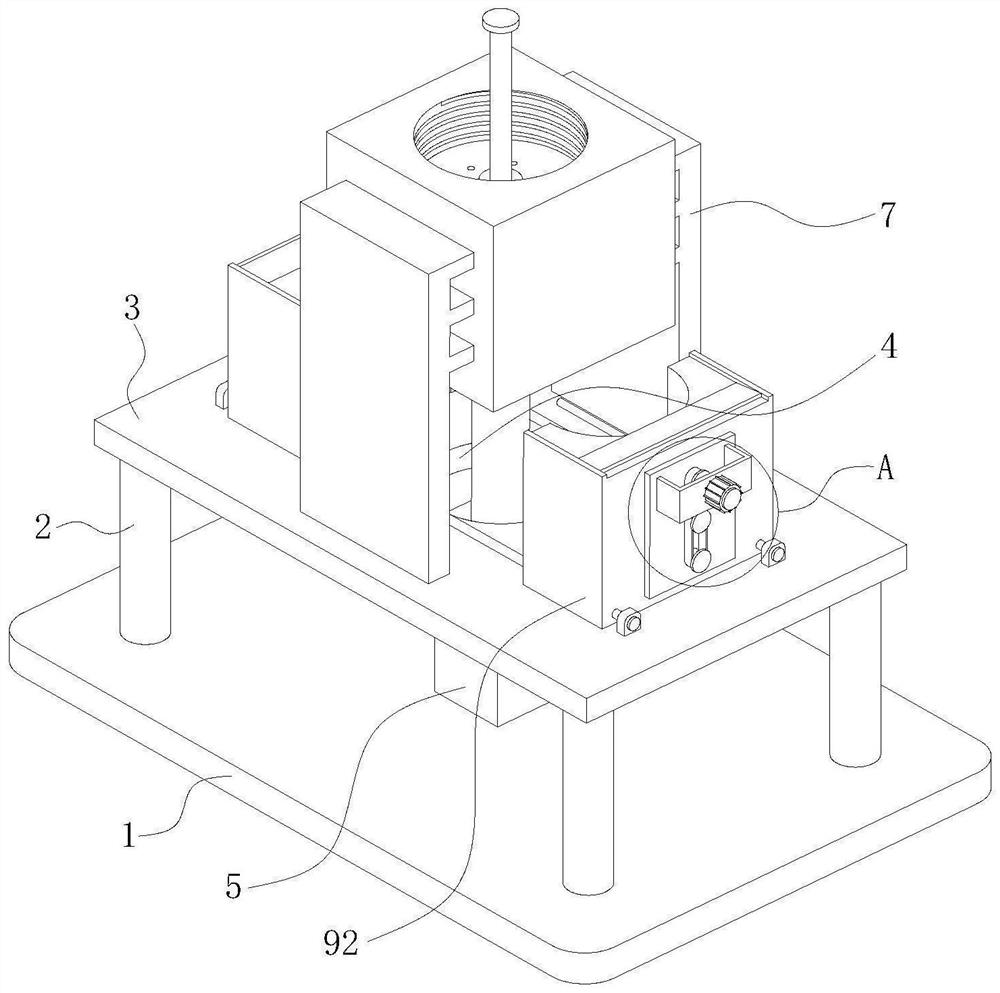

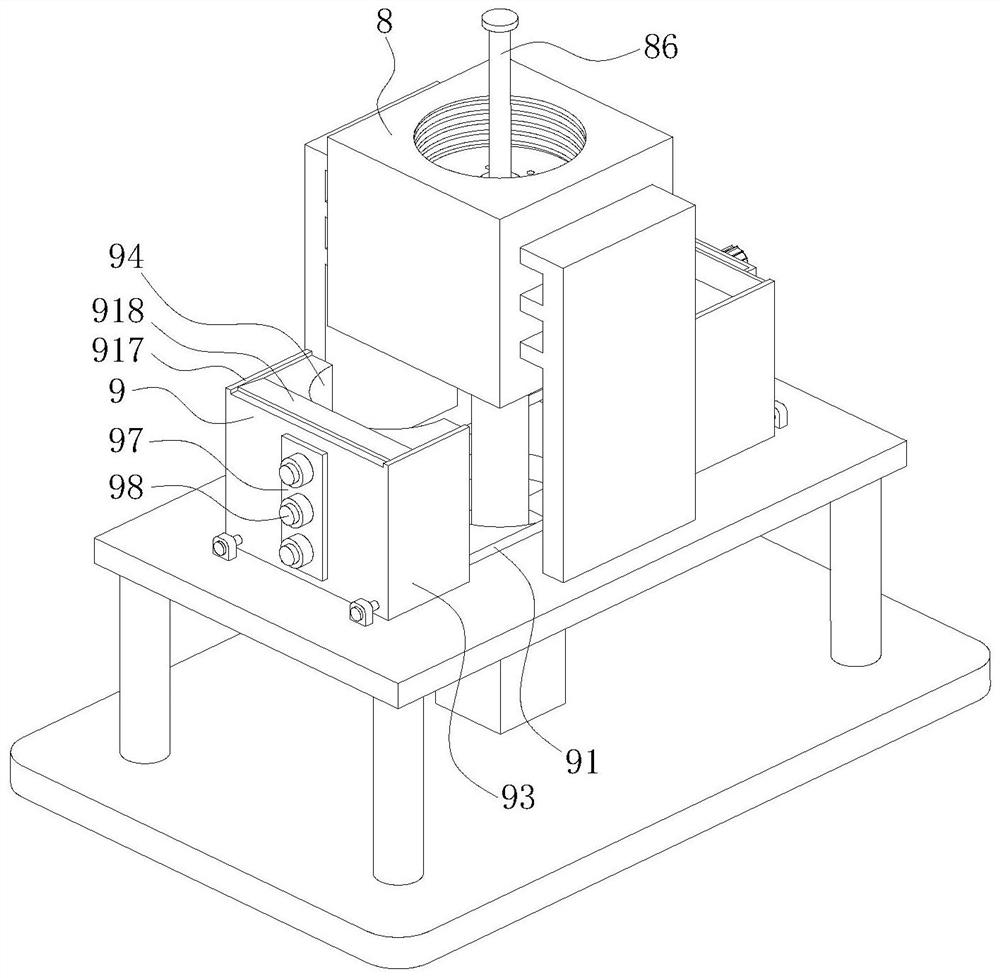

A kind of porous activated carbon preparation process

ActiveCN111943201BReduce molding qualityEvenly distributedCarbon compoundsActivated carbonCarbonization

The invention belongs to the technical field of activated carbon, and specifically relates to a preparation process of porous activated carbon, which includes the following steps: step 1, drying and grinding: carbonizing and grinding the sawdust after drying, to obtain dry carbon powder; step 2, processing and molding: Extrude the carbon powder, and then use a mold to process the carbon powder into a cylindrical carbon block; step 3, open pores: open pores on the surface of the formed cylindrical carbon block; wherein, steps 2 and 3 use a porous Activated carbon preparation is mechanically coordinated. The invention reduces the strength difference of each part of the cylindrical activated carbon after molding, and improves the molding quality; the invention reduces the extrusion force of the plunger on the activated carbon during the process of opening the cylindrical activated carbon, and avoids the need for cylindrical activated carbon. There are cracks inside.

Owner:蜂窝活性炭有限公司

A kind of high-strength polypropylene material and preparation method thereof

ActiveCN105383029BCrystallization morphology can be controlledModulation of Crystalline MorphologyHigh intensityCrystal habit

The invention discloses a preparation method of a high-strength polypropylene material. The preparation method is characterized in that in the machining process, the crystal habit of polypropylene is regulated and controlled, and therefore the mechanical performance of polypropylene is improved. In the machining process, a certain shear and two-way stretch force field is applied to polypropylene melt by regulating the number and type of force assembling units, under the action of the force field, the crystal habit of polypropylene is developed into shish-kebab structures orientated in different directions, the stretch strength of the polypropylene material can be remarkably improved, and the difference of the mechanical strength, in the extrusion direction, of the polypropylene product and the mechanical strength in the direction perpendicular to the extrusion direction, of the polypropylene product is weakened. The force assembling units are added to existing traditional extrusion equipment, operation is easy, continuous production can be achieved, control is convenient, quality is stable, production efficiency is high, and good industrial and market prospects are achieved; and the method can be widely applied to preparing high-strength polypropylene plate, sheet and film materials.

