Height adjusting device for inlaid piece of mould

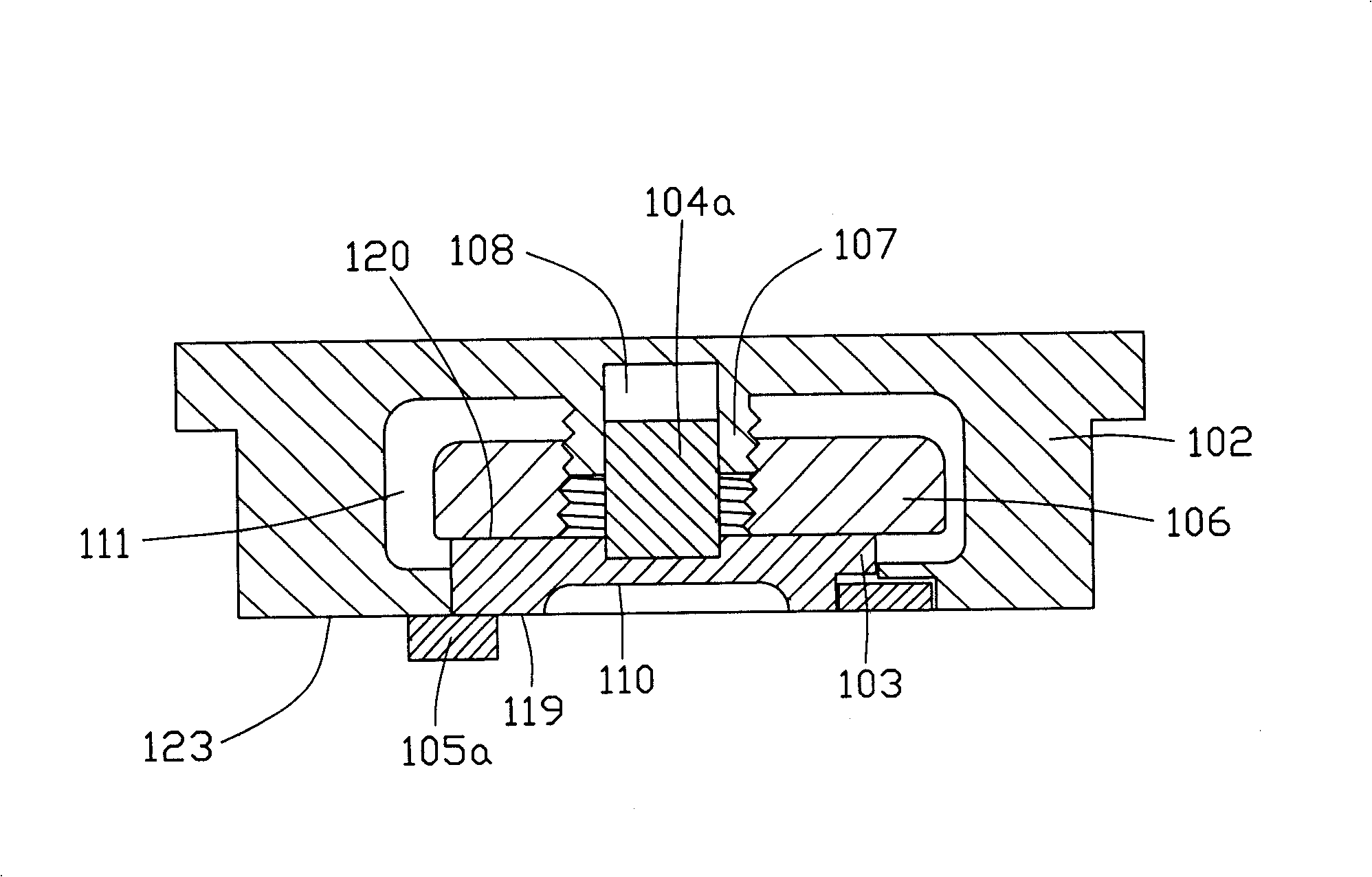

A height adjustment device and insert technology, applied in the field of molds, can solve the problems of material consumption, increased mold manufacturing costs, and difficult processing of cylinder 107, and achieve the effect of simple structure and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

