High-strength polypropylene material and preparation method thereof

A polypropylene material and polypropylene technology, applied in the field of polymer material processing, can solve the problems of difficulty in meeting the performance requirements such as transparency and safety of polypropylene materials, and achieve good industrial application prospects, high production efficiency, and significant enhancement effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Polypropylene (1005, Formosa Plastics, Taiwan) was selected as the experimental material, and its melt index was 0.5g / 10min (210°C, 2.16Kg). Vacuum dry in an oven at 80°C for 12h.

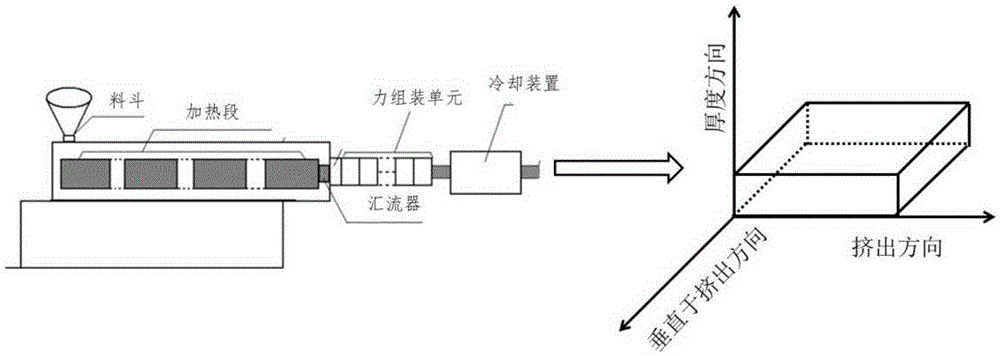

[0037] (2) Put the dried pellets into a multi-stage stretching device consisting of an extruder (1), a confluence (2), a force assembly unit (3), and a cooling roller (4) (see figure 1 ) in the extruder. After the continuous division-deformation-stacking action of the force assembly unit, it flows out from the discharge port and is cooled by a traction cooling roller to obtain a polypropylene material with a thickness of about 1.5mm. Then the samples were annealed in a vacuum environment at 145°C for 12h.

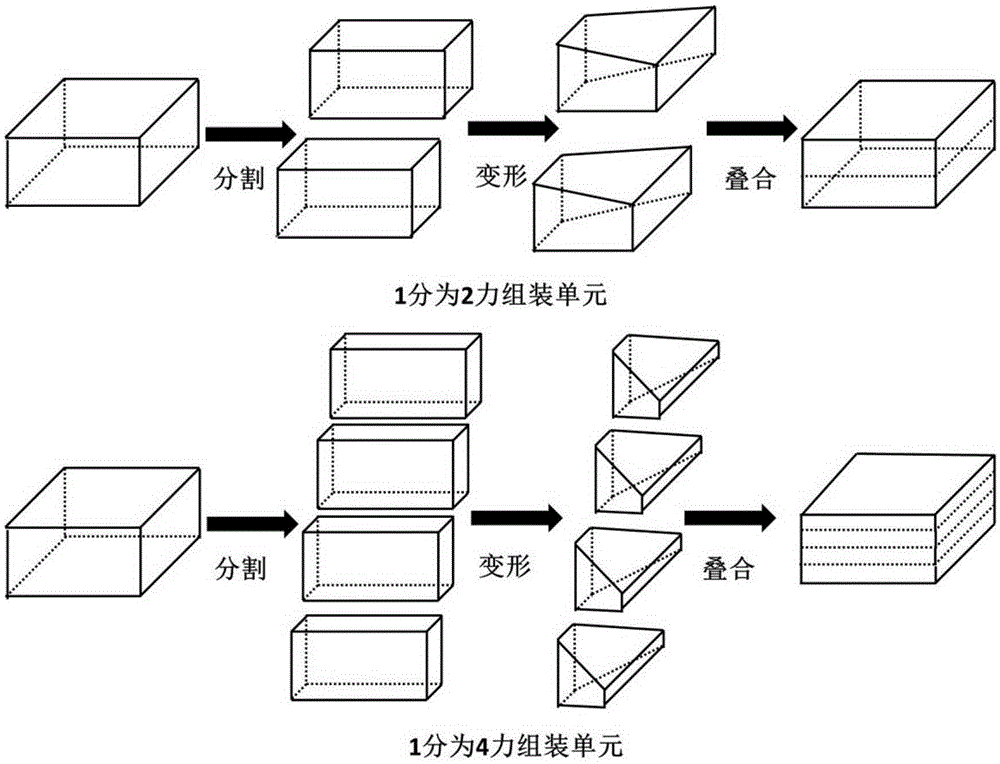

[0038] In this embodiment, the force assembly unit adopts three 1 divided into 2 force assembly units.

