Method of improving fatigue strength of aluminum alloy welding joint

A fatigue strength, aluminum alloy technology, applied in the field of aluminum alloy welding, can solve problems such as low efficiency and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

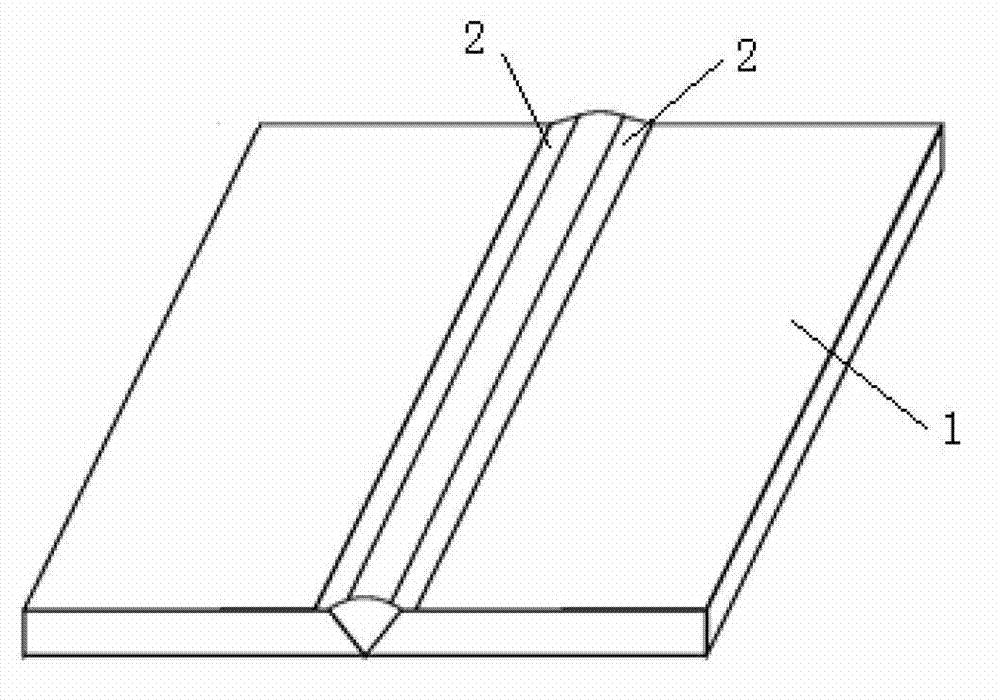

[0025] Example: A fatigue strength improvement test was performed on the welds of aluminum alloy A6061-T6 specimens.

[0026] The MIG welding test conditions and process parameters are as follows:

[0027] (1) Plate: A6061-T6 size 260×80×6mm (rectangular);

[0028] (2) Welding wire: A4043-WY φ1.2mm;

[0029] (3) Welding current 200A; welding voltage 21V; welding speed 0.5m / min; Ar gas flow rate 25L / min; V-shaped groove.

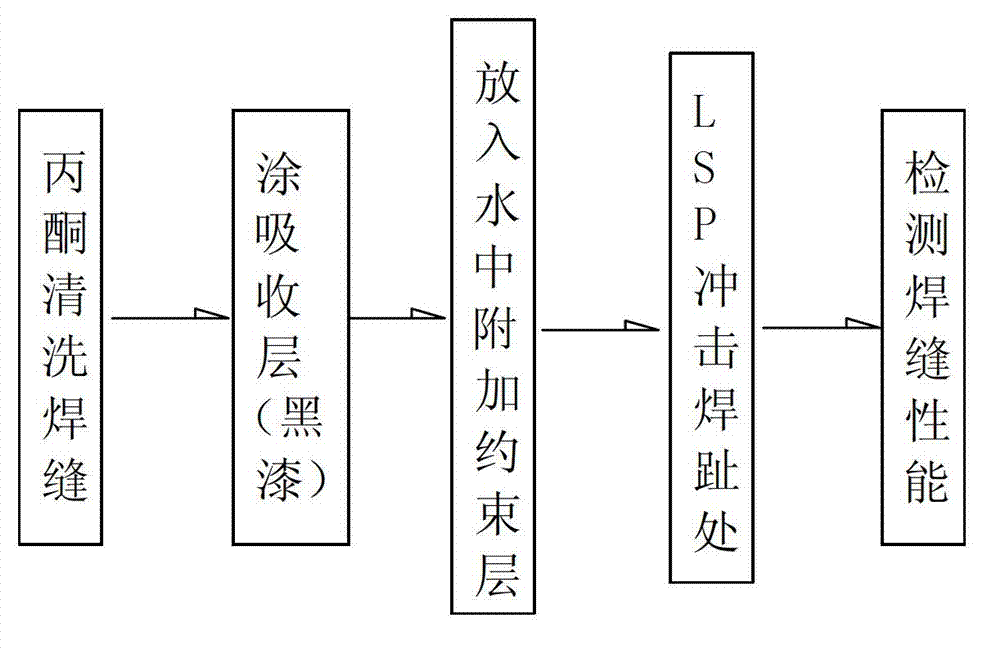

[0030] Before impact treatment, clean the weld with acetone, and coat the absorption layer-black paint on the left and right sides of the weld toe within a range of about 3.5mm; fix the test piece on the fixture and place it in the constrained layer (water layer).

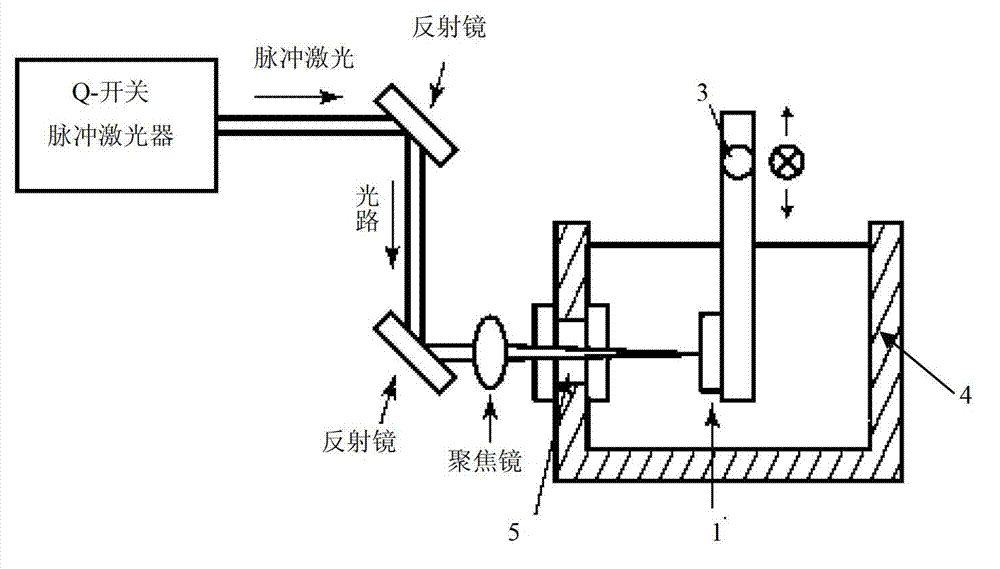

[0031] Laser surface impact treatment conditions: laser type Nd:YAG laser, wavelength 532nm, frequency 60Hz, laser pulse width 8ns, single pulse energy 100mJ, focus spot diameter 0.6mm, laser pulse peak power density is about 4.5GW / cm 2 , The overlap area of the surface spots is 35%, and the pulse energy d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peak power density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com