A kind of porous activated carbon preparation process

A porous activated carbon and preparation technology, applied in the field of activated carbon, can solve problems such as cracks in cylindrical activated carbon, differences in the strength of cylindrical activated carbon, and uneven distribution density of carbon powder, so as to reduce the difference in strength, improve the molding quality, and reduce extrusion. The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

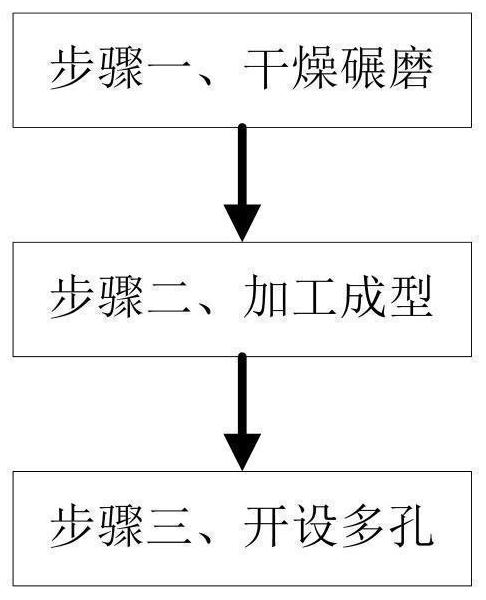

[0034] Such as figure 1 As shown, the present embodiment provides a porous activated carbon preparation process, comprising the following steps:

[0035] Step 1. Drying and milling: After the sawdust is dried, it is carbonized and pulverized to obtain dry charcoal powder.

[0036] Step 2, processing and forming: the carbon powder is mixed with additives and then extruded into a cylindrical carbon block.

[0037] Step 3, opening pores: opening pores on the surface of the formed cylindrical carbon block.

