Treatment and construction method for grooving underground diaphragm wall encountering with underground stirring pile

A technology of underground diaphragm wall and construction method, which is applied in the direction of drilling equipment and methods, excavation, sheet pile walls, etc., and can solve the problem that the quality of underground diaphragm wall trough formation and construction progress are greatly affected, and the process of underground diaphragm wall trough formation is offset Problems such as inclination can be solved to achieve good social benefits, ensure smoothness, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

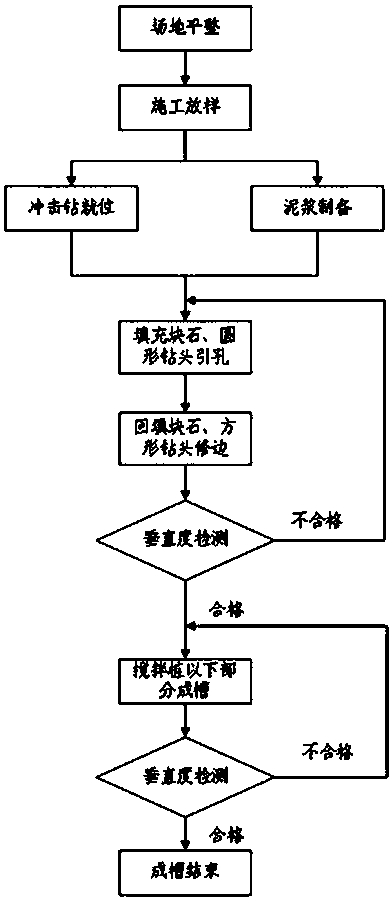

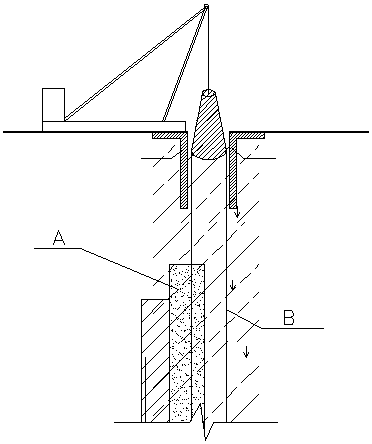

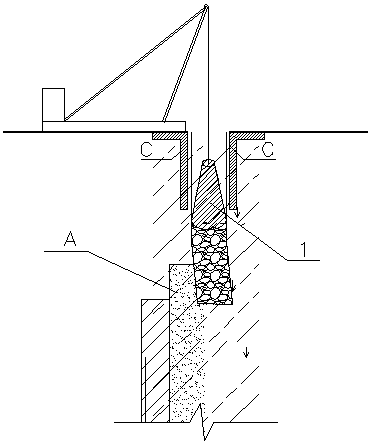

[0048] Such as Figure 1 to Figure 6 Shown, underground diaphragm wall of the present invention becomes groove and encounters underground mixing pile processing construction method, carries out according to the following steps:

[0049] (1) Construction preparation;

[0050] Corresponding to the occupation of restricted mixing piles, impact drilling rigs, and slotting machines, level the construction site, build sediment pools and mud pools, set up warning signs, and at the same time do a good job in drainage of the job site, and dig and set up temporary drainage ditches within the construction area , to ensure that the construction site does not accumulate water.

[0051] (2) Determine the scope of the mixing pile invasion and the position of the lead hole;

[0052] According to the completion drawing of the foundation pit enclosure of the existing structure, the position depth of the restricted mixing pile is initially determined, and then the soil in the groove section ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com