A method of making canvas shoes

A processing method and canvas technology, which is applied to footwear, shoe soles, heel pads, etc., can solve the problems of sole fixing, rubber skin wrinkles, unevenness, etc., and achieve the effects of avoiding wrinkles, avoiding shaking, and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

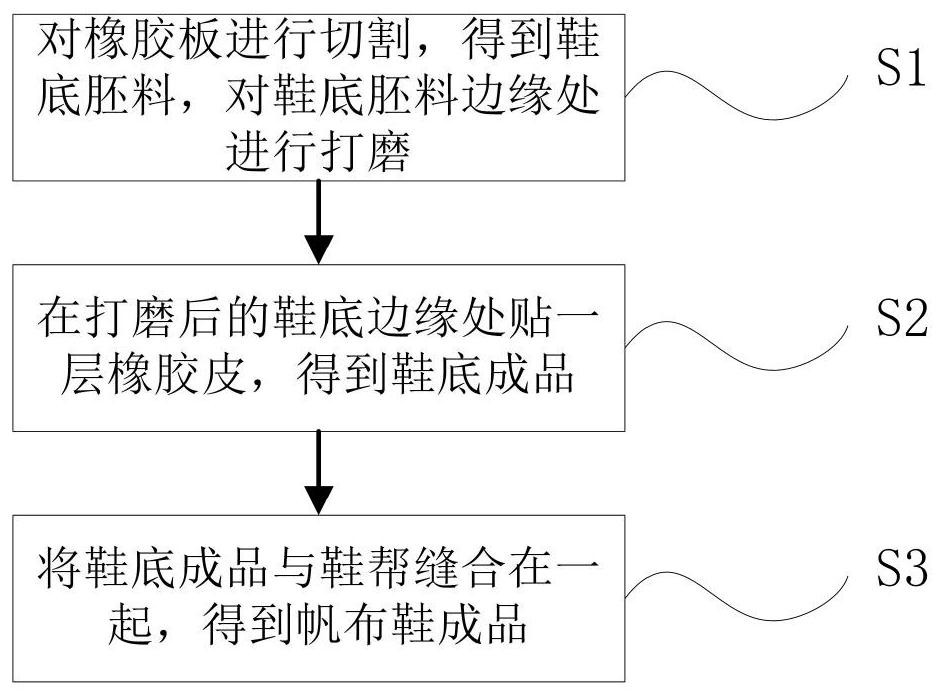

[0041] like figure 1 As shown, the present embodiment provides a method for making canvas shoes, comprising the following steps:

[0042] Step 1: Making the sole: cutting the rubber plate to obtain the sole blank, and grinding the edge of the sole blank.

[0043] Step 2, sole welt: paste a layer of rubber leather on the side of the front half of the polished sole to obtain the finished sole.

[0044] Step 3, sewing and forming: sewing the finished sole and the upper together to obtain the finished canvas shoes.