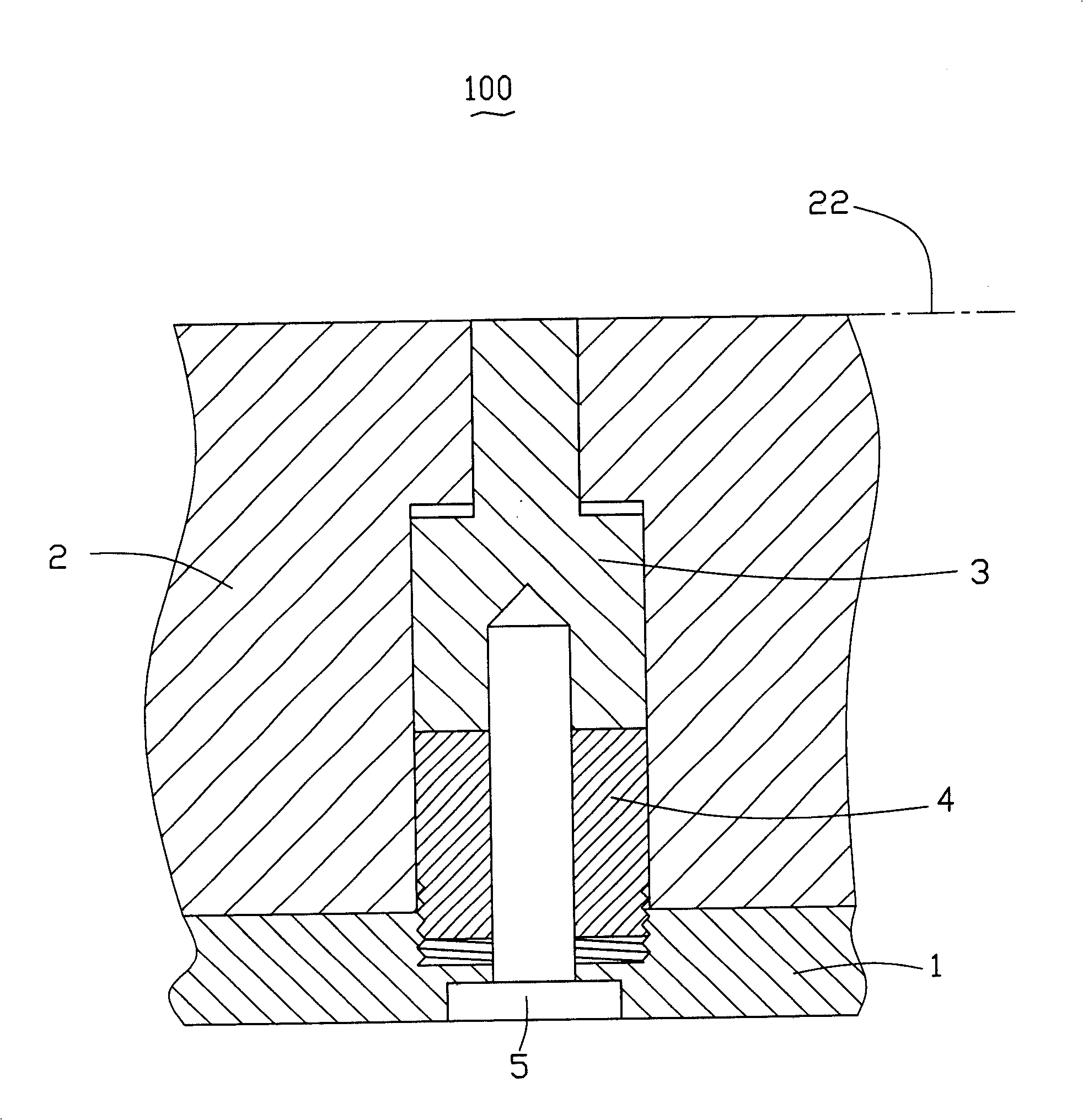

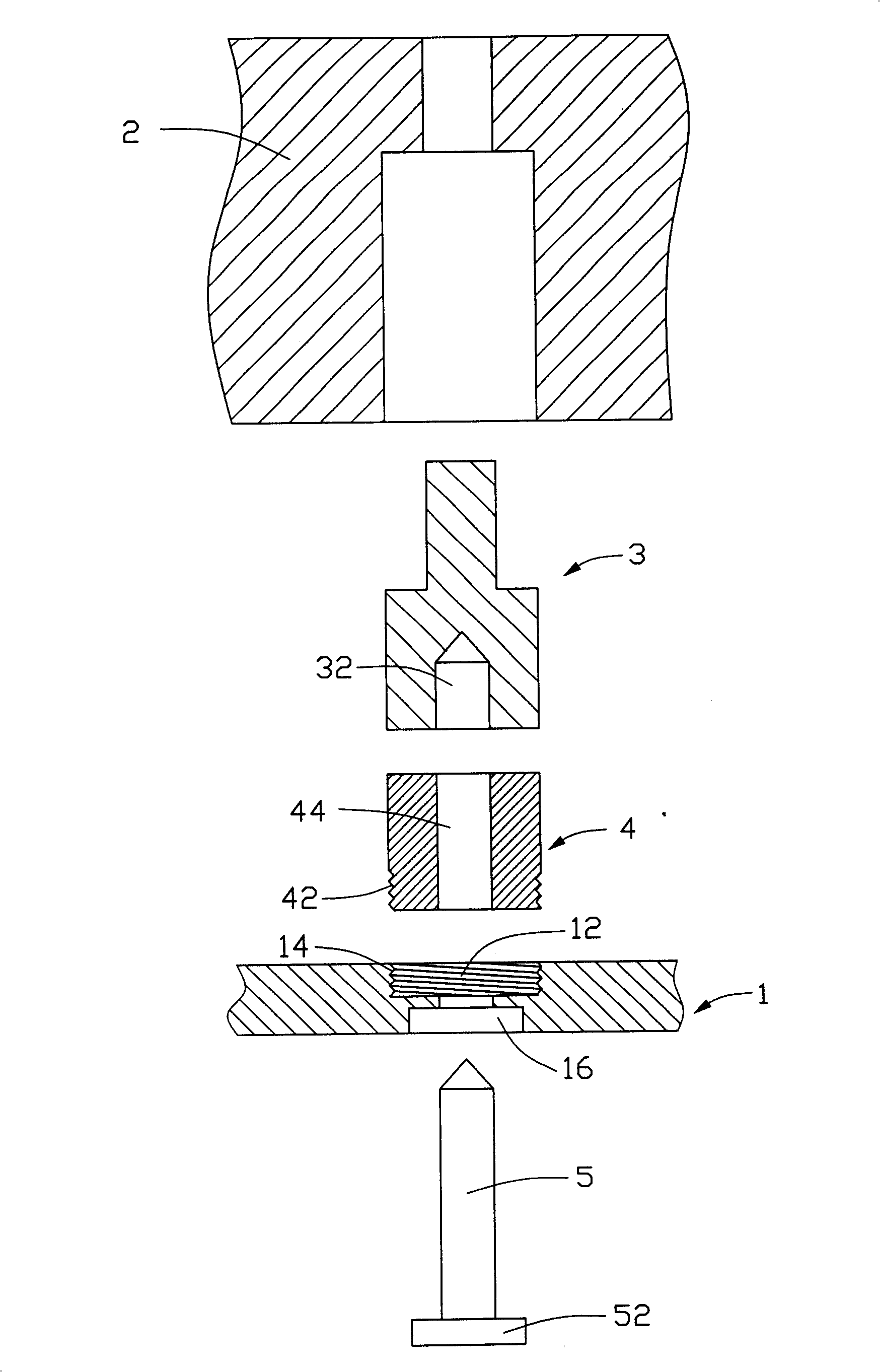

[0016] like figure 2 As shown, the height adjusting device 100 of the mold insert according to the first embodiment of the present invention includes a template 1 , a module 2 , an insert 3 , a spacer 4 and a screw 5 . The module 2 is installed on the template 1 , the insert 3 and the spacer 4 placed below it are installed in the module 2 and the template 1 , and the screws 5 are used to fix the insert 3 in the module 2 .

[0017] like image 3 As shown, a circular hole 12 is opened on the template 1, and the inner surface of the hole 12 is provided with an internal thread 14; the spacer 4 is cylindrical, and its lower end is provided with an external thread 42. In addition, coaxial circular holes 32 , 44 and 16 are provided on the insert 3 , spacer 4 and template 1 respectively, so that the screws 5 can be inserted when the insert 3 is fixed. The hole 32 on the insert 3 is a blind hole, and its inner surface is provided with an internal thread (not shown) that matches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com