Production method for Gamma-TiAl alloy bar

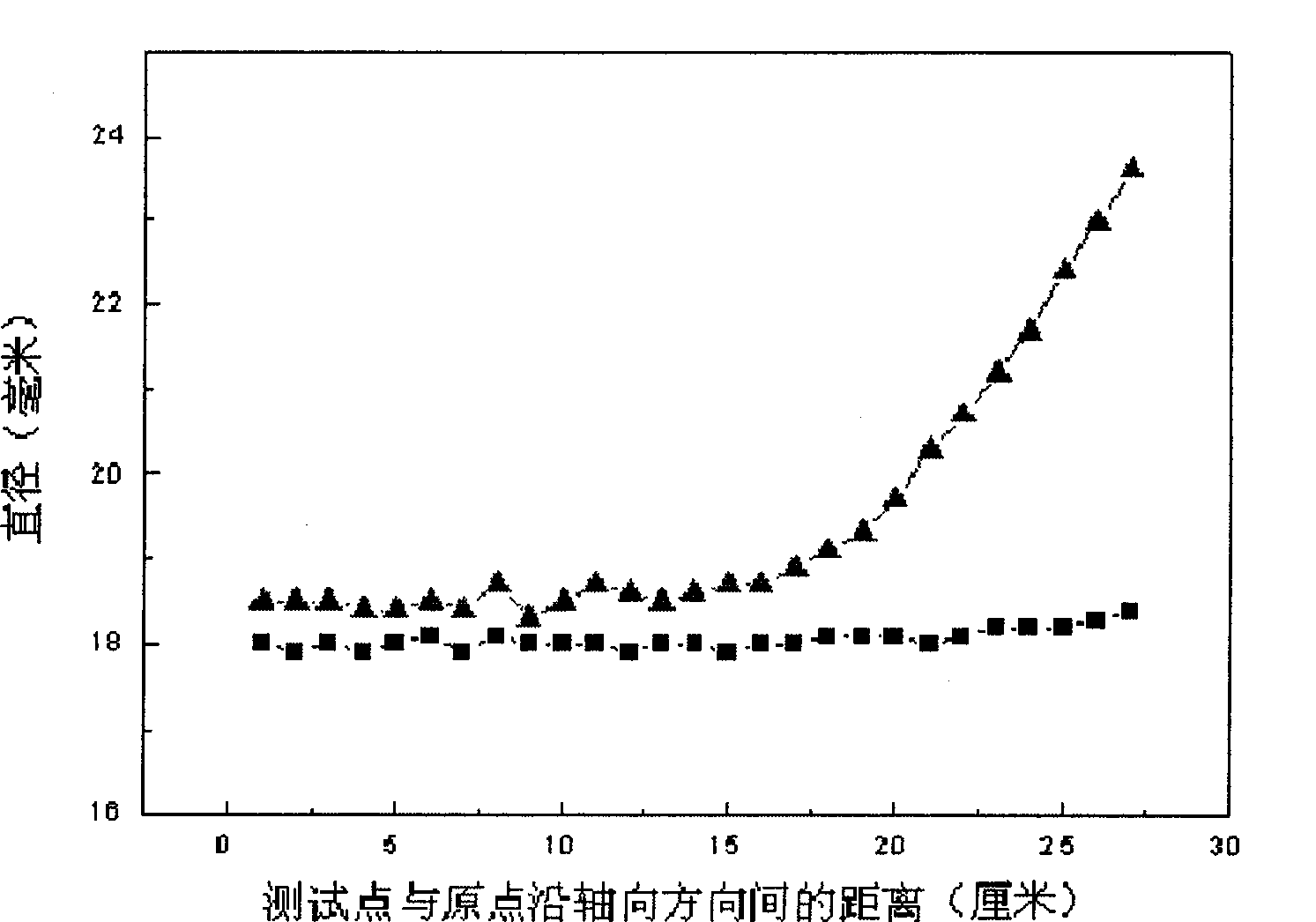

A technology for alloy bars and alloy ingots, which is applied in the field of alloy bar preparation, can solve the problems of uneven bar structure and grain size, bar surface cracking, uneven diameter and thickness, and achieves uniform diameter and thickness and improves strength. , the effect of uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

