Patents

Literature

40results about How to "Reduce impact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

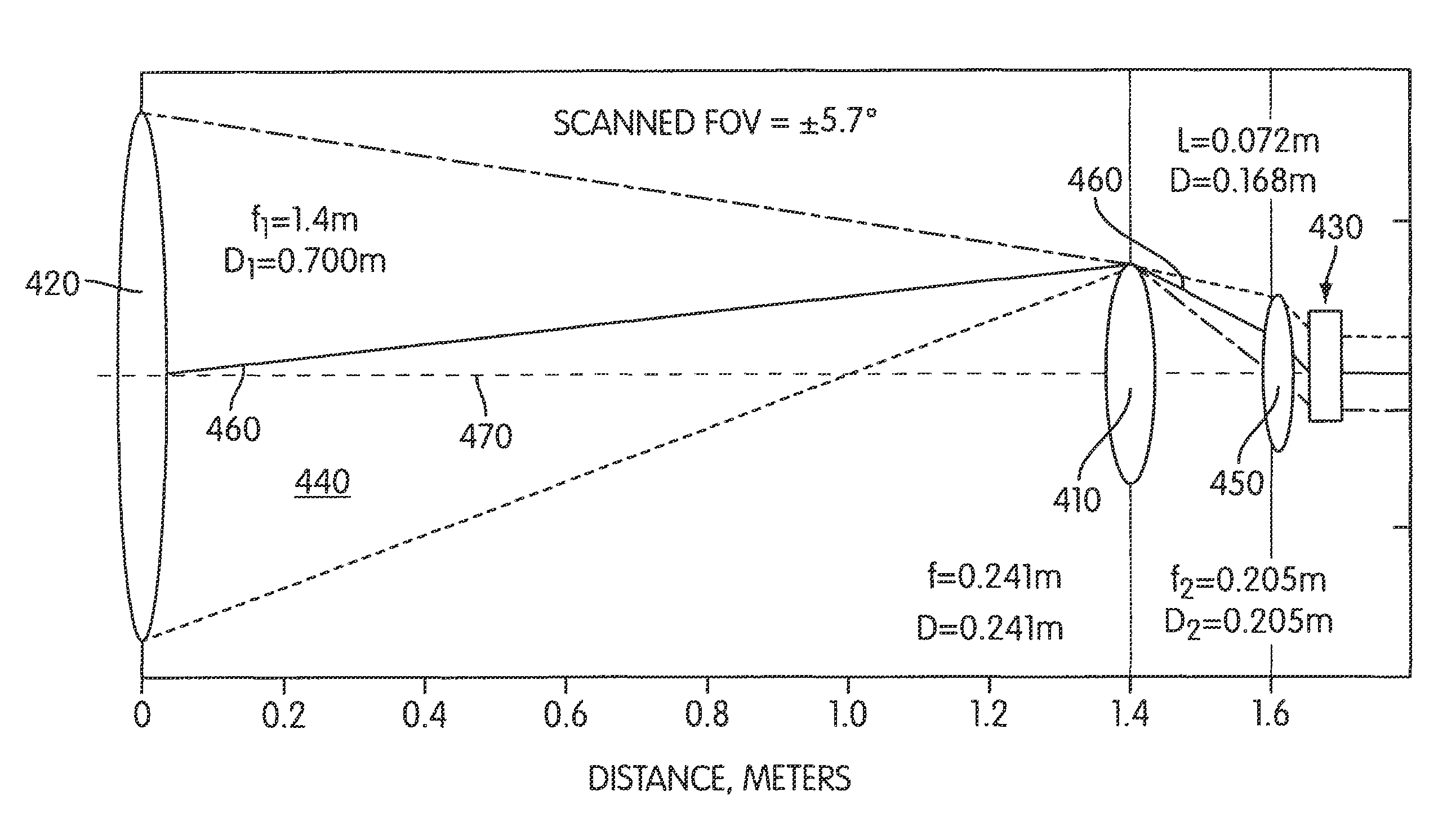

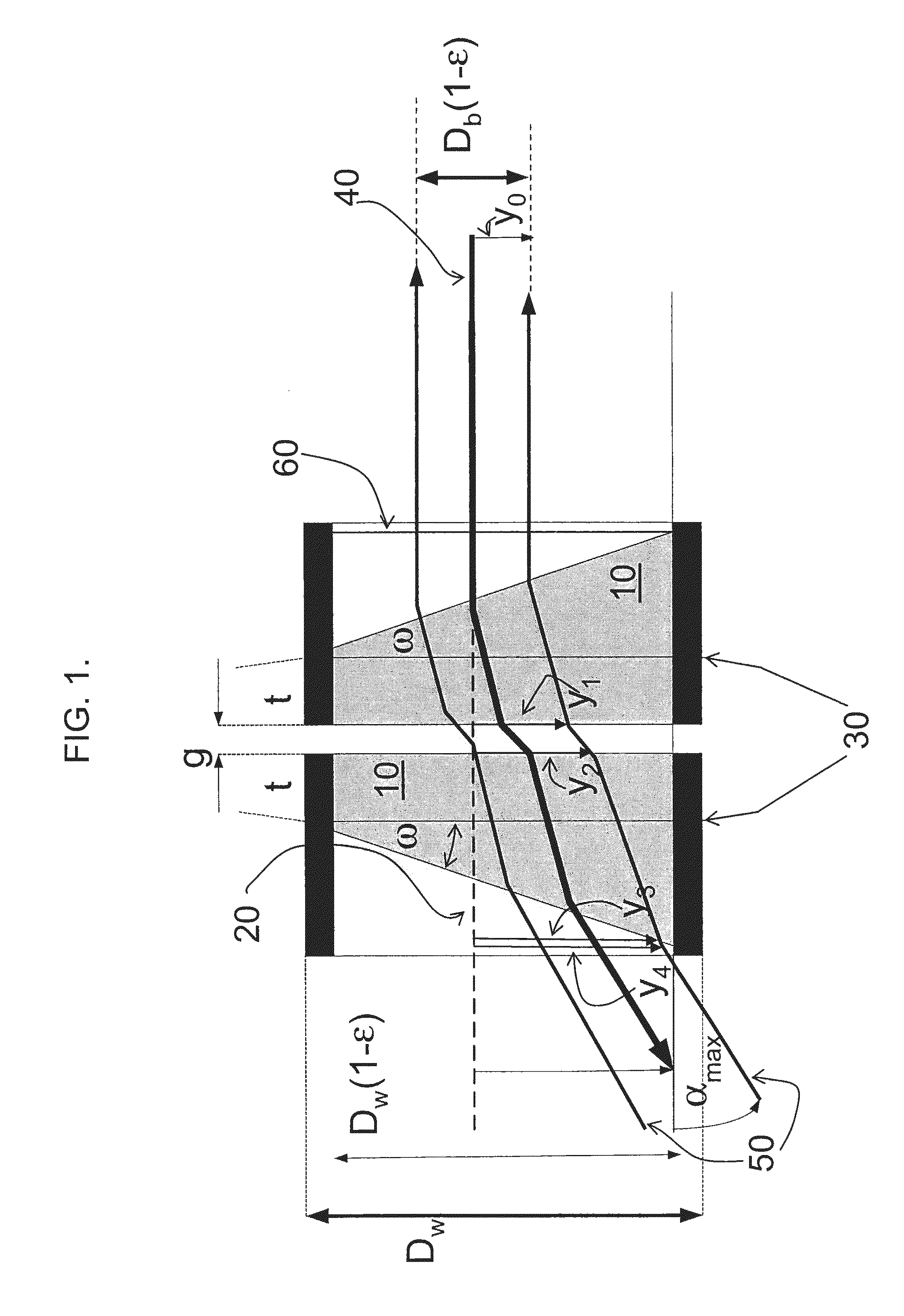

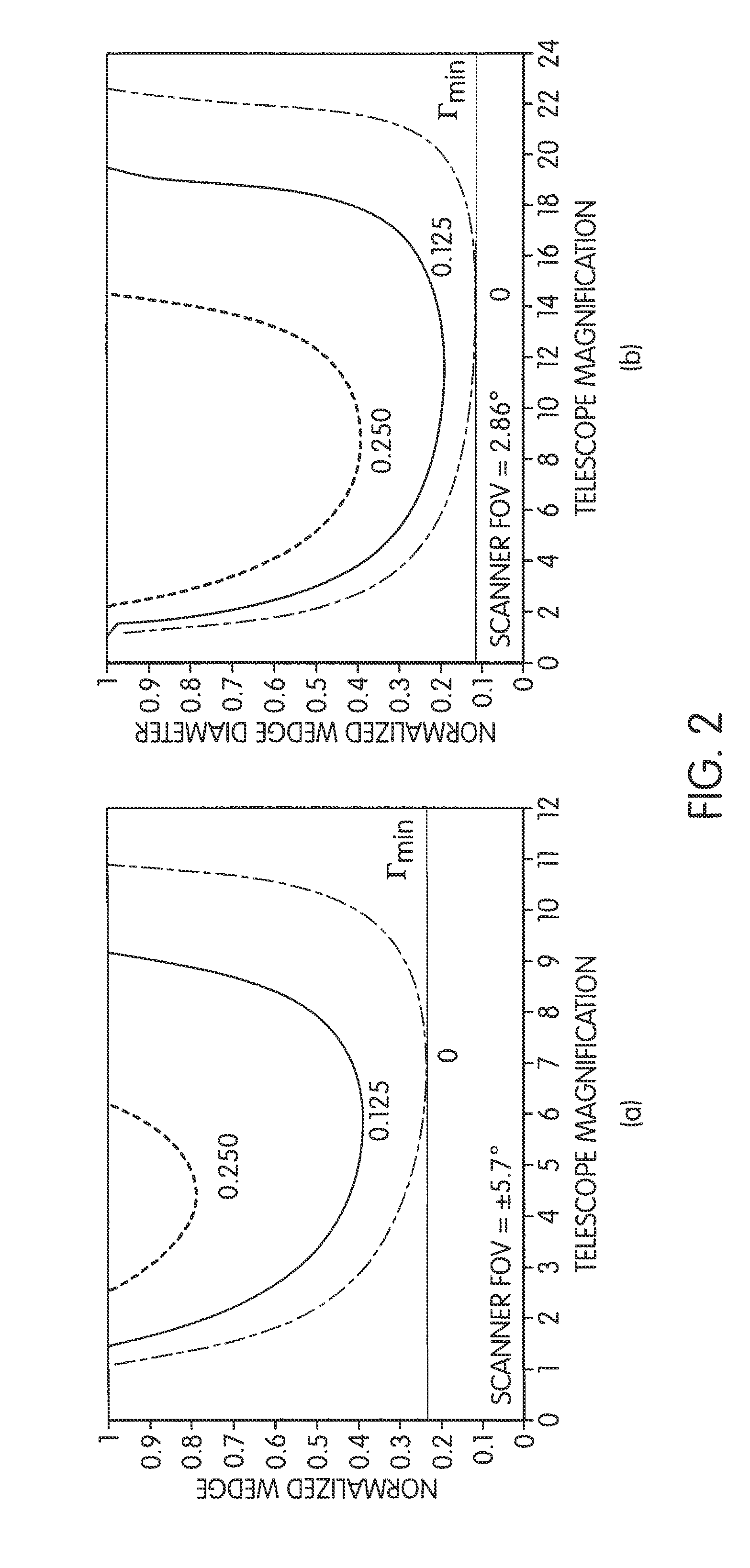

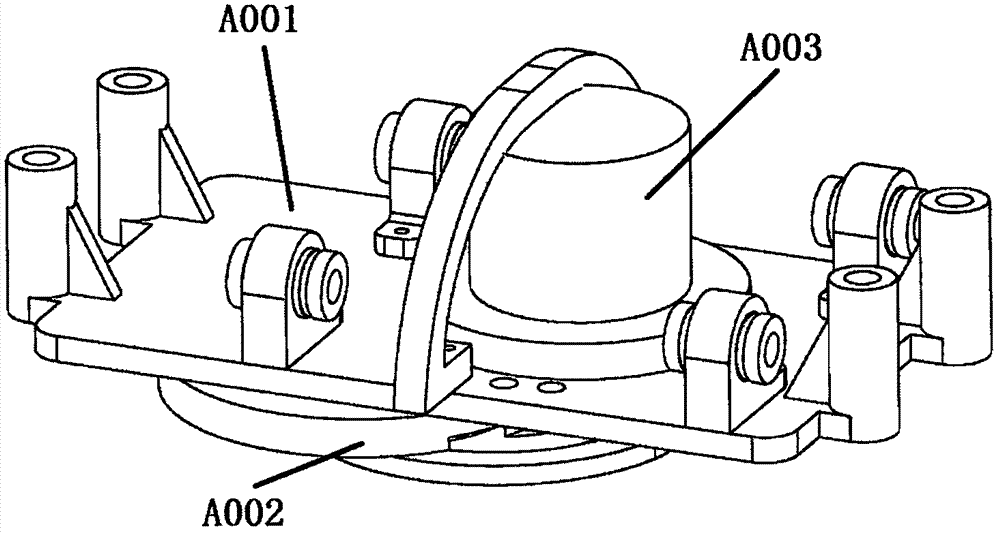

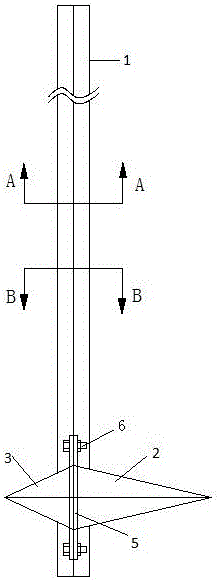

Telescope with a wide field of view internal optical scanner

ActiveUS8144312B2Reduce impact areaOptical rangefindersSpectrum investigationWide fieldOptical scanners

A telescope with internal scanner utilizing either a single optical wedge scanner or a dual optical wedge scanner and a controller arranged to control a synchronous rotation of the first and / or second optical wedges, the wedges constructed and arranged to scan light redirected by topological surfaces and / or volumetric scatterers. The telescope with internal scanner further incorporates a first converging optical element that receives the redirected light and transmits the redirected light to the scanner, and a second converging optical element within the light path between the first optical element and the scanner arranged to reduce an area of impact on the scanner of the beam collected by the first optical element.