Owner:SICHUAN UNIV

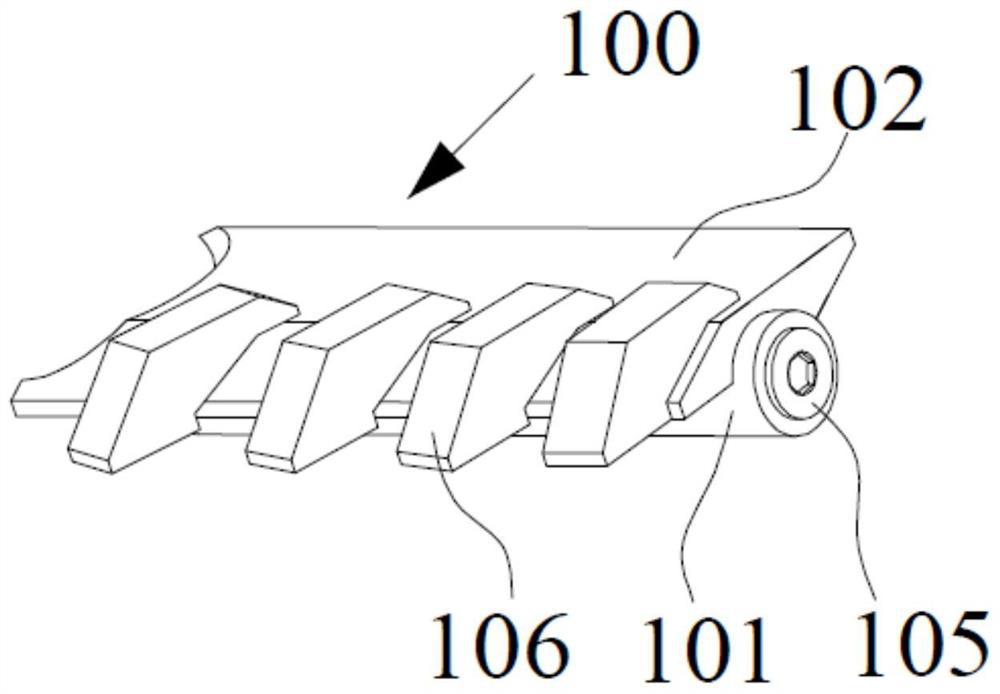

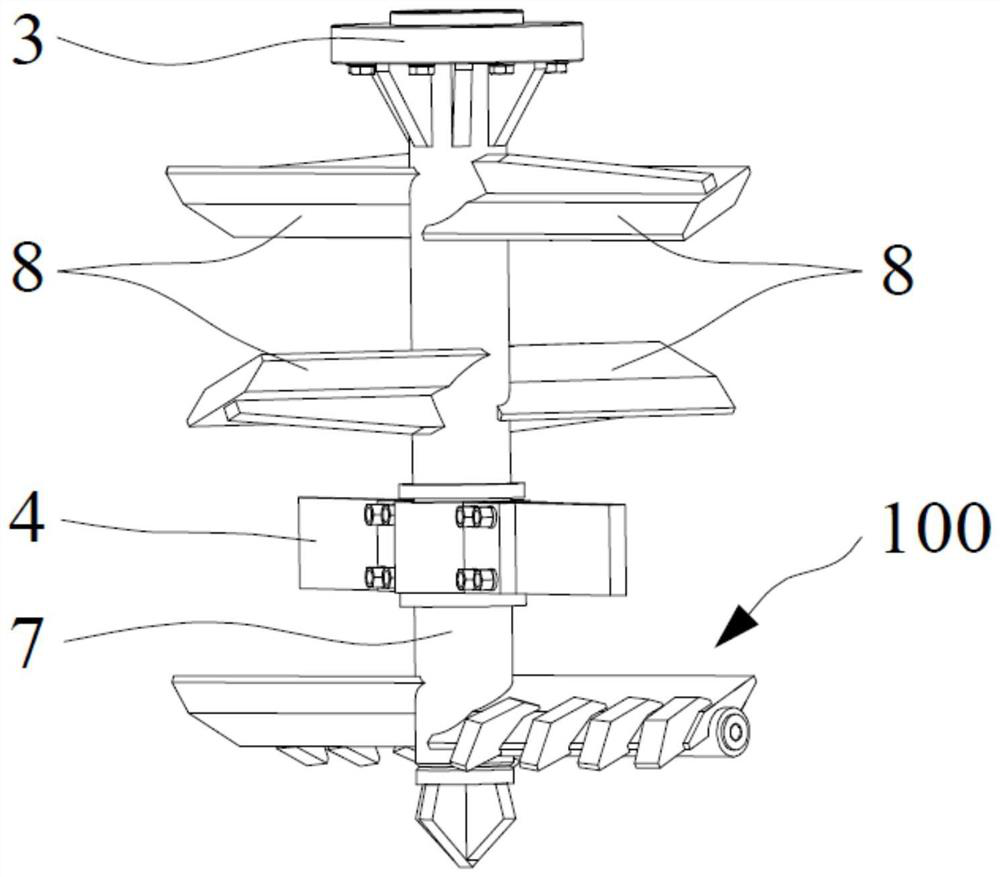

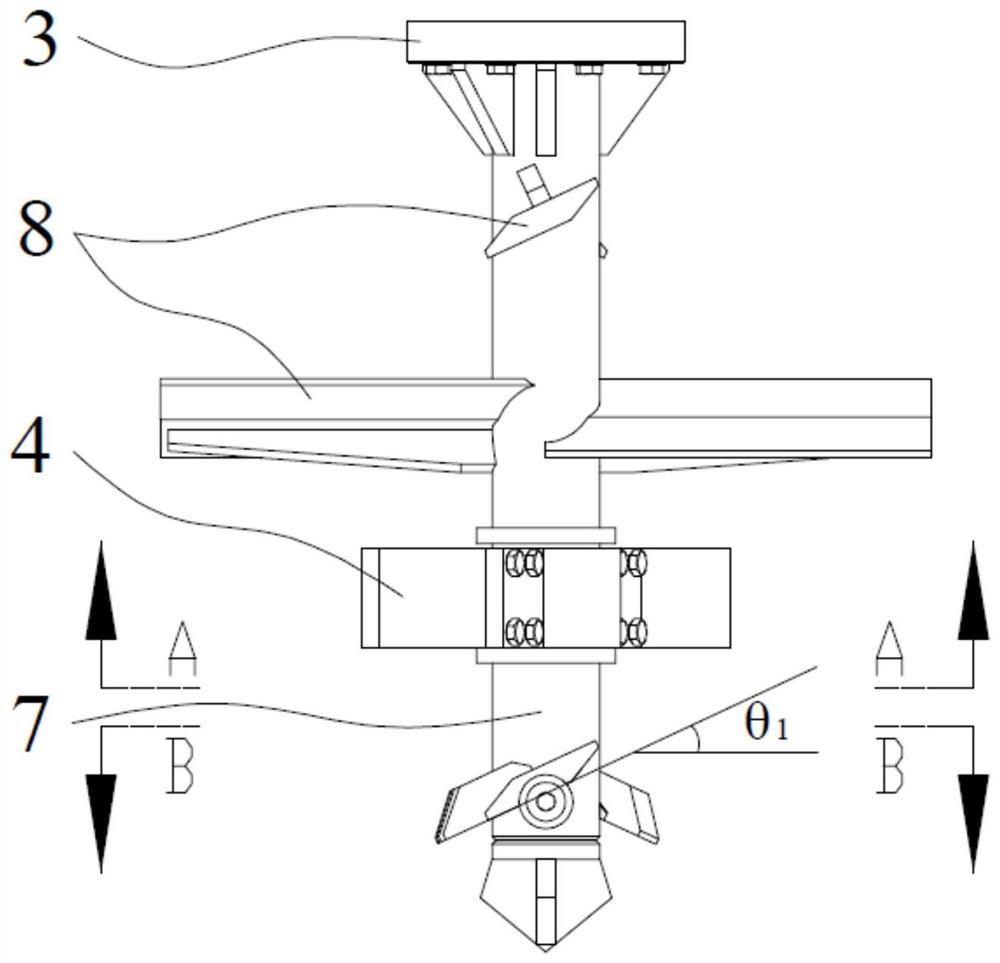

Guniting digging and cutting structure for large-diameter wet spraying mixing pile construction drilling tool