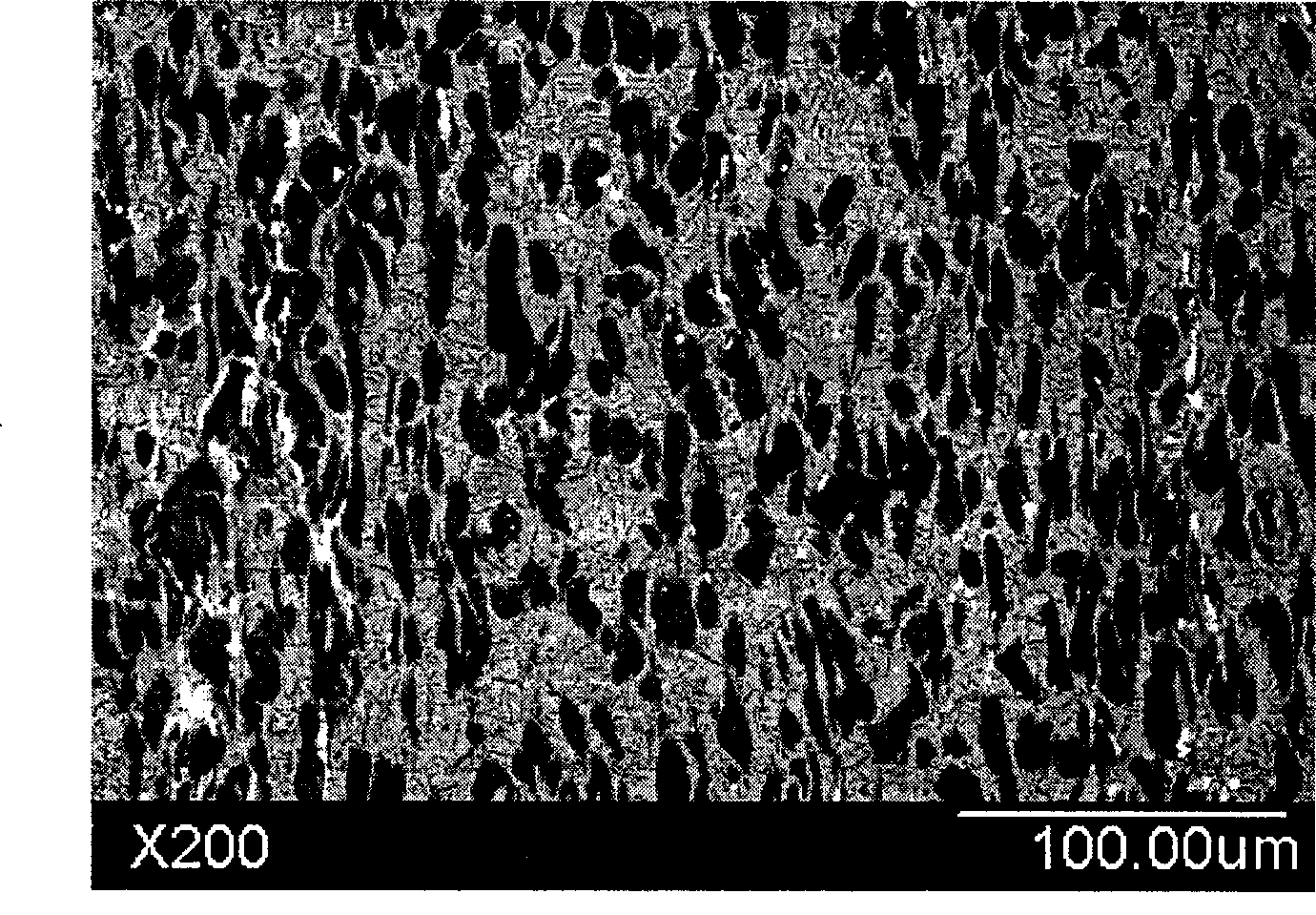

[0007] Specific Embodiment 1: The preparation method of γ-TiAl alloy rods in this embodiment is carried out according to the following steps: 1. Place the γ-TiAl alloy ingot in a hot isostatic pressing furnace, Insulate in an argon atmosphere for 4 to 5 hours, then cool out of the furnace with the furnace, and then place it under the condition of 1250-1300 ° C for homogeneous annealing for 12 to 24 hours, and then cool it out of the furnace; 2. Cutting in the annealed γ-TiAl alloy ingot A cylinder of the required size is wrapped with aluminum silicate fiber with a thickness of 2-7mm, and then placed in the middle of a stainless steel tube with a wall thickness of 2-7mm, and the two ends of the stainless steel tube are covered with stainless steel plates with a thickness of 2-7mm. Carry out welding and sealing under argon atmosphere to obtain sheathing blanks; 3. Put the sheathing blanks in acetone solution for 3-6 minutes, take out the sheathing blanks and dry them, and then pl...

specific Embodiment approach 2

[0012] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the heat preservation is carried out in an argon atmosphere at 1260° C. and 135 MPa for 4.5 hours. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 1, the heat preservation is carried out in an argon atmosphere at 1270° C. and 130 MPa for 4 hours. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com