Solar photovoltaic fence for oil well

A solar photovoltaic and oil well technology, applied in the direction of solar thermal energy, solar thermal power generation, solar collectors, etc., can solve the problems of photovoltaic panel damage, photovoltaic fence support bending, photovoltaic fence damage, etc., and achieve the effect of avoiding excessive wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

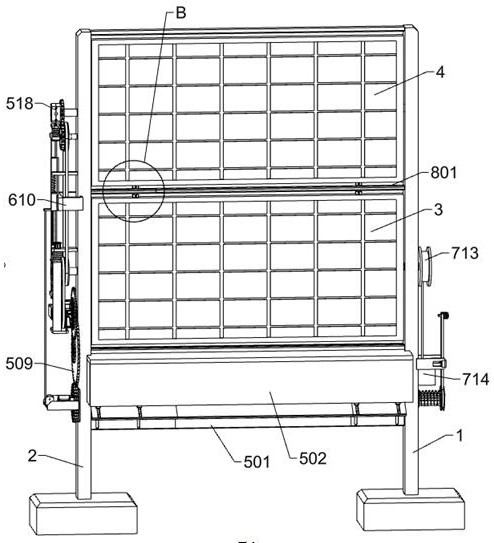

[0035] A kind of solar photovoltaic fence for oil well, such as Figure 1-Figure 15 As shown, it includes a first mounting frame 1, a second mounting frame 2, a first photovoltaic panel 3, a second photovoltaic panel 4, a turning mechanism, a fixing mechanism and a reset mechanism, and the second mounting frame 2 is set on the first mounting frame 1 On the left side, the first mounting frame 1 and the second mounting frame 2 are vertically arranged, and the first mounting frame 1 and the second mounting frame 2 are connected with the first photovoltaic panel 3 and the second photovoltaic panel 4 through the rotating shaft rotation inside, The first photovoltaic panel 3 and the second photovoltaic panel 4 are vertically arranged, and the shafts on the left and right sides of the first photovoltaic panel 3 and the second photovoltaic panel 4 pass through the first mounting frame 1 and the second mounting frame 2, and the second The photovoltaic panel 4 is located on the upper si...

Embodiment 2

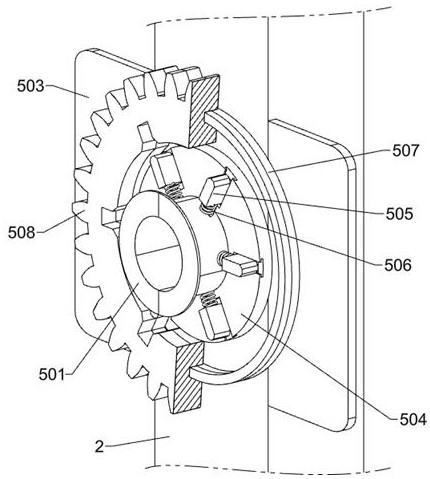

[0038] On the basis of Example 1, such as Figure 1-Figure 8 As shown, the turning mechanism includes a power assembly, a power cut-off assembly, a first fixed frame 512, a fixed shaft 512a, a first synchronous pulley 513, a second synchronous pulley 514, a third synchronous pulley 515, a fourth gear 516, The fifth gear 517, the limit fixed block 518, the first sliding rod 519 and the first spring 520, the power assembly is located at the lower part between the inner side of the first installation frame 1 and the second installation frame 2, and the power assembly is located at the first photovoltaic panel 3, the power cut-off assembly is located at the lower part of the left side of the second installation frame 2, the power cut-off assembly is mechanically matched with the power assembly, the first fixing frame 512 is fixedly connected to the lower part of the rear side of the second installation frame 2, and the first fixing A fixed shaft 512a is rotatably connected to the ...

Embodiment 3

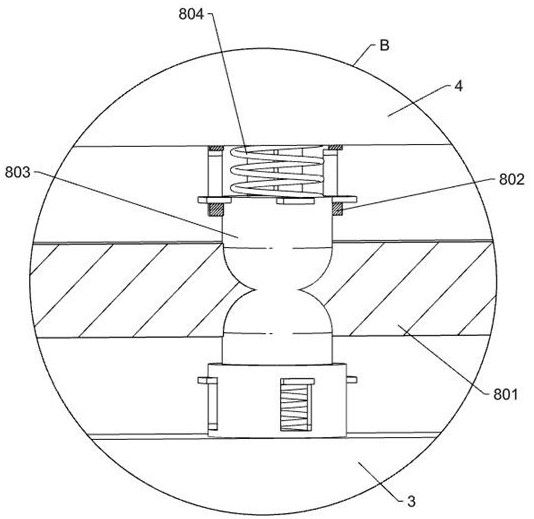

[0050] On the basis of Example 2, such as Figure 16 As shown, it also includes a limit mechanism. The limit mechanism includes a limit fixing plate 801, a fixed seat 802, a fourth sliding rod 803 and a seventh spring 804. The limit fixing plate 801 is fixed on the first mounting frame 1 and the second Between the inner sides of the mounting frame 2, the upper, lower, left and right sides of the limit fixing plate 801 are provided with circular holes, and the upper side of the first photovoltaic panel 3 and the lower side of the second photovoltaic panel 4 are fixedly connected with fixed holes. Seat 802, the fourth sliding rod 803 is slidably connected in the fixed seat 802, the inner end of the fourth sliding rod 803 is set as a semicircular ball, the middle part of the fixed seat 802 is provided with a seventh spring 804, and the two ends of the seventh spring 804 are fixed on Adjacent to the fixing seat 802 and the fourth sliding rod 803 , the inner end of the fourth slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com