Owner:INTERGRAPH

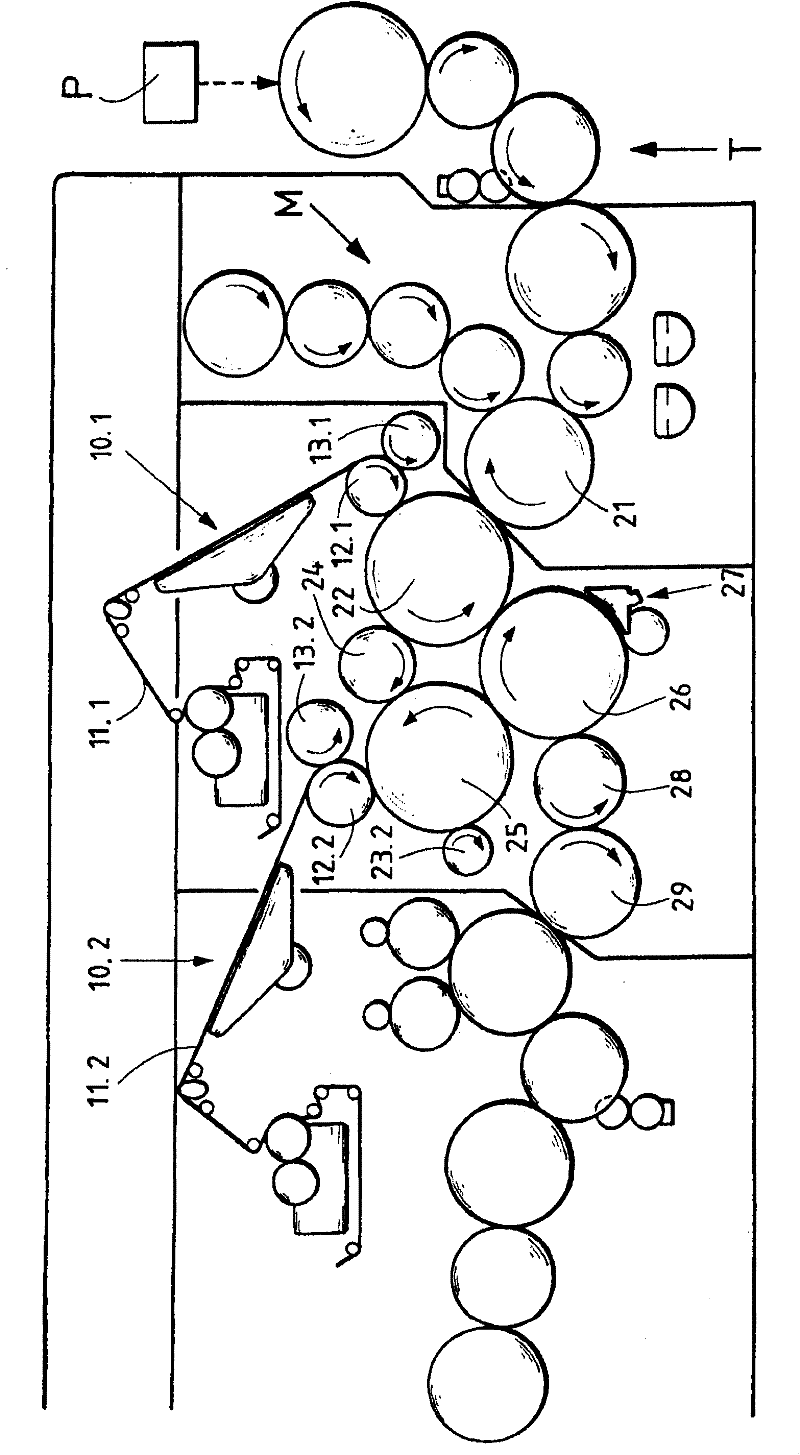

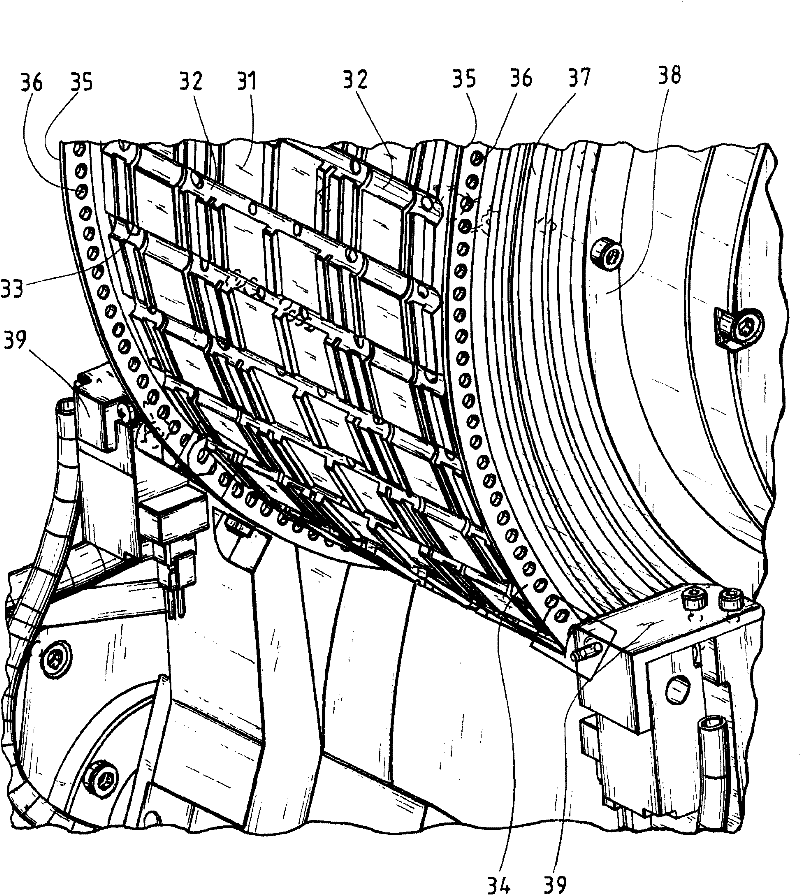

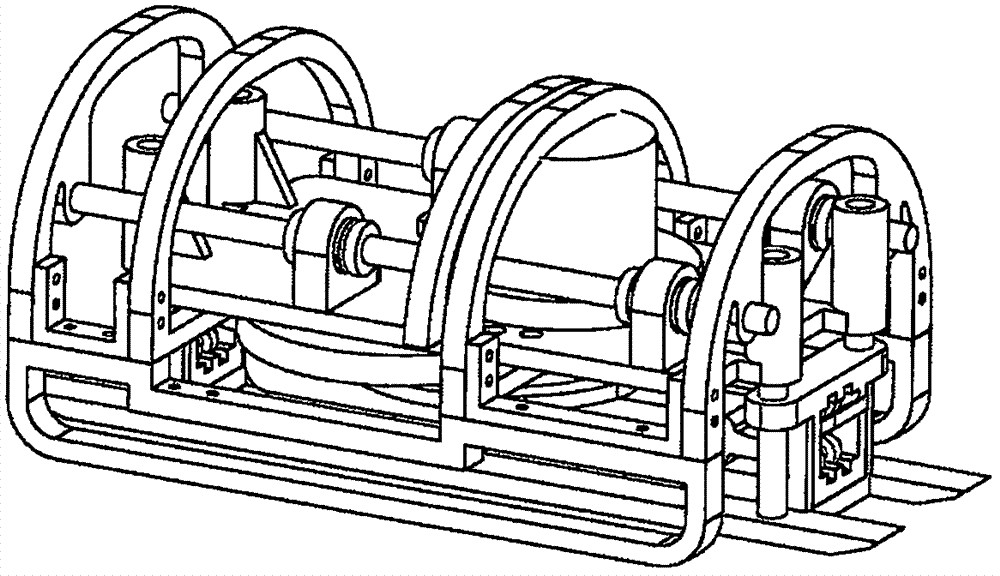

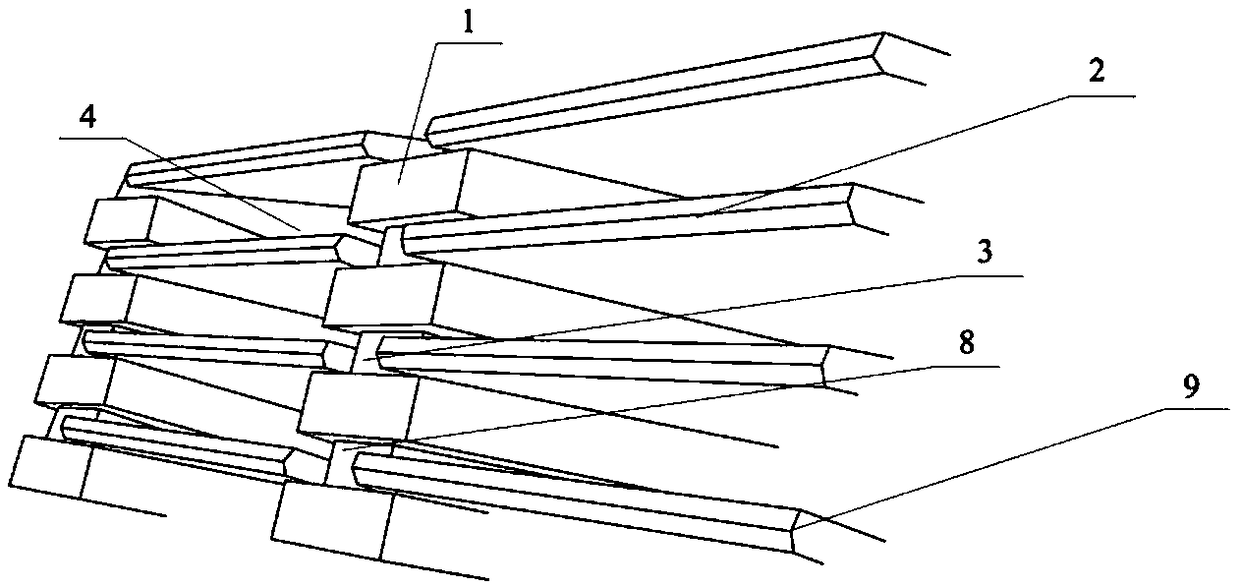

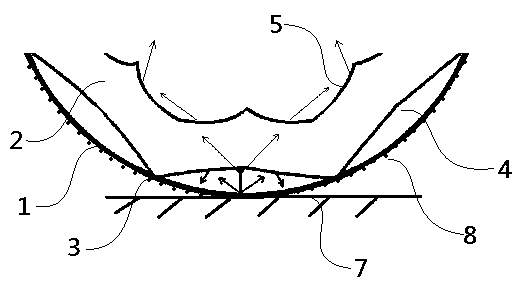

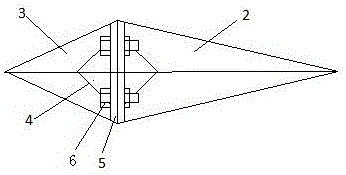

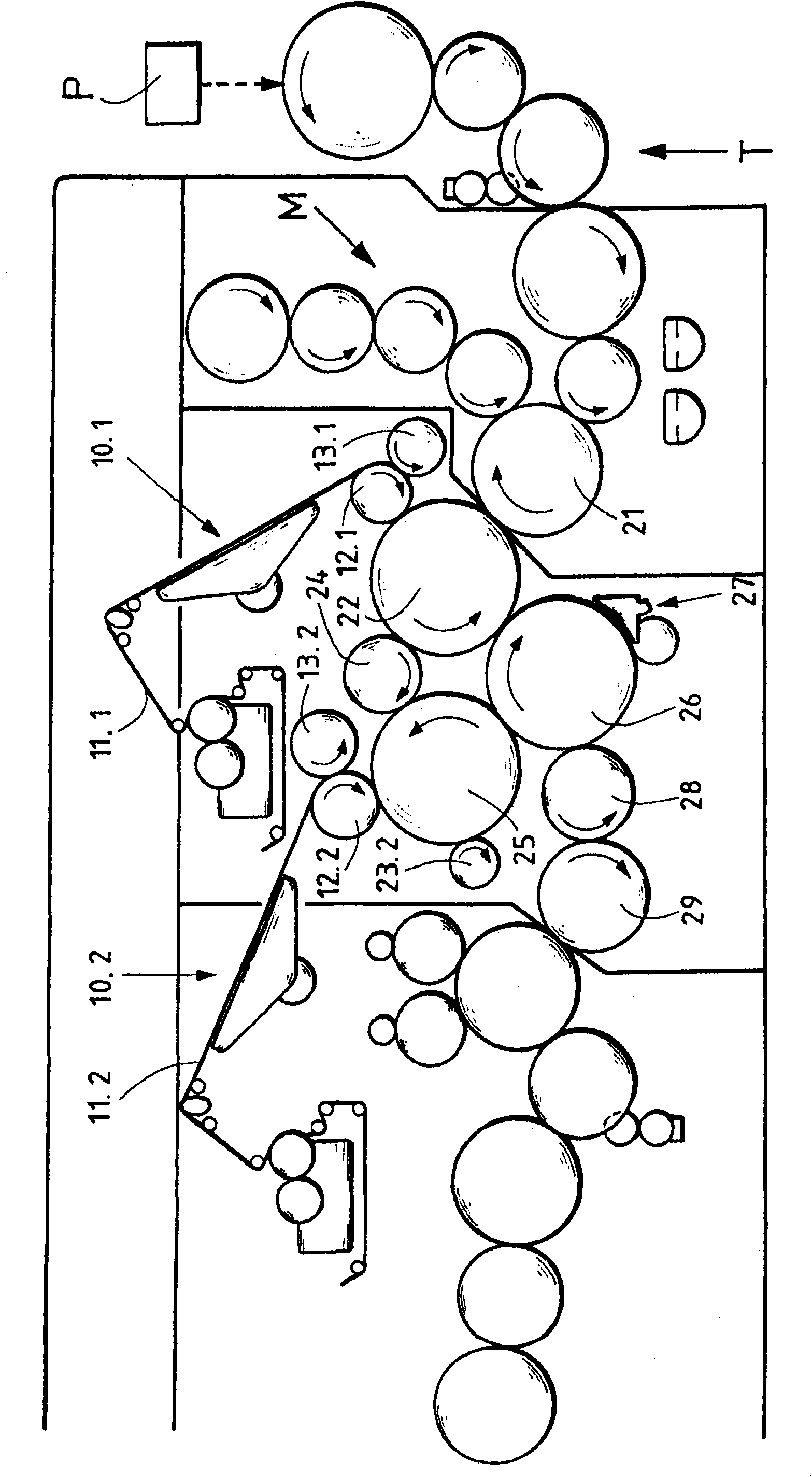

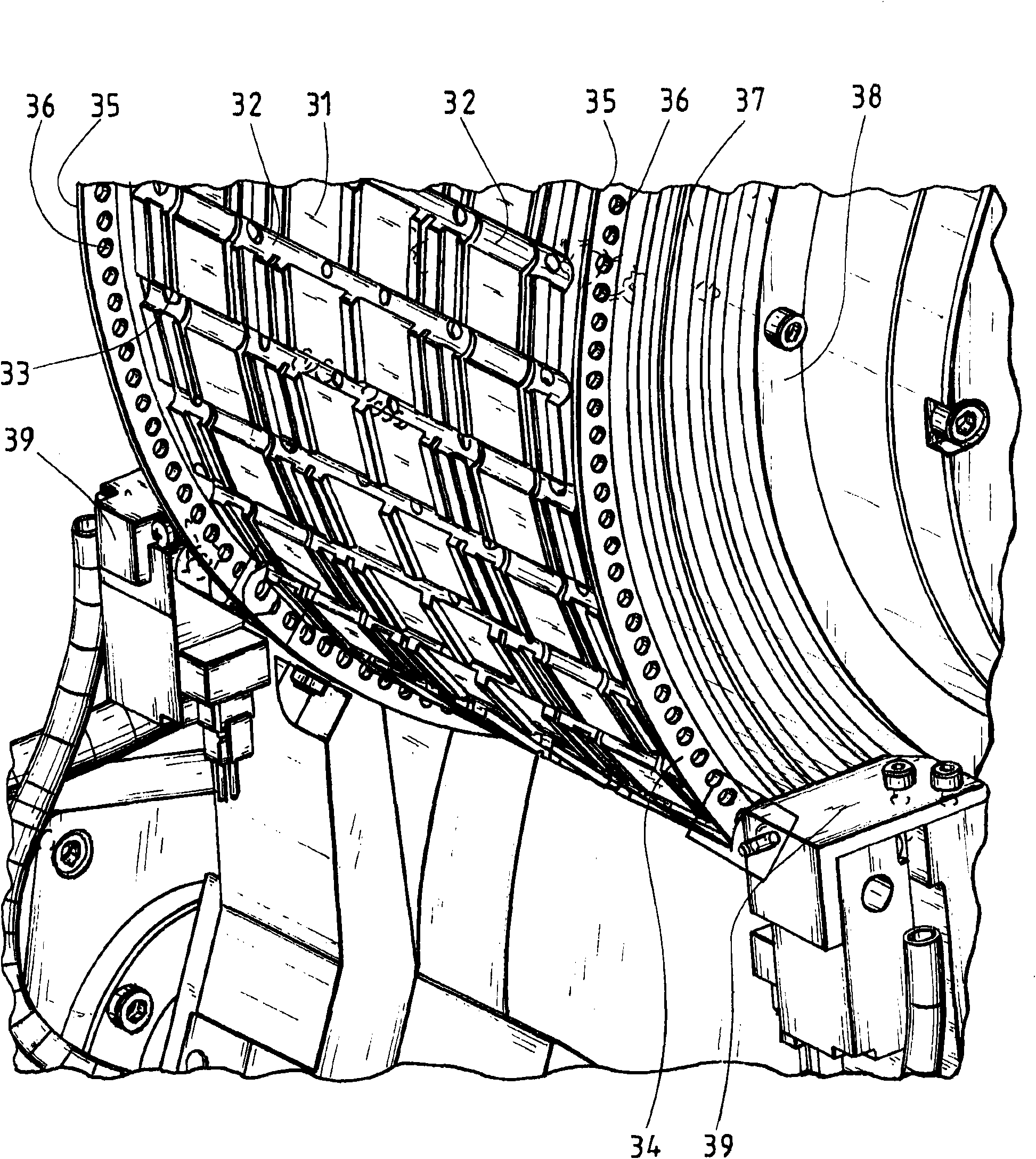

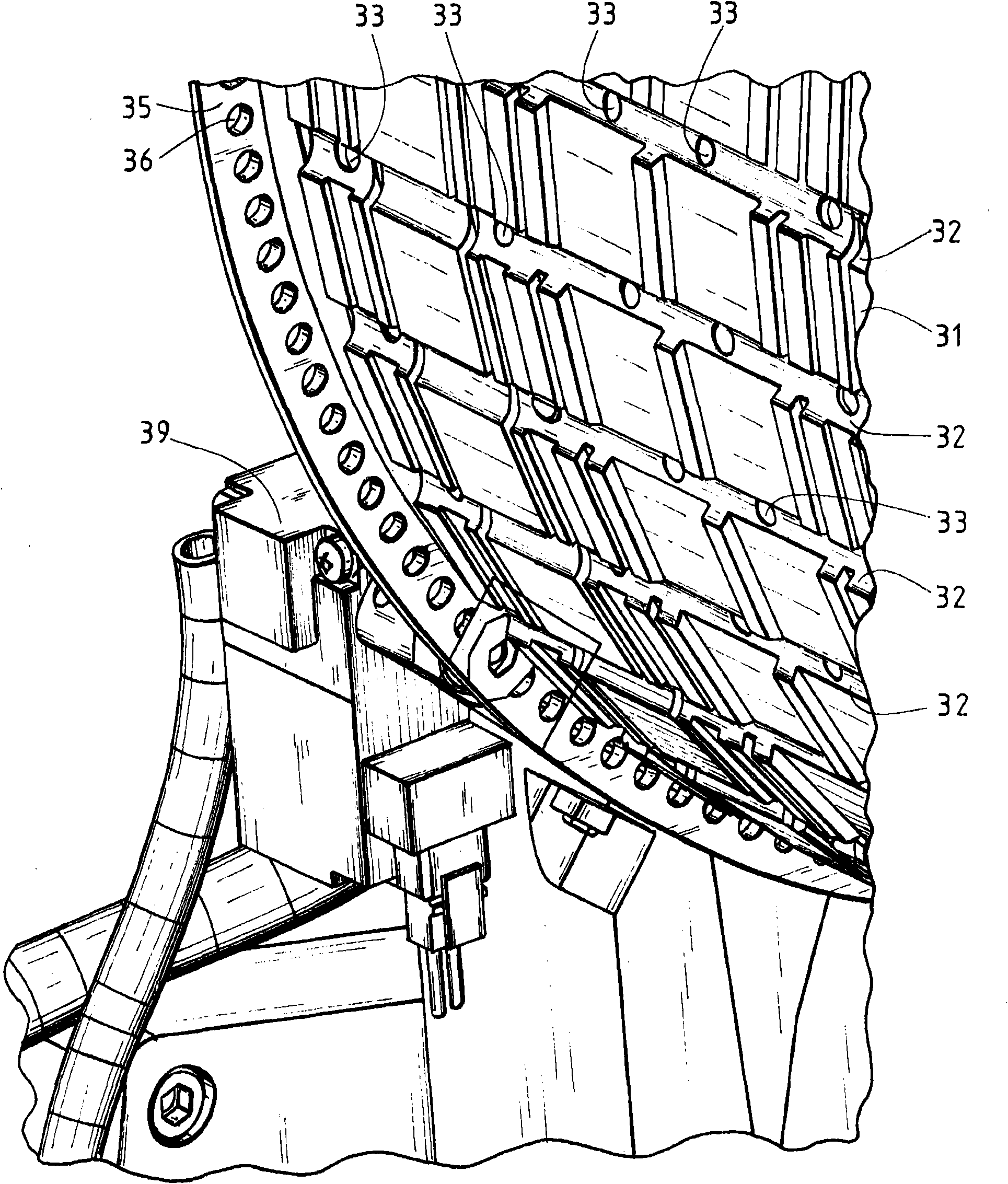

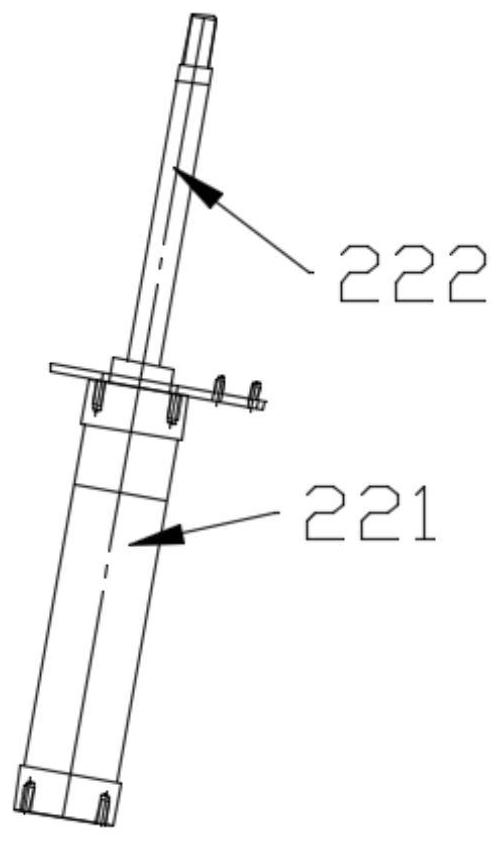

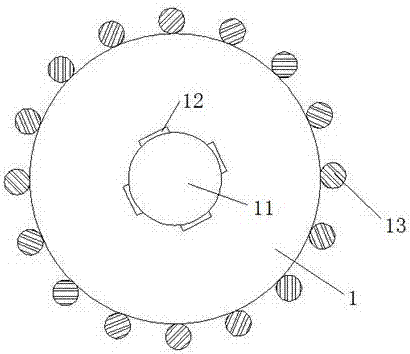

Swash plate, pusher drum and machine for the tobacco processing industry

InactiveCN101744364AGood running and swinging conditionRelieve pressureCigarette manufactureEngineeringSwash

The present invention relates to a swash plate, a pusher drum and a machine for the tobacco processing industry, wherein, the swash plates (34,45) used for conveying rollers (31,41) of tobacco processing industry are suitable for being configured on the side surface of one pusher drums (31,41) for a purpose that a rod-shaped product (43) of tobacco processing industry rotates simultaneously with the grooves (32,42,52) used for accommodating the product (43), so as to move the product (43) along an axial direction in the grooves (32,42,52), wherein the swash plates are provided with through holes (36,54) on one circumference. The radius of the circumference is consistent with a radial distance between the grooves (32,42,52) and a rotation axis of the conveying rollers (31,41). The through holes and the grooves (32,42,52) of the pushing drums (31,41) are arranged in one line at the assembling state of swash plates (34,45). Additionally the invention relates to the pusher drums (31,41) with the swash plate according to the invention, and a machine which is provided with the pusher drum according to the invention for the tobacco processing industry. The swash plates (34,45) are further improved so that at least one through hole (58) is expanded along a circumferential direction on the periphery, and is partially configured not overlapped with the grooves (32,42,52) and / or the other through hole (55,60) is provided on the circumference at least, wherein the through hole is not overlapped with the grooves (32,42,52).

Owner:HAUNI MASCHINENBAU AG

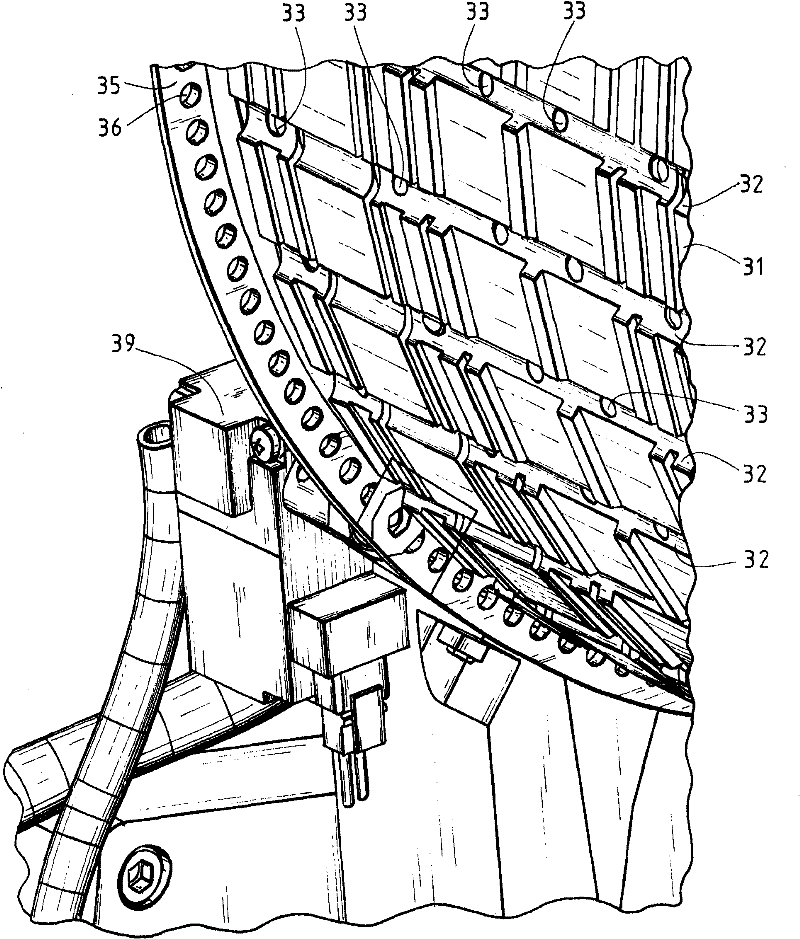

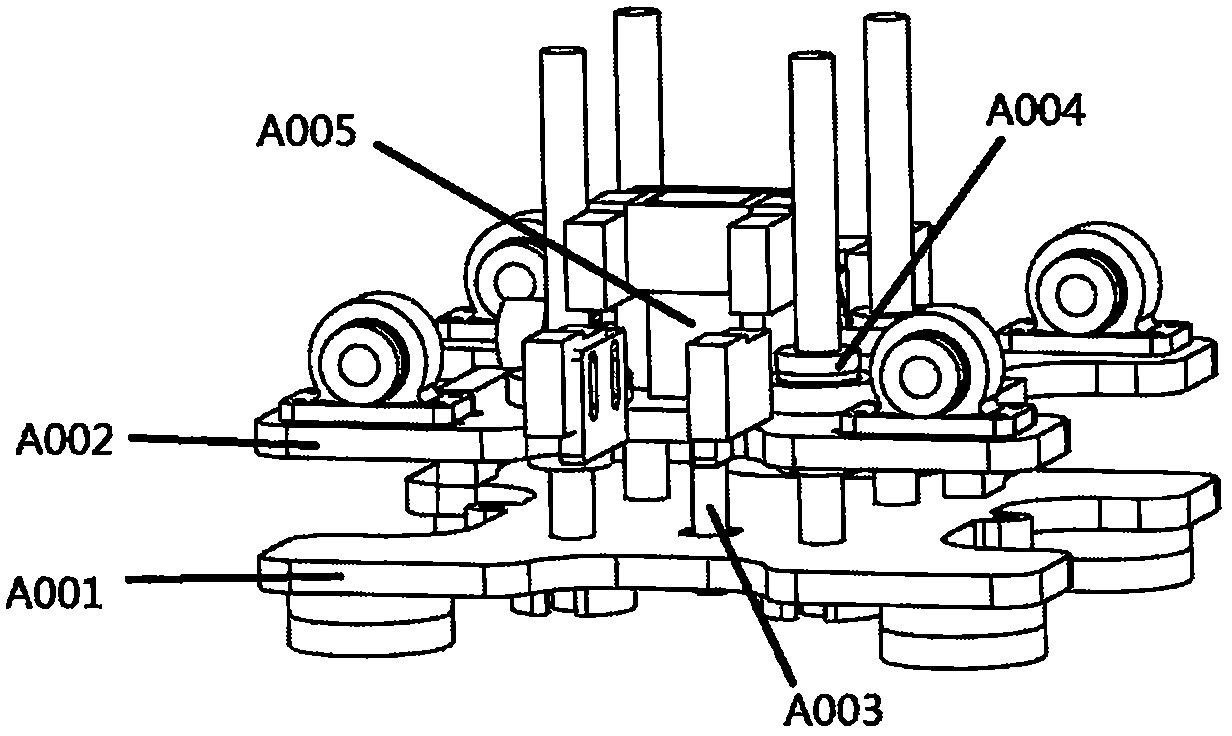

Eddy kinetic energy gas flow material smashing and material-liquid separation pulping device

InactiveCN104818635AGuaranteed stabilityEliminate shakingPaper recyclingRaw material divisionLiquid stateLiquid water

The invention provides an eddy kinetic energy gas flow material smashing and material-liquid separation pulping device. The eddy kinetic energy gas flow material smashing and material-liquid separation pulping device mainly comprises an eddy material smashing device and a liquid pulp generation device. The eddy kinetic energy gas flow material smashing and material-liquid separation pulping device is characterized by achieving material-liquid separation, using eddy kinetic energy gas flow to smash materials firstly, and then mixing the smashed materials with liquid water so as to generate pulp liquid. The eddy kinetic energy gas flow material smashing and material-liquid separation pulping device achieves tangential entering of gas and generates loop currents through a gas inlet pipeline tangent to the outer side edge of the bottom of an outer cylinder, achieves the purposes of increasing eddy kinetic energy in an eddy material smashing area and improving gas flow agitation efficiency in a liquid and material mixing area through an inner cylinder, achieves smashed material screening and blocking prevention through an inner cone hole, and achieves material and liquid mixing and stirring through a smashed material conveying pipe.

Owner:UNIV OF JINAN

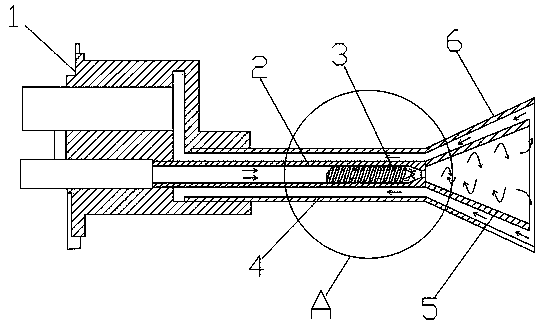

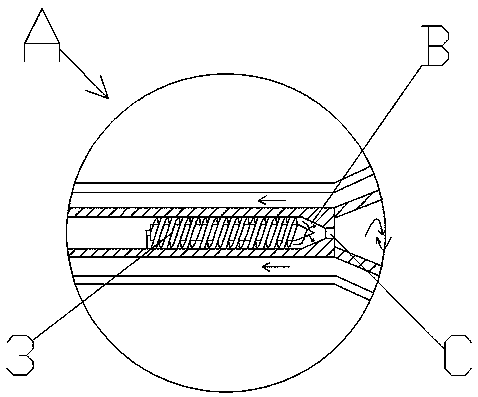

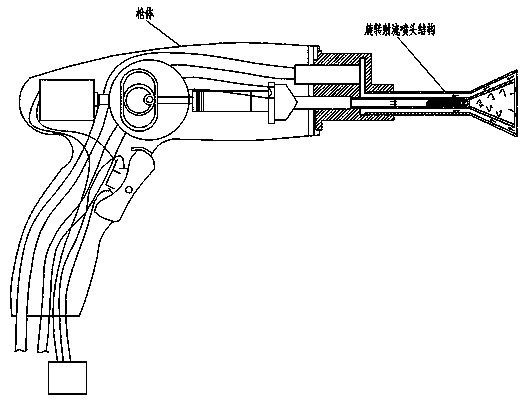

Rotary jet flow sprayer structure for washing gun

PendingCN110038740AReduce impact areaIdeal wound washing effectCannulasEnemata/irrigatorsSpray nozzleWater jet

The invention discloses a rotary water jet flow nozzle structure for a washing gun. A head body combination port, a liquid medicine spraying pipe, a spiral generator, a liquid medicine recycling pipe,a first protection cover and a second protection cover are included. The liquid medicine spraying pipe is sleeved with the liquid medicine recycling pipe, the liquid medicine spraying pipe and the liquid medicine recycling pipe are connected in a washing gun cavity, and the head end of the liquid medicine recycling pipe is connected with the position of the head body combination port. The spiralgenerator is fixedly connected to the outlet position in the liquid medicine spraying pipe through a support. The outlet position of the liquid medicine spraying pipe is provided with a conical cavitystructure and a transition area. The first protection cover is connected with the liquid medicine spraying pipe. The second protection cover is connected with the liquid medicine recycling pipe. Thespiral generator is adopted so that longitudinal impact flowing can be converted into three-dimensional flowing with a certain tangential speed, the jetted fluid has the longitudinal speed and also has radial and tangential component speed, rotary jet flow is formed, the jet flow entrainment and mixing are enhanced through washing liquid, the impact area is enlarged, the impact pressure intensityis reduced, and a more ideal wound surface washing effect is achieved.

Owner:吴丹凯

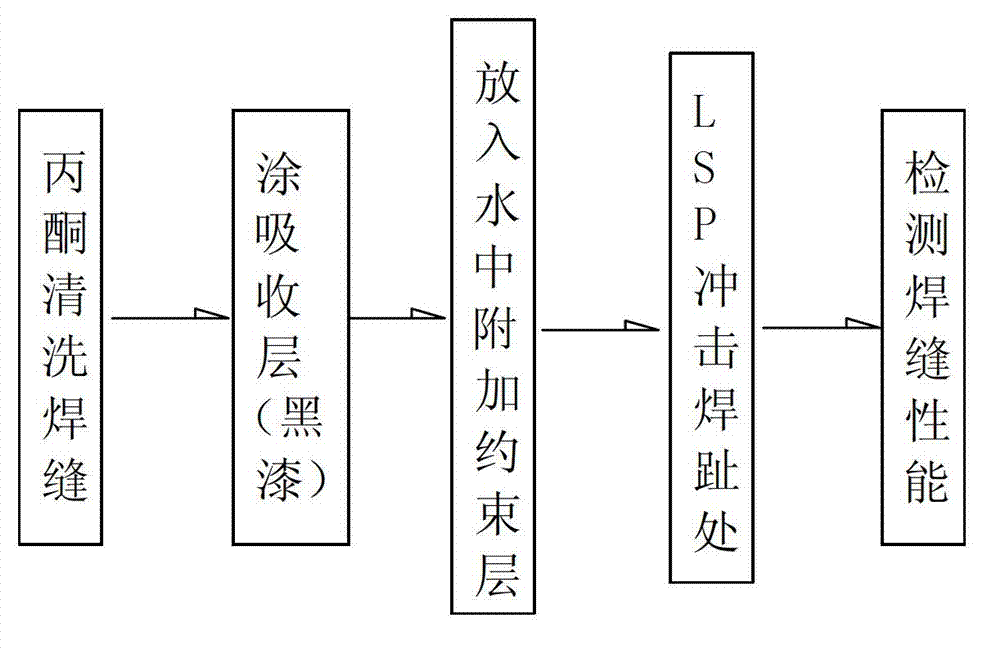

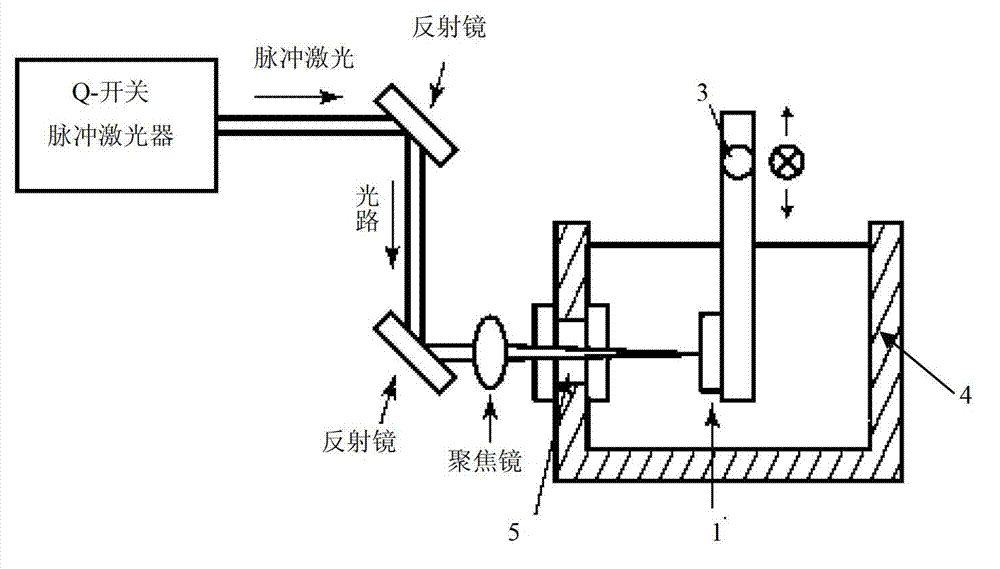

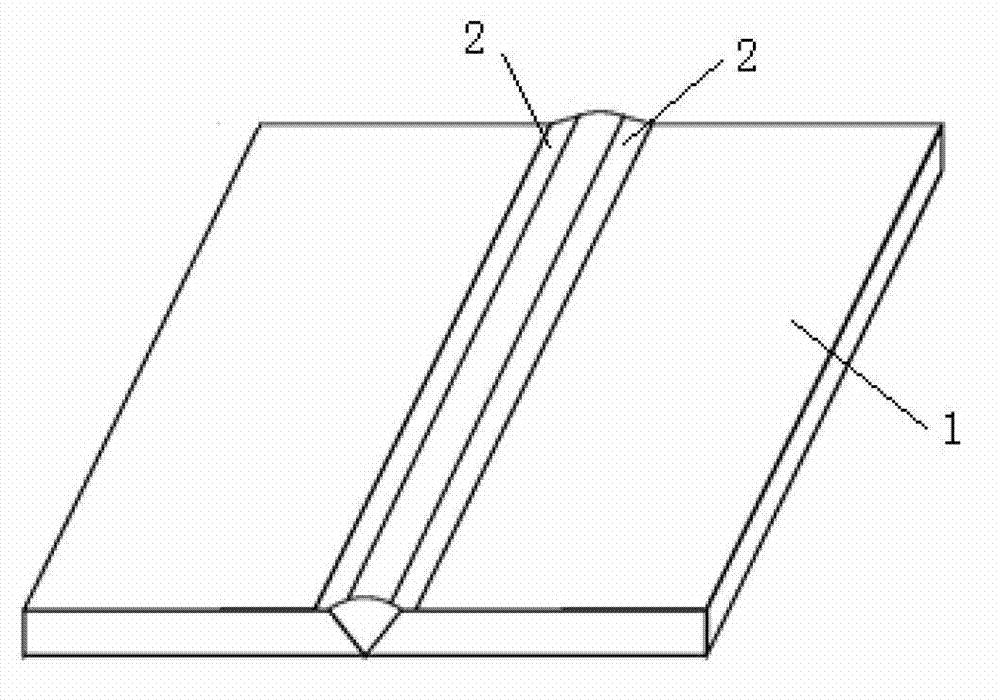

Method of improving fatigue strength of aluminum alloy welding joint

InactiveCN103111759AImprove fatigue resistanceReduce stress concentrationLaser beam welding apparatusLaser frequencyUltimate tensile strength

The invention relates to the field of aluminum alloy welding joint, in particular to a method of improving fatigue strength of the aluminum alloy welding joint. The method of improving the fatigue strength of the aluminum alloy welding joint is characterized in that the fatigue strength of the aluminum alloy welding joint is improved due to the fact that laser is used for shocking two side areas of the aluminum alloy welding joint. The method of improving the fatigue strength of the aluminum alloy welding joint includes a first step of washing the welding joint with acetone before processing, coating a carbon black paint coating layer on an area with a 3mm-4mm width at two sides of an aluminum alloy test piece weld toe, and sinking a test piece into water; a second step of adjusting a focus lamp to guarantee a restraint layer to be 50-80mm in the water, shocking the area with the 3mm-4mm width at two sides of the test piece weld toe, wherein the parameters are as follows: the laser wave length is 532nm-535nm, the laser frequency is 60Hz, the monopulse laser energy is 100mJ-120mJ, and the laser pulse peak power density is about 4.5 GW / cm -5GW / cm. Compared with the prior art, the method of improving the fatigue strength of the aluminum alloy welding joint has the advantages of being small in shocking area and greatly improving the shocking strengthening efficiency when being compared with a shocking strengthening technology of the whole welding joint.

