Device for measuring surface shape of high-reflection mirror

A measuring device and high-reflection technology, which is applied in the direction of measuring device, reflective surface test, optical device, etc., can solve the problems of surface shape accuracy, inaccurate results, filter lines, etc. The effect of sharpening and reducing intensity differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

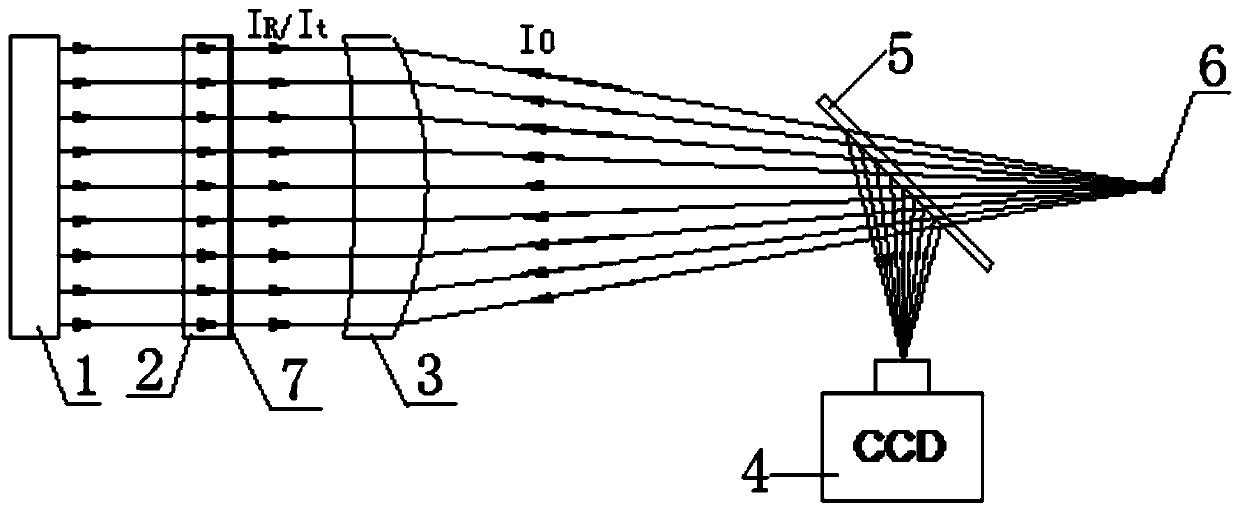

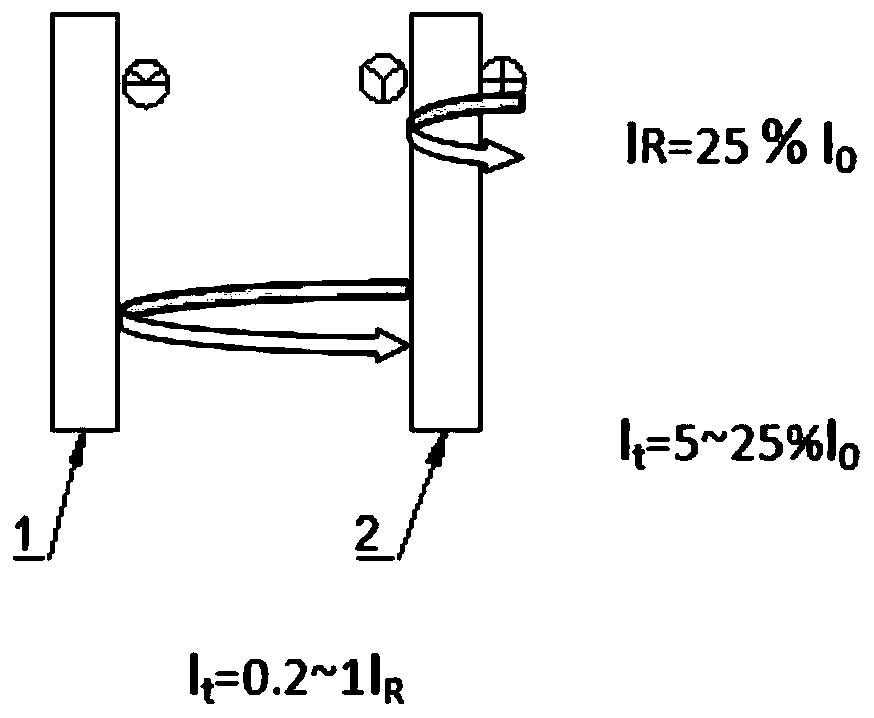

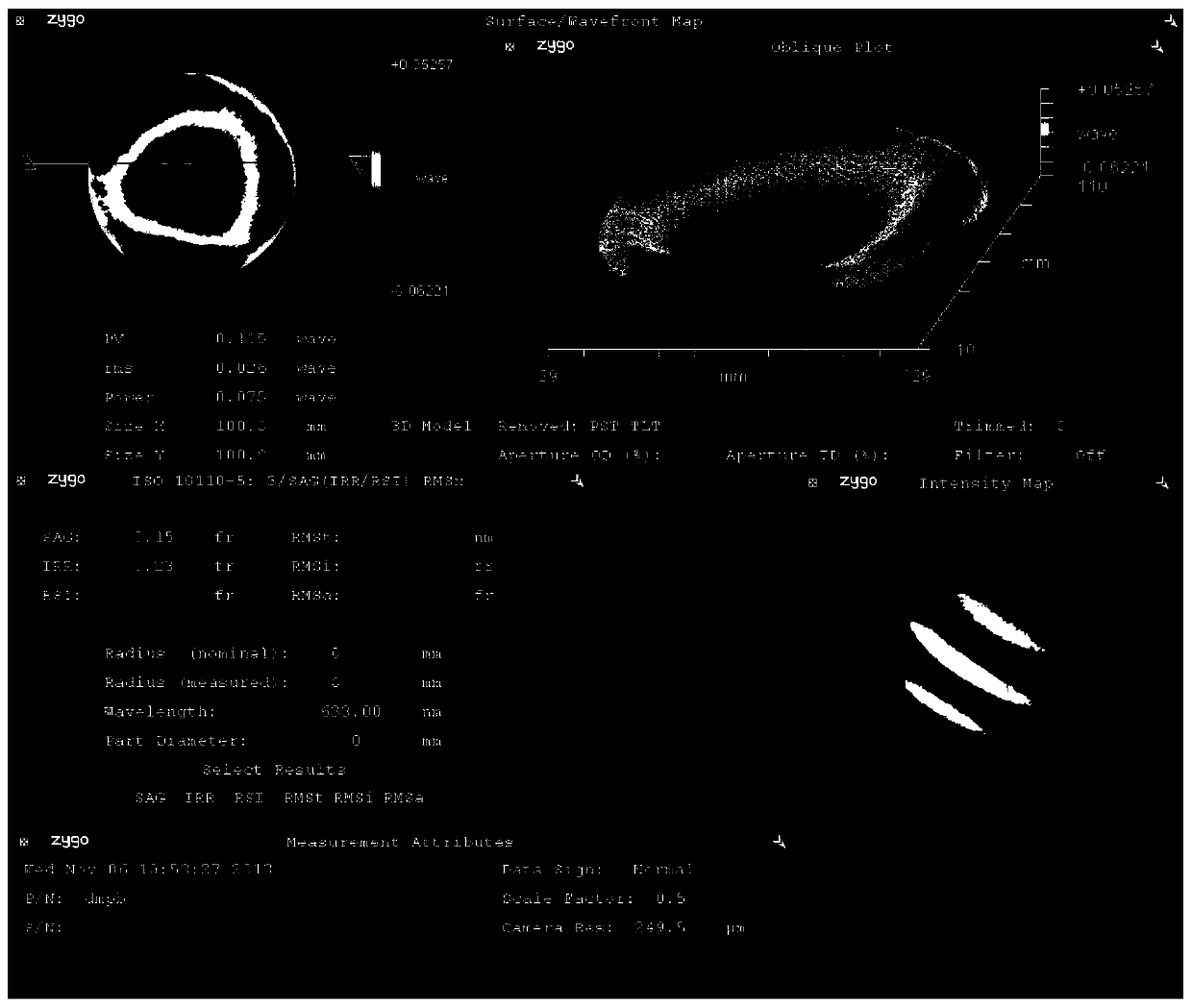

[0017] Such as figure 1 As shown, the measuring device of the high reflective mirror surface shape of the present invention comprises light source 6, beam splitter 5, collimator 3, standard mirror 2 and CCD imaging system 4; The front surface of standard mirror 2 is coated with spectroscopic film 7; Light source 6 emits After the light beam passes through the beam splitter 5, the point light source is converted into parallel light by the collimator 3. When the parallel incident light Io passes through the standard mirror 2, a part of the light is reflected back by the standard mirror 2 coated with the spectroscopic film 7 (for I R ), another part of the light reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com