Swash plate, pusher drum and machine for the tobacco processing industry

A technology of conveying rollers and oscillating disks, which is applied in the fields of tobacco, cigarette manufacturing, and applications. It can solve the problems of poor efficiency, strength and orientation clustering, vibration of oscillating disks, and inaccurate blowing, and achieve the running state and swinging state. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the figures, identical or identical elements and / or parts are identified with the same reference numerals, so that they do not need to be described again.

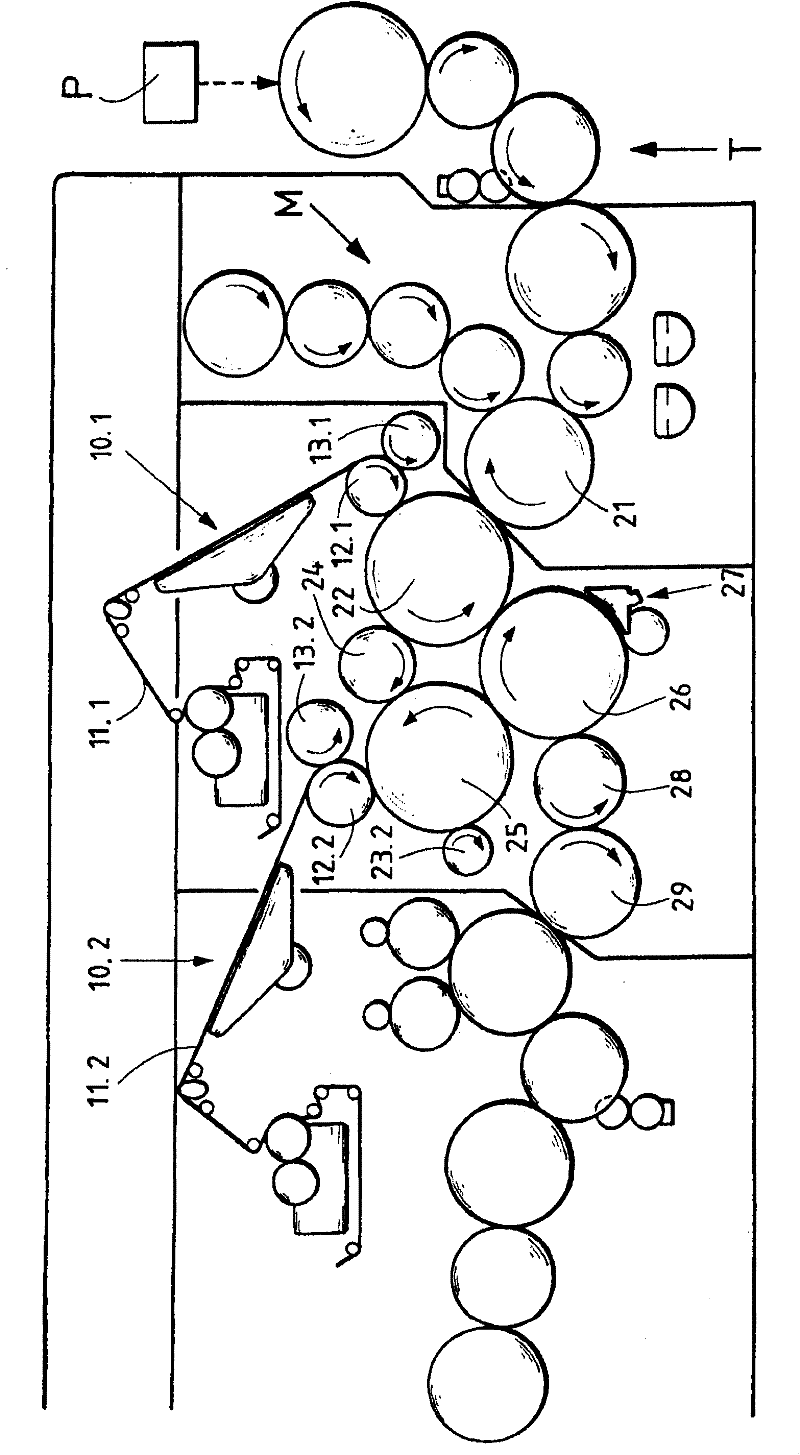

[0039] exist figure 1 The front view in Fig. 1 shows partly a filter-tipping machine which receives tobacco rods of twice the use length from a schematically depicted cigarette maker P by means of a drum arrangement T. A cigarette rolling machine named "PROTOS" by a patent applicant is already well known.

[0040] On its delivery path to the splicing drum 21 the tobacco rod of twice the usage length is cut and separated. The filter rods with twice the length are transported to the splicing drum 21 through another drum arrangement, and the filter rods are respectively inserted between two shredded tobacco rods kept at a certain distance along the axial direction. An arrangement of tobacco rod-filter rod-tobacco rod combinations arranged one after the other across the axial direction is thus formed on the splici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com