Owner:鞍山煜宸科技有限公司

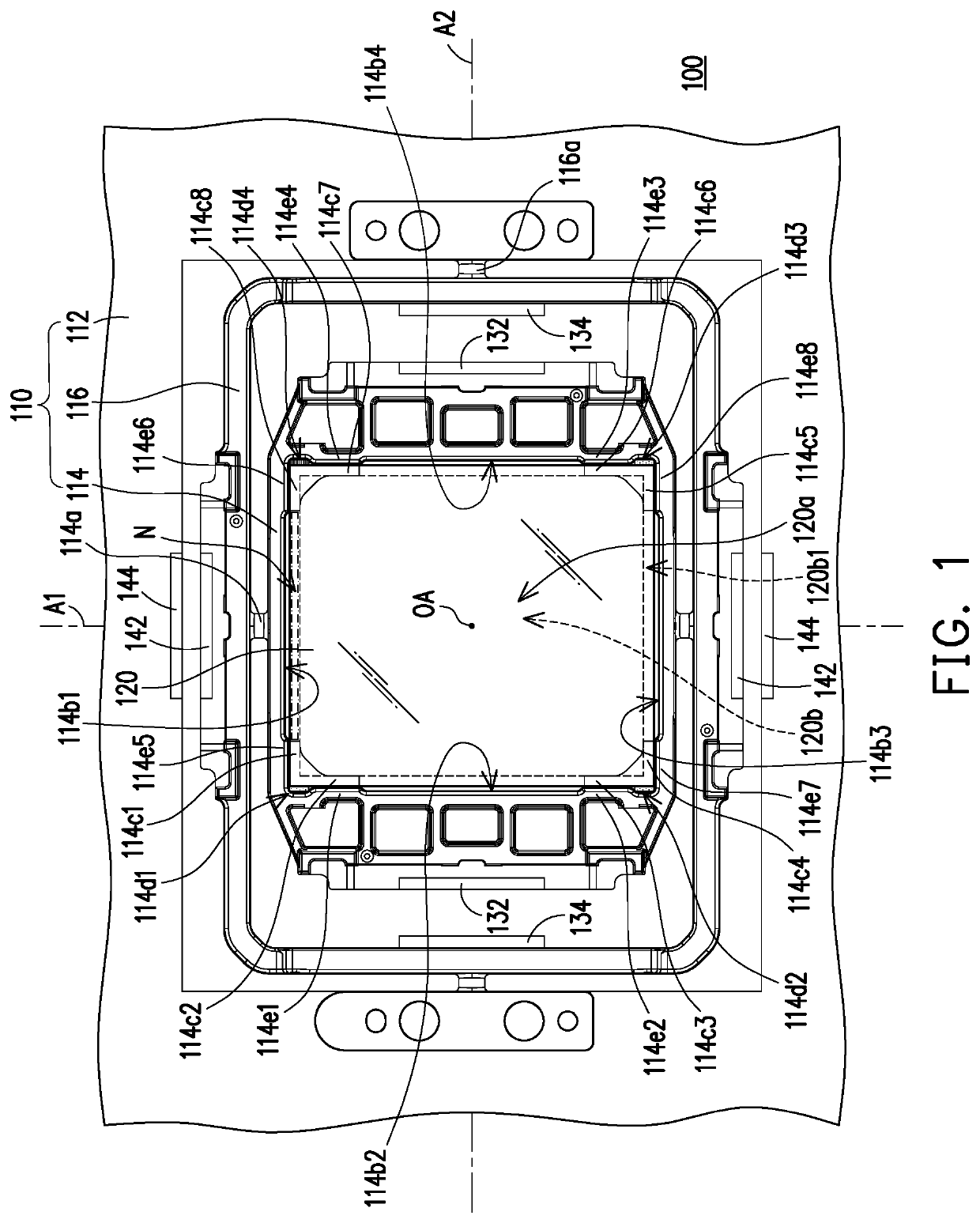

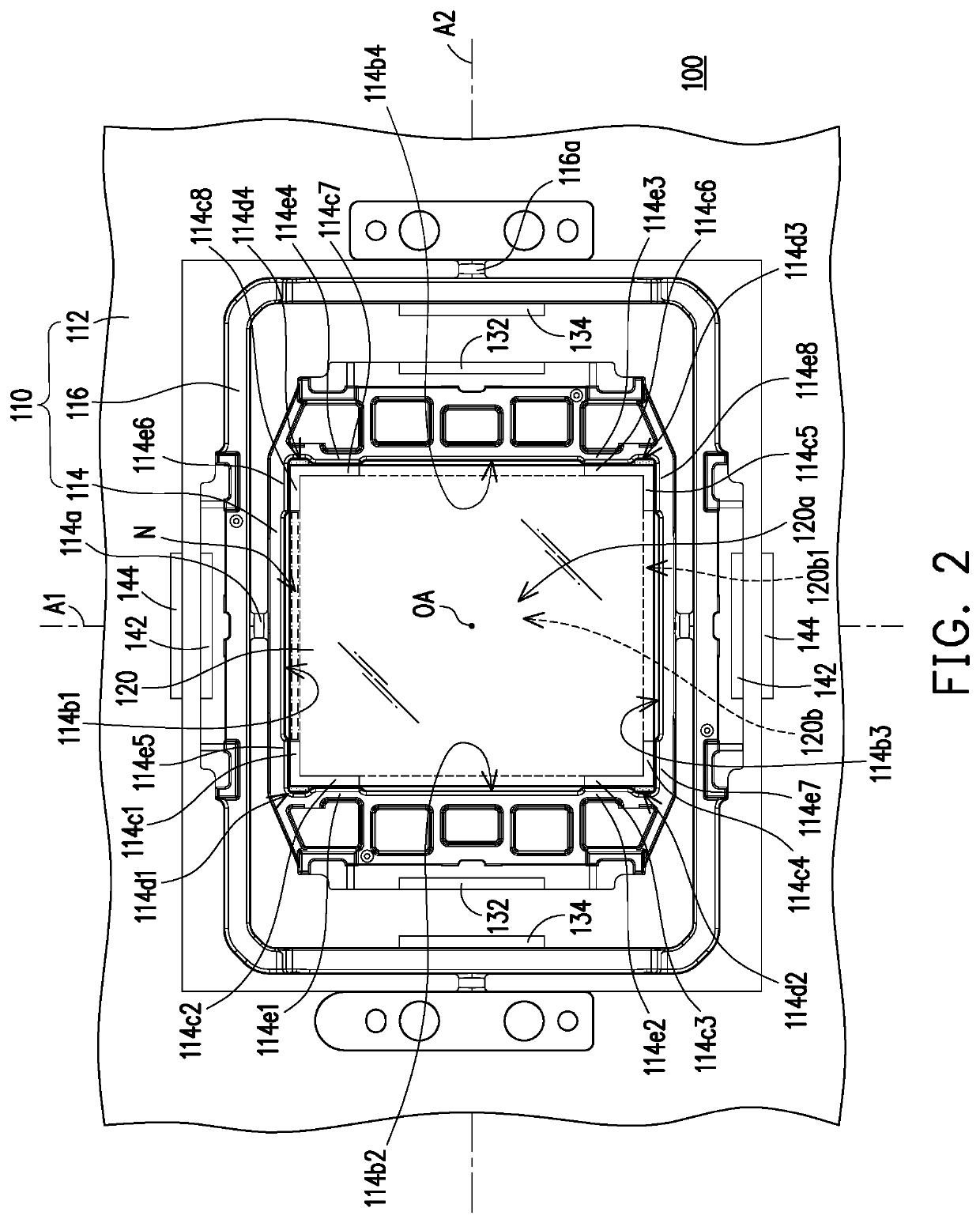

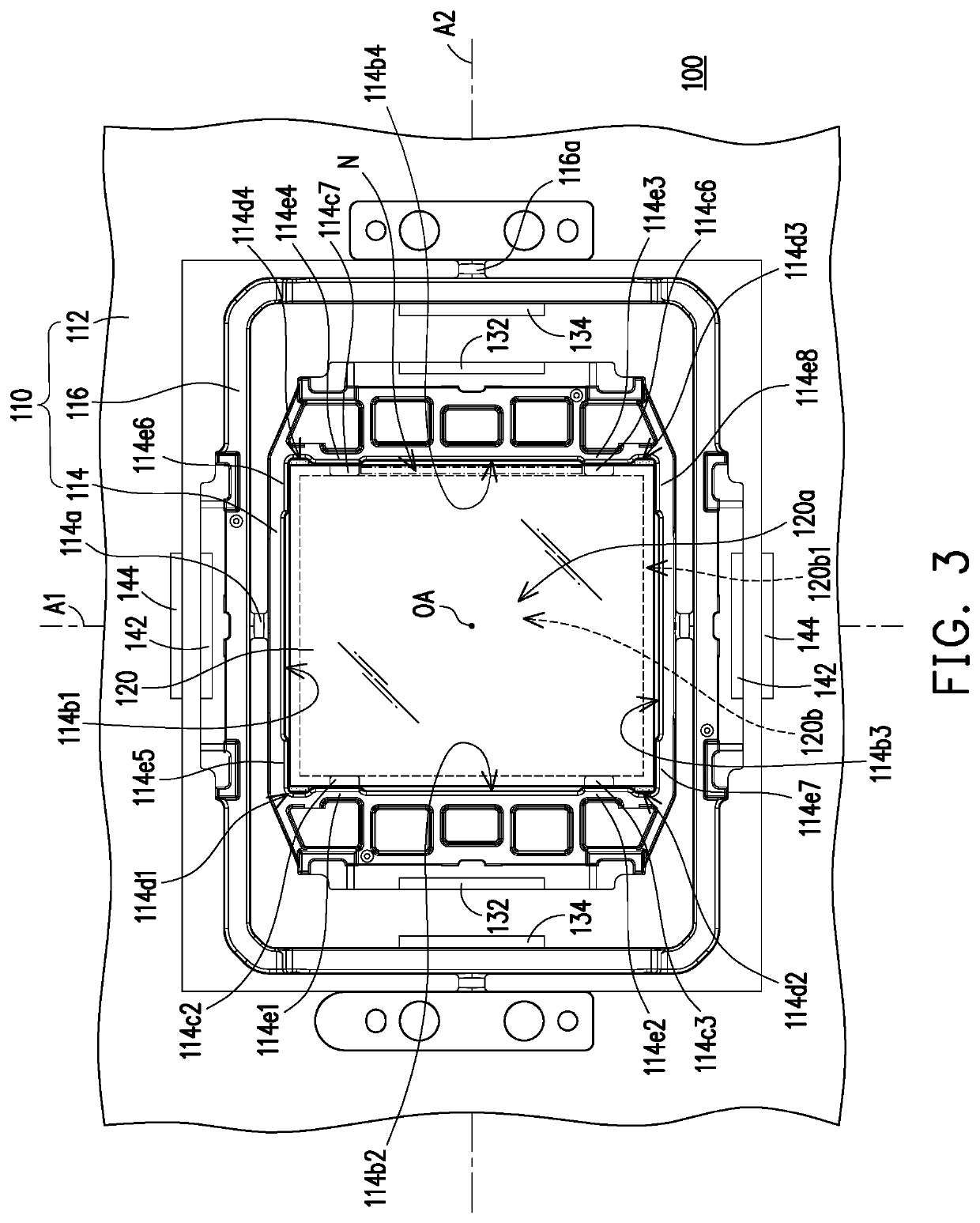

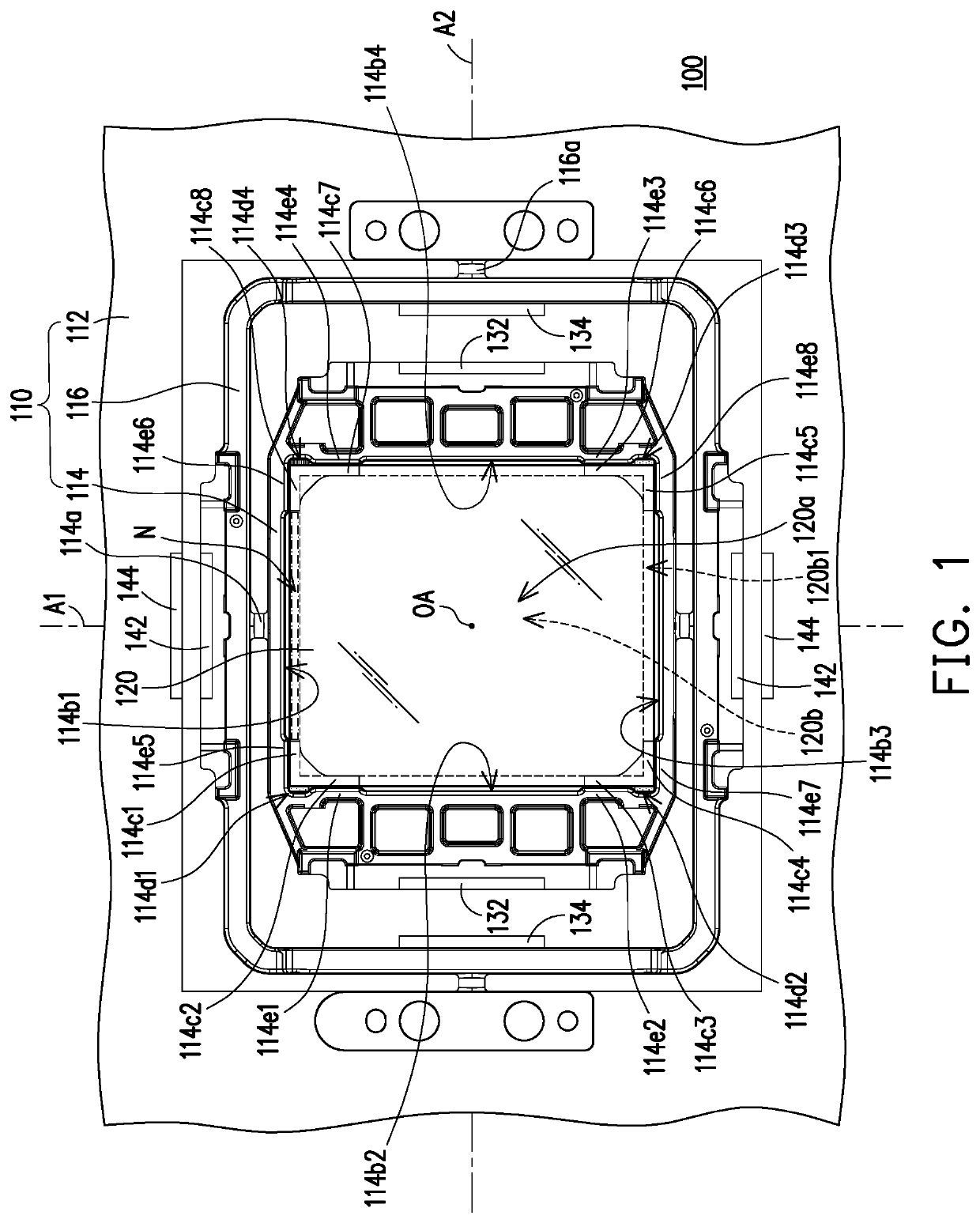

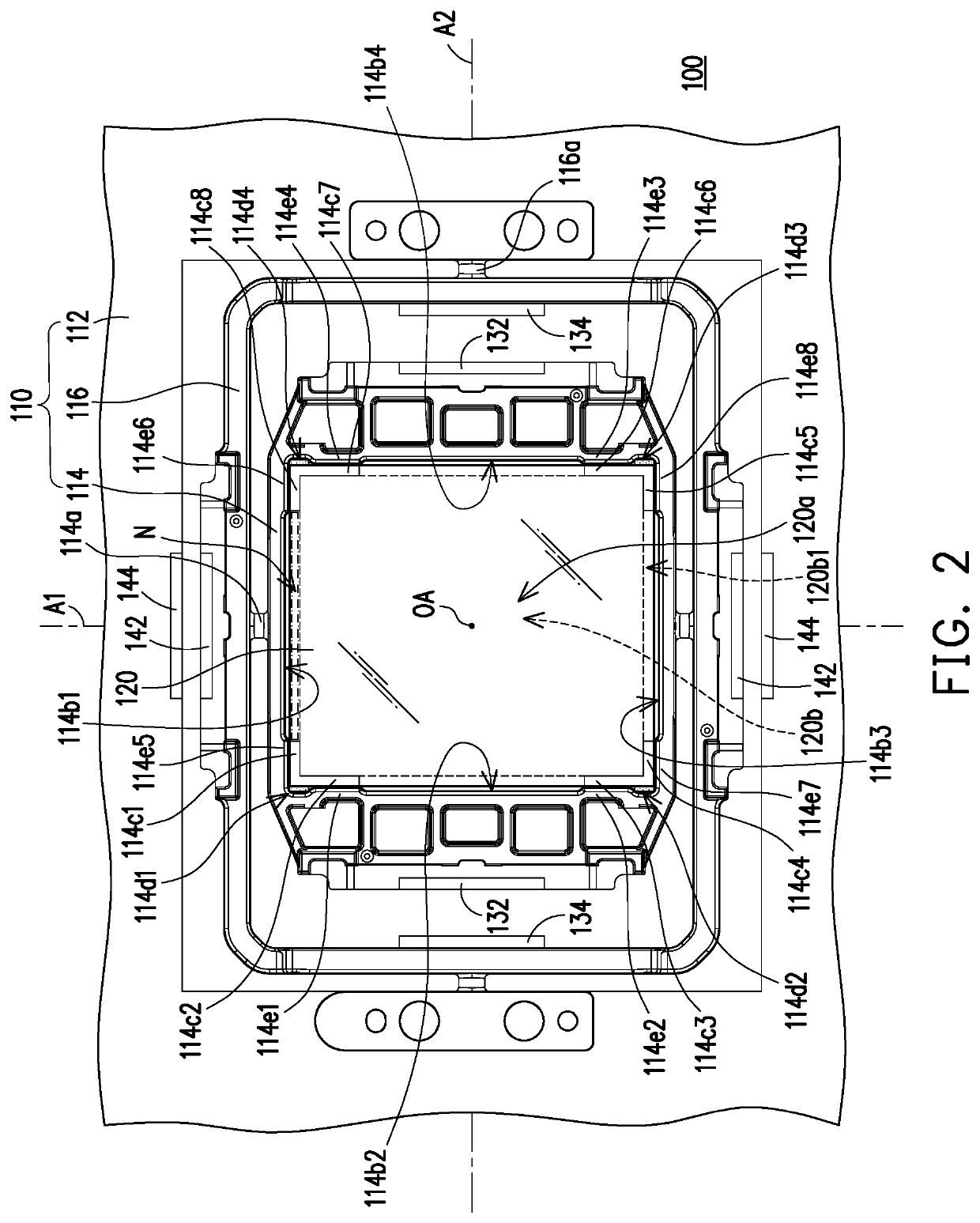

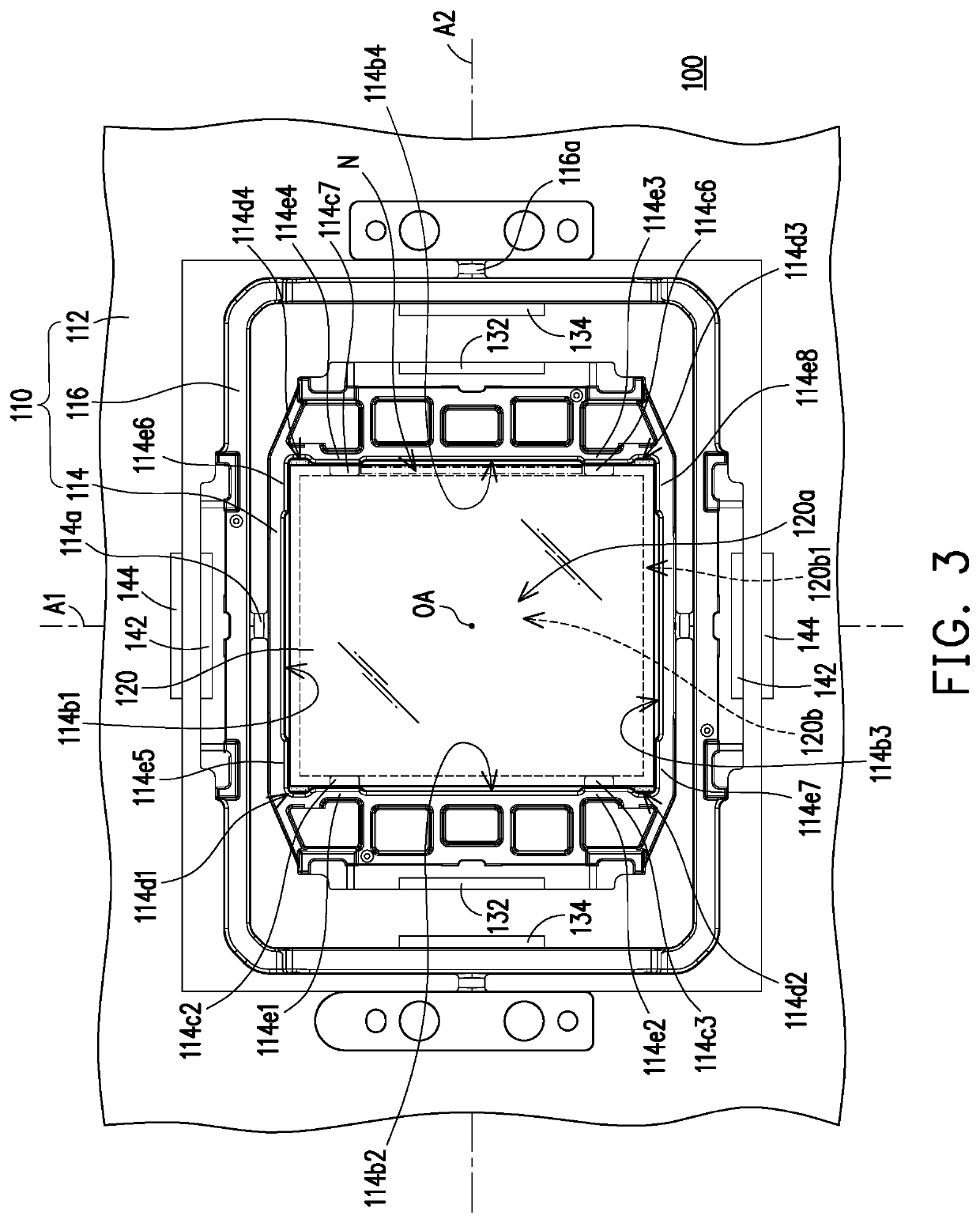

Optical device

ActiveUS20200264445A1Reduce or eliminate the noise generated during its operationReduce supportStatic indicating devicesProjectorsEngineeringMaterials science

An optical device including a holder and a light transmissive plate is provided. The holder includes a first frame and a second frame connected to each other, and the first frame is located inside the second frame. A light transmissive plate is disposed inside the first frame and has a surface. The first frame has at least one inner surface and includes at least one surface supporting part, and the surface supporting part extends along a direction from the inner surface of the first frame to the center of the first frame, and the surface of the light transmissive plate is at least partially supported by the surface supporting part of the first frame. The surface supporting part is non-continuously distributed along the inner surface of the first frame. The disclosure further provides a projector including the optical device.