PendingCN114753359AReduce intensity differencesHigh strengthBulkheads/pilesMechanical engineeringDrill bit

The invention relates to a guniting digging and cutting structure for a large-diameter wet spraying mixing pile construction drilling tool, which comprises a drill bit center rod, a guniting digging and cutting unit is arranged in the radial direction of the drill bit center rod, the guniting digging and cutting unit comprises a guniting channel and a digging and cutting wing plate, and the digging and cutting wing plate is fixed on the outer wall of the drill bit center rod. One end of the slurry spraying channel is communicated with a slurry flowing channel arranged on the drill bit center rod, the slurry spraying channel is located below the digging and cutting wing plate and is parallel to the length direction of the digging and cutting wing plate, and a slurry spraying through seam is formed in the axial direction of the slurry spraying channel; the method has the characteristics of uniformly spreading the curing agent slurry along the radius of the pile body, effectively improving the pile body quality and the construction efficiency of the stirring pile, reducing the dosage of the curing agent and the like, and also has the characteristics of effectively preventing the slurry spraying pipe from being blocked, easily cleaning the blocked pipe and the like.

Owner:浙江坤德创新岩土工程有限公司

Electro-optical filter

InactiveUS7755720B2Reduce intensity differencesLight intensity differenceTelevision system detailsNon-linear opticsOptical propertyLight intensity

The present invention provides an electro-optical filter for filtering light from an object. The filter is arranged for receiving the light via a first imaging element and comprises a plurality of reflective elements for receiving and reflecting the light. Each reflective element has an optical property that is dependent on an intensity of the light at or near the reflective element. The optical property controls local filtering of the light intensity in a manner such that, above a predetermined intensity threshold, the filter reduces intensity differences of light originating from bright and dark regions of the object.