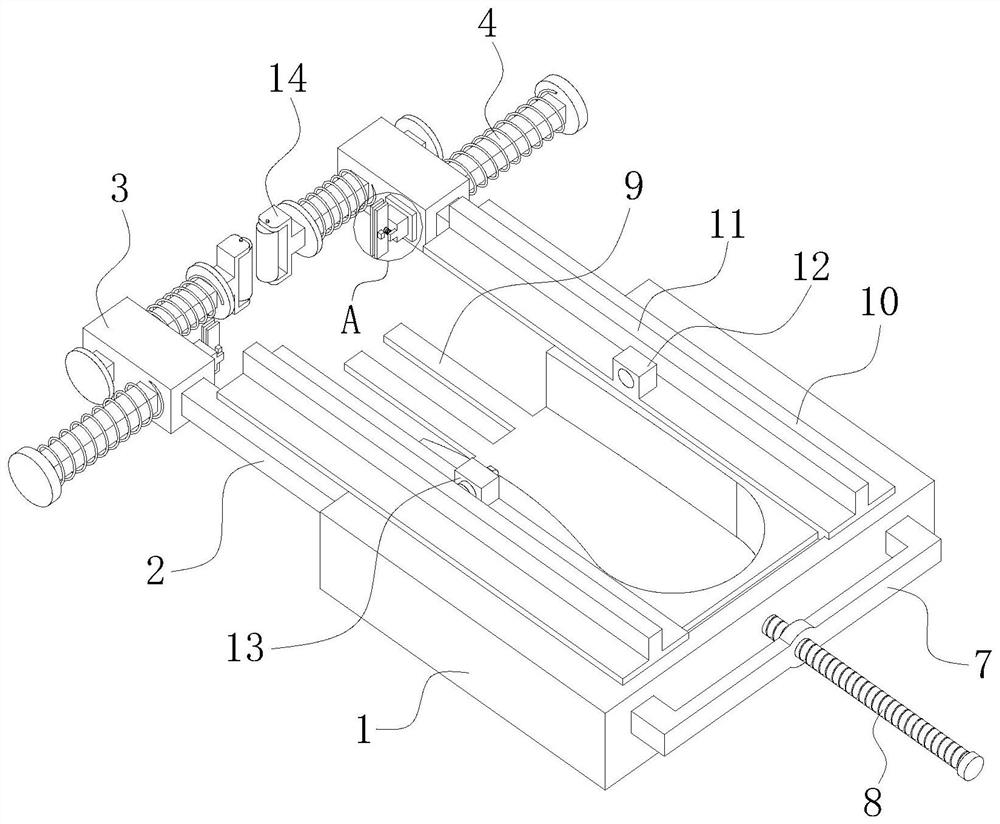

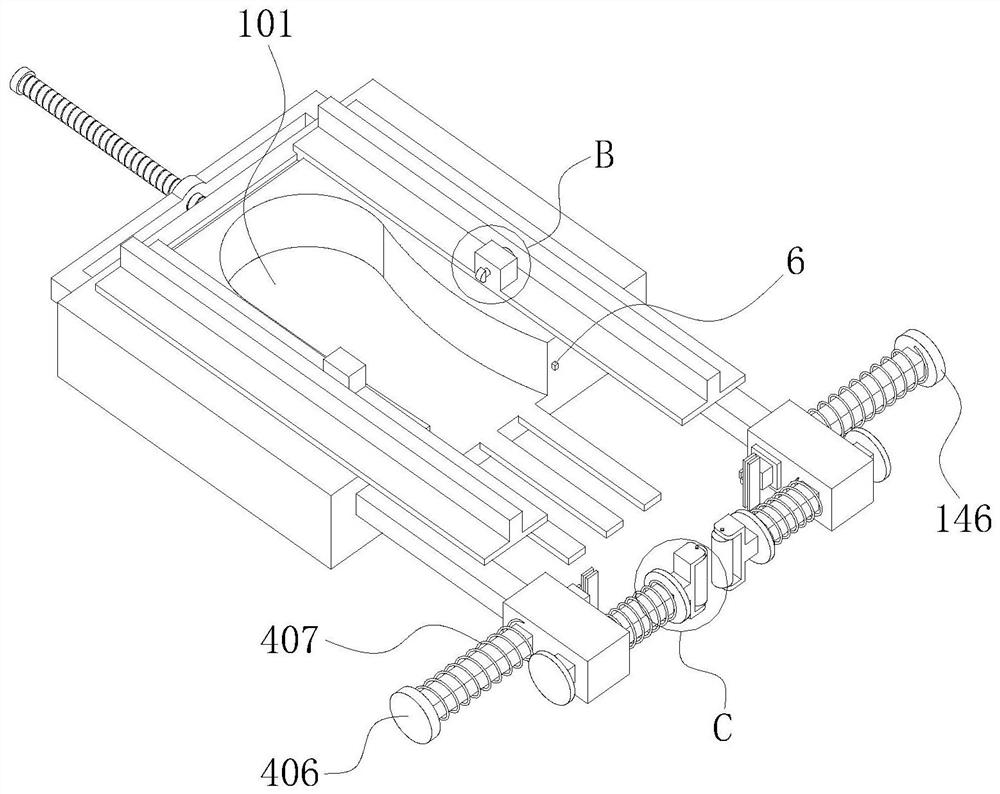

[0045] Among them, step 2 adopts such as Figure 2 to Figure 8 The canvas shoe manufacturing and processing device shown in the figure is completed. The canvas shoe manufacturing and processing device includes a square seat 1. The top surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com