Owner:CORETRONIC

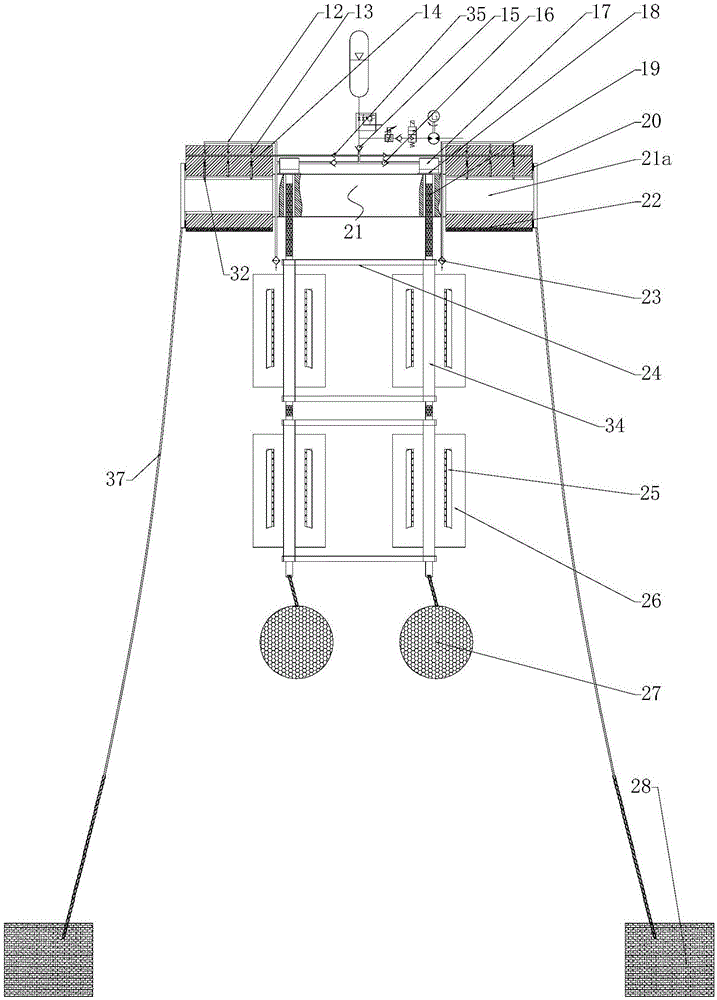

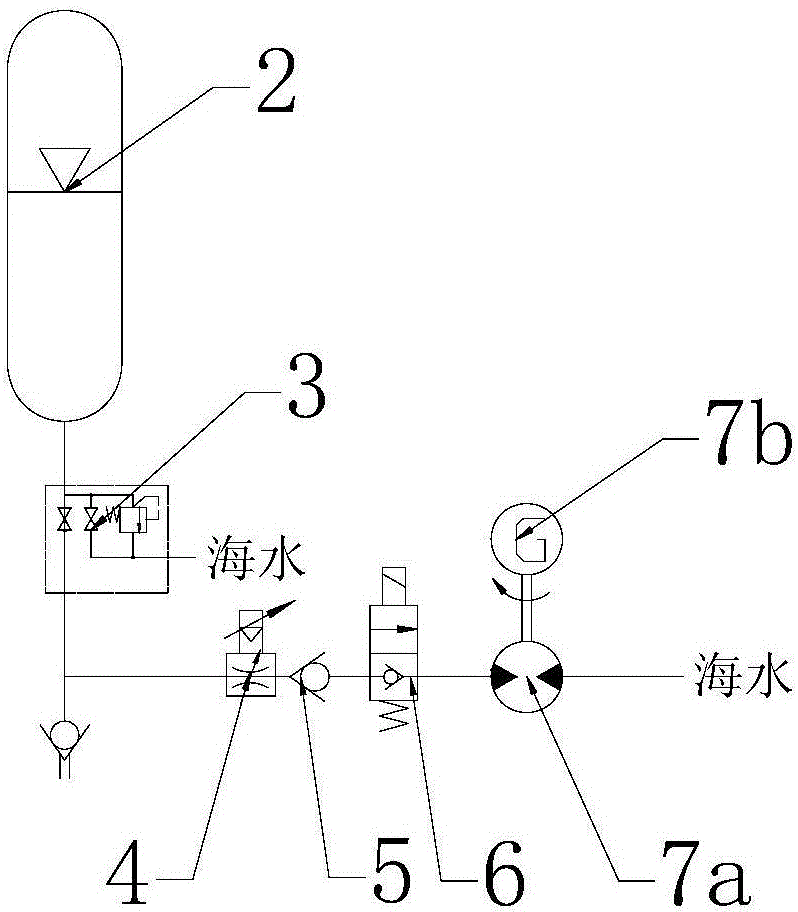

Flexible breakwater system

ActiveCN106351172ARealize the effect of wave eliminationAvoid collisionBreakwatersQuaysElectricityHydraulic motor

The invention provides a flexible backwater system, comprising at least one backwater device, wherein the device comprises a power generating platform comprising a main float and floats uniformly disposed at four corners of the main float. The float is swung around the main rotor with the wave, and the surface of the main rotor is wavy; The first hydraulic device comprising a first filter, combination of a plurality of main damper and a hydraulic damper disposed inside the float and a plurality of hydraulic damper, the first check valve; the hydraulic power generation device comprising a auxiliary check valve, an accumulator, a relief valve, a proportional valve, a third check valve, an on-off valve, a hydraulic motor and a hydraulic valve and a driving motor connecting to the flexible backwater system. The flexible backwater system not only has good backwater effect, but also can generate electricity.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

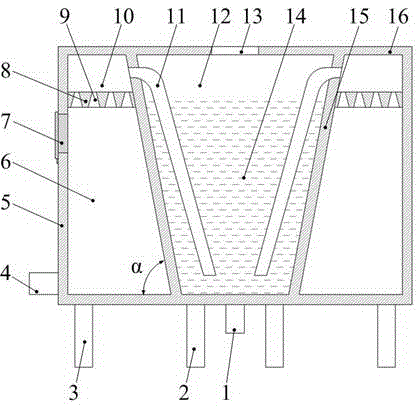

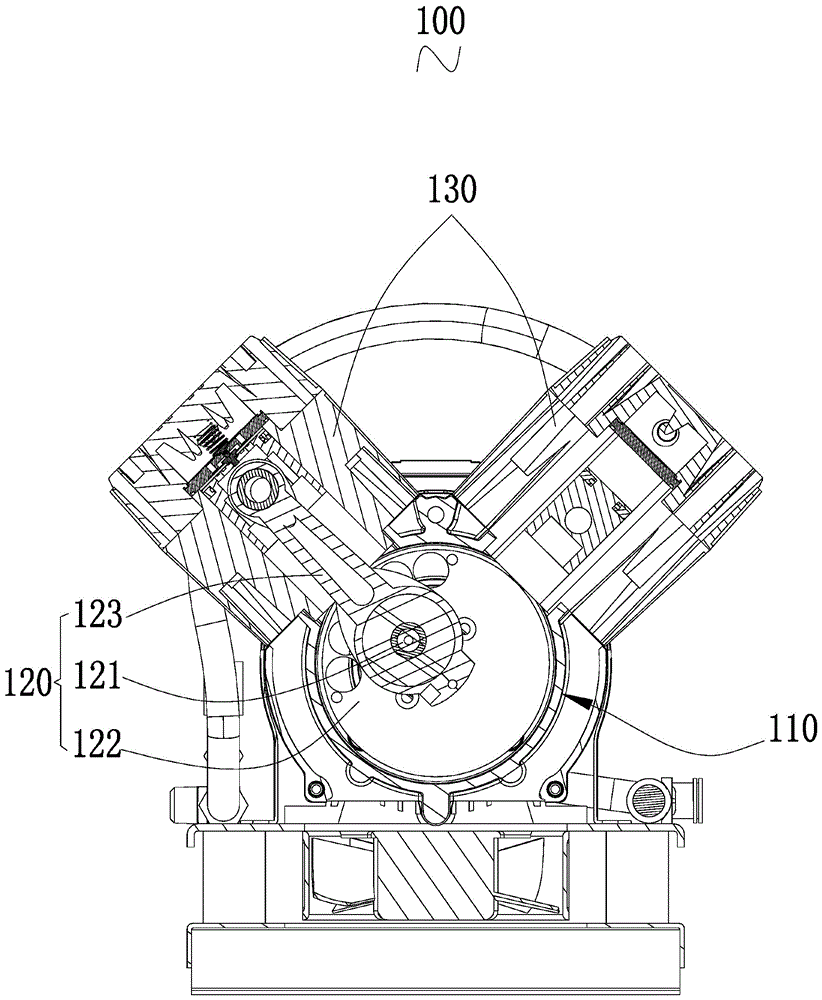

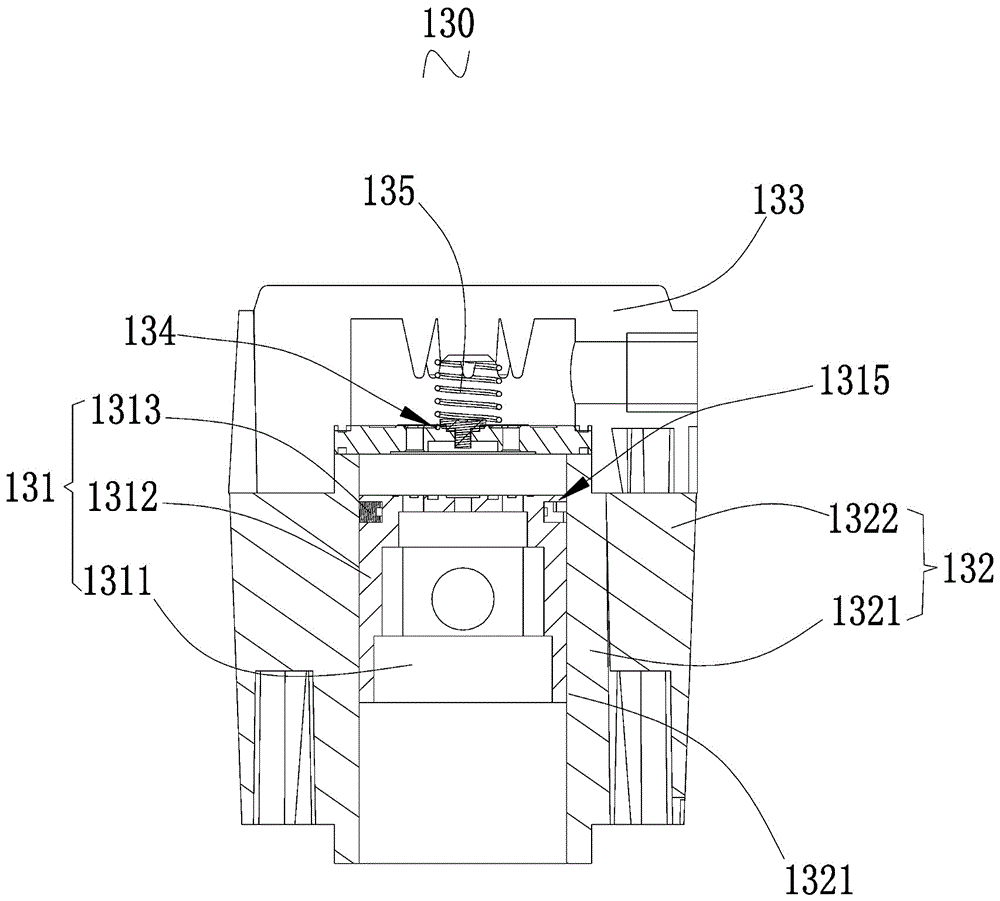

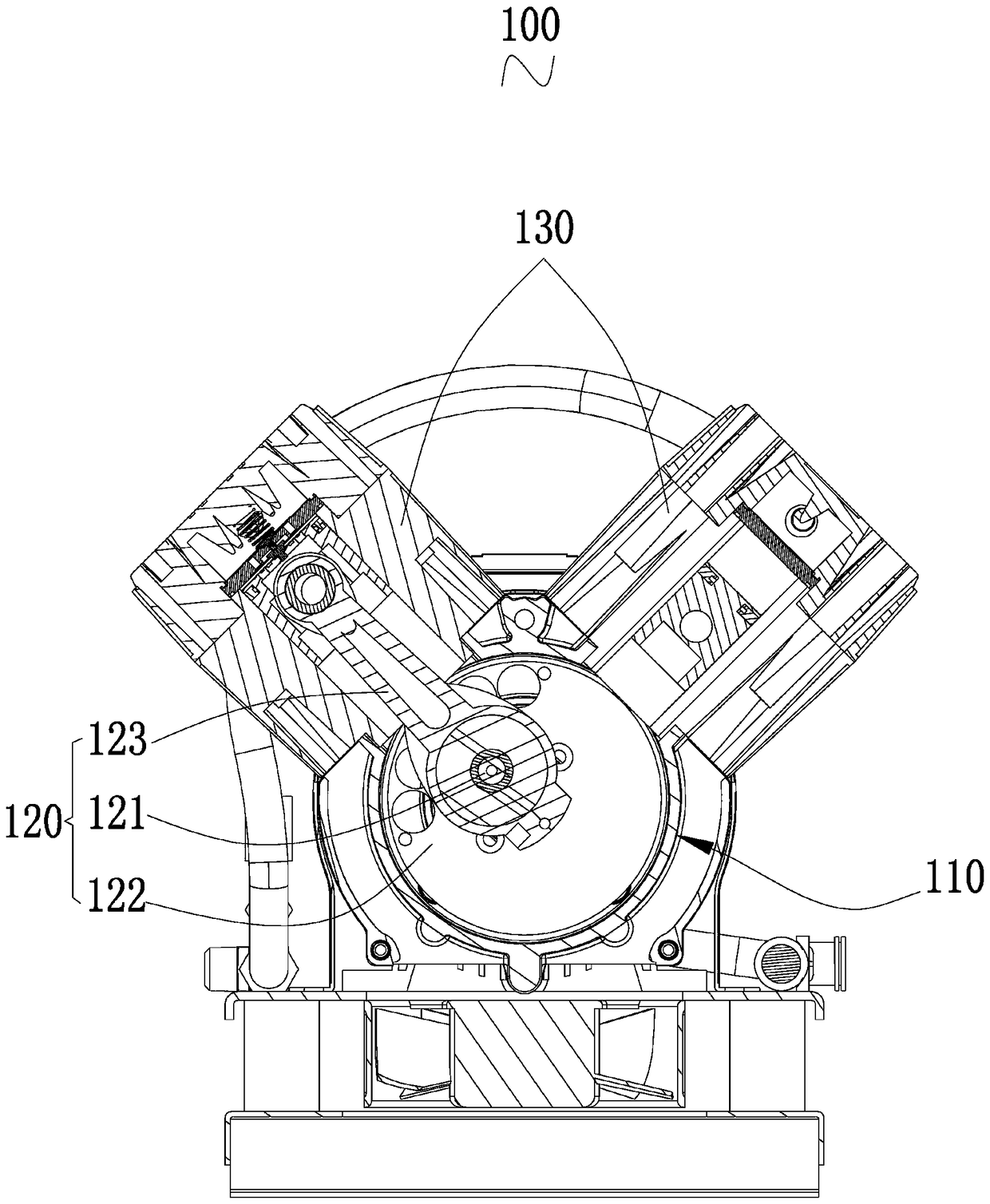

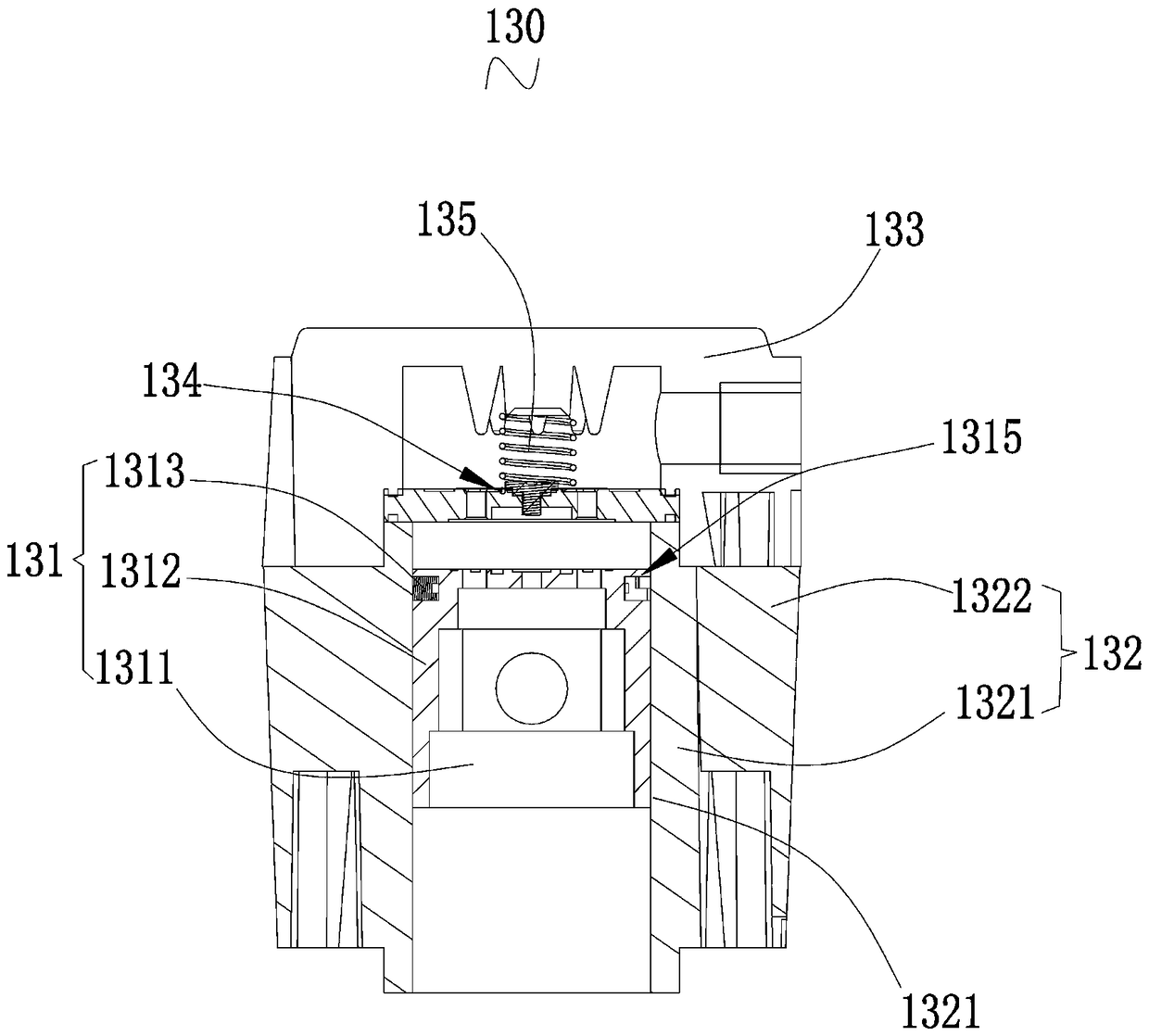

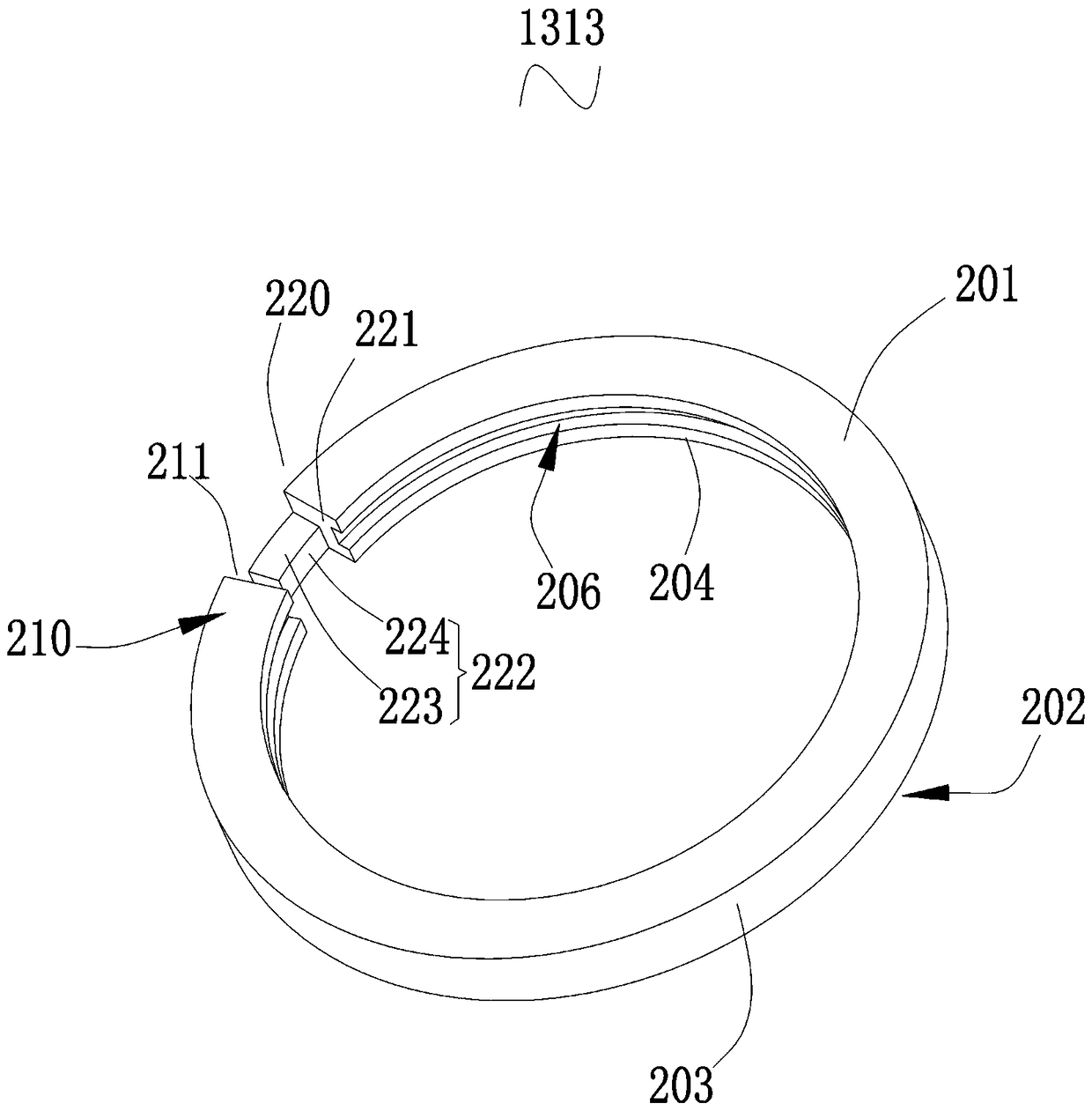

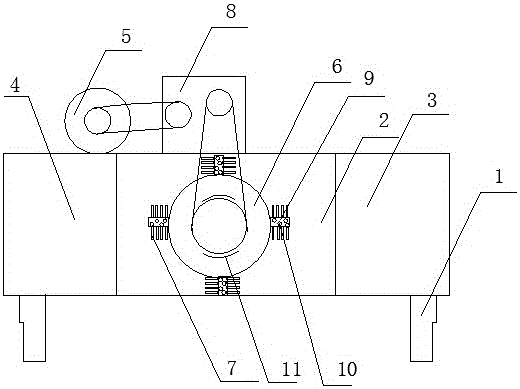

Low-energy-consumption oilless silence air compressor

ActiveCN106523320AReduce friction heatIncrease exhaustPiston ringsPositive displacement pump componentsEngineeringAir compressor

The invention discloses a low-energy-consumption oilless silence air compressor. The low-energy-consumption oilless silence air compressor comprises at least one air cylinder assembly. Each air cylinder assembly comprises a piston and an air cylinder containing the piston, wherein a ceramic film layer is arranged on the inner wall of a cylinder sleeve of the air cylinder, the piston comprises a piston body, a composite material layer arranged on the outer side of the piston body in a sleeving manner, a piston ring embedded in the outer side of the composite material layer, and the piston ring and the composite material layer are made of the same materials and prepared through carbon material containing composite materials. During work, each piston reciprocates in the corresponding cylinder sleeve, each piston ring rubs with the ceramic film layer on the inner wall of the corresponding cylinder sleeve, the composite material layer on the outer side of each piston body plays a guiding role in the corresponding cylinder sleeve, and therefore the friction coefficient between each piston and the corresponding cylinder sleeve is reduced, and efficiency is improved.

