Cement soil mixing pile construction method considering intensity uniformity

A technology of cement-soil mixing pile and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of uneven distribution of cement slurry and uneven mixing of cement and soil, so as to improve the difference in soil strength and improve The effect of improving the pile quality and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

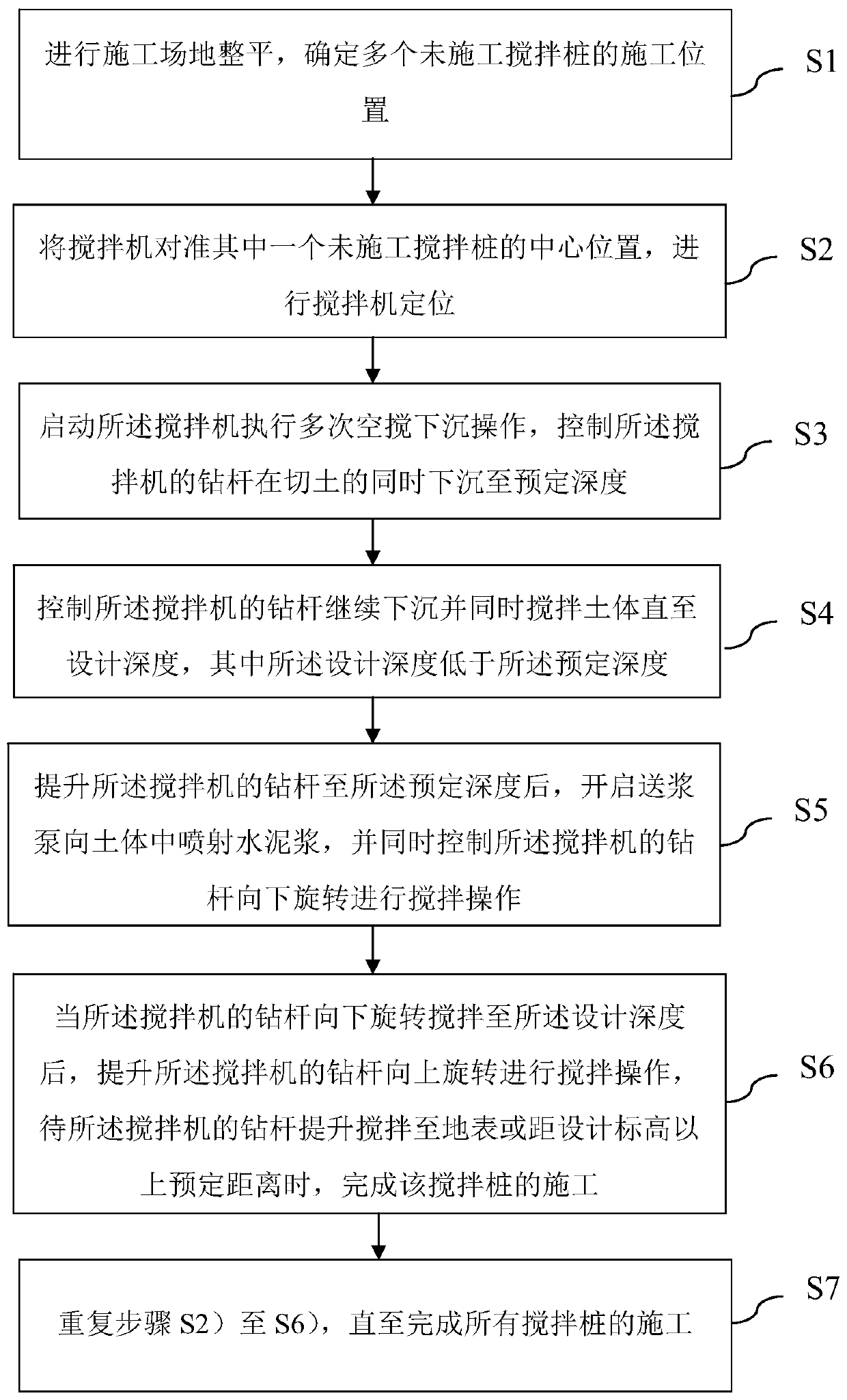

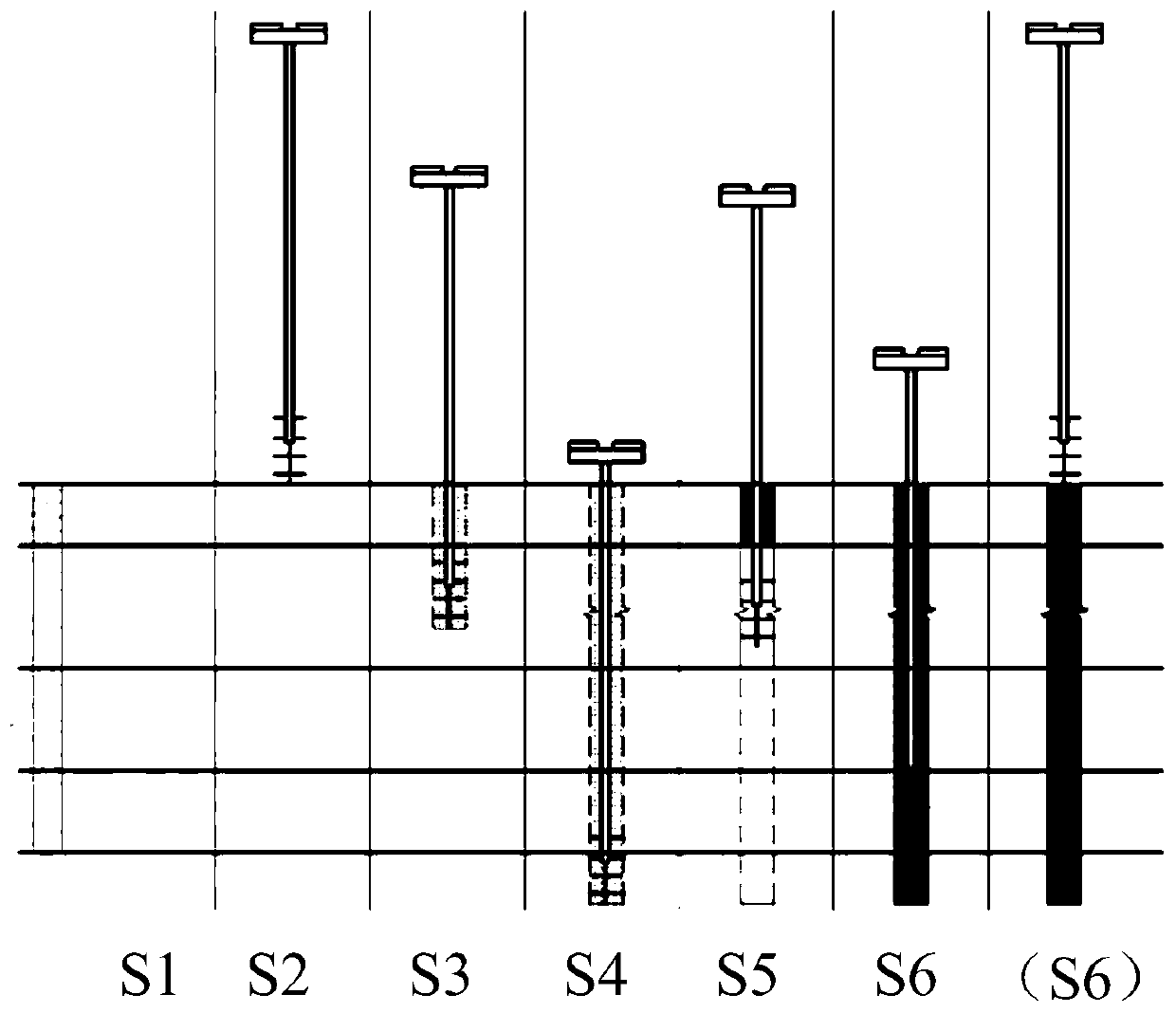

Method used

Image

Examples

Embodiment approach

[0033]According to an embodiment of the present invention, preferably, the drill rod of the mixer has a forward and reverse rotating agitating drill bit, so as to ensure better empty mixing quality and improve mixing uniformity.

[0034] According to the technical solution of the present invention, step S5) after lifting the drill pipe of the mixer to the predetermined depth, turn on the slurry pump to spray cement slurry into the soil, and simultaneously control the drill pipe of the mixer to rotate downward for stirring Operation: While spraying the cement slurry, the sprayed cement slurry is fully mixed with the soil by stirring.

[0035] According to one embodiment of the present invention, in step S5) in the case that the water content of the actual soil is relatively high, the water-cement ratio of the cement slurry can be selected to be 0.5, and the specific gravity of the slurry is determined to be 1.823, so that the water-cement ratio after the air stirring The soil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com