Protective shoe toecap made of long fiber reinforced thermoplastic resin and manufacture thereof

A thermoplastic resin, protective shoe technology, applied in shoe uppers, footwear, footwear, etc., can solve the problems of thermal deterioration, higher production costs, increased scrap rate, etc., to reduce the difference in strength, reduce material costs, and improve The effect of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

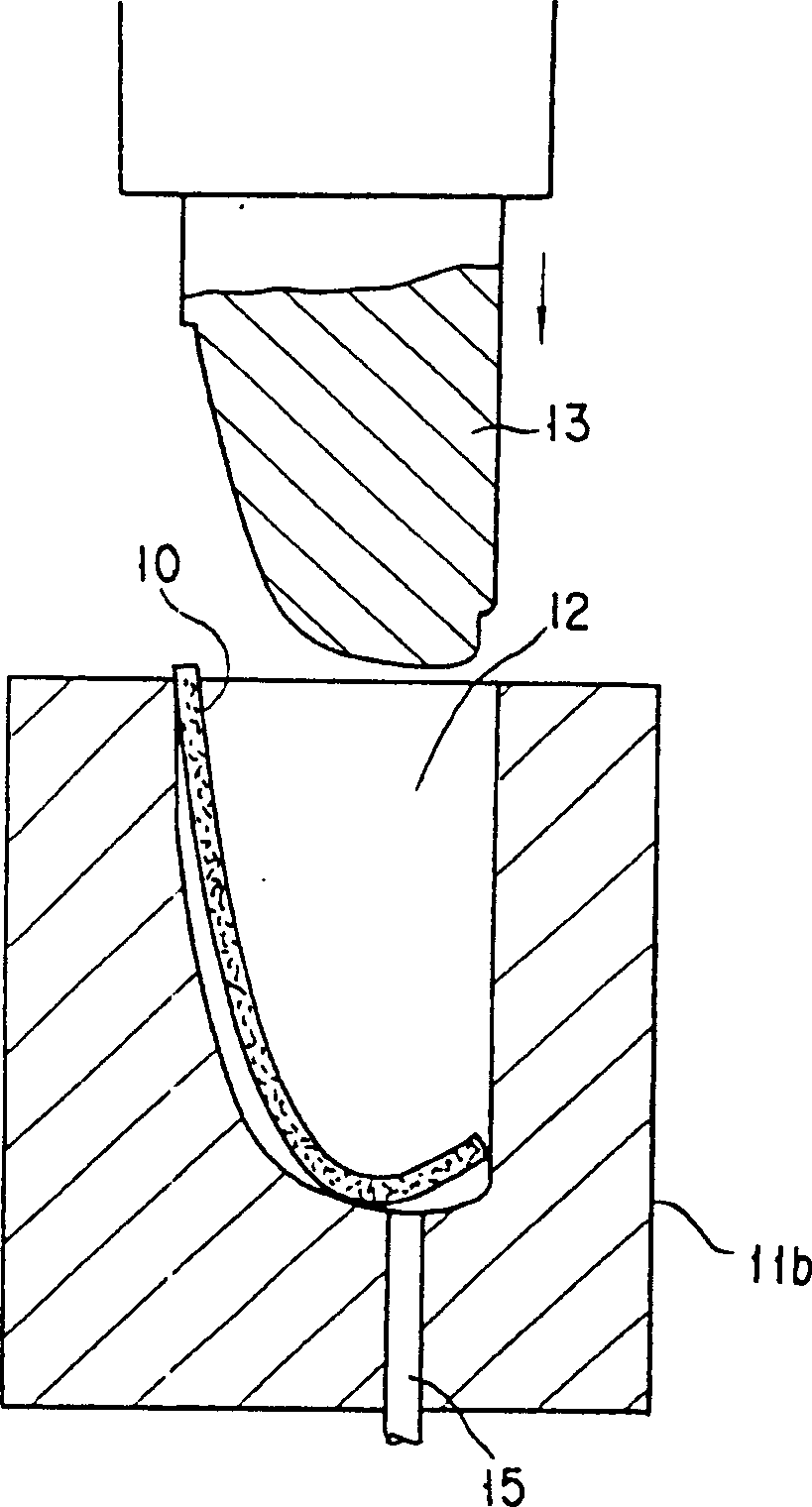

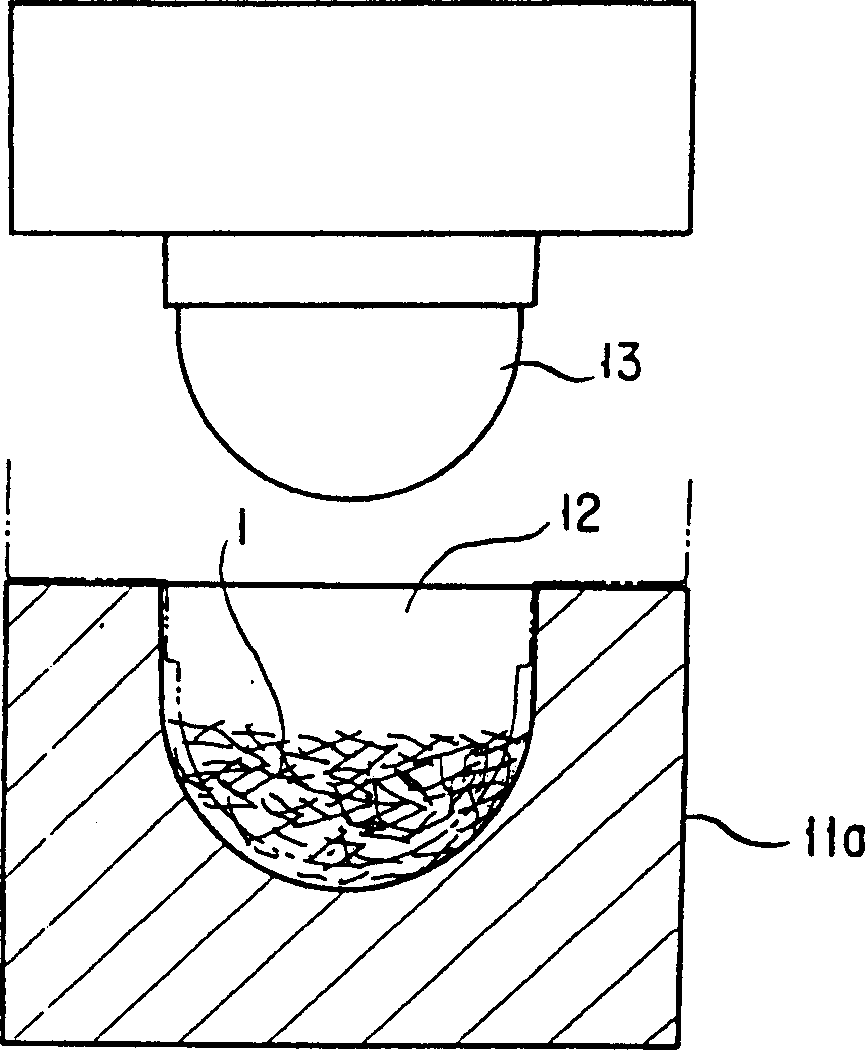

[0050] Fiber pellets of long fiber-reinforced thermoplastic resin (50% by volume of glass fibers contained in polypropylene) cut into 20 mm in length and about 0.5 mm in diameter were weighed, and the pellets were heated in a mold to be shaped. Carry out plasticizing treatment (at a pressure of 0.5kg / cm 2 And the temperature is 210° C. for 0.5 minutes), so as to preliminarily prepare a pseudo toe cap with a curved part. Then, the obtained pseudo toe cap is put into a toe cap forming mold (main mold), and the toe cap is heated at 400kg / cm 2 Compression molding is carried out at 135°C under high pressure to produce a toe cap.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com