[0039] like figure 1 As shown in , the discharge port of the extruder in the multi-stage stretching device is connected with the feed port of the confluence, the discharge port...

Embodiment 2

[0042] (1) Polypropylene (1005, Formosa Plastics, Taiwan) was selected as the experimental material, and its melt index was 0.5g / 10min (210°C, 2.16Kg). Vacuum dry in an oven at 80°C for 12h.

[0043] (2) Put the dried pellets into a multi-stage stretching device consisting of an extruder (1), a confluence (2), a force assembly unit (3), and a cooling roller (4) (see figure 1 ) in the extruder. After the continuous division-deformation-stacking action of the force assembly unit, it flows out from the discharge port and is cooled by a traction cooling roller to obtain a polypropylene material with a thickness of about 1.5mm. Then the samples were annealed in a vacuum environment at 145°C for 12h. Among them, the temperatures of the feeding port, conveying section, melting section, and homogenizing section of the single-screw extruder (1) are respectively 155°C, 205°C, 215°C, and 215°C; °C, 210 °C.

[0044] In this embodiment, the force assembly unit adopts seven force assemb...

Embodiment 3

[0047] (1) Polypropylene (1005, Formosa Plastics, Taiwan) was selected as the experimental material, and its melt index was 0.5g / 10min (210°C, 2.16Kg). Vacuum dry in an oven at 80°C for 12h.

[0048] (2) Put the dried pellets into a multi-stage stretching device consisting of an extruder (1), a confluence (2), a force assembly unit (3), and a cooling roller (4) (see figure 1 ) in the extruder. After the continuous division-deformation-stacking action of the force assembly unit, it flows out from the discharge port and is cooled by a traction cooling roller to obtain a polypropylene material with a thickness of about 1.5mm. Then the samples were annealed in a vacuum environment at 145°C for 12h. Among them, the temperatures of the feeding port, conveying section, melting section, and homogenizing section of the single-screw extruder (1) are respectively 155°C, 205°C, 215°C, and 215°C; °C, 210 °C.

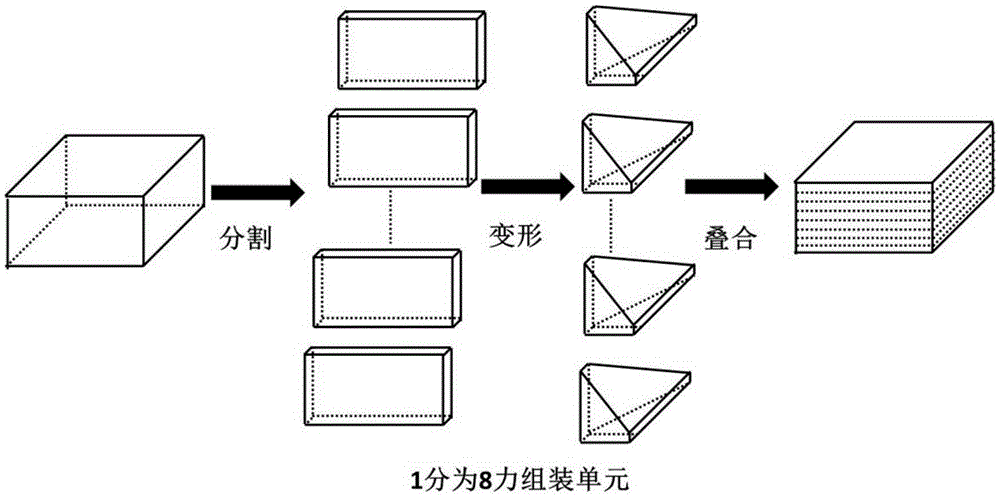

[0049] In this embodiment, the force assembly unit adopts 7 1 divided into 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com