Owner:厦门闳图盛道科技有限公司

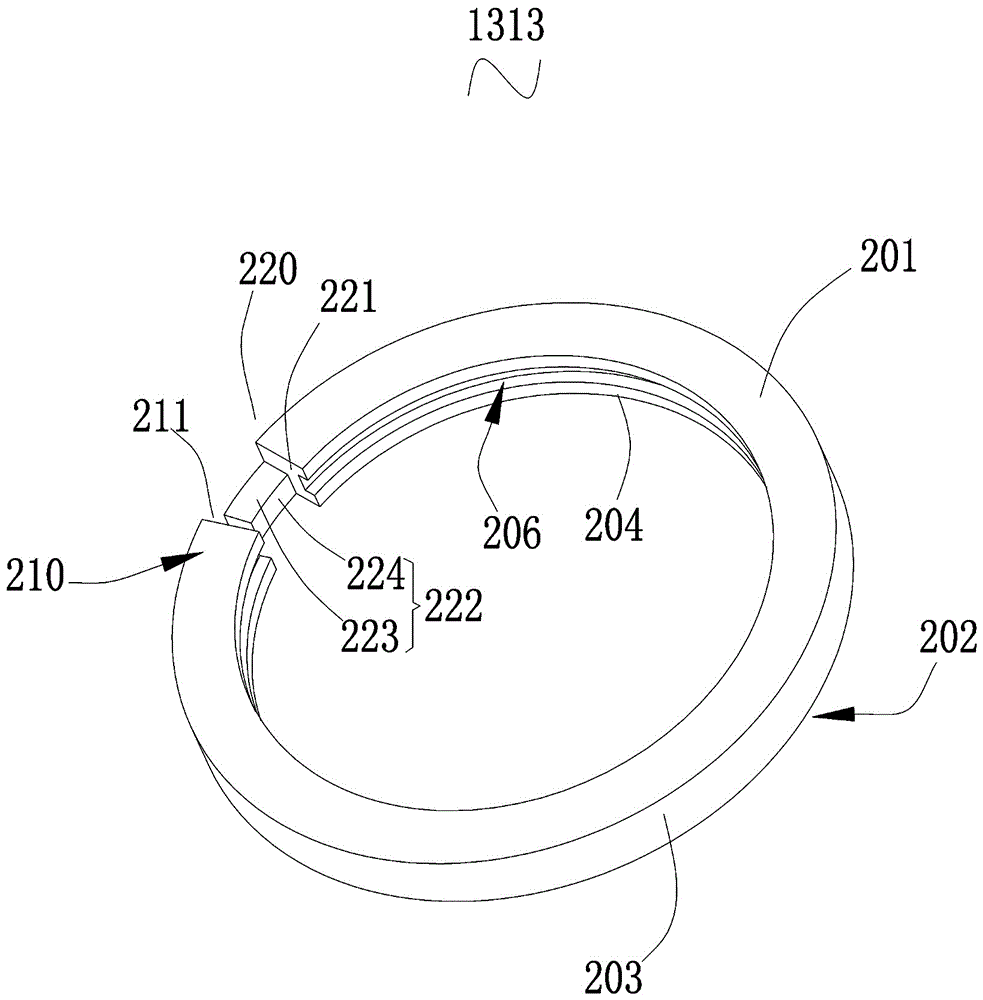

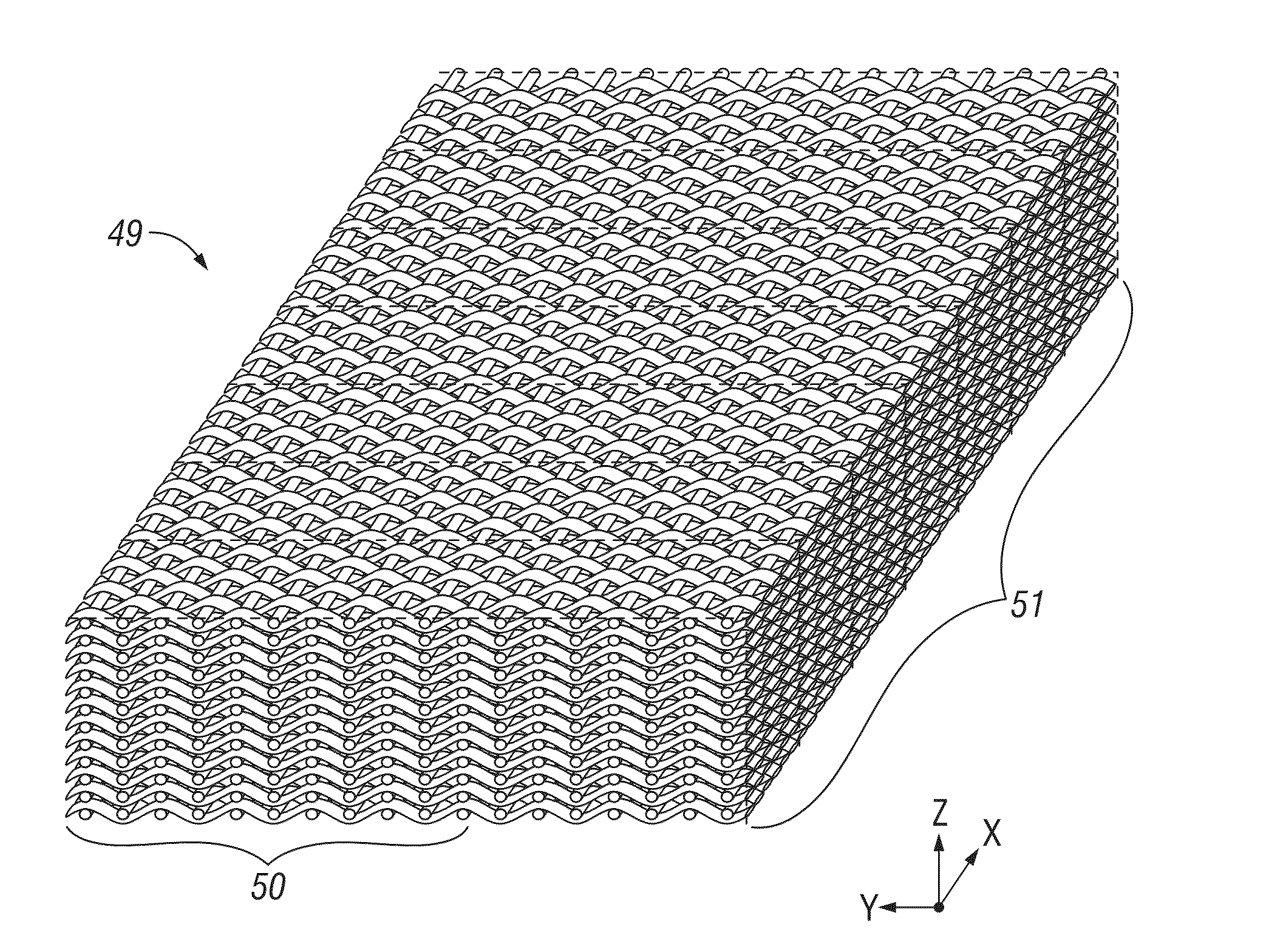

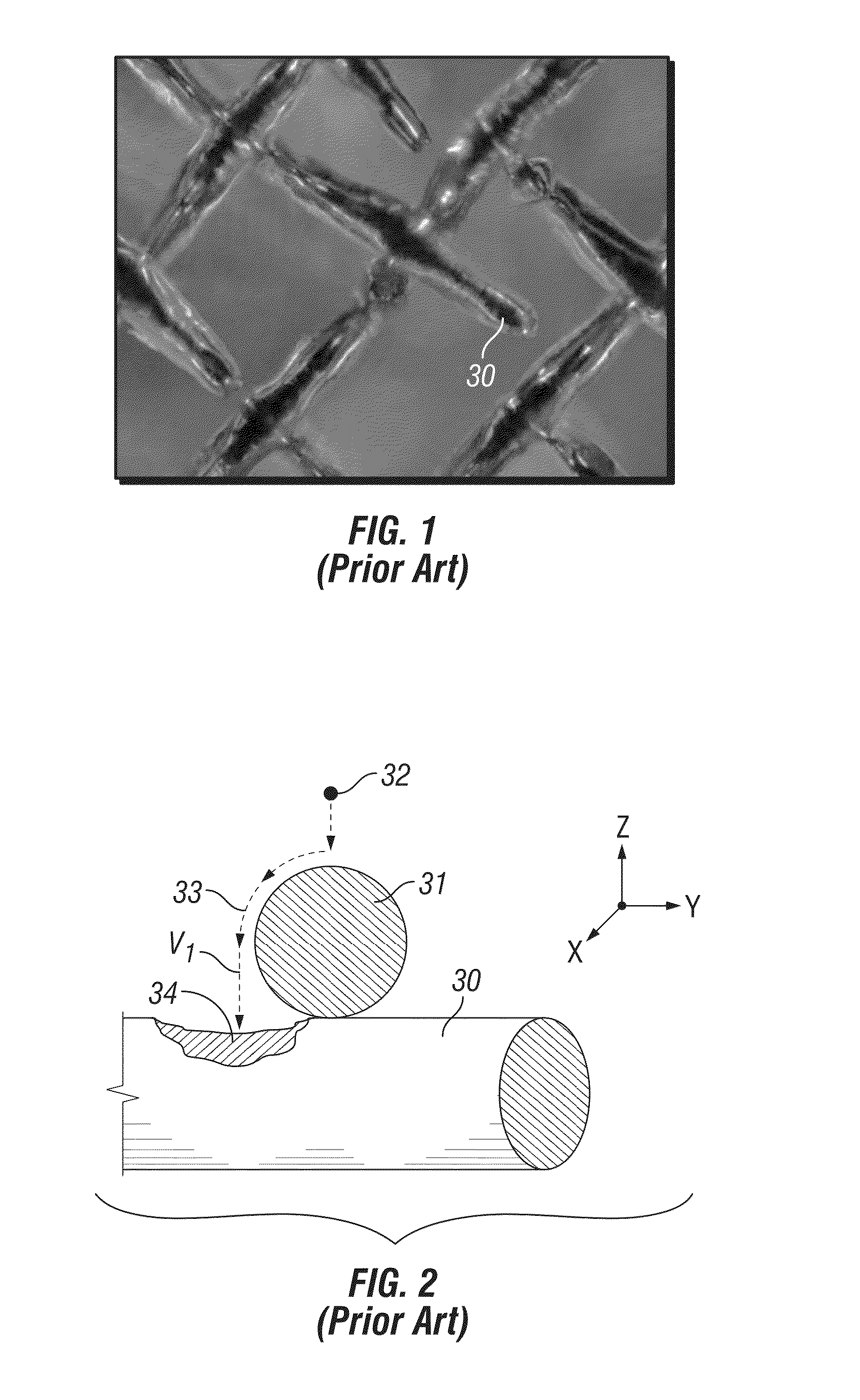

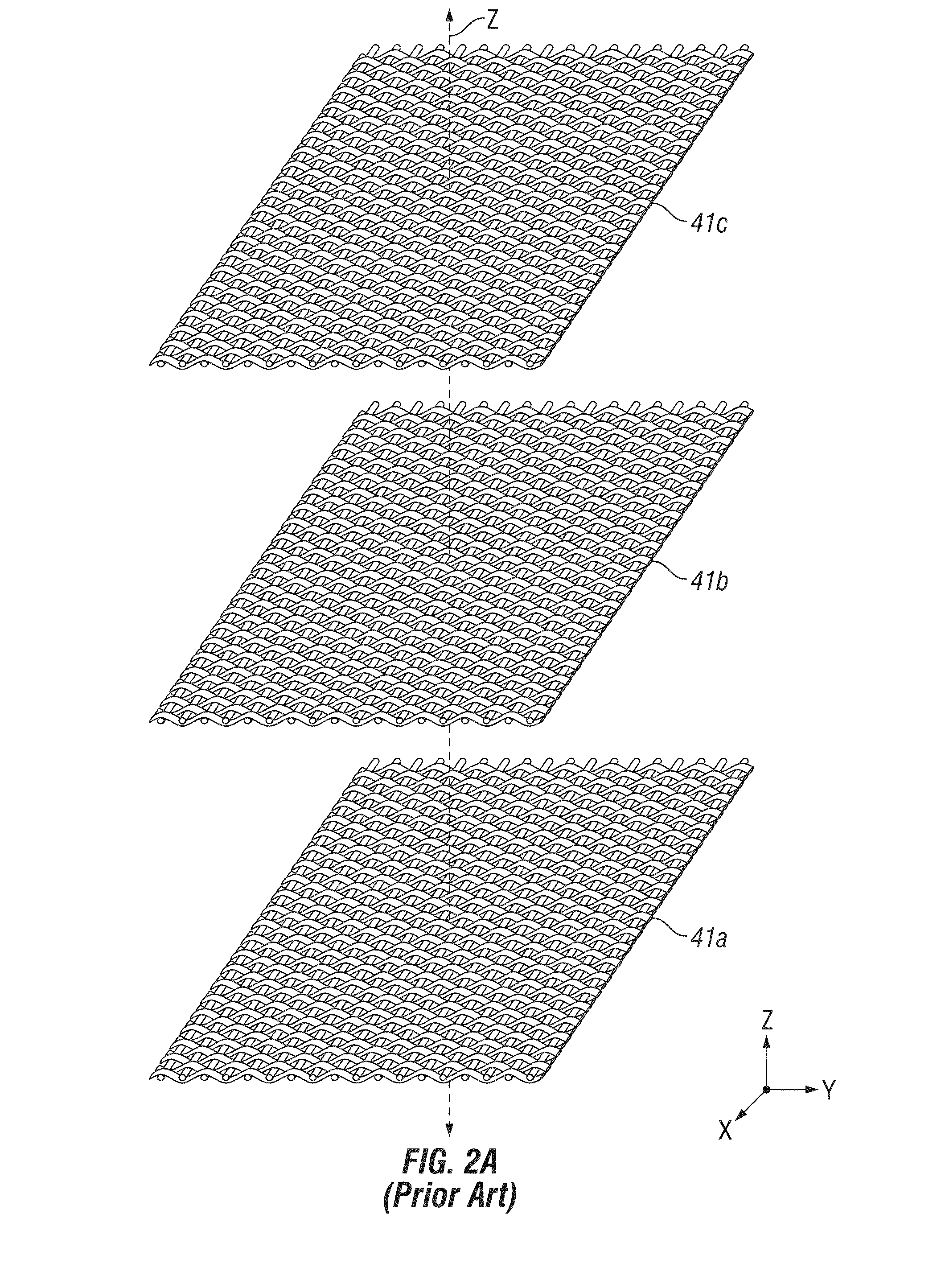

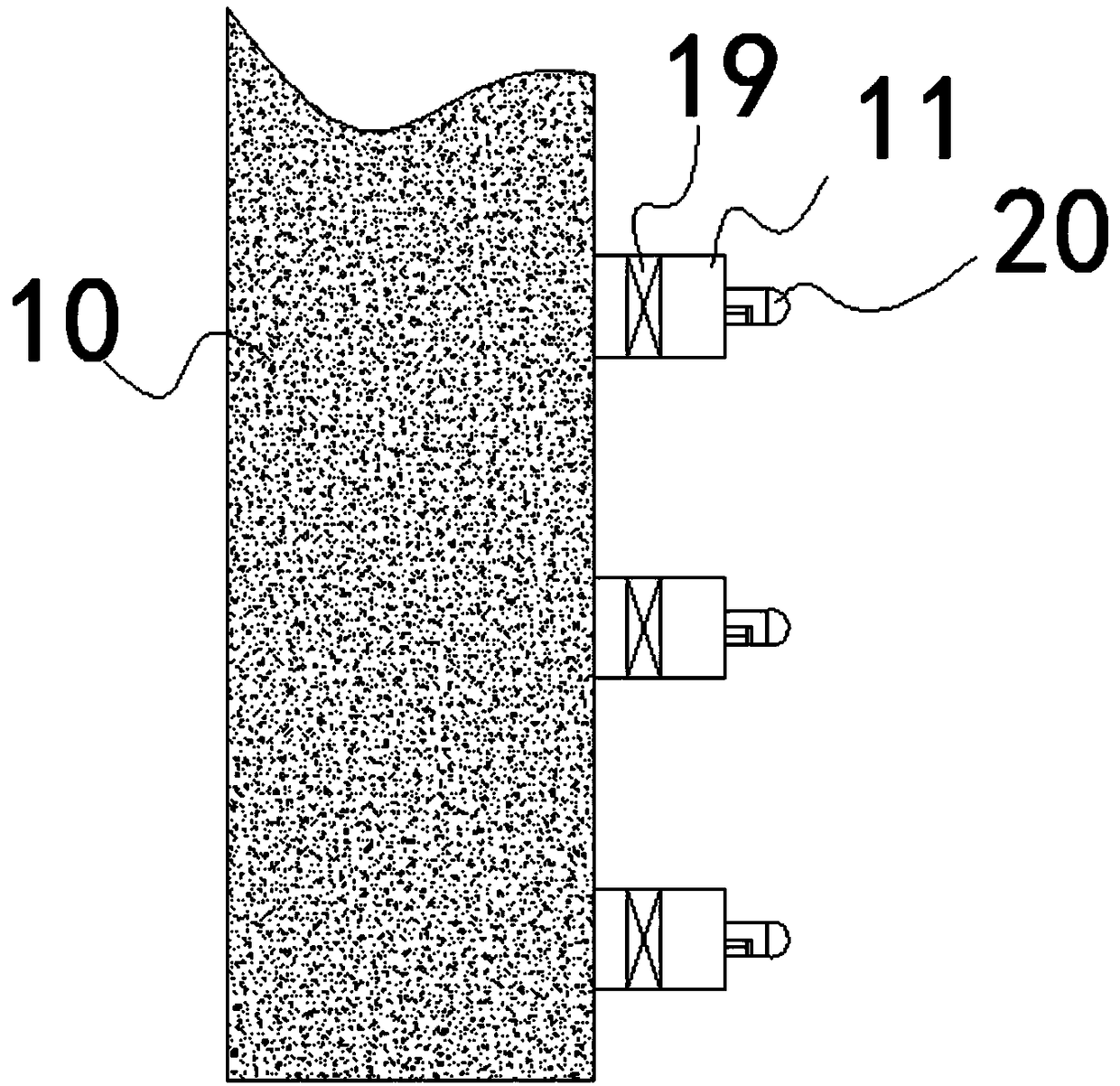

Method, System and Apparatus of Erosion Resistant Filtering Screen Structures

InactiveUS20150152716A1Reduce impact areaFluid removalLoose filtering material filtersProduction tubingSand filter

An improved particle or sand filtering apparatus, method and system is disclosed. The apparatus may be adapted to filter particles or sand from a particle-laden hydrocarbon fluid by employing a stacked multi-layered screen in an X-Y plane and having at least one screen comprised of a plurality of first wires and a plurality of second wires that are woven. The stacked screen may be placed within a production tubing in a wellbore for the production of hydrocarbons from the wellbore. The apparatus is configured to facilitate passage of particle-laden fluid through the screen in a direction that is substantially parallel to an X-Y plane of the screen.

Owner:CHEVROU USA INC

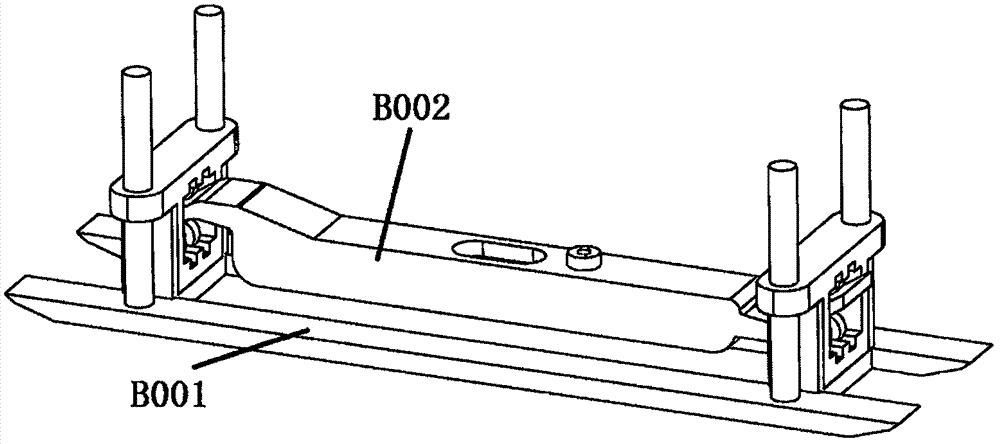

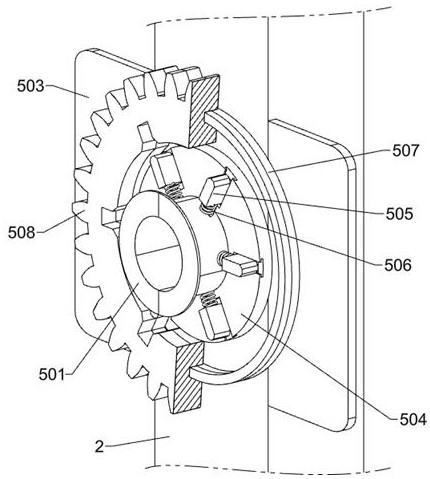

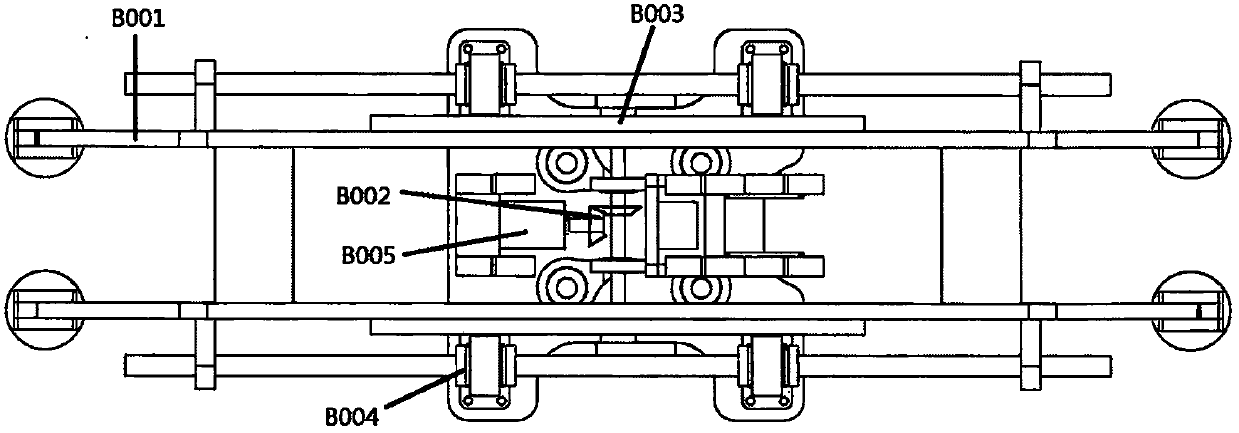

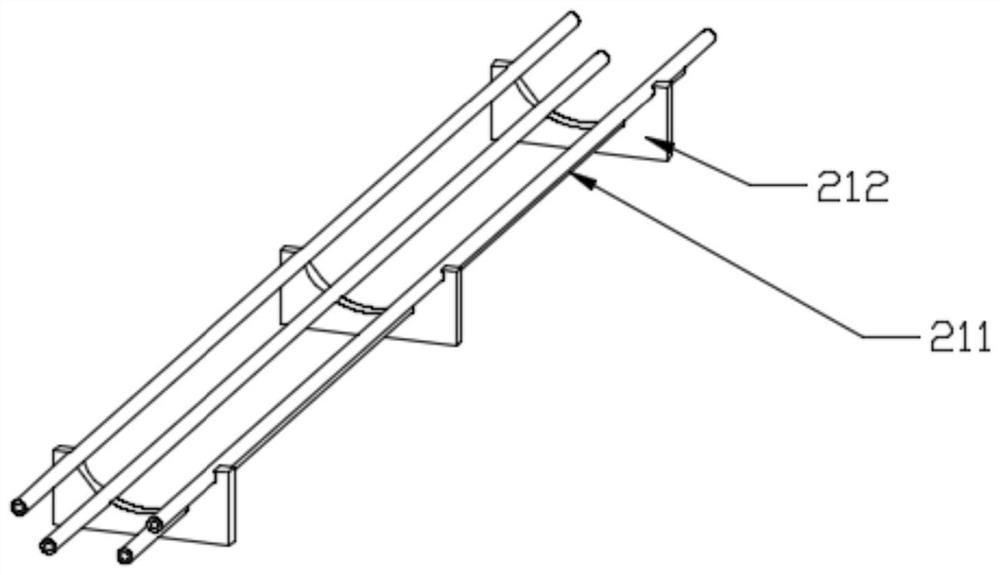

Flat wriggling crawling system based on composite cam

InactiveCN107539386ARealize Alternate SupportAchieve rotation forwardVehiclesSmall amplitudeEngineering

The invention discloses a flat wriggling crawling system based on a composite cam. The flat wriggling crawling system is synergistically composed of a plurality of mechanical bionic joint units; in each joint unit, a small amplitude of transverse movement generated by the composite cam is utilized by a lifting module to drive a driving sliding block to move front and back, and a driving face on the driving sliding block drives an inner foot to move up and down, so that the inner foot and an outer foot make contact with the ground alternately, and alternating support of the inner foot and the outer foot of each joint unit is achieved; a large amplitude of transverse movement generated by the composite cam is utilized by a front-back moving module to drive the outer foot to move front and back, and alternate going forward of the inner foot and the outer foot is achieved by alternating support of the inner foot and the outer foot; marching, steering and obstacle-crossing of the system aresynergistically achieved by all the joints; and by applying flat design, the whole height is reduced, combat efficiency is improved, physical energy consumption of soldiers is reduced, and the area of a projectile touching face is reduced.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

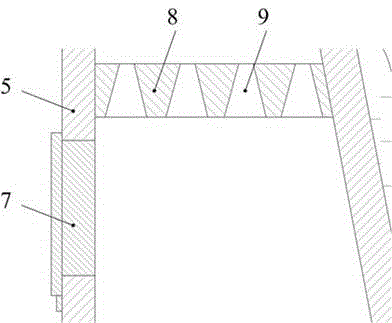

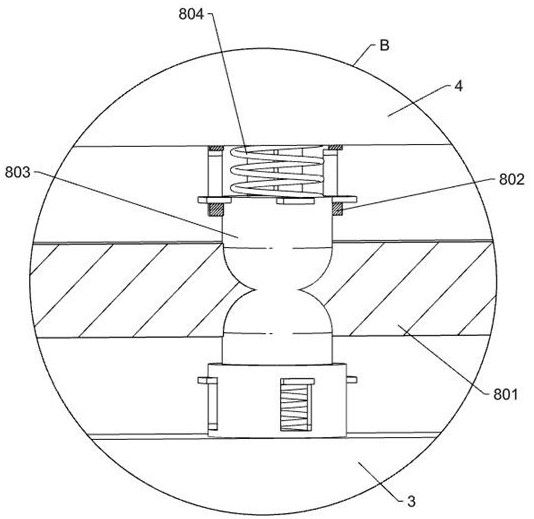

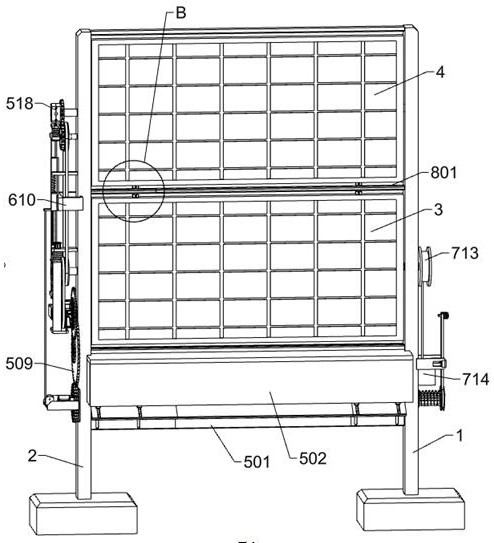

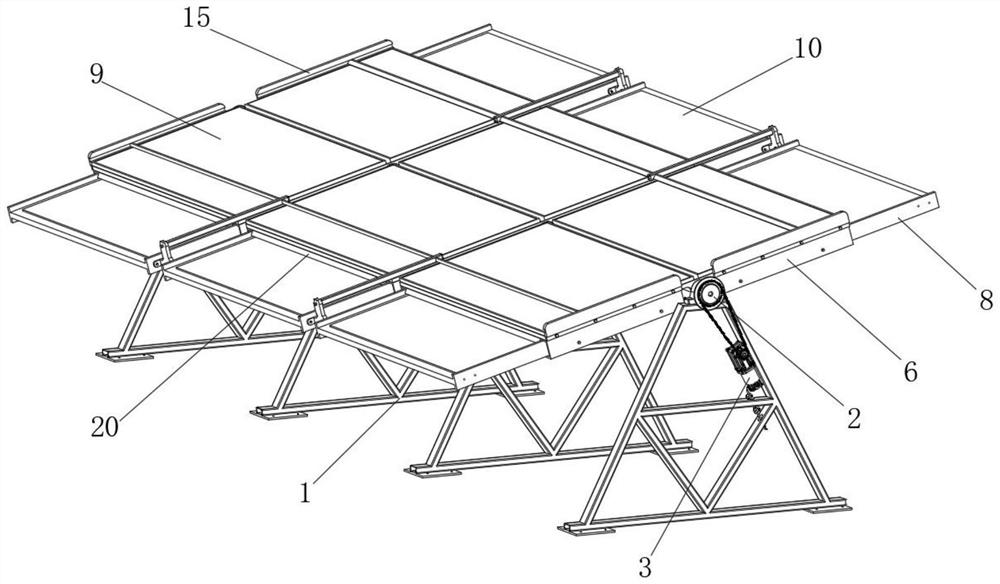

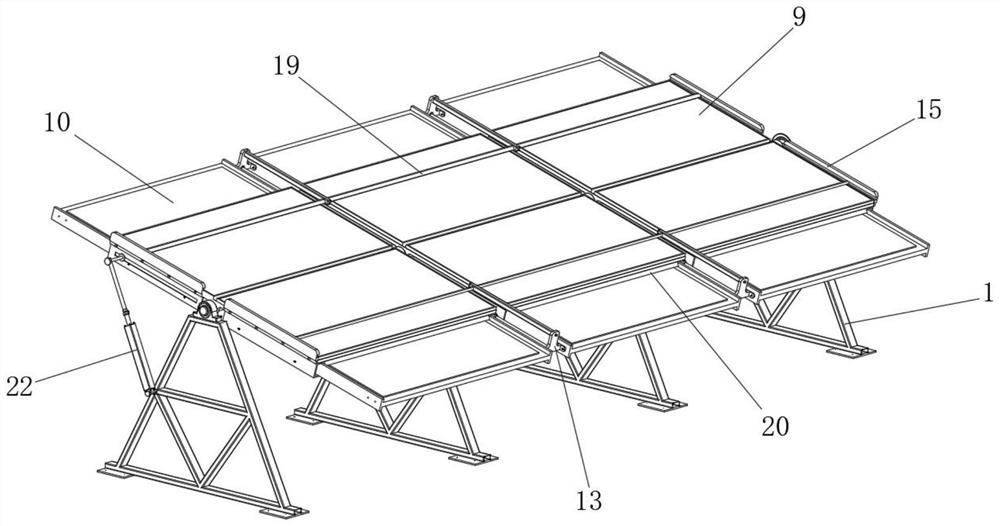

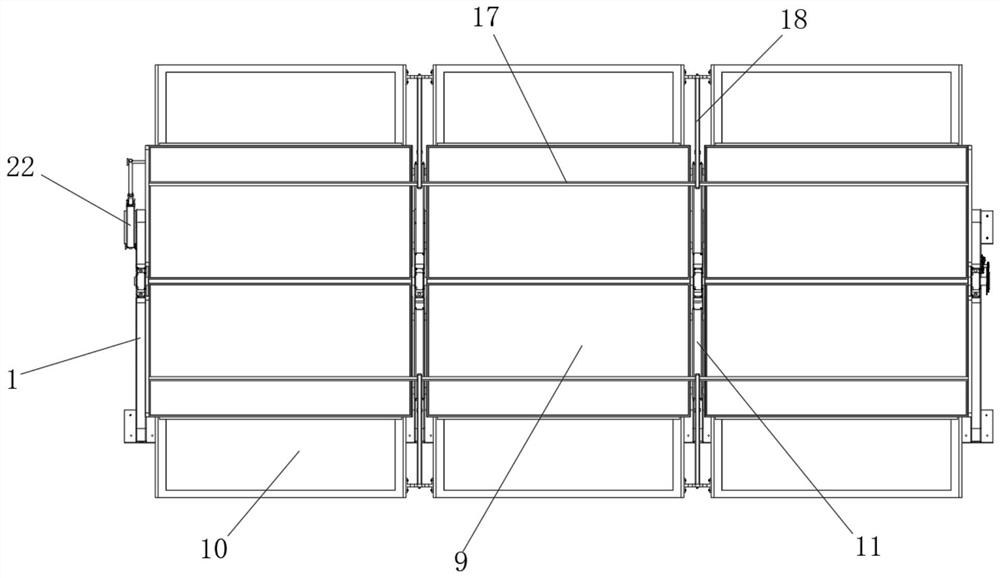

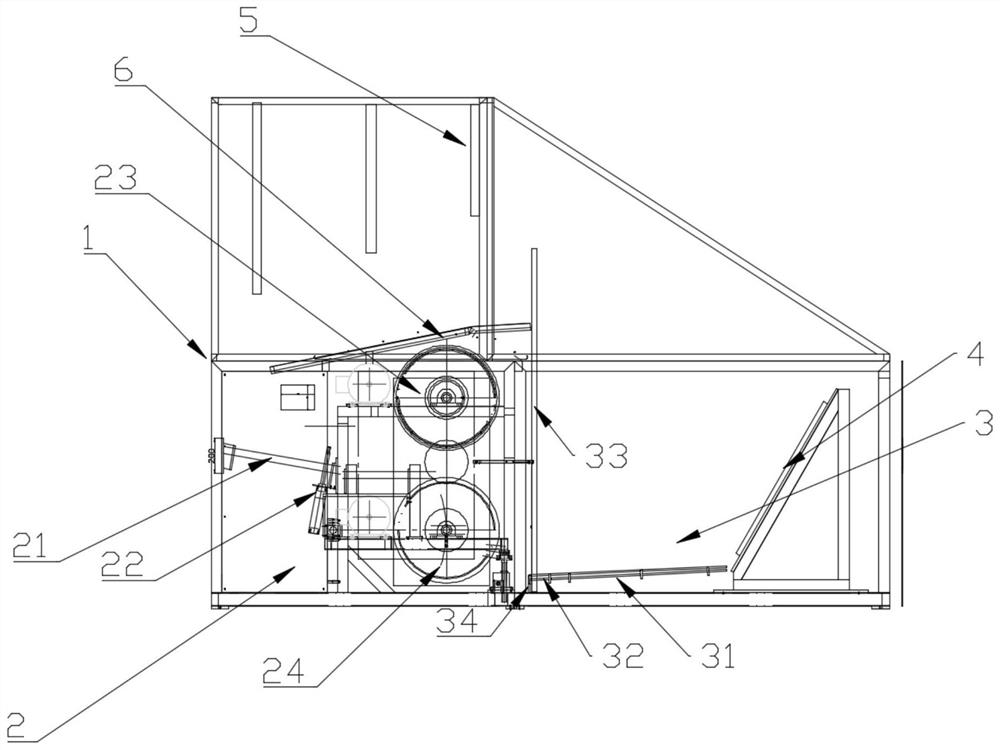

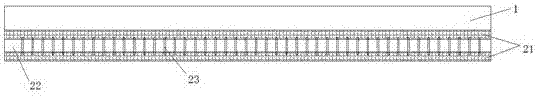

Solar photovoltaic fence for oil well

ActiveCN114337502AAvoid damageReduce impact areaPhotovoltaic supportsSolar heating energyStone particleEngineering physics