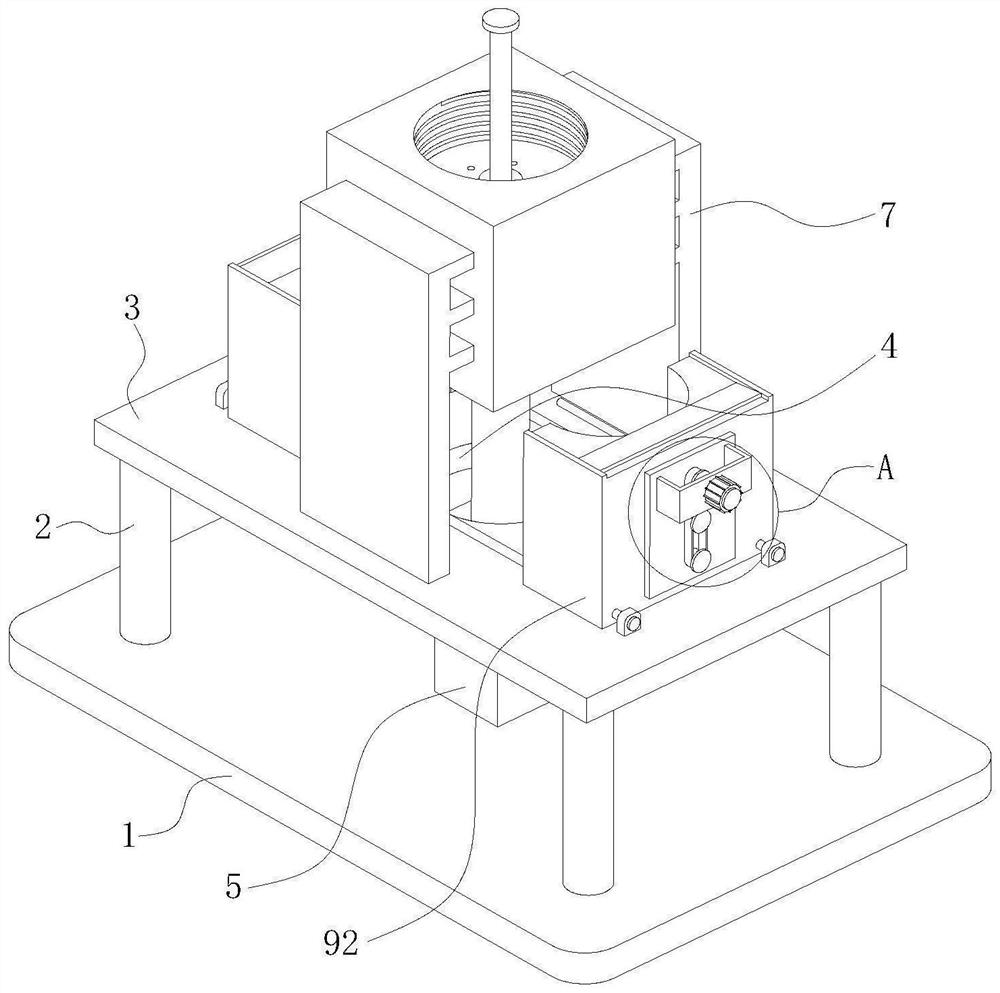

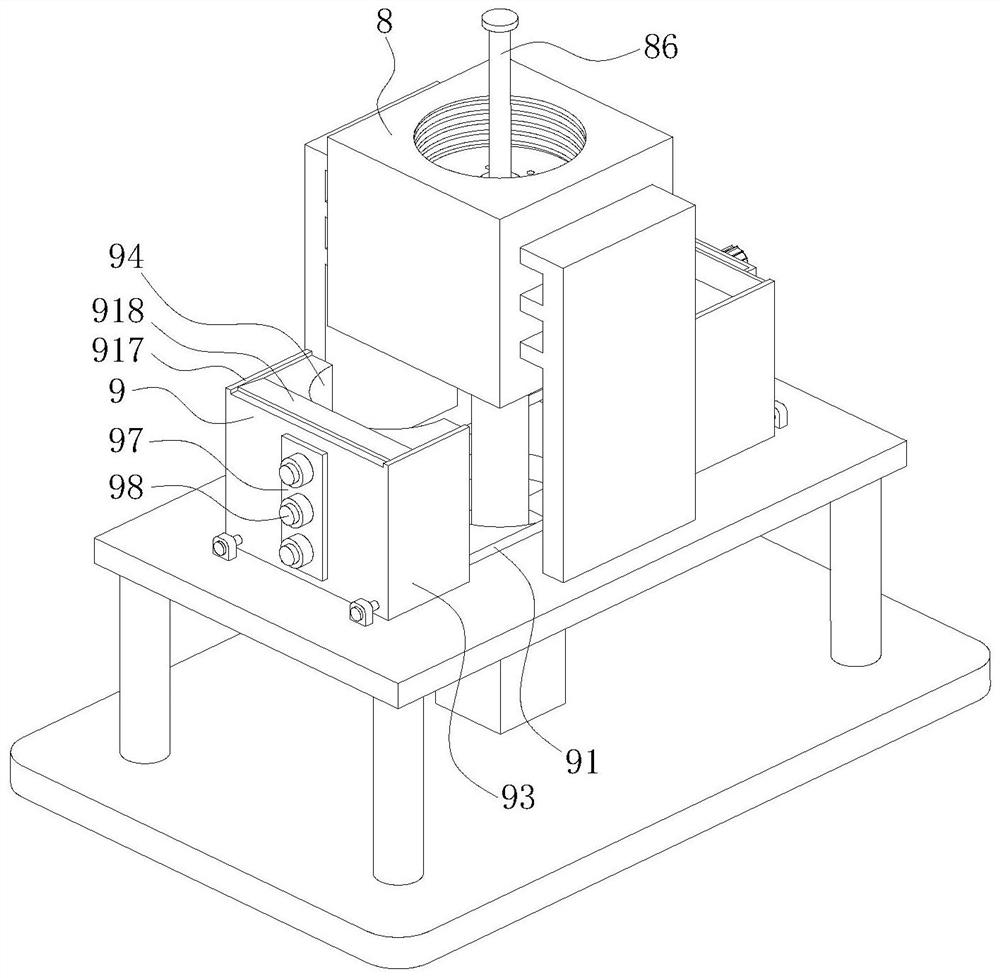

[0038] Among them, step 2 and step 3 adopt such as Figure 2 to Figure 6 A kind of porous activated carbon preparation machinery as shown is cooperated and completed, and described porous activated carbon preparation machinery comprises horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com