Phase change microcapsule as well as preparation and application thereof

A phase change microcapsule and core material technology, applied in the field of phase change microcapsules, preparation and application, can solve the problems of complex operation of low melting point metal dispersion technology, limited energy storage density of phase change materials, poor dispersion uniformity, etc. Thermal conductivity and mechanical strength, good thermal conductivity, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

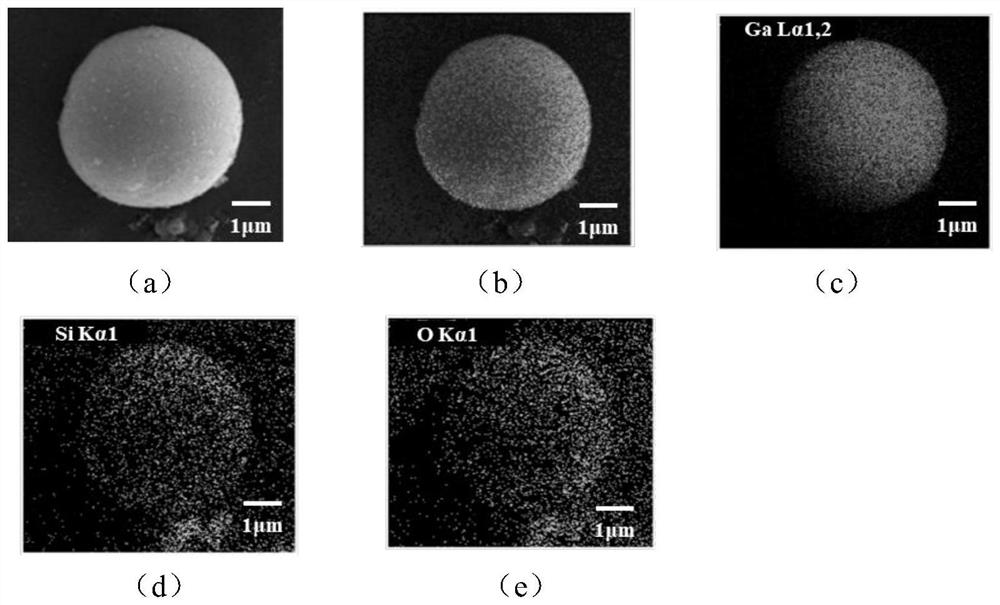

[0029] 1 g of sodium dodecyl sulfate was weighed and dissolved in a mixed solution of 45 mL of deionized water and 30 mL of absolute ethanol, heated in a water bath at 35°C, and magnetically stirred at 500 rpm for 30 minutes to obtain a dispersant solution. Weigh 10 g of metal gallium in a beaker, and heat gallium to a molten state at a temperature higher than the melting point of gallium. The dispersant solution prepared above was poured into a beaker containing molten gallium, and sheared at 5000 rpm for 5 min. After shearing, it was transferred to an ultrasonic cell pulverizer and sonicated for 3 min to obtain a stable gallium microsphere suspension. Transfer the suspension to a three-necked round-bottomed flask equipped with a polytetrafluoroethylene stirring rod, add 10 g of methyltriethoxysilane, set the rotation speed to 500 rpm and stir for 30 minutes, then add hydrochloric acid to adjust the pH to 2 to 3, and continue stirring. Reaction 6h. After the reaction, the pr...

Embodiment 2

[0032] Accurately weigh 1 g of sodium dodecyl sulfate and dissolve it in a mixed solution of 45 mL of deionized water and 30 mL of absolute ethanol, heat in a water bath at 35°C, and magnetically stir at 500 rpm for 30 minutes to obtain a dispersant solution. Weigh 10 g of metal gallium in a beaker, and heat gallium to a molten state at a temperature higher than the melting point of gallium. The dispersant solution prepared above was poured into a beaker containing molten gallium, and sheared at 5000 rpm for 5 min. After shearing, it was transferred to an ultrasonic cell pulverizer for 8 min to obtain a stable gallium microsphere suspension. Transfer the suspension to a three-necked round-bottomed flask equipped with a polytetrafluoroethylene stirring rod, add 12 g of methyltriethoxysilane, set the rotation speed to 500 rpm and stir for 30 minutes, then add hydrochloric acid to adjust the pH to 2-3, and continue stirring. The reaction was carried out for 6 hours. After the re...

Embodiment 3

[0034] Accurately weigh 1.2 g of cetyl trimethyl ammonium bromide, dissolve it in a mixed solution of 45 mL of deionized water and 30 mL of absolute ethanol, heat in a water bath at 35°C, and magnetically stir at 500 rpm for 30 minutes to obtain a dispersant solution. Weigh 10 g of metal gallium in a beaker, and heat gallium to a molten state at a temperature higher than the melting point of gallium. Pour the above prepared dispersant solution into a beaker containing molten gallium, and shear at 8000 rpm for 5 min. After shearing, transfer it to an ultrasonic cell pulverizer for 3 min to obtain a stable gallium microsphere suspension. Transfer the suspension to a three-necked round-bottomed flask equipped with a polytetrafluoroethylene stirring rod, add 10 g of ethyl orthosilicate, set the rotation speed to 500 rpm and stir for 30 minutes, then add ammonia water to adjust the pH to 9-10, and continue stirring for 16 hours. . After the reaction, the product solution was filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com