Additive manufacturing system for large-size workpiece manufacturing

An additive manufacturing and large-scale technology, applied in the field of additive manufacturing systems, can solve problems such as the limitation of the forming format of the galvanometer system, and achieve the effect of ensuring the consistency of forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

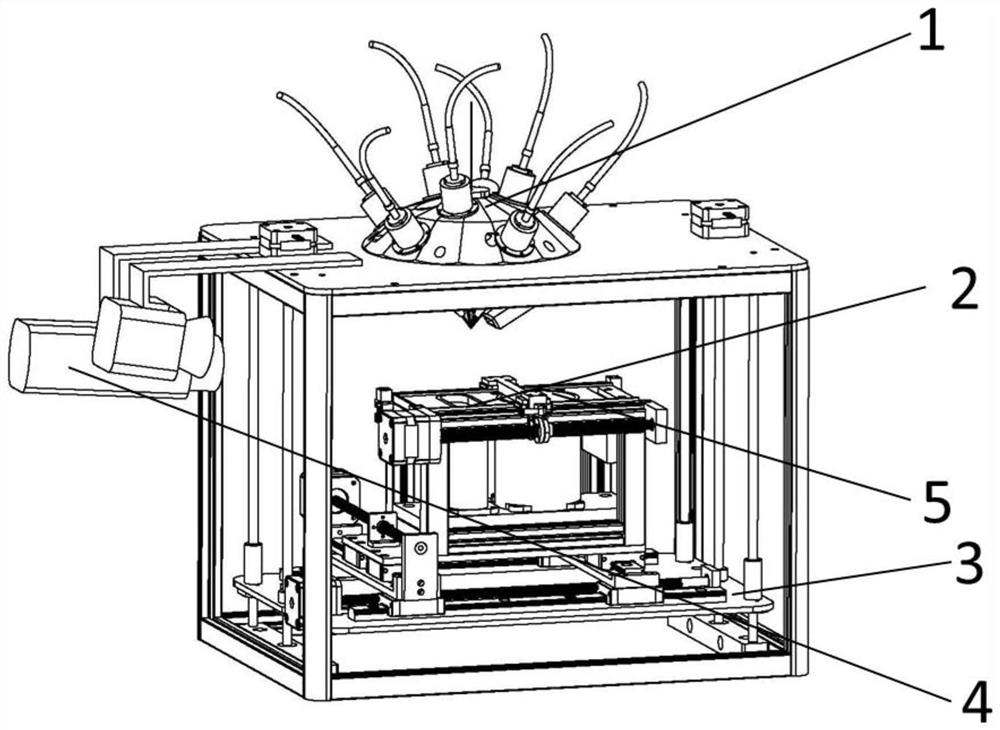

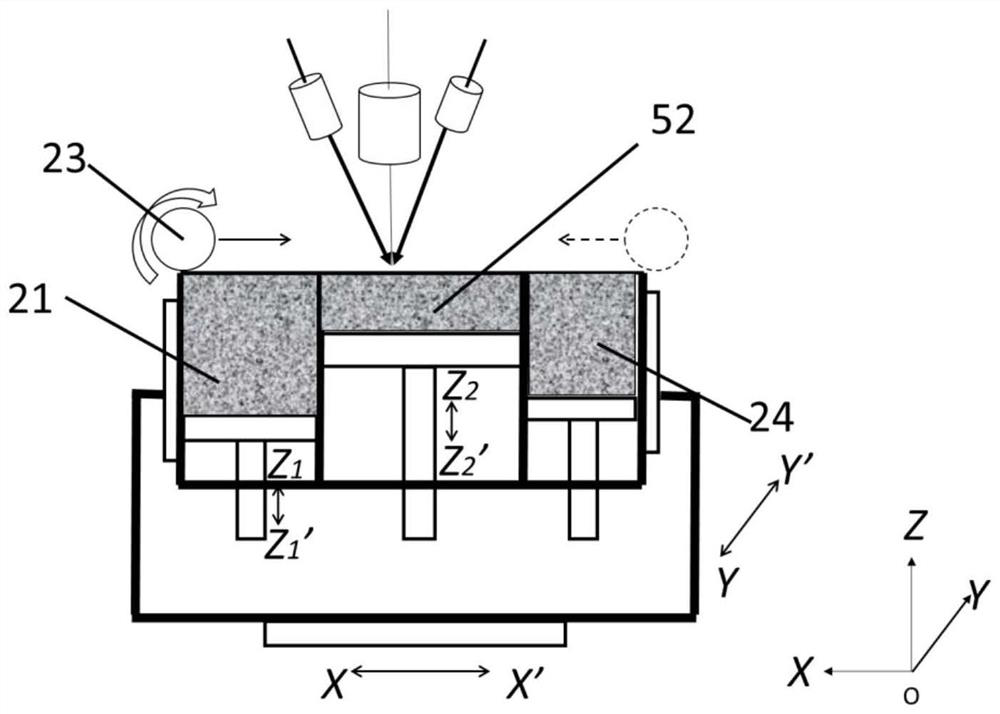

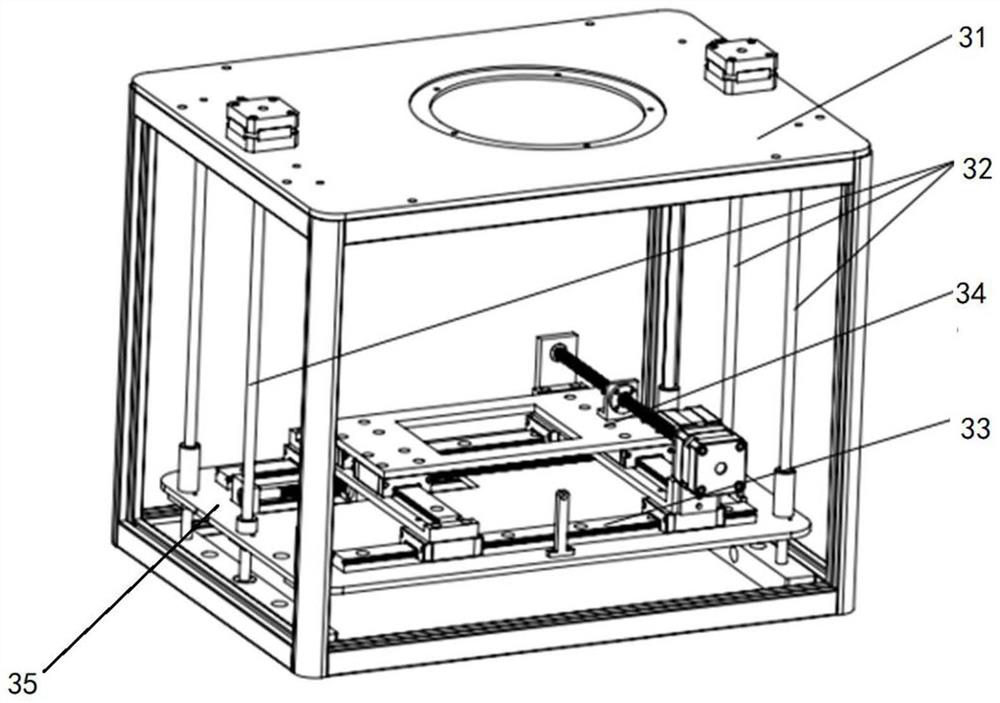

[0073] Such as Figure 1a-Figure 4 As shown, the present invention includes:

[0074] The forming table 5 is used to support the 3D printed workpiece;

[0075] Powder laying mechanism 2, used for laying raw material powder for 3D printing on forming table 5;

[0076] The wire conveying mechanism 6 is used to convey the raw material wire for 3D printing to the forming table 5;

[0077] The 3D printing head 1 is fixedly installed above the forming table 5 (for example, directly above, or obliquely above), and is used to fuse the raw material powder or / and raw material filaments with a laser beam converging on one point and then stack them on the forming table 5 into a workpiece;

[0078] The motion mechanism 3 is used to drive the forming table 5 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com