Owner:LIVE TECH

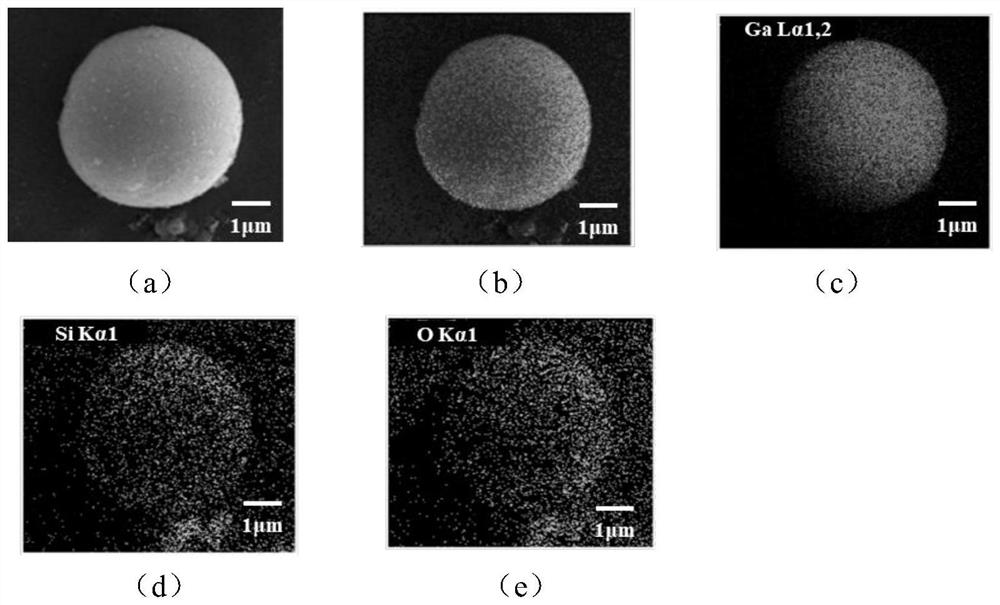

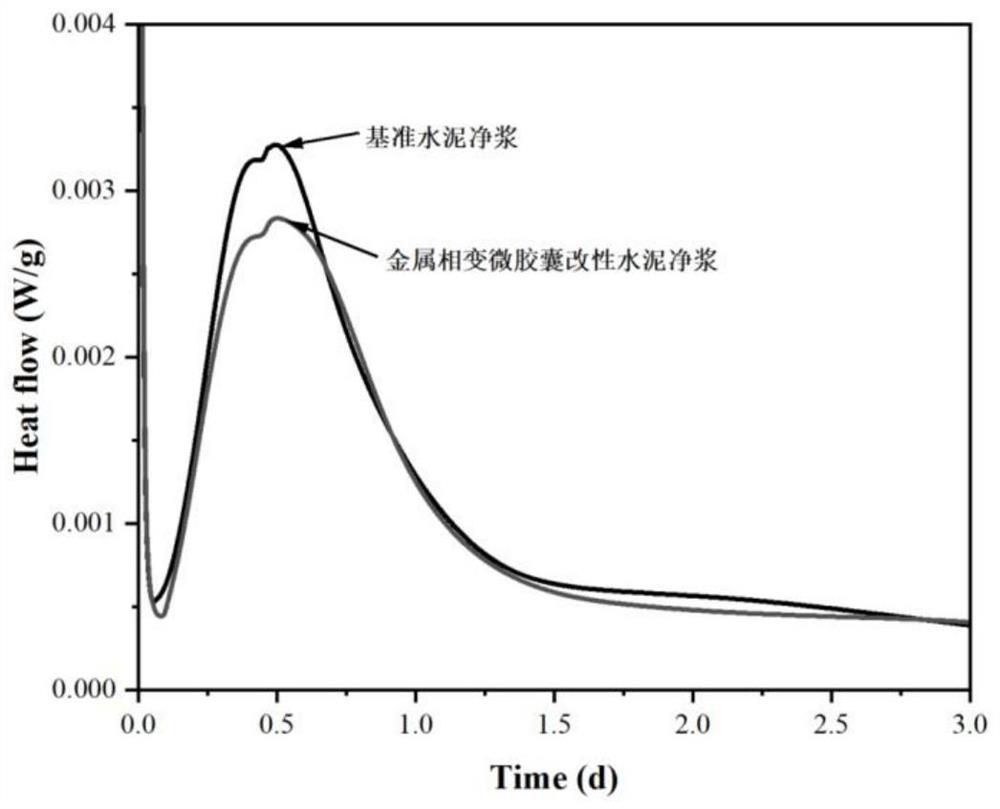

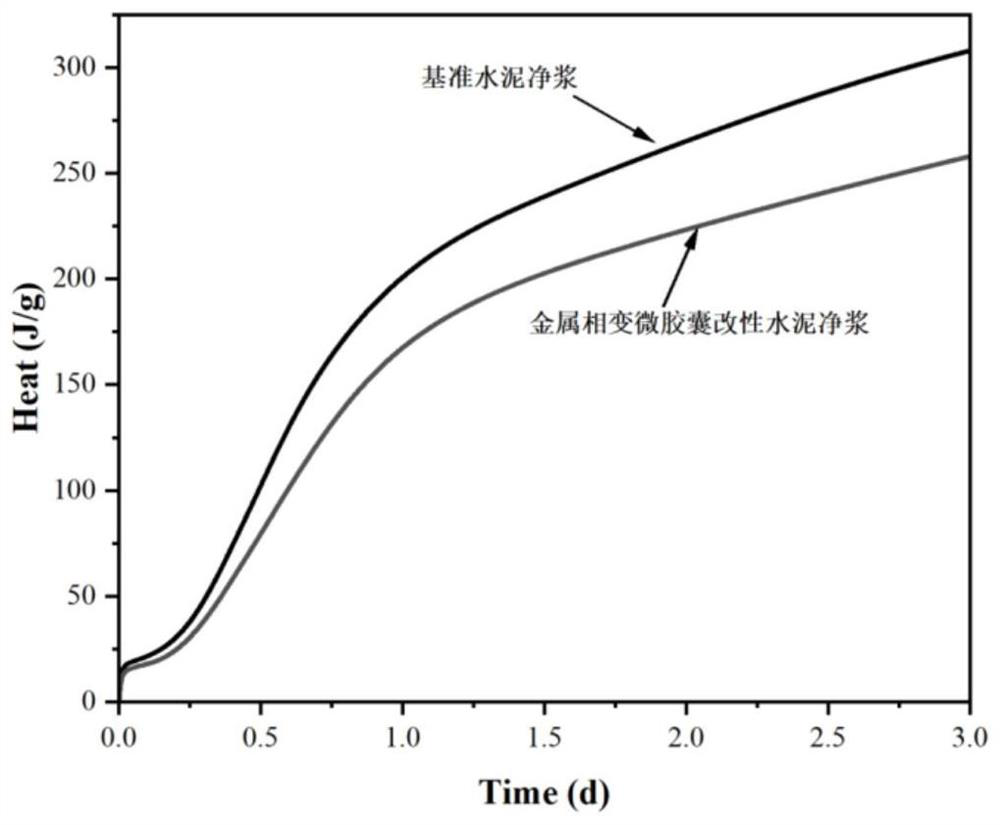

Phase change microcapsule as well as preparation and application thereof

The invention discloses a phase change microcapsule, preparation and application, the phase change microcapsule is a spherical particle composed of a core material and a shell layer coating the core material, the inorganic shell layer is silicon dioxide, and the metal core material is gallium. The preparation method comprises the following steps: adding molten metal into a solution containing a surfactant, and obtaining a stable metal microsphere suspension under the synergistic effect of high-speed stirring and intense ultrasound; and transferring the suspension into a three-neck flask, adding a silicon dioxide precursor, adjusting the pH value, and stirring for reaction to obtain the silicon dioxide coated gallium phase change microcapsule. The phase change microcapsule prepared by the method has the advantages of controllable particle size, large energy storage density, strong thermal conductivity, good mechanical property and the like, has good compatibility with building materials, and can be used for regulating and controlling the hydration heat release rate and heat release amount of cement.

Owner:SOUTHEAST UNIV

An array substrate, a touch display panel and a touch display device

ActiveCN108648683BImprove brightness uniformityReduce intensityStatic indicating devicesInput/output processes for data processingShift registerScan line

The present invention provides an array substrate, a touch display panel and a touch display device. The number of inverters in the second cache unit is smaller than the number of inverters in the first cache unit, or, the number of inverters in the second cache unit The size of the inverter is smaller than the size of the inverter in the first cache unit, or the number of inverters in the second cache unit is smaller than the number of inverters in the first cache unit, and the inverter in the second cache unit The size of the phaser is smaller