The invention relates to the field of photovoltaic power generation fences, in particular to a solar photovoltaic fence for an oil well. The technical problems that impact force generated by strong wind acts on a photovoltaic panel, a photovoltaic fence support is bent, a photovoltaic fence is damaged, and meanwhile due to the fact that the wind speed is too high and impurities such as sand and stone particles impact the photovoltaic panel, the photovoltaic panel is damaged and cannot be used normally are solved. According to the technical scheme, the solar photovoltaic fence for the oil well comprises a first mounting frame, a second mounting frame and a turnover mechanism, the second mounting frame is arranged on the left side of the first mounting frame, the first mounting frame and the second mounting frame are vertically arranged, and the turnover mechanism is arranged on the left side of the second mounting frame. According to the invention, through the arrangement of the turnover mechanism, wind rapidly passes through the space between the first photovoltaic panel and the second photovoltaic panel, the impact force area of the wind on the first photovoltaic panel and the second photovoltaic panel is reduced, and the damage caused by the bending of the first mounting rack and the second mounting rack is avoided.

Owner:胜利油田大源节能设备有限公司

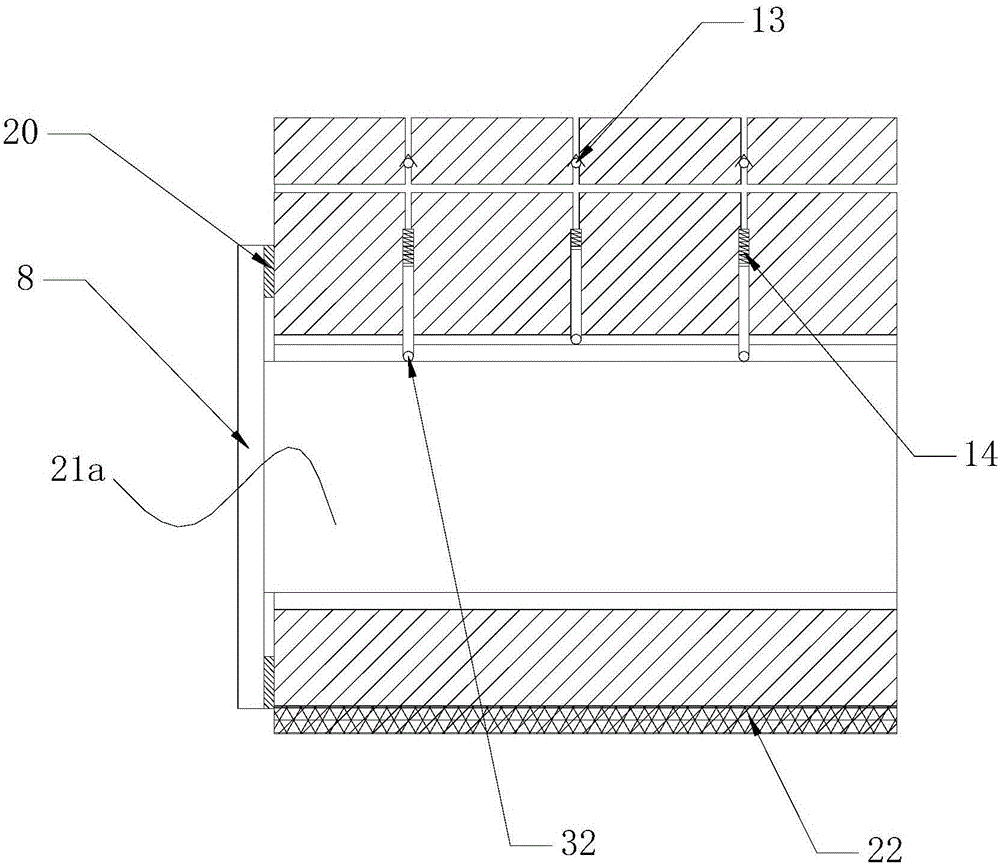

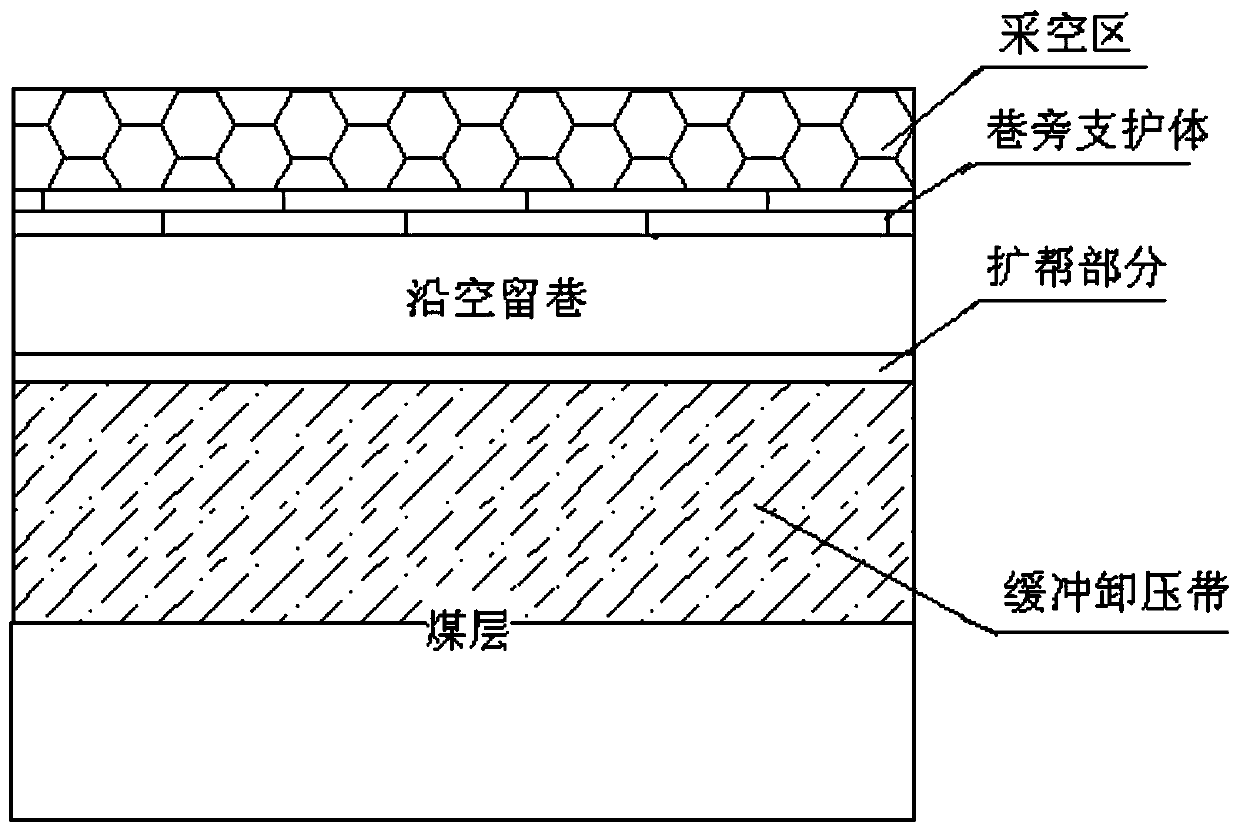

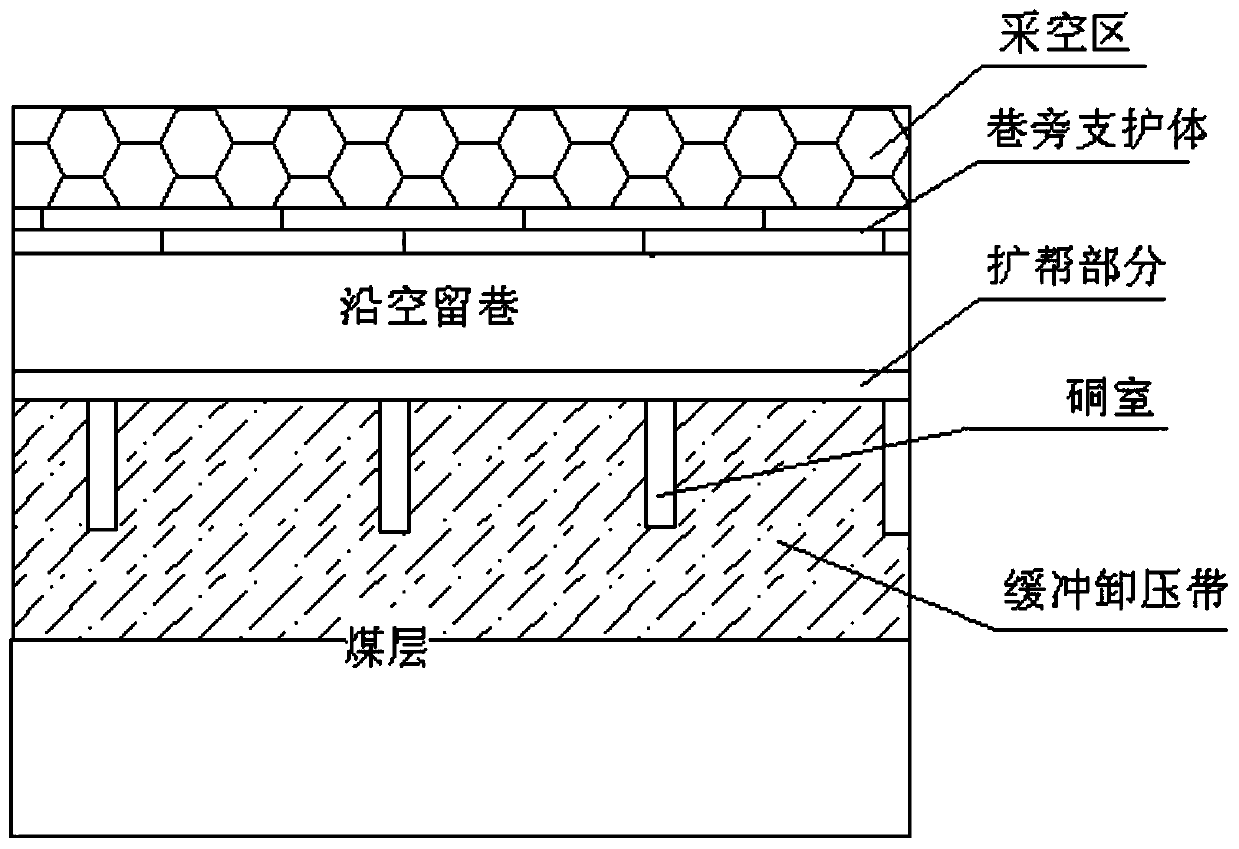

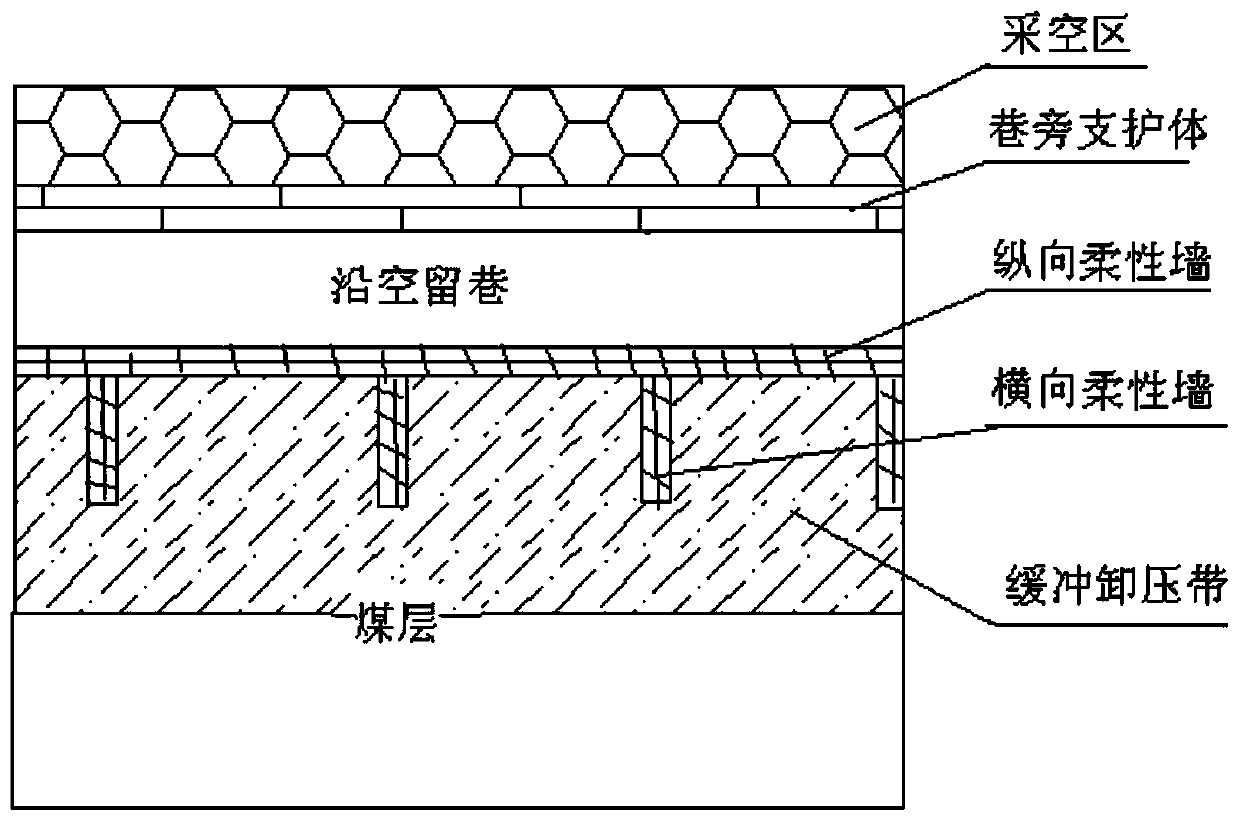

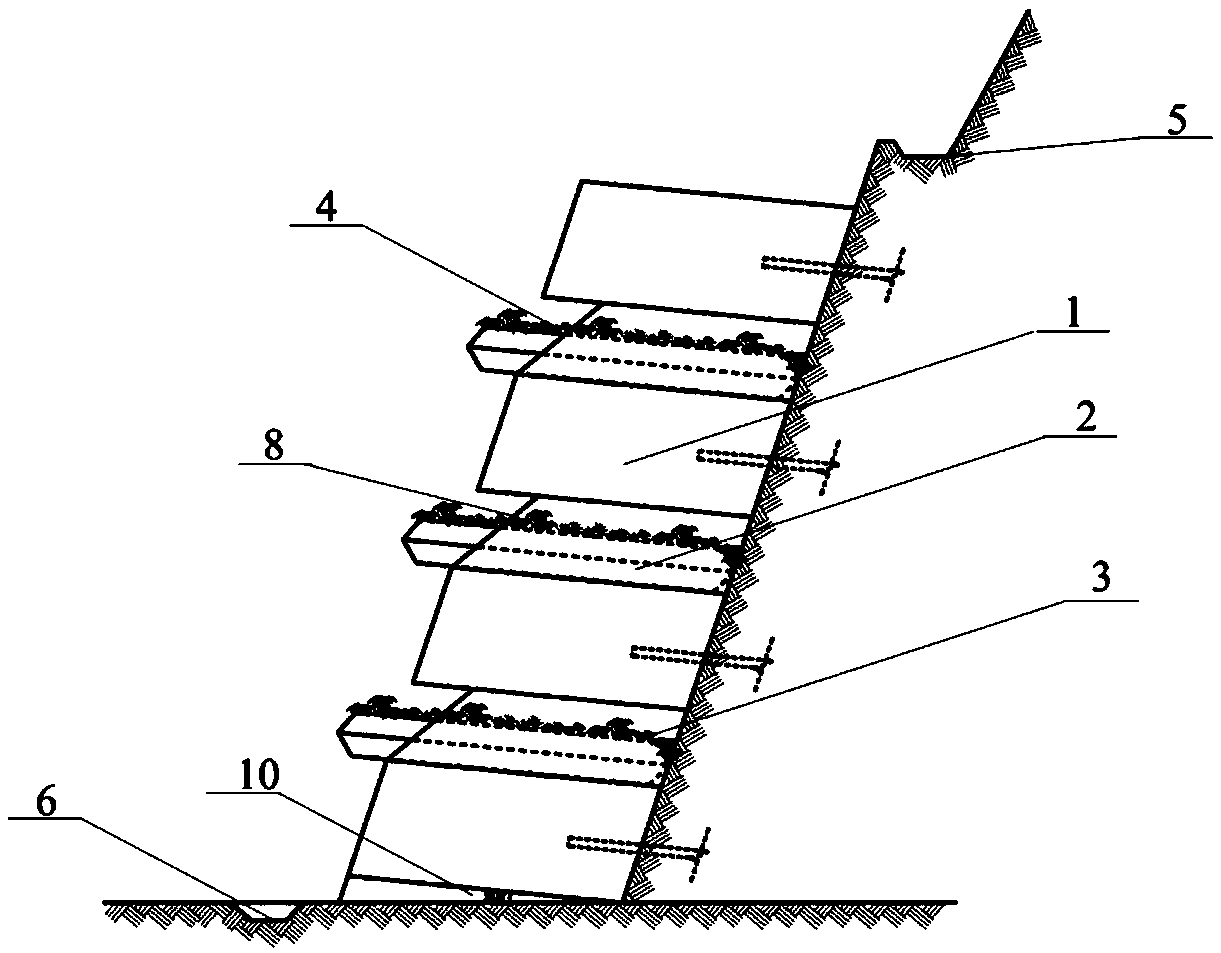

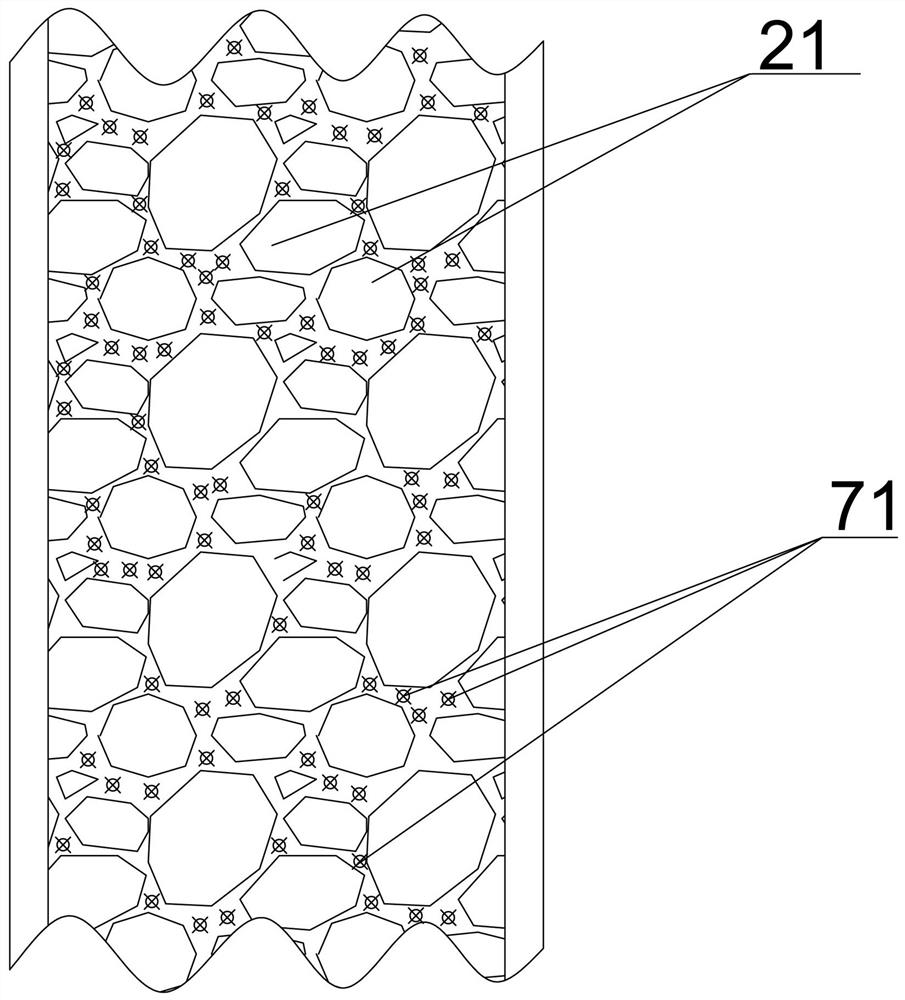

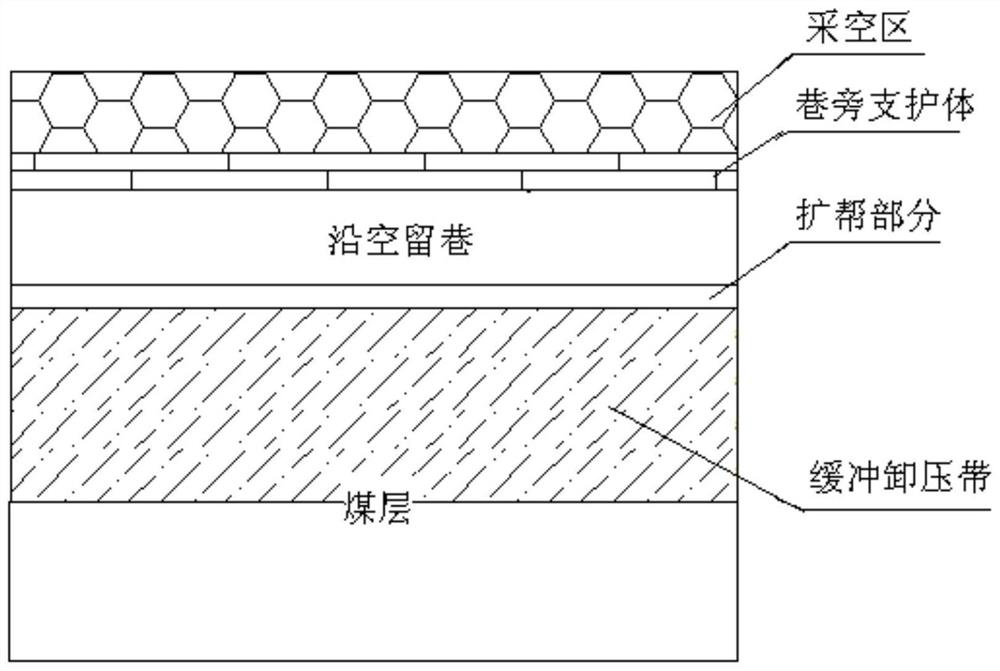

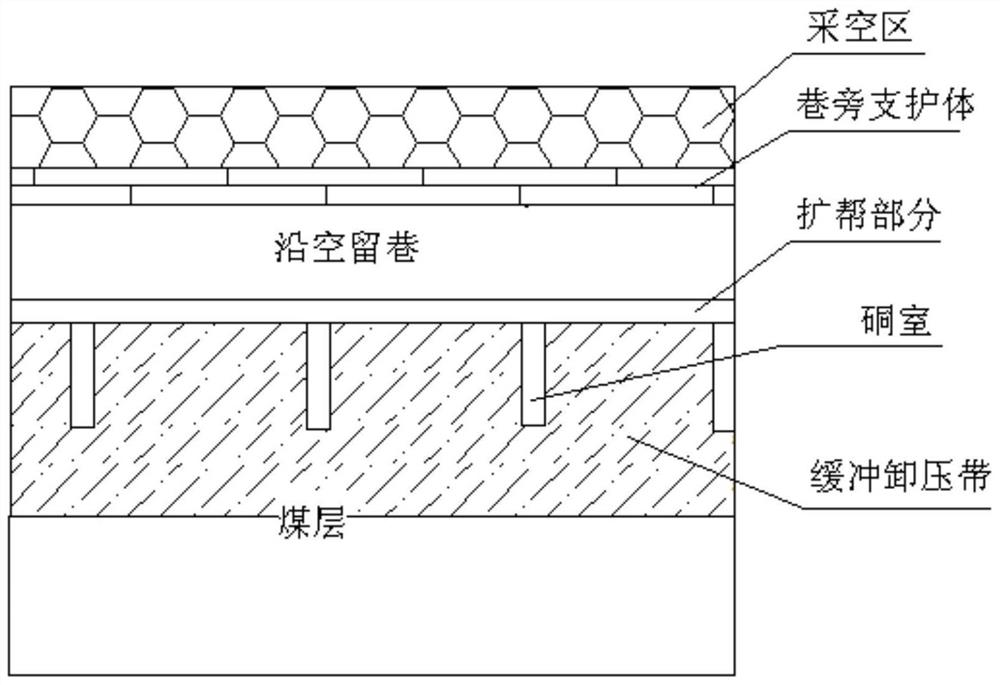

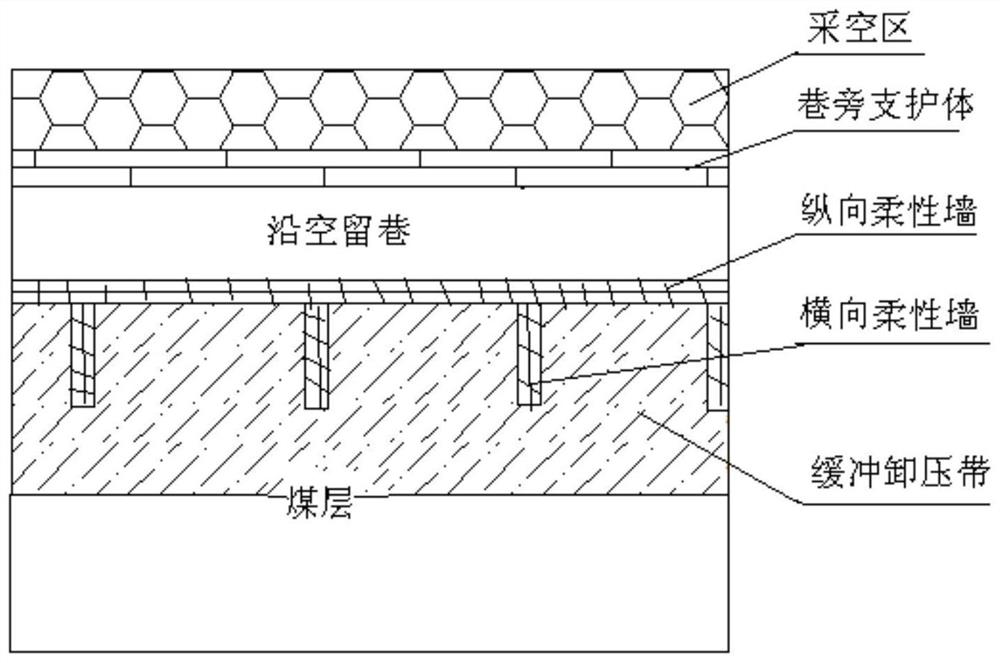

Wide lane and flexible chamber wall hard roof gob-side entry rock burst prevention method

ActiveCN110145307AChange stress distributionChange the impact propertiesUnderground miningBlastingStress distributionRock bolt

The invention discloses a wide lane and flexible chamber wall hard roof gob-side entry rock burst prevention method. The method is characterized in that firstly, rib expanding and bottom cutting are performed on the coal wall side of an original gob-side entry, a coal body which is generated after rib expanding is put in a woven bag, and a buffering pressure relief zone is made manually on the rib-expanded coal wall along the gob-side entry; a chamber is excavated in a coal side of one side of a working surface, conventional anchor bolt supporting is performed on a chamber roof, and transverseflexible walls are formed after backfilling is finished; the woven bag filled with materials is used as a wall material, longitudinal flexible walls are built along the rib-expanded space position; the stress distribution of a coal bed is changed by manually making the buffering pressure relief zone, and occurrence of rock burst is prevented; and a flexible combined body is formed by the transverse flexible walls and the longitudinal flexible walls, and the functions of partition, dynamic load relief and impact strength reduction are achieved.

Owner:SHANDONG UNIV OF SCI & TECH

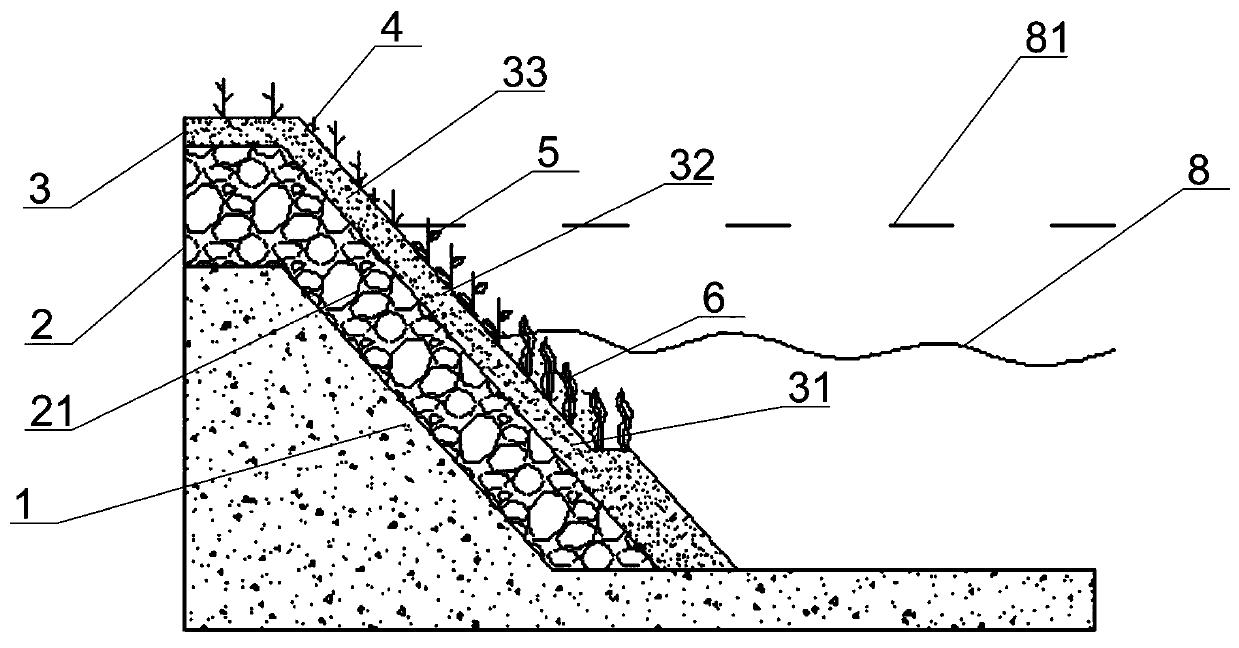

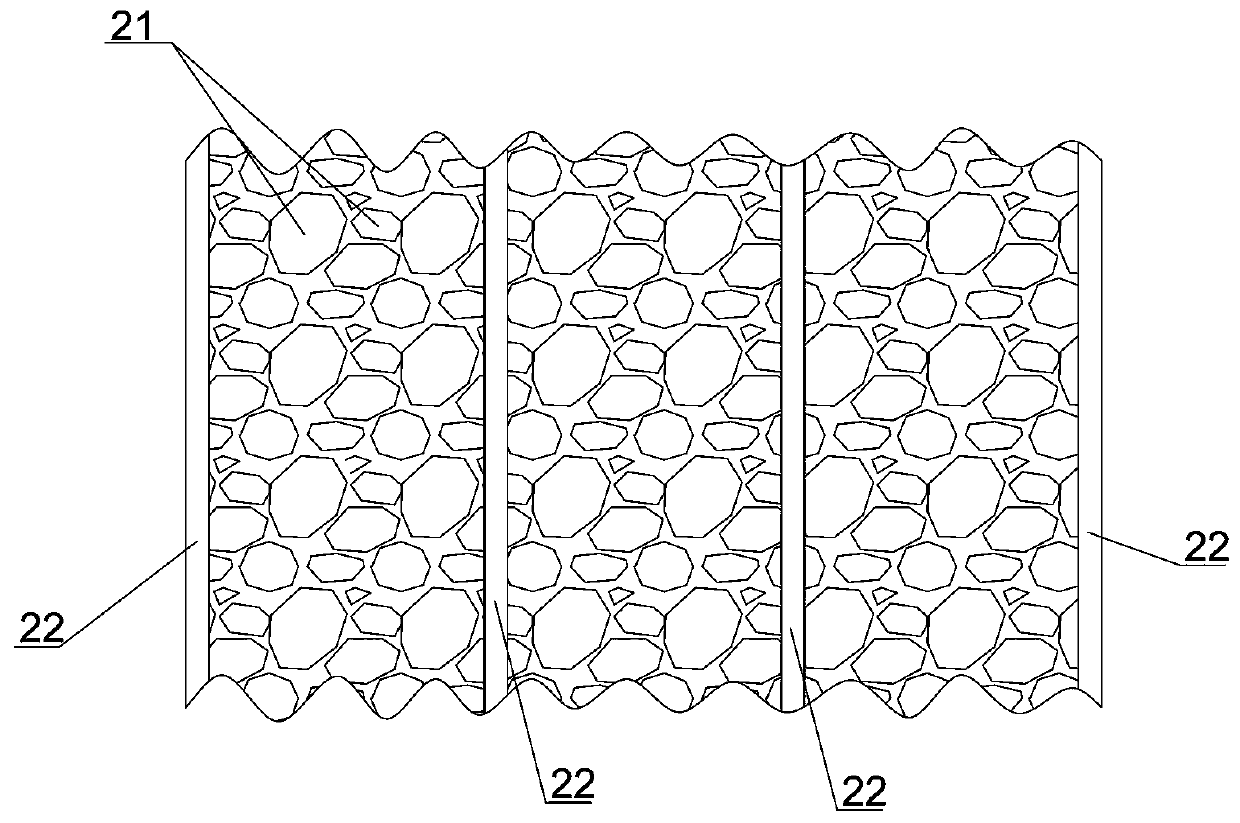

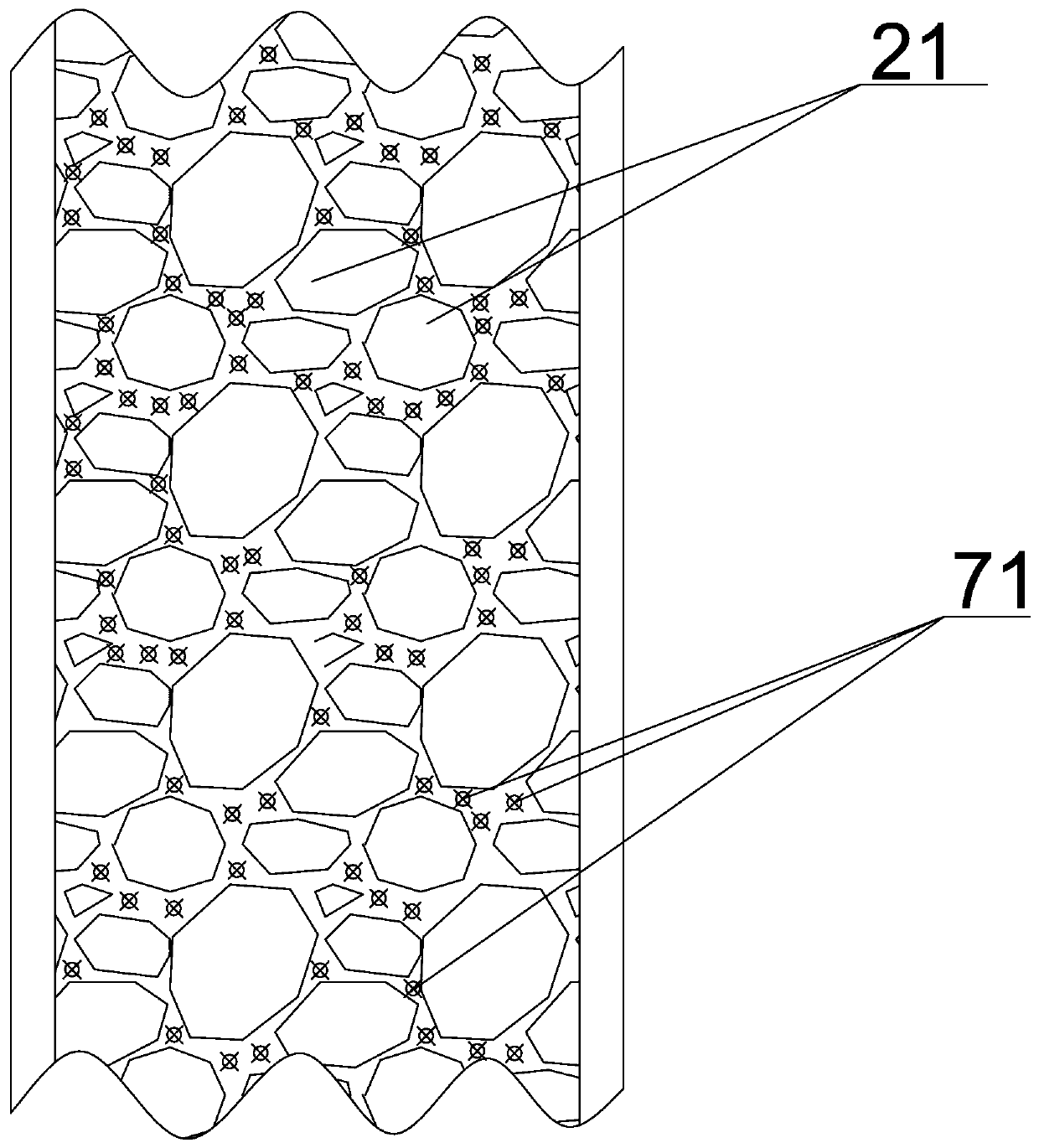

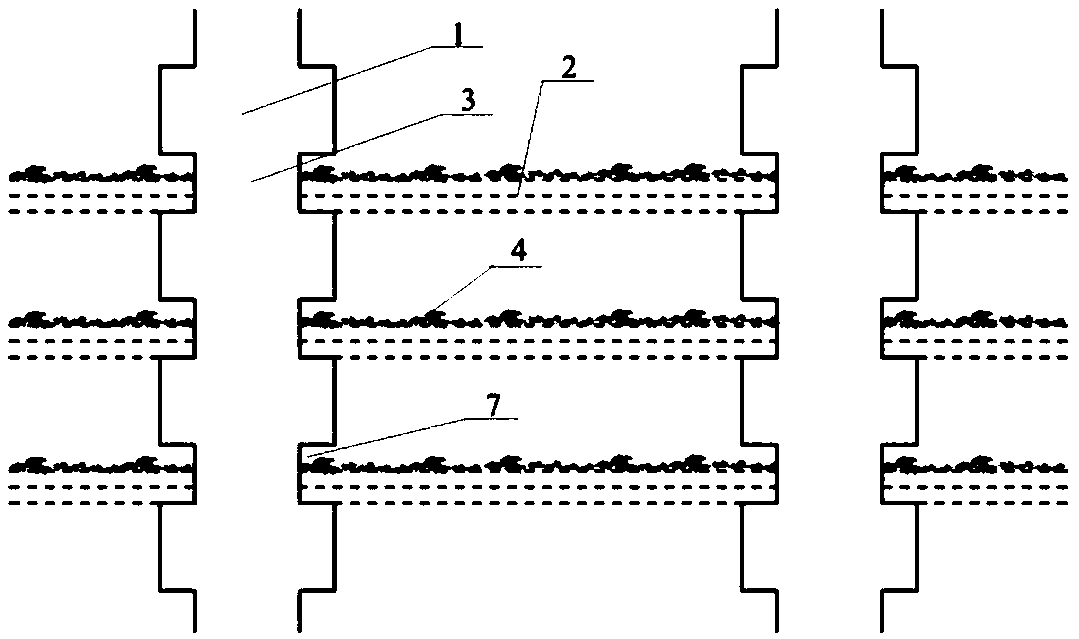

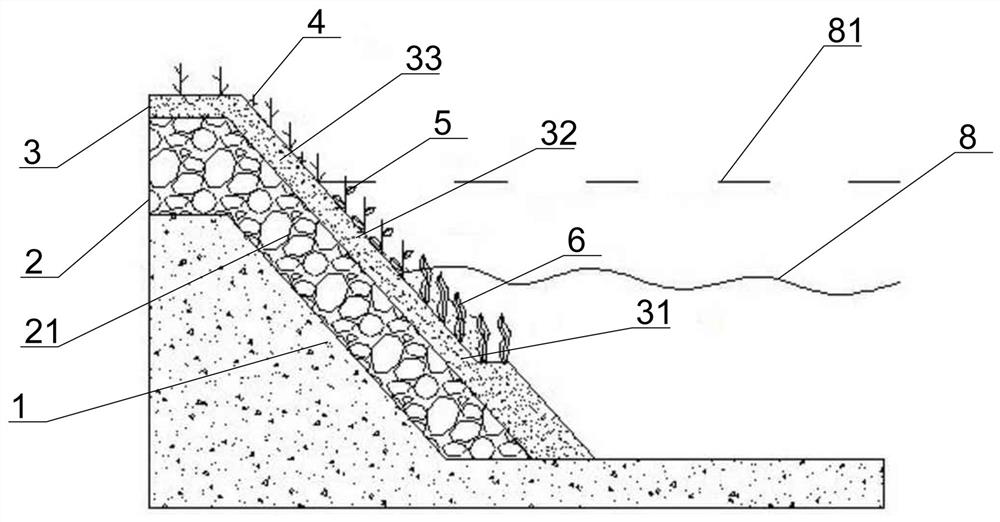

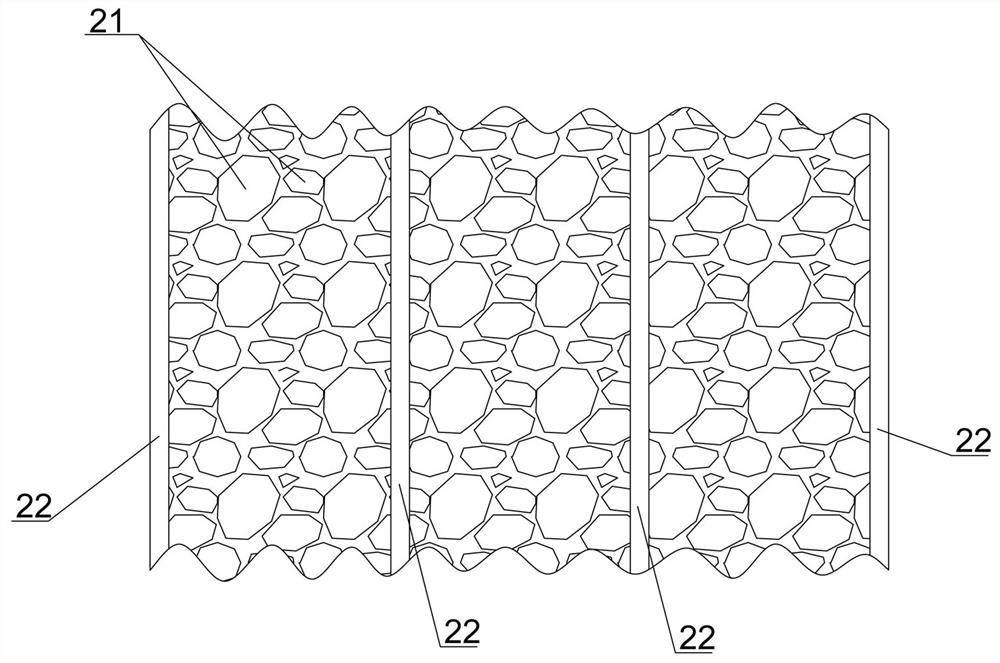

Plant organic combination compound ecological protection slope and construction method

ActiveCN110984073ASafe and stable structureStrong ability to resist water erosionCoastlines protectionPlant cultivationEnvironmental resource managementPlanting seed

The invention discloses a plant organic combination compound ecological protection slope and a construction method. The plant organic combination compound ecological protection slope comprises a gelatinized sand gravel layer which takes riverbed sand gravel, cement and coal ashes as main raw materials, the gelatinized sand gravel layer has a safe and stable structure and is high in high water flowwashing resistance; during laying, a formwork is used for carrying out pouring layer by layer from bottom to top, so that construction is convenient, requirements on a laying terrain are low, in addition, plants can take roots in the pore of the gelatinized sand gravel layer, and in addition, a complicated pore structure of the gelatinized sand gravel can prevent plant seeds from being taken awayby water flows. The invention provides the plant organic combination compound ecological protection slope and the construction method. The ecological protection slope has an obvious surface greeningeffect, has a safe and stable structure and is high in erosion resistibility. In addition, the ecological protection slope is provided with an ecological bag containing ETS (ecological treatment system) ecological florae, the ecological protection slope can reduce an area, which is impacted by water flows, of the ecological bag, and the service life of the ecological bag is prolonged. In addition,an ecological protection slope laying method is convenient and simple, has a wide applicable range and has a low requirement condition for terrains.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Optical device

ActiveUS11506908B2Reduce or eliminate the noise generated during its operationReduce supportStatic indicating devicesProjectorsEngineeringMaterials science

Owner:CORETRONIC

Distributed solar power generation device and power generation system based on Internet of Things control

PendingCN114884447AImprove fetch rateAvoid lighting effectsPhotovoltaic supportsSolar heating energyElectric machineEngineering

The invention relates to the technical field of photovoltaic power generation, and discloses a distributed solar power generation device and system based on Internet of Things control, rotating frames are rotated by a certain angle by turning over a motor so as to obtain an optimal illumination angle, and meanwhile, a certain fixing effect is achieved on a rotating shaft and the plurality of rotating frames, so that the rotating shaft and the plurality of rotating frames can be fixed. A plurality of driving air cylinders are controlled to operate at the same time, so that a plurality of driving telescopic rods drive telescopic blocks to move in opposite directions, and then a plurality of extension frames are driven by a plurality of connecting blocks to extend towards one side from the lower part of a corresponding rotating frame under the guide action of corresponding guide columns and T-shaped sliding grooves; therefore, the multiple solar sailboards and the extension sailboard are fully exposed under illumination, more radiation energy is obtained in unit time, the solar energy obtaining rate is improved, compared with the prior art that multiple sailboards are vertically distributed, the daylighting influence among the multiple sailboards can be avoided, the overall height of the device can be reduced, and the high-altitude risk is reduced.

Owner:侯新刚

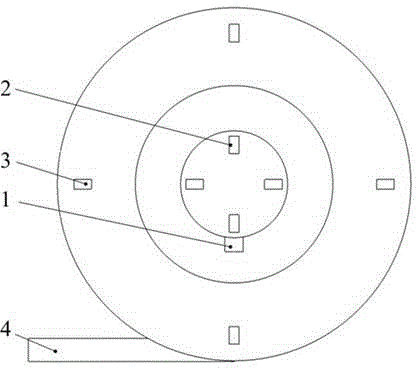

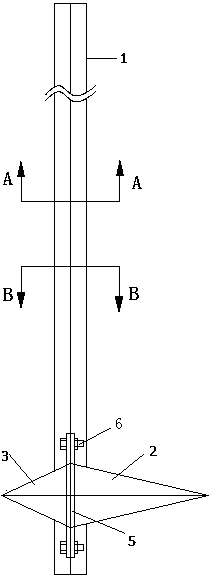

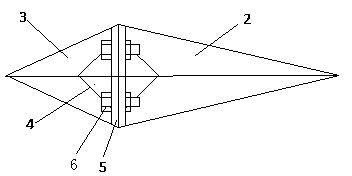

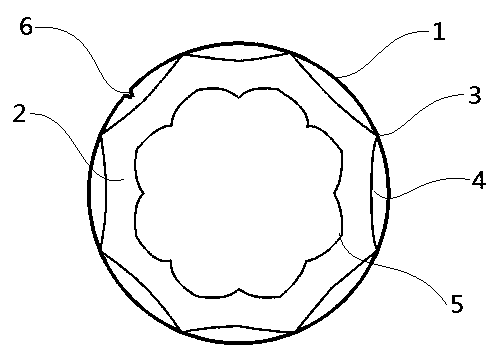

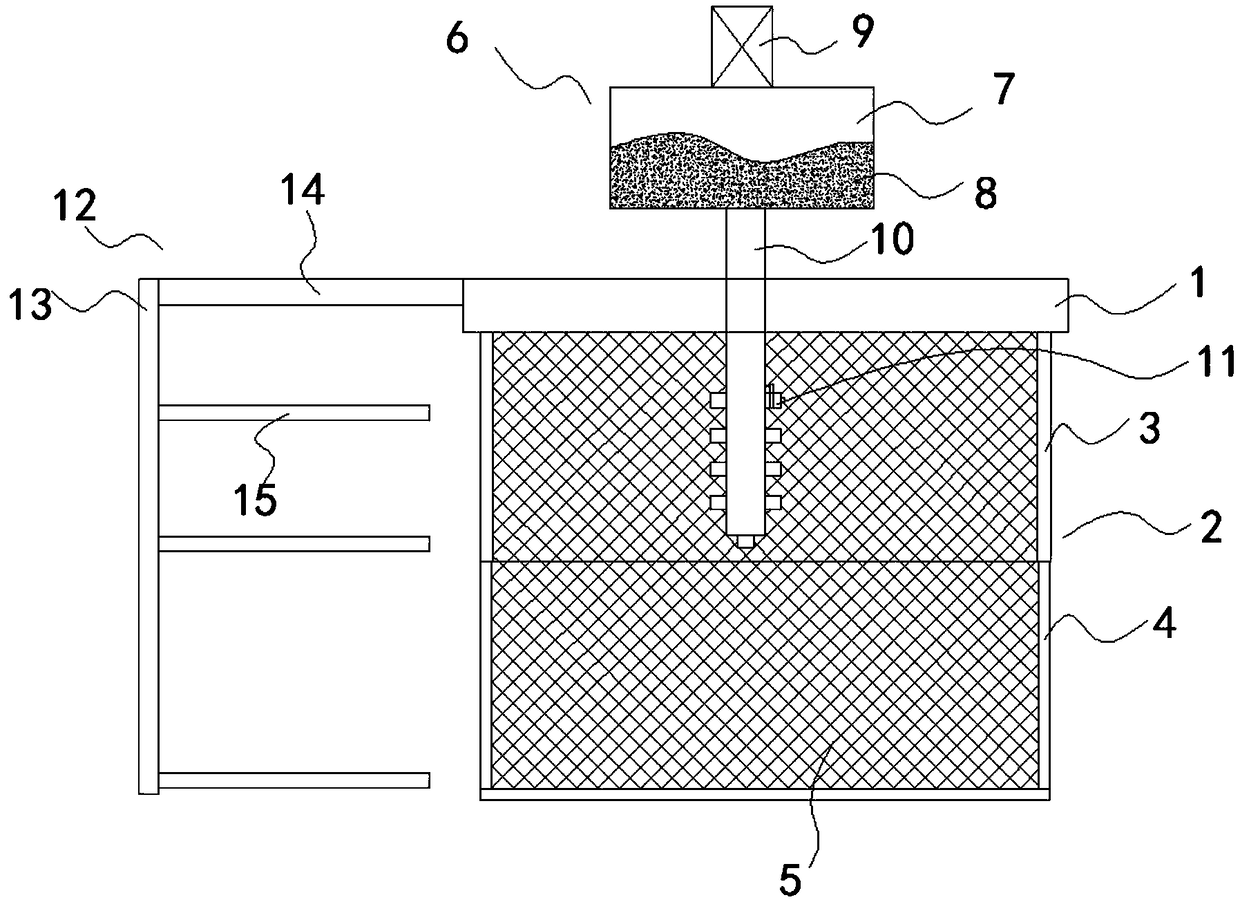

Pulp pool stirring blade

ActiveCN104028156AReduce resistanceReduce impact areaMixer accessoriesPulp and paper industryImpact area

The invention discloses a pulp pool stirring blade which comprises a stirring rod with the diamond-shaped cross section. Stirring blade bodies are arranged at the lower end of the stirring rod and comprise front blades and rear blades; triangular grooves are formed in the longitudinal direction of connecting ends of the front blades and the rear blades and are attached to the stirring rod; the longitudinal thickness and the horizontal width of the front blades and the rear blades are respectively reduced from the connecting ends to the outer ends of the front and rear blades; connecting pieces are arranged at the upper and lower ends of the front blades and the rear blades; each connecting piece comprises a middle bending part and flat side edges on two sides; each middle bending part is bent in a V shape; bolt holes are formed in the flat side edges on two sides; the stirring blade bodies are fixed at the lower end of the stirring rod through bolts. The pulp pool stirring blade is simple in structure; one corner of the diamond-shaped stirring rod is aligned to the advancing direction in the process of stirring by the stirring rod in a pulp pool around the circumference, so that the impact area between the stirring rod and paper pulp can be effectively reduced, the resistance of paper pulp on the stirring rod is reduced, and the stirring power consumption is reduced.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

Slope protection and greening device

The invention provides a slope protection and greening device. The slope protection and greening device is composed of a plurality of cement concrete poured vertical beams parallelly and vertically arrayed at equal distances, and multiple layers of detachable transverse structures. The detachable transverse structures are composed of cuboid cement plates, special-shaped grooves are formed in eachvertical beam at equal distances, and the two ends of the cuboid cement plates are matched with the special-shaped grooves; and after mounting, each cuboid cement plate is inserted into the special-shaped grooves of the two corresponding adjacent vertical beams in a spliced mode, a planting area is formed between every two cuboid cement plates in the up-down direction and the two corresponding adjacent vertical beams, and in this way, the net-shaped slope protection and greening device is formed. The slope protection and greening device is low in construction cost, easy to construct, stable, good in drainage and convenient to maintain, the landscape of a greened slope is pleasant, climbing and crossing of wild animals are facilitated, and the slope protection and greening device is especially suitable for steep and unstable slopes formed by various engineering construction such as slope greening on a highway and mine management, or natural factors.