than the size of the inverter in the first buffer unit, therefore, by reducing the signal amplification effect of the second buffer unit in the second shift register unit, the transmission of the second shift register unit to the second The intensity of the scanning signal of the scanning line, so that the intensity difference between the intensity of the scanning signal output by the first scanning line and the intensity of the scanning signal output by the second scanning line can be reduced, and then the brightness of the conventional display area and the brightness of the notch display area can be reduced difference, improving the brightness uniformity of the display panel.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

A kind of high-toughness B-containing hot-rolled low-carbon bainite steel plate and its production method

The invention provides a high-toughness B-containing hot-rolling low-carbon bainite steel plate. The high-toughness B-containing hot-rolling low-carbon bainite steel plate comprises the following components in percentage by weight: 0.030 to 0.080 percent of C, 1.50 to 1.80 percent of Mn, 0.10 to 0.40 percent of Si, less than or equal to 0.0050 percent of S, less than or equal to 0.015 percent of P, 0.030 to 0.060 percent of Nb, 0.008 to 0.020 percent of Ti, less than or equal to 0.10 percent of V, 0.020 to 0.060 percent of Alt, 0.0010 to 0.0025 percent of B, 0.20 to 0.50 percent of Cr, less than or equal to 0.30 percent of Mo and the balance of Fe and unavoidable impurities. In the production process of the steel plate, the problems that the existing B-containing hot-rolling low-carbon bainite steel plate has great fluctuation of strength and impact toughness are solved by utilizing a laminar flow section cooling process, the B-containing hot-rolling low-carbon bainite steel plate withsmall fluctuation of strength and impact toughness is obtained, and the application of the high-toughness B-containing hot-rolling low-carbon bainite steel plate to the construction machinery industry is facilitated.

Owner:ANYANG IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com