Owner:CHINA ACAD OF TRANSPORTATION SCI

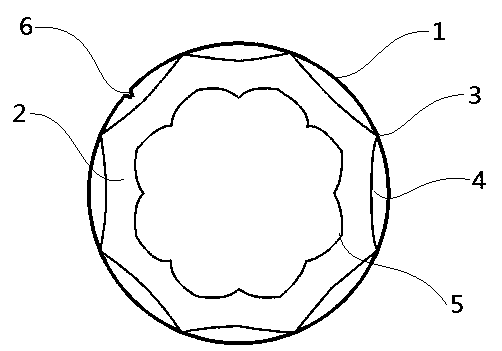

Noise reduction inflatable hollow ball

The invention relates to the field of sports appliances, in particular to a noise reduction inflatable hollow ball. The invention aims at providing the noise reduction inflatable hollow ball which comprises a hollow ball body and an inflating hole, wherein a noise reduction layer is arranged on the inner wall of the ball body; a recessed part is formed on the surface, towards the inner wall of theball body, of the noise reduction layer; the noise reduction layer and the inner wall of the ball body are fixed in a mode of using a plurality of parts in uniform contact; the elasticity of the ballbody is not influenced; meanwhile, the noise reduction area of the noise reduction layer is increased; the spreading of the noise can be blocked through a recessed cavity; a recessed part is also formed in the surface, towards the ball center, of the noise reduction layer; the area of the noise reduction layer is further increased; and small bulges are also arranged on the outer surface of the ball body.

Owner:米建军

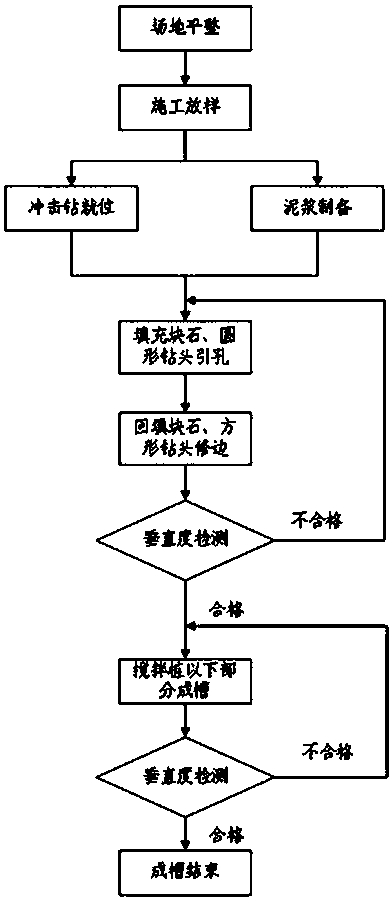

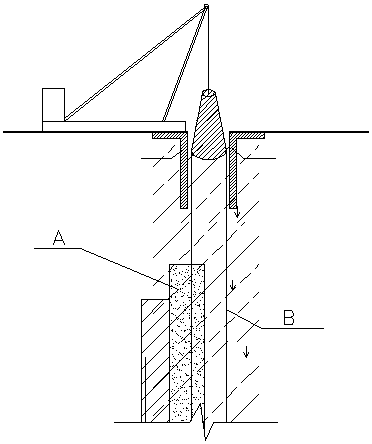

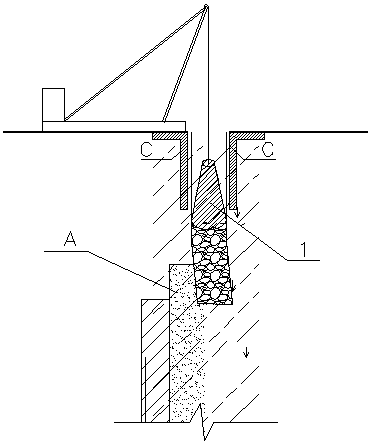

Treatment and construction method for grooving underground diaphragm wall encountering with underground stirring pile

InactiveCN110159190ASolve the speed problemSolve quality problemsFlushingExcavationsSlurry wallHardness

The invention discloses a treatment and construction method for grooving an underground diaphragm wall encountering with an underground stirring pile. The construction method comprises the following steps: (1) judging a beyond-limit range and a hole guiding position of the stirring pile; (2) putting a percussion hammer in position and preparing slurry; (3) guiding a hole by a round drill bit and filling the hole with rock blocks; (4) trimming the hole by a square drill bit and filling the hole with the rock blocks; and (5) grooving a groove section below the depth range of the stirring pile. By means of a method which comprises the steps of backfilling gravels, using the round percussion drill to impact the beyond-limit stirring pile in advance, brushing a wall by the square percussion drill to control the perpendicularity and then grooving by using a grooving machine, the construction method solves the problem that the grooving speed of the grooving machine is slow and the grooving quality is hard to control as the strata in the grooving range are not uniform in hardness as a result of beyond-limit of the stirring pile in a construction process of the underground diaphragm wall, so that the progress of station construction is completed on schedule while the cost is saved, and a good economical benefit is obtained.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

A low energy consumption oil-free silent air compressor

ActiveCN106523320BReduce coefficient of frictionIncrease exhaustPiston ringsPositive displacement pump componentsReciprocating motionPiston ring

The invention discloses a low-energy-consumption oilless silence air compressor. The low-energy-consumption oilless silence air compressor comprises at least one air cylinder assembly. Each air cylinder assembly comprises a piston and an air cylinder containing the piston, wherein a ceramic film layer is arranged on the inner wall of a cylinder sleeve of the air cylinder, the piston comprises a piston body, a composite material layer arranged on the outer side of the piston body in a sleeving manner, a piston ring embedded in the outer side of the composite material layer, and the piston ring and the composite material layer are made of the same materials and prepared through carbon material containing composite materials. During work, each piston reciprocates in the corresponding cylinder sleeve, each piston ring rubs with the ceramic film layer on the inner wall of the corresponding cylinder sleeve, the composite material layer on the outer side of each piston body plays a guiding role in the corresponding cylinder sleeve, and therefore the friction coefficient between each piston and the corresponding cylinder sleeve is reduced, and efficiency is improved.

Owner:厦门闳图盛道科技有限公司

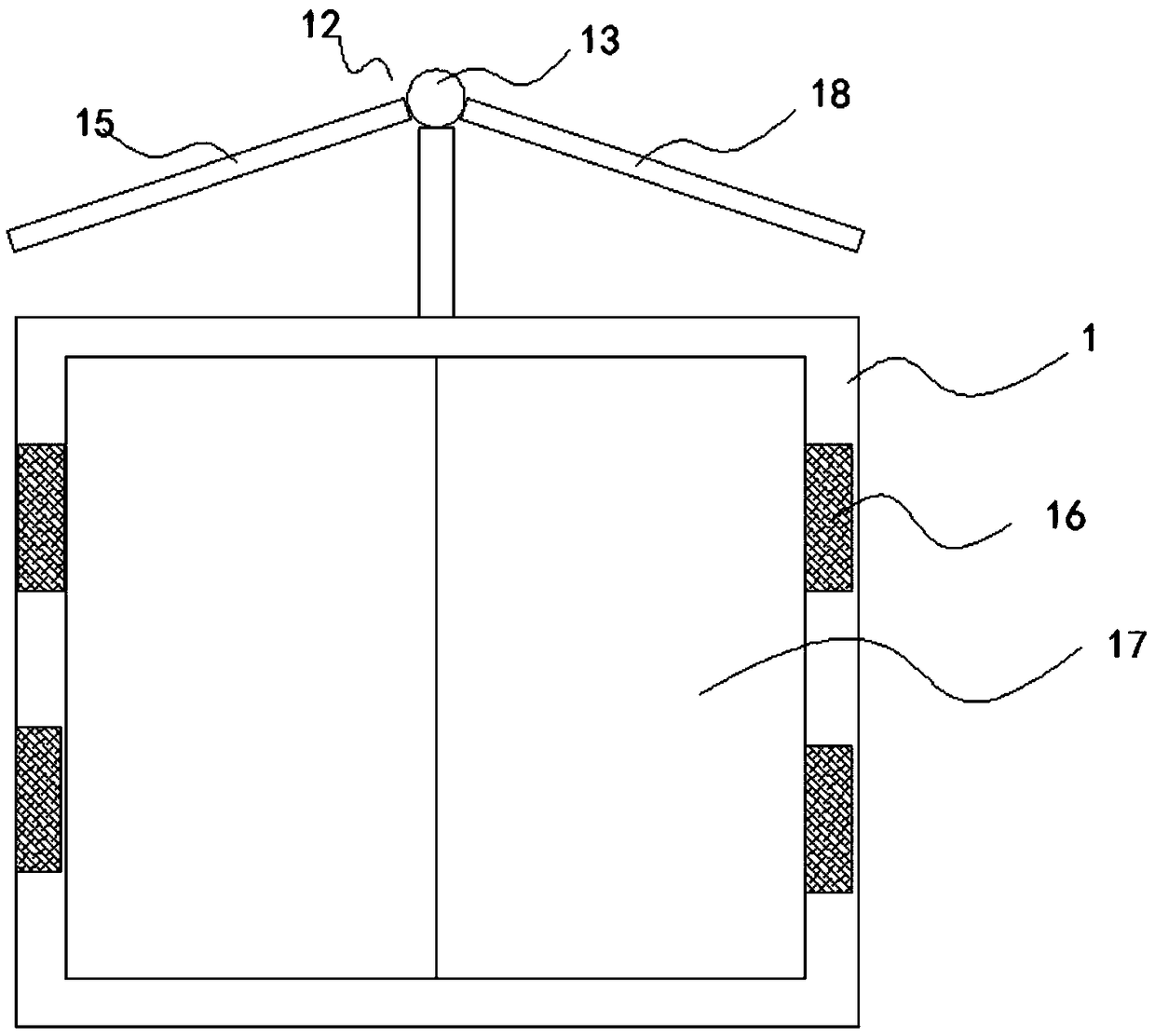

Aquaculture tank

InactiveCN109156398ASolve technical problems that are easily washed awayReduce impact areaClimate change adaptationPisciculture and aquariaWater flowEngineering

The invention discloses an aquaculture tank. The aquaculture tank comprises a floating platform, net cages, a sundries blocking apparatus, a feeding apparatus and a control module, wherein a through hole is formed at the plane center of the floating platform, the through hole divides the floating platform into at least two aquaculture units with equal areas, the net cages are arranged in the aquaculture units, each net cage comprises a frame body with a cuboid structure and a net arranged on the sides and bottom of the frame body, the sundries blocking apparatus is arranged ahead the net cages, the sundries blocking apparatus comprises a circular rod vertically arranged right ahead the net cages and left guide rods and right guide rods arranged on the circular rod in pairs, the feeding apparatus comprises a sealed feed storage cavity, a pressurizer, a feed conveying pipe, nozzles and quantitative valves, the control module comprises a controller, water flow sensors and pressure sensors, the water flow sensors are arranged on the side walls of the net cages, the pressure sensors are arranged on the nozzles, the controller is connected with an electric telescopic rod and controls theelectric telescopic rod according to water flow velocity signals, and the controller is connected with the quantitative valves and controls the opening and closing of the quantitative valves according to pressure signals of the pressure sensors.

Owner:NANJING ZHIQIAO AGRI CO LTD

slurry tank stirring device

ActiveCN104028156BReduce resistanceReduce impact areaMixer accessoriesPulp and paper industryImpact area

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

Pulp-separating machine with adjustable rotating speed

InactiveCN105887542ASimple and reasonable structureEasy to manufacturePulp beating methodsDesign technologyElectric machine

The invention relates to a separating machine, specifically relates to a pulp-separating machine with an adjustable rotating speed and belongs to the technical field of design of the separating machine. The pulp-separating machine comprises a rack, a separating chamber, a feeding port, a discharging port and a motor, wherein a separating shaft is arranged in the separating chamber; a grid net baffle plate is arranged on the feeding port; a stick thorn is arranged on the separating shaft; an embossment is arranged on the separating shaft; a through hole is formed on the embossment; the stick thorn is arranged on the part with through holes at intervals on the embossment; the pulp-separating machine is characterized in that a gearbox is arranged; a power output shaft of the motor is connected with a power input shaft of the gearbox through a chain; the power output shaft of the gearbox is connected with the separating shaft through the chain; an overload protection device is arranged on the motor; a fuse is arranged as the overload protection device; a quick shutdown device is arranged on an axial external circle of the separating shaft. Through the pulp-separating machine with the adjustable rotating speed, in the specific operation, we can realize the adjustment for the rotating speed of the separating shaft by adjusting the gearbox, and the overload protection device is arranged for protecting the motor.

Owner:DANYANG ZHENGLIAN INTPROP OPERATIONS MANAGEMENT CO LTD

Swash plate, pusher drum and machine for the tobacco processing industry

The swash plate has troughs for receiving bar-shaped articles which are arranged to co-rotate in synchronized manner. The swash plate is adjusted to a side surface of a conveyor drum for transverse-axial conveying of the bar-shaped articles of the tobacco processing industry. A through hole extends on a circumference circle in the circumferential direction and is formed not to partly overlap with the troughs. An independent claim is also included for a tobacco processing machine with a tobacco stock-filter plug-tobacco stock group.

Owner:HAUNI MASCHINENBAU AG

A plant organic combination compound ecological slope protection and its construction method

ActiveCN110984073BSafe and stable structureStrong ability to resist water erosionCoastlines protectionPlant cultivationEnvironmental resource managementPlanting seed

The invention discloses a compound ecological slope protection of plant organic combination and its construction method, which comprises a gelled sandy gravel layer with riverbed sandy gravel, cement and fly ash as main raw materials. The gelled sandy gravel layer has a safe and stable structure and is resistant to water erosion Strong ability; when laying, the formwork is used to pour layer by layer from bottom to top. It can also prevent plant seeds from being carried away by water flow; the present invention provides a plant organic combination compound ecological slope protection and its construction method. The group of ecological bags and ecological slope protection can reduce the area of the ecological bag impacted by the water flow, prolong the service life of the ecological bag, and the laying method of the ecological slope protection is simple and convenient, with a wide range of applications and low terrain requirements.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Prevention method of rockburst in roadway retained by hard roof with wide roadway and flexible chamber wall

ActiveCN110145307BChange stress distributionChange the impact propertiesUnderground miningBlastingArchitectural engineeringRock bolt

Owner:SHANDONG UNIV OF SCI & TECH

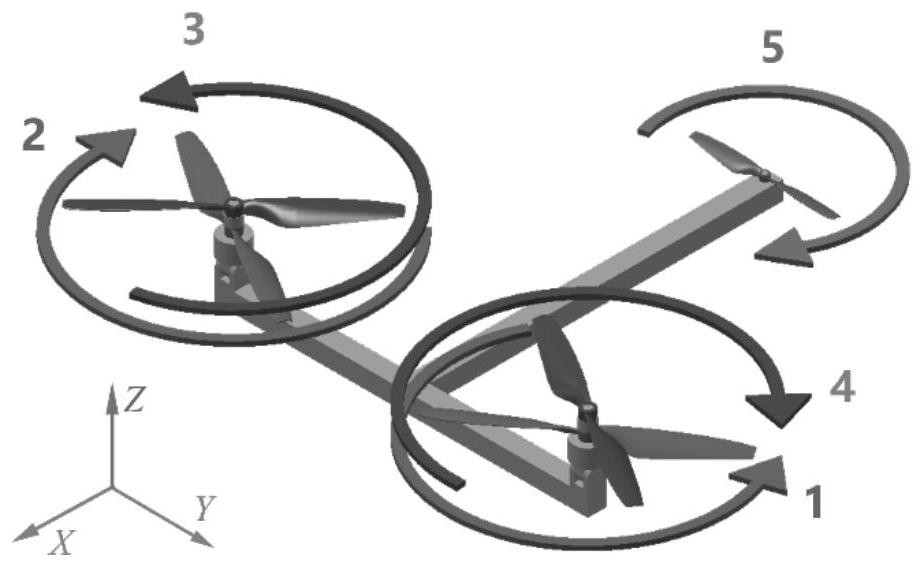

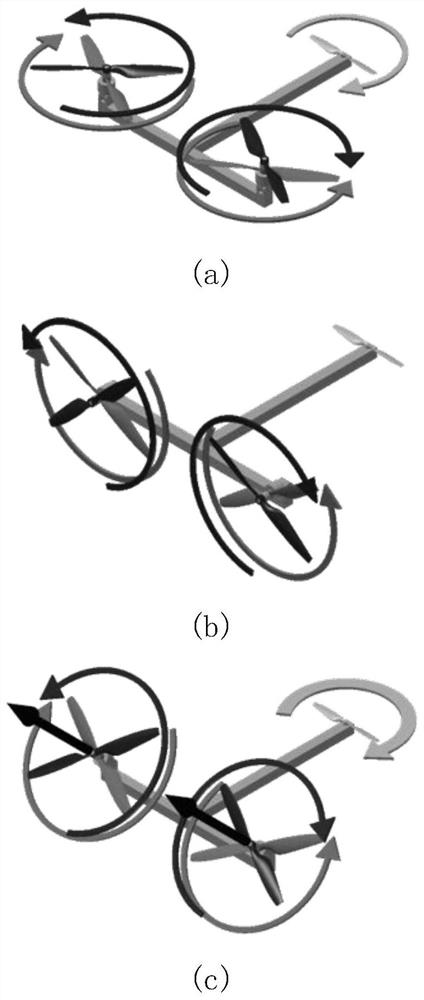

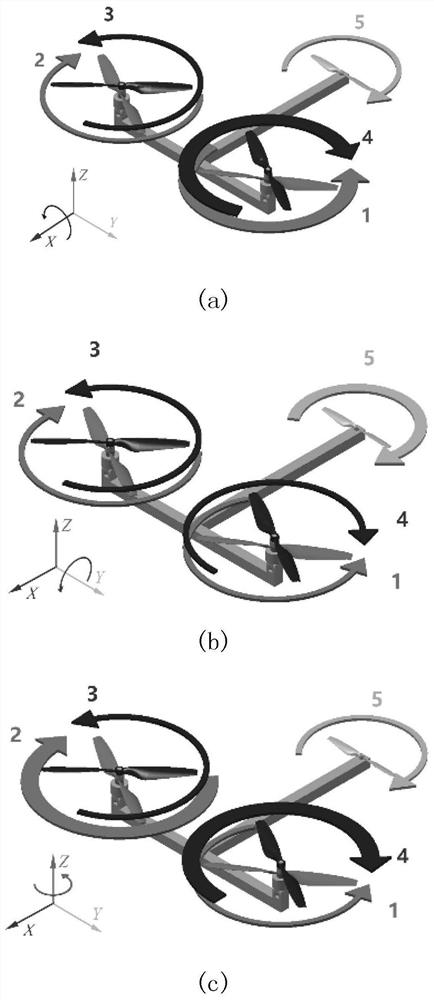

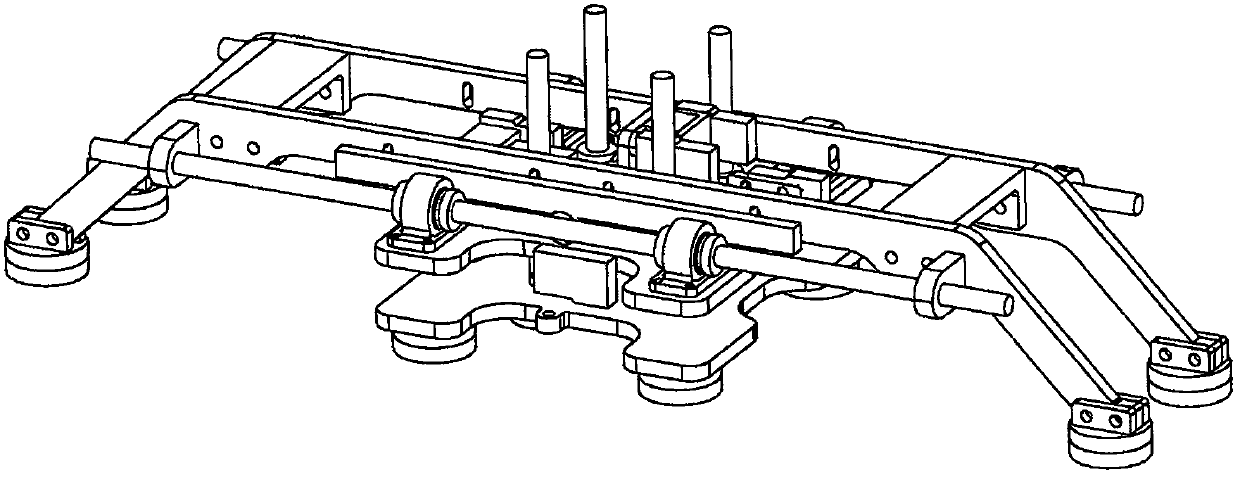

A tilt-rotor aircraft and its driving method

ActiveCN111619796BStable jobLow powerEfficient propulsion technologiesVertical landing/take-off aircraftsFlight vehicleElectric machinery

The invention discloses a tilt-rotor aircraft and a driving method thereof, belonging to the technical field of small aircraft. The tilt-rotor aircraft includes three rotor shafts, five rotors, a motor and a mixer. The three rotor shafts are arranged in an inverted triangle and can rotate around the plane of the fuselage; a lift rotor is installed on the tail rotor shaft; it is located in the front A pair of coaxial tilting rotors are respectively installed on the two rotor shafts, that is, the upper and lower rotors are installed on the same rotor shaft, and the upper and lower rotors rotate in opposite directions and rotate at the same speed; and the two pairs of tilting Among the rotors, the two rotors on the same layer rotate in opposite directions, and the two rotors on different layers rotate in the same direction. In the present invention, the aircraft can still work stably under the conditions of dynamic performance changes; the present invention adopts a coaxial structure, which is still controllable as long as the two tilt rotors on one side do not fail at the same time; the volume of the aircraft and the key power are reduced. For the unit impact area, only two sets of tilting mechanisms are required.

Owner:DALIAN UNIV OF TECH

A Flat Peristaltic Crawling System Based on Helical Auxiliary Mechanism

InactiveCN107538478BRealize circular motionAchieve marchProgramme-controlled manipulatorGear wheelElectric machinery

The invention discloses a flat creeping system based on a screw pair mechanism. The flat creeping system is synergistically composed of a plurality of mechanical bionic joint units. An up-down supporting module utilizes a screw pair to transfer circular movement into linear movement, so that the up-down movement of a supporting platform or a supporting base is completed. A front-back moving modulemakes the direction of the motor output power to be changed through a bevel gear, the circular movement is changed into the linear movement through a gear and a rack, so that the front-back movementof a foot or the supporting platform is completed. A control module utilizes a travel switch to promote next movement at a limiting position, thus circulatory movement and alternate movement of the front-back moving module or the up-down supporting module are achieved, and accordingly marching forward of each joint unit is achieved. Marching forward, steering and obstacle climbing of the flat creeping system are achieved through synergism of each joint, by adopting the flat design, the whole height is lowered, the fighting efficiency is improved, the energy expenditure of soldiers is reduced,and the area of a bomb landing face is decreased.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

Ball impact resistance test equipment

PendingCN112683479AReduce jumpingPrevent jumpingMaterial strength using repeated/pulsating forcesShock testingBall impactImpact area

The invention discloses ball impact resistance test equipment which comprises a rack, and a launching mechanism, a reset mechanism, a rebound plate, a buffer mechanism and a guide plate which are arranged in the rack, wherein the launching mechanism projects a ball to the rebound plate, the ball is rebounded into the buffer mechanism through the rebound plate, the impact of the ball is absorbed by the buffer mechanism and the ball falls onto the guide plate, and the ball is guided into the launching mechanism through the guide plate. The material blocking mechanism is arranged in the material channel, and balls slide to the drum wheel at the same height during each test, so that it is guaranteed that test parameters of each time are the same, and the accuracy of a detection result is improved; the material blocking mechanism adopts a cylindrical blocking rod, so that the impact area between the material blocking mechanism and the ball is reduced, and bounce of the ball is reduced; and the material channel adopts a plurality of cylindrical rods, so that bounce of the ball on the material channel is reduced or even avoided, the detection time is further saved, and the detection efficiency is improved. The buffering mechanism conducts multi-stage buffering through the multiple layers of buffering blankets, so that impact force of the ball is effectively absorbed, and bounce of the ball and impact on the rack are reduced.

Owner:大加利(太仓)质量技术检测中心有限公司

Circuit board punching mold and punching method thereof

The invention provides a circuit board punching mold and a punching method thereof. The circuit board punching mold comprises a body, and is characterized in that a boss is arranged at the center of the body, and the boss is symmetrically provided with reinforcing ribs; the edge of the body is symmetrically provided with pushing and fixing parts which are higher than the body by 1-10 mm; and the body is integrally connected with the pushing and fixing parts. By means of circuit board cooperation of relatively densely-distributed force unloading holes drilled in advance, and then by means of the pushing and fixing parts designed on the mold punching edge, about 1 / 3 impacting area of the mold is reduced; because of reduction of the stress area, the pressure intensity of the mold on a hard circuit board is increased; and by means of cooperation with the force unloading holes of the circuit board, the cohesion resultant force originally formed because glass fiber cloth is buckled silk by silk is cut off and disorganized roughly, and the offsetting force on the mold caused by the strength of the hard circuit board is weakened.

Owner:惠州市